A kind of method for the dehydration of mixture of hexachlorobenzene and potassium fluoride

A technology of potassium fluoride and hexachlorobenzene, applied in organic chemistry, halogen substitution preparation, etc., can solve problems such as reactor corrosion, potential safety hazards, equipment damage, etc., and achieve the effects of reducing corrosion, complete dehydration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

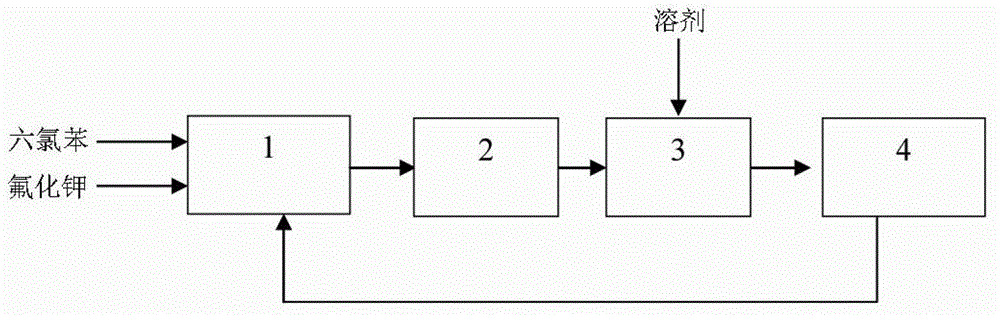

Method used

Image

Examples

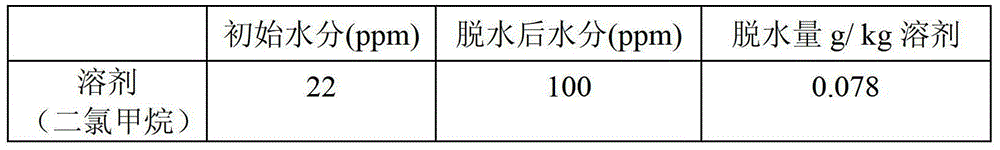

Embodiment 1

[0021] Add 130 g of raw materials hexachlorobenzene, 260 g of active potassium fluoride, and 400 g of solvent dichloromethane into the reactor. After the addition is completed, the reactor is heated to 40-50° C., and the temperature is maintained for 30 hours. After opening the valve, the solvent Evaporate and condense for recovery. Measure solvent moisture data.

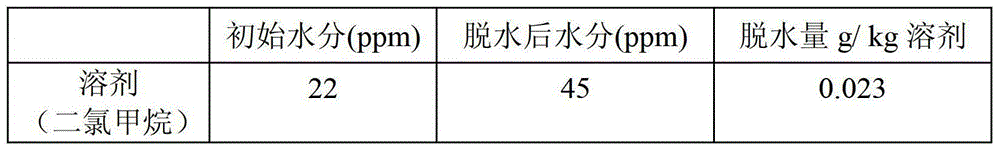

Embodiment 2

[0023] According to the operation steps of Example 1, keeping other things unchanged, benzene is used as the solvent, the temperature of the reactor is controlled to be 80-90° C., and the moisture content of the solvent is measured.

Embodiment 3

[0025] According to the operation steps of Example 1, keeping other things unchanged, toluene was used as the solvent, the temperature of the reactor was controlled to be 110-120° C., and the moisture content of the solvent was measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com