Medical waste treatment device

A technology of medical waste and treatment equipment, which is applied in the field of medical waste treatment equipment, can solve the problems of cumbersome process, pollution and other problems that require a lot of effort, medical staff replace the sterilization position of medical waste at intervals, and achieve the effect of improving sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A medical waste treatment device, such as figure 1 As shown, it includes a first support frame 1, a casing 2, a lower hopper 3, a crushing assembly 4 and a steam sterilization assembly 5, the top of the first support frame 1 is fixedly connected to the casing 2, and the upper part of the front side of the casing 2 is provided with a lower hopper 3 , The upper part of the casing 2 is left and right symmetrically provided with a crushing assembly 4, and the lower part of the casing 2 is provided with a steam sterilization assembly 5.

[0064]When the medical staff need to crush medical waste, the medical staff first need to pour an appropriate amount of medical waste into the lower hopper 3, and the medical waste in the lower hopper 3 will slide into the shell 2. When the medical waste is located in the shell 2, the medical personnel need to control the expansion and contraction of the crushing assembly 4. When the crushing assembly 4 is stretched, the crushing assembly 4...

Embodiment 2

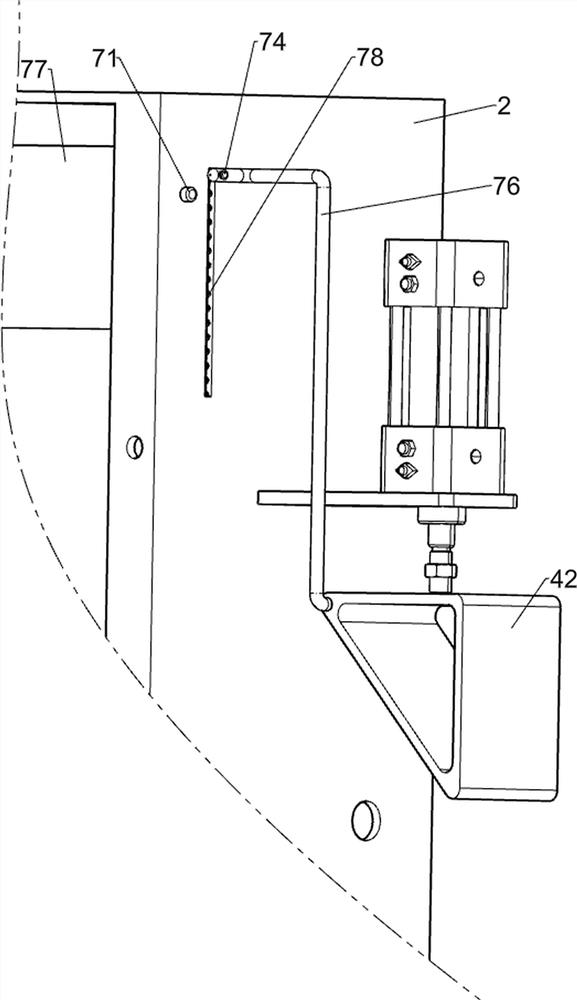

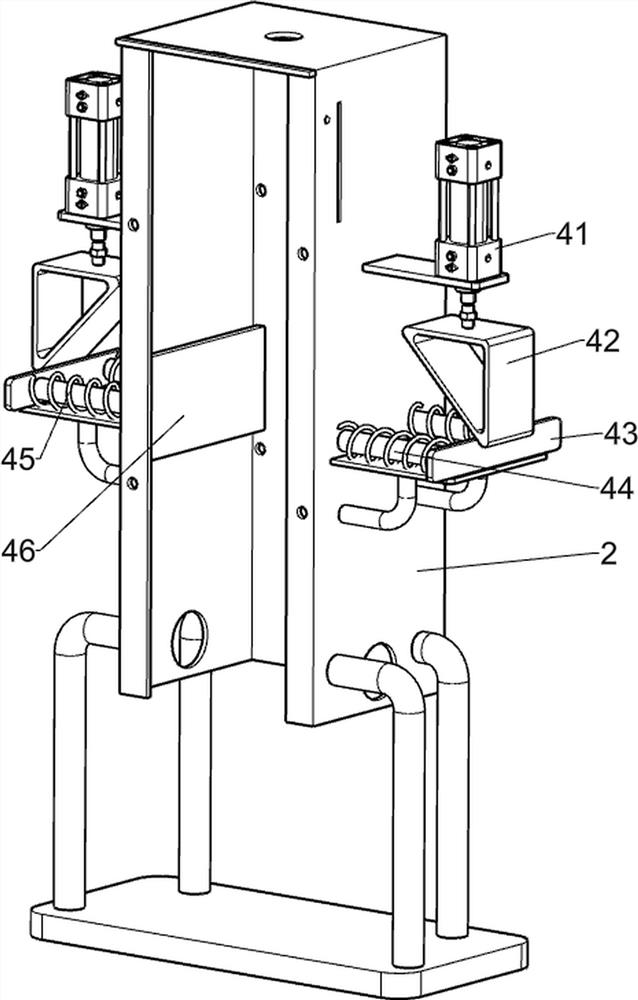

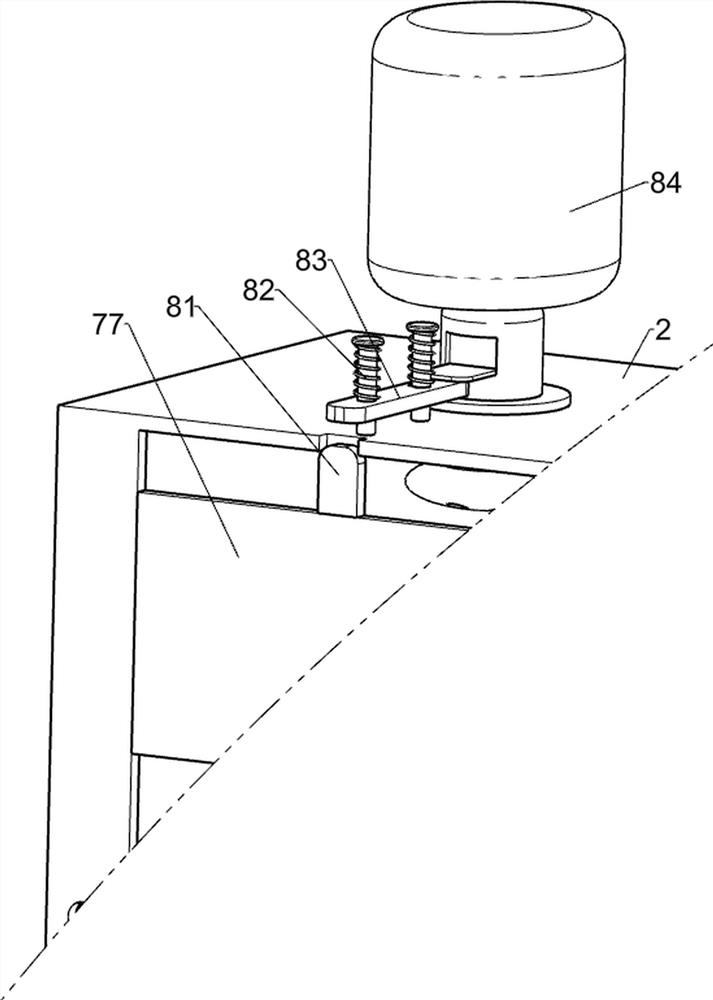

[0066] In a preferred embodiment of the present invention, as figure 2 As shown, the crushing assembly 4 includes a cylinder 41, a wedge block 42, a push plate 43, a guide rod 44, a first compression spring 45 and a pressing plate 46, and the left and right sides of the upper part of the casing 2 are all connected with the cylinder 41 by bolts. The bottom end of telescopic rod 78 is fixedly connected with wedge-shaped block 42, and the left and right symmetrical sliding type in the middle part of shell 2 is provided with guide rod 44, is positioned at the outer end of guide rod 44 on the same side and is connected with push plate 43, and guide rod 44 is sleeved with the first A compression spring 45, the two ends of the first compression spring 45 are respectively connected on the guide rod 44 and the push plate 43, the wedge block 42 is in contact with the pressure plate 46, and the inner end of the guide rod 44 on the same side is connected with the pressure plate 46 , The ...

Embodiment 3

[0069] In a preferred embodiment of the present invention, as figure 1 with Figure 3-Figure 8 As shown, the steam sterilization assembly 5 includes a steam pipeline 51, a valve 52 and a nozzle 53. A steam pipeline 51 is connected between the left and right sides of the lower part of the casing 2. A valve 52 is installed in the middle of the rear side of the steam pipeline 51. The front of the steam pipeline 51 Nozzles 53 are welded at the inner ends of the sides, and the nozzles 53 are located in the shell 2 .

[0070] The crushed medical waste may pollute the ground, so when the crushed medical waste falls down, the medical staff need to open the valve 52. After the medical staff opens the valve 52, part of the steam will be squeezed into the steam pipe 51, the steam in the steam pipe 51 will be sprayed onto the crushed medical waste through the nozzle 53, and then the steam can sterilize the medical waste. When the medical staff do not need to sterilize the medical waste t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com