Ball perforating equipment for amusement article processing

A ball and play technology, applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve the problems of difficult cleaning of waste and inability to achieve precise drilling, and achieve the effect of chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

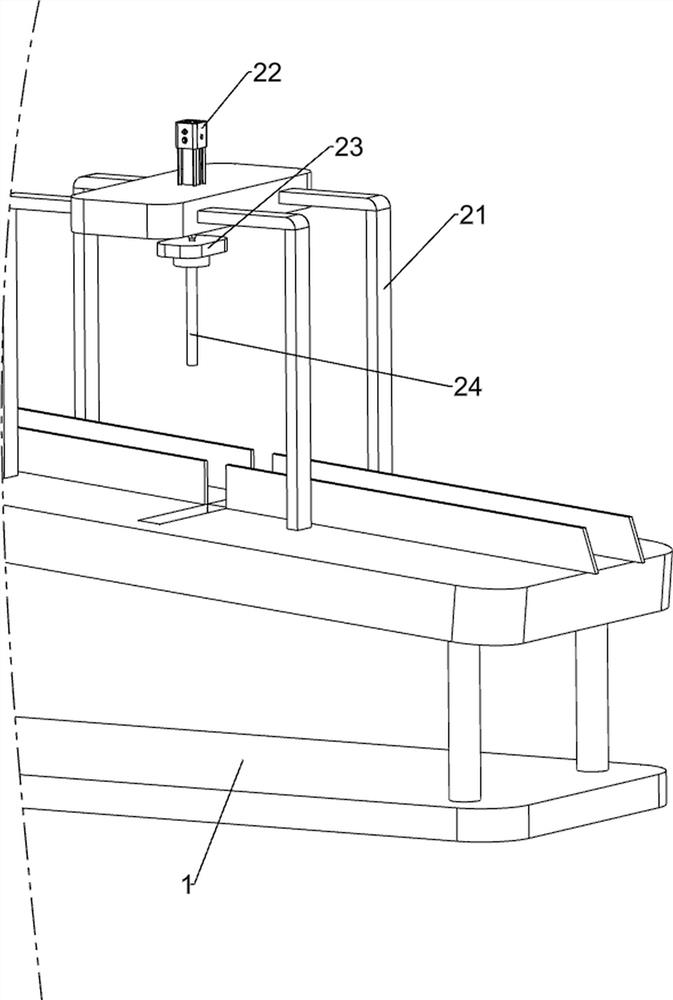

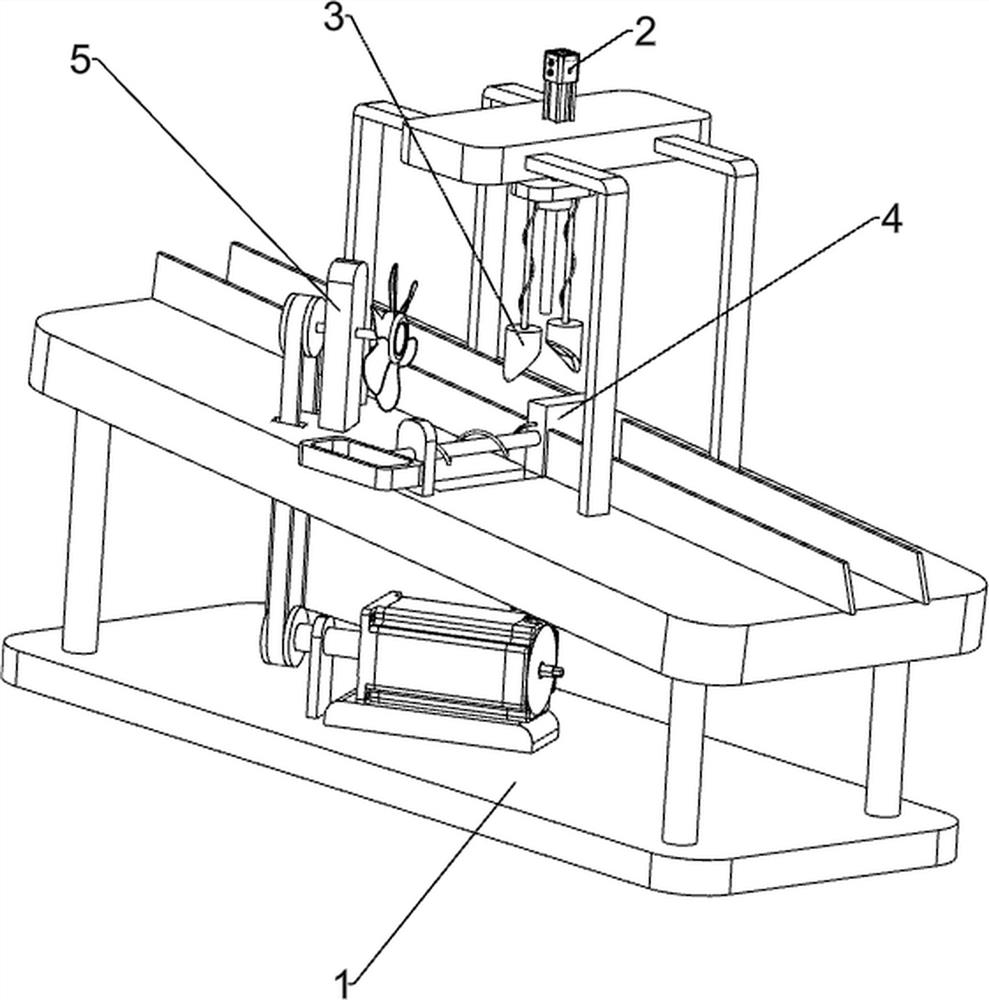

[0022] A ball piercing equipment for Wenwan processing, such as Figure 1-Figure 3 As shown, it includes a base 1 , a drilling mechanism 2 and a fixing mechanism 3 , the top of the base 1 is provided with the drilling mechanism 2 , and the bottom of the drilling mechanism 2 is provided with the fixing mechanism 3 .

[0023] When people want to perforate balls, they can use this kind of bead perforating equipment for Wenwan processing. First, the user places the balls on the upper base 1, and then starts the drilling mechanism 2 to drill holes. Mechanism 2 drives the fixing mechanism 3 to move downward, and fixes the ball on the upper side of the base 1 first, then the drilling mechanism 2 contacts the ball to drill the ball. After the drilling is completed, the drilling mechanism 2 drives The fixing mechanism 3 moves upward, and the fixing mechanism 3 is far away from the ball to realize the reset action.

[0024] The drilling mechanism 2 includes a first support frame 21, a ...

Embodiment 2

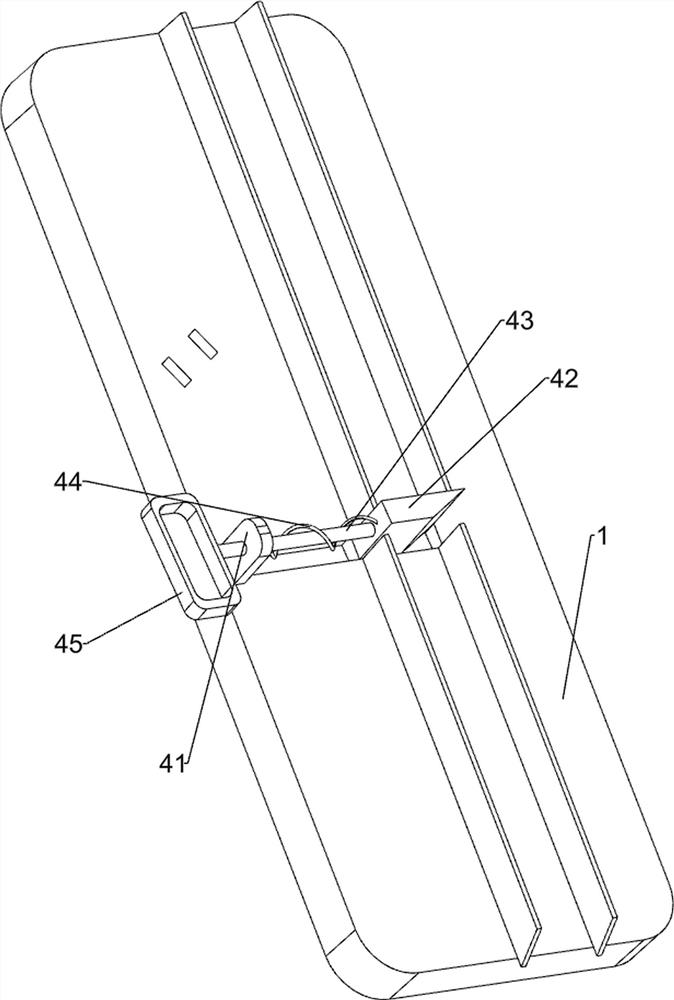

[0029] On the basis of Example 1, such as Figure 4 with Figure 5 As shown, it also includes a blanking mechanism 4. The top of the front side of the base 1 on the upper side is provided with a blanking mechanism 4. The blanking mechanism 4 includes a second support frame 41, a baffle plate 42, a second telescopic rod 43, a second Two springs 44 and handles 45, the second support frame 41 on the front side top of the base 1 on the upper side, the second support frame 41 top is provided with the second telescopic rod 43, the second telescopic rod 43 front end is provided with the handle 45, the second telescopic The rear end of the rod 43 is provided with a baffle 42 , the second spring 44 is wound on the second telescopic rod 43 , the second spring 44 is connected to the second support frame 41 around the front end, and the second spring 44 is connected to the baffle 42 around the rear end.

[0030] The base 1 on the upper side is inclined to the right. When the ball rolls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com