Full-automatic corrosion equipment for preparing printed circuit board

A printed circuit board, fully automatic technology, applied in the direction of printed circuit manufacturing, printed circuit, removal of conductive materials by chemical/electrolytic methods, etc., can solve the problems of uneven corrosion of circuit boards, easy damage to water pumps, etc., to save corrosion time , high work efficiency, good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

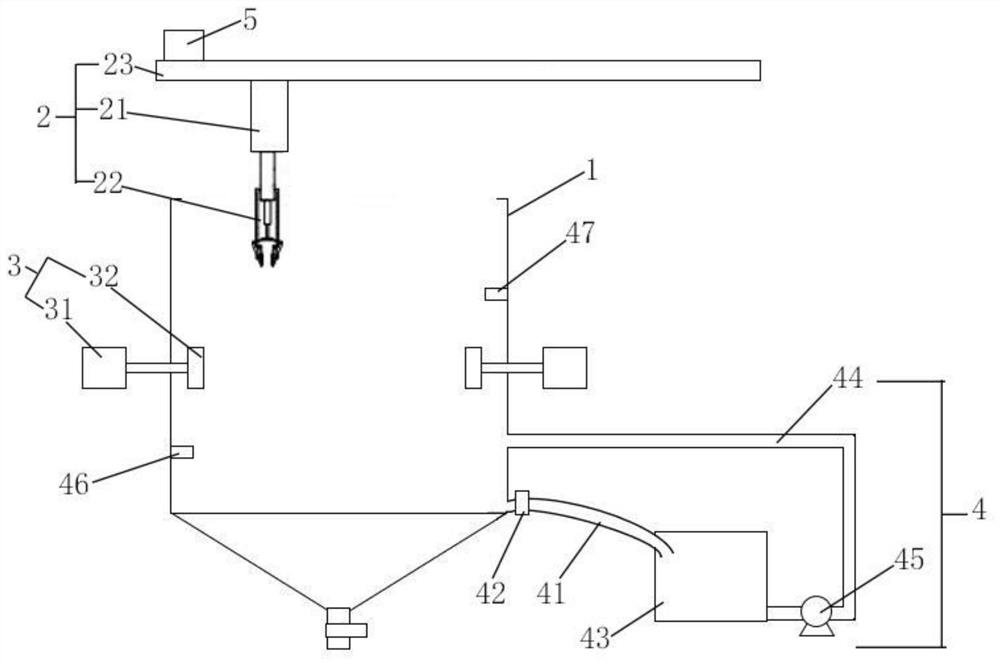

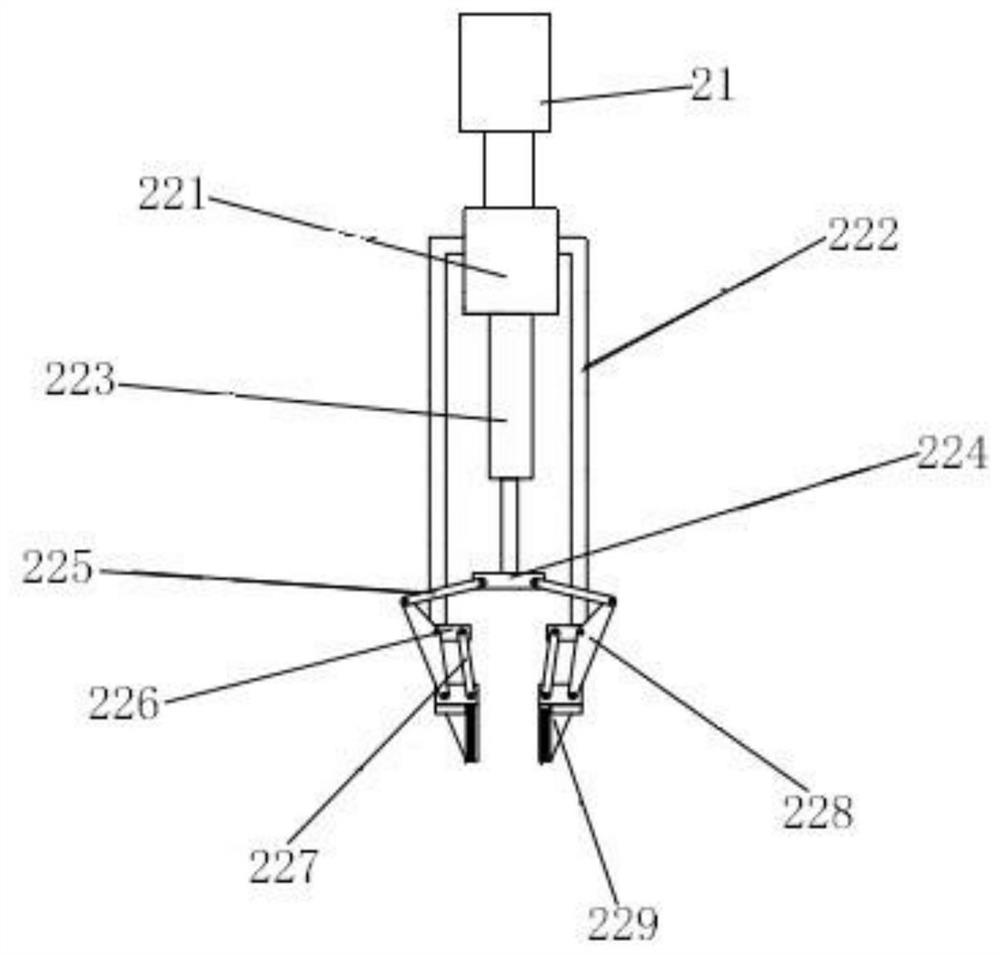

[0035] refer to figure 1 , this embodiment provides a fully automatic etching equipment for the preparation of printed circuit boards. The fully automatic corrosion equipment includes a box body 1 , a grasping mechanism 2 , a stirring mechanism 3 , a liquid replenishing mechanism 4 and a control mechanism 5 .

[0036] Wherein, a gripping mechanism 2 is arranged above the box body 1 for grabbing the circuit board, and placing the circuit board in the corrosive liquid in the box body 1 for corrosion.

[0037] A stirring mechanism 3 is provided on the side wall of the box 1 for stirring the corrosive solution in the box 1 to make the concentration of the corrosive solution in the box 1 uniformly mixed, thereby achieving uniform corrosion of the circuit board.

[0038] The tank 1 is also equipped with a liquid replenishing mechanism 4 for replenishing the corrosive liquid in the tank 1; when the corrosive liquid in the tank 1 is used for a period of time, the concentration of the...

Embodiment 2

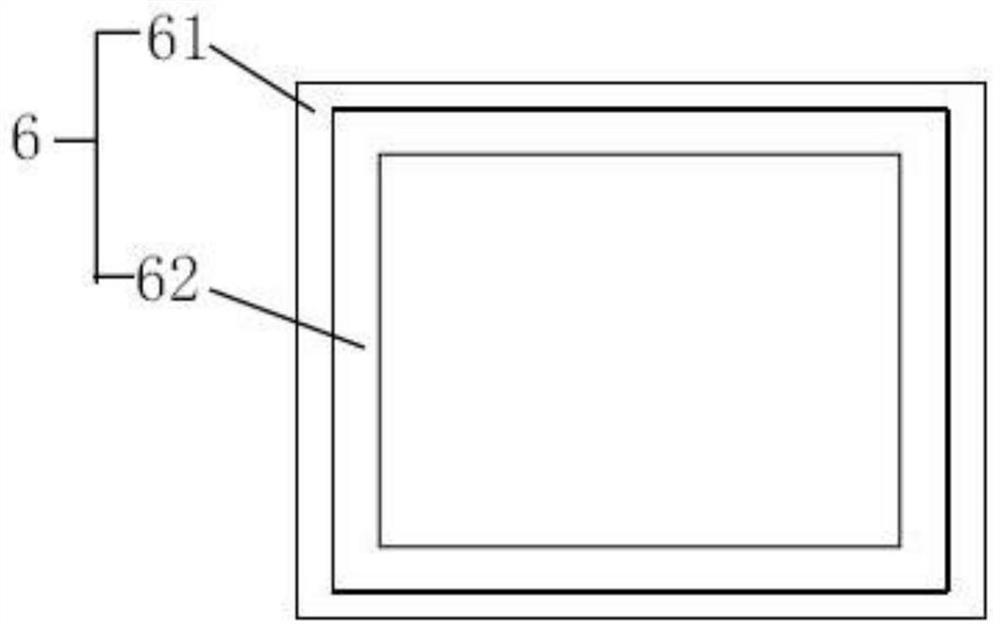

[0057] Different from Embodiment 1, the fully automatic corrosion equipment also includes several fixing mechanisms 6 for fixing circuit boards, referring to image 3 , several fixing mechanisms 6 are arranged at the lower part of the grabbing mechanism 2, and the fixing mechanism 6 is grabbed by the grabbing mechanism 2. Setting the fixing mechanism 6 can prevent the grasping mechanism 2 from directly contacting the circuit board, thereby preventing the grasping mechanism 2 from damaging the circuit board.

[0058] Wherein, the fixing mechanism 6 includes an outer frame body 61 and a rubber strip 62 arranged inside the outer frame body 61 , and the rubber strip 62 is provided with a groove for clamping the circuit board. Since the rubber strip 62 is made of soft material, it will not damage the circuit board. Grooves are provided on the rubber strip 62, which can block the circuit board and prevent it from falling during the movement. A layer of anti-corrosion layer is also...

Embodiment 3

[0060] Different from Example 2, refer to Figure 4 The fixing mechanism 6 further includes at least two inner baffles 63 , the inner baffles 63 are arranged inside the outer frame 61 , and the inner baffles 63 and the outer frame 61 are connected by a third electric telescopic rod 64 . The inner side of the inner baffle 63 is provided with a rubber strip 62, and the outer side of the inner baffle 63 is connected with the outer frame body 61 through the third electric telescopic rod 64, and the third electric telescopic rod 64 drives the inner baffle 63 to move to adapt to different sizes. circuit board.

[0061] The number of inner baffles 63 in this embodiment is four, and the number corresponding to the third electric telescopic rod 64 is also four. The movement of the inner baffle 63 is driven by the expansion and contraction of the third electric telescopic rod 64, and then it can be applied Corrosion of circuit boards of different sizes.

[0062] In the description of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com