Wood waste recovery device

A technology of wood waste and recovery device, which is applied in the field of wood processing, can solve problems such as frequent operation and shutdown, and achieve the effects of improving recovery efficiency, avoiding blockage, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are provided in order to further understand the present invention better, are not limited to the best implementation mode, and do not limit the content and protection scope of the present invention, anyone under the inspiration of the present invention or use the present invention Any product identical or similar to the present invention obtained by combining features of other prior art falls within the protection scope of the present invention.

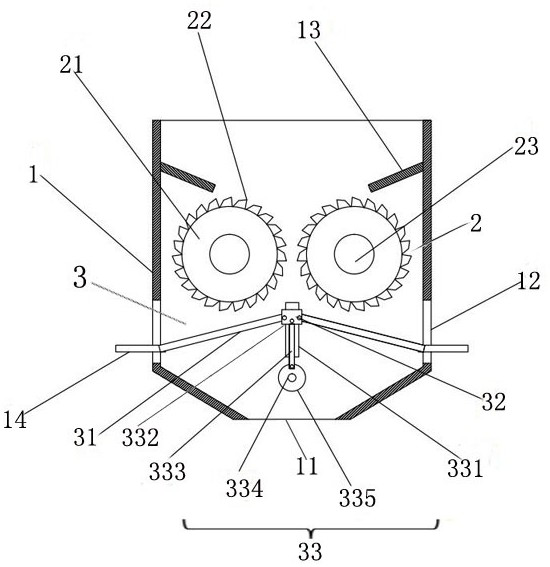

[0024] see figure 1 , The wood waste recovery device in the embodiment of the present application includes a body 1 with a cavity, the body 1 is provided with a first discharge port 11 and a second discharge port 12, and the second discharge port 12 is provided with a horizontal guide Sheet 14;

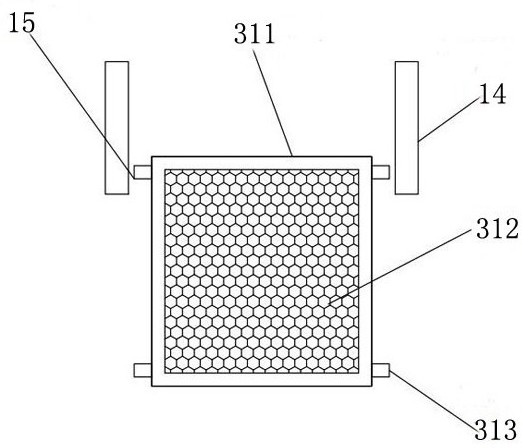

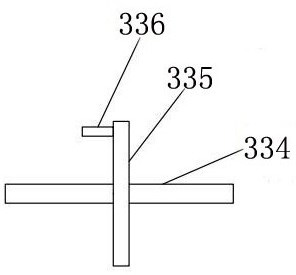

[0025] The screening mechanism 3 is used to screen the crushed waste materials. The screening mechanism 3 includes a screen 31, a connecting piece 32 and a driving device 33; one end of the screen 31 is slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com