Forming and sintering process of PANACEA material

A technology of process and sintering section, which is applied in the field of forming and sintering process of PANACEA materials, can solve the problems of lattice expansion, large size, graying of material surface, etc., and achieve the effect of reducing labor cost, reducing sintering cost and improving sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

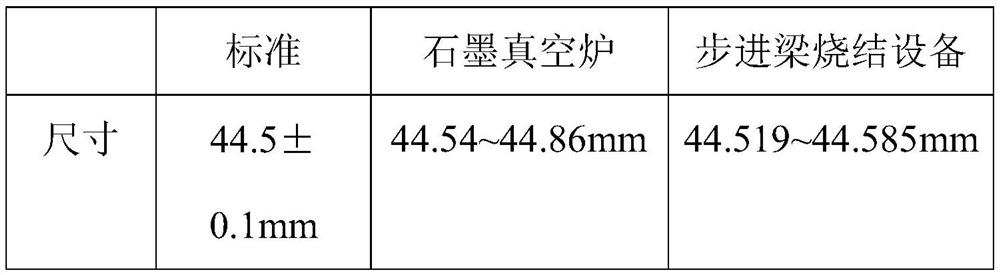

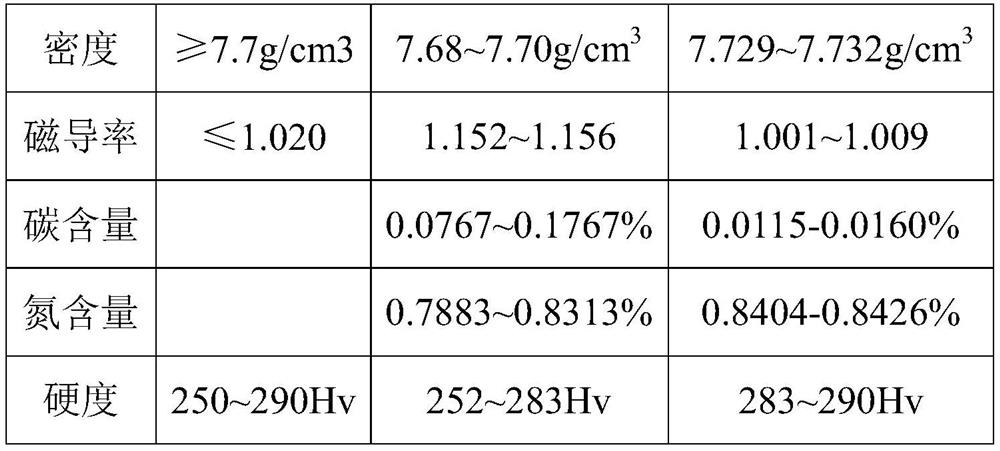

[0017] The present invention will be further described in detail below.

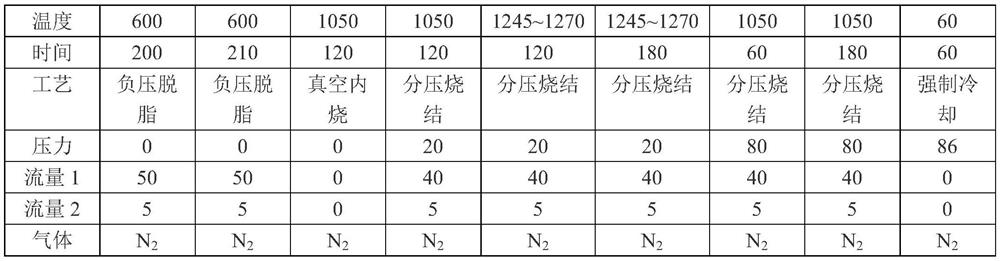

[0018] The sintering process of the present invention adopts walking beam sintering equipment for processing, and the walking beam sintering equipment includes a degreasing section, a sintering section and a cooling section, and the N2 flow rate in the furnace is kept at 30Nm 3 / h, the furnace pressure is maintained at 18mbar, the walking beam cycle is maintained at 112s, the feeding transmission rate is controlled by the walking beam, and the powder feeding is first transferred from the feeding section to the degreasing section to remove the remaining binder .

[0019] The degreasing section includes five preheating temperature zones, the temperature of the first preheating zone is 300-350°C, the temperature of the second preheating zone is 400-450°C, the temperature of the third preheating zone is 500-550°C, the fourth preheating zone The zone temperature is 600-650°C, and the fifth preheating zone te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com