Full-automatic endoscope cleaning and disinfecting machine

A fully automatic cleaning and disinfection technology, applied in the direction of disinfection, dryers, cleaning methods and utensils, etc., can solve problems such as unsatisfactory cleaning requirements, loss of effective information, unreasonable cleaning methods, etc., to avoid dead ends in cleaning and disinfection, Improve decontamination efficiency and facilitate traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

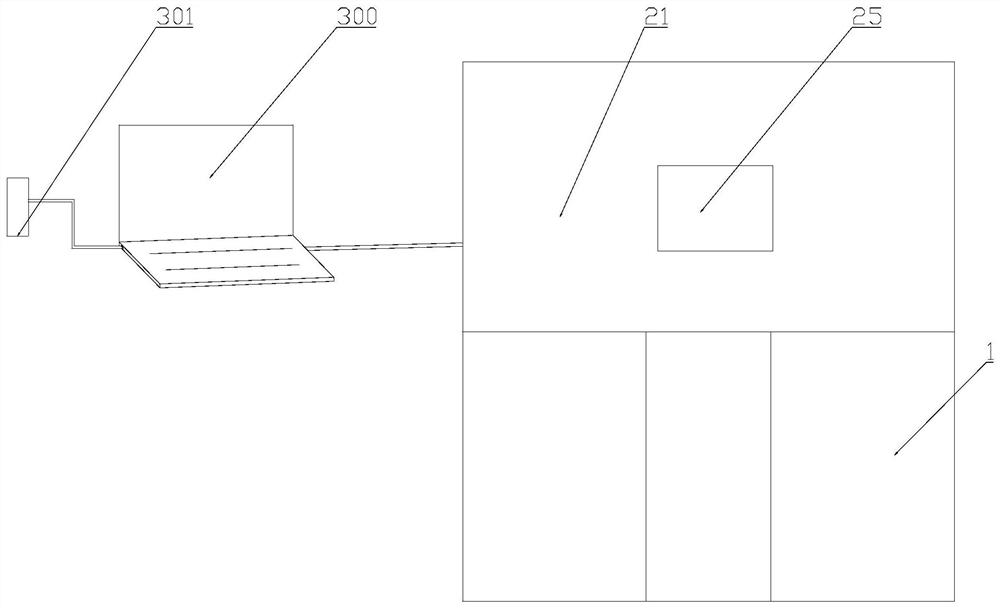

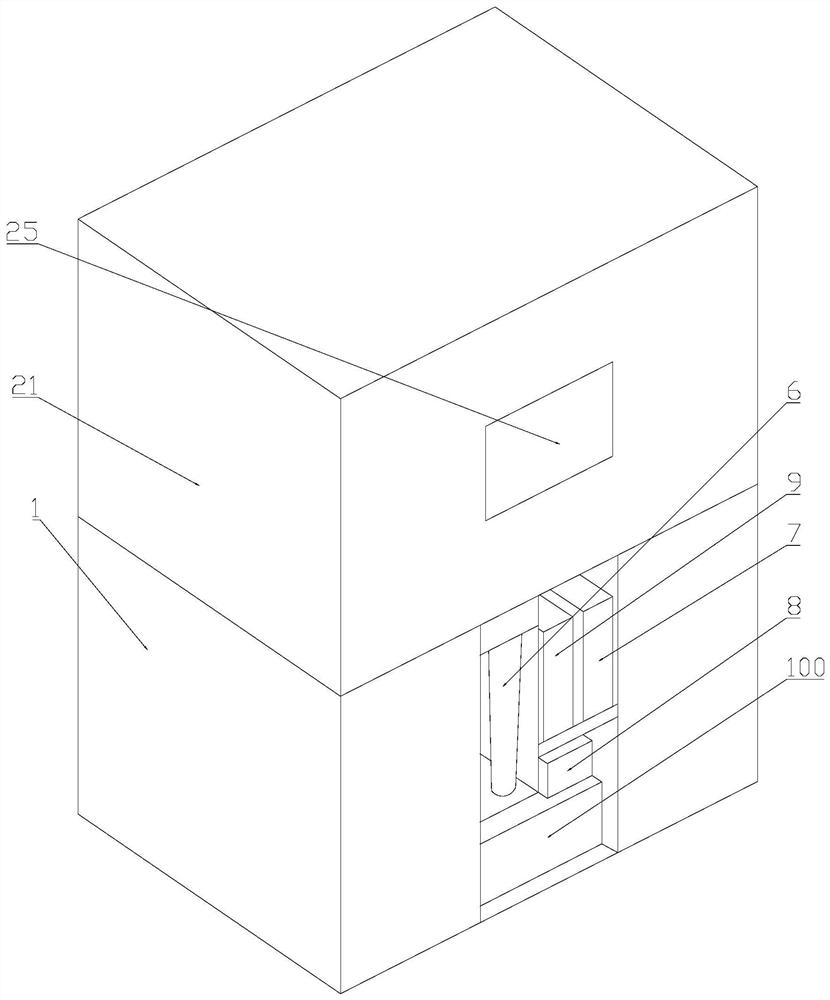

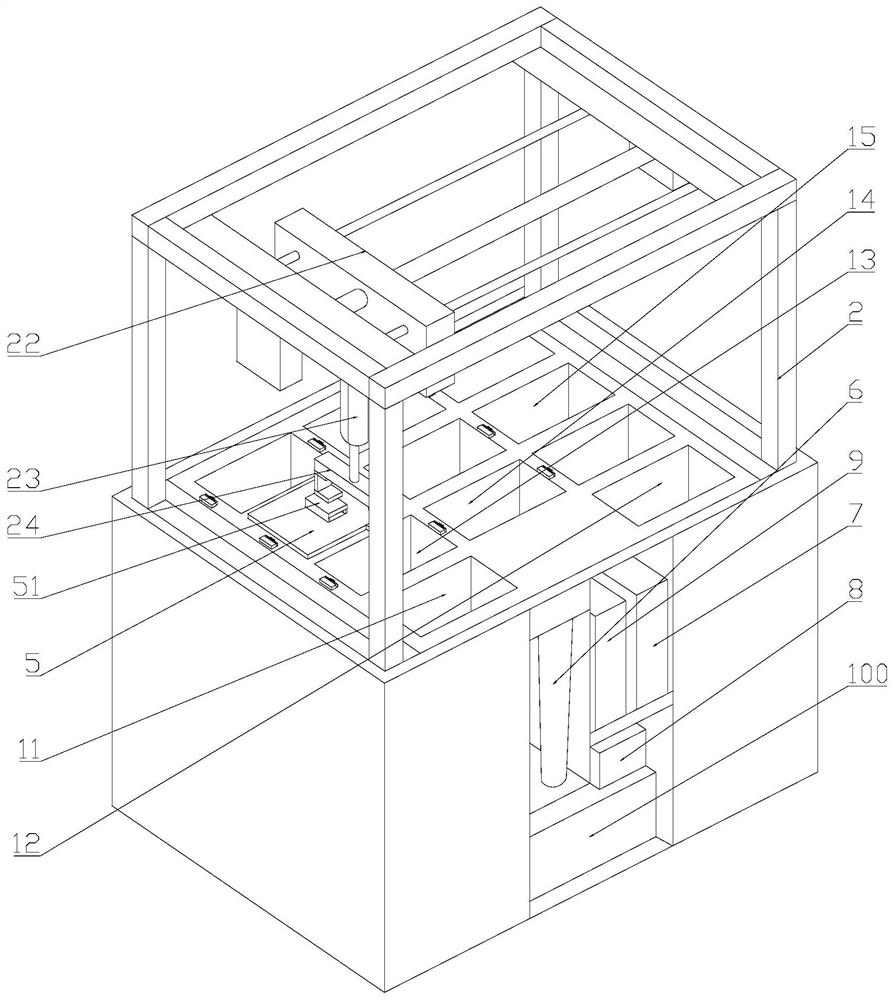

[0066] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, a fully automatic endoscope cleaning and disinfecting machine includes a box body 1 and an endoscope grid frame. A support 2 is provided on the working surface of the box body 1, and a machine is provided on the working surface of the box body 1 around the support 2. The casing 21 and the working surface of the box body 1 are provided with a slot 11 for putting the endoscope grid frame to be cleaned and disinfected, a tank 12 for removing the cleaned and disinfected endoscope grid frame, and at least three sets of cleaning tank groups, each group of cleaning tank groups includes a cleaning tank 13. One disinfection tank 14 and one drying tank 15, one cleaning tank 13, one disinfection tank 14 and one drying tank 15 of each cleaning tank group use the same cleaning and disinfection tank 3.

[0067] One ...

Embodiment 2

[0103] like Figure 13 and Figure 14 As shown, a fully automatic endoscope cleaning and disinfection machine, compared with Embodiment 1, differs in that the interface assembly includes a second pipe joint 364 facing directly upward, and the connecting pipe assembly is a second connecting pipe 552, The second connecting pipe 552 is arranged in the cover body 5 and corresponds to the second pipe joint 364. The other end of the second connecting pipe 552 is provided with a connecting joint 56 corresponding to the endoscope, which simplifies the interface assembly and further reduces the automatic The production cost of the endoscope washer-disinfector is the same as that of Embodiment 1, and there is no special limitation here, and it also belongs to the scope of protection of the present invention. Its structural features and effects are also the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com