Numerical control clamp system used for numerical control machine tool and using method of numerical control clamp system

A technology of CNC machine tool and fixture system, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., and can solve the problem of not being able to meet the requirements of inner hole clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

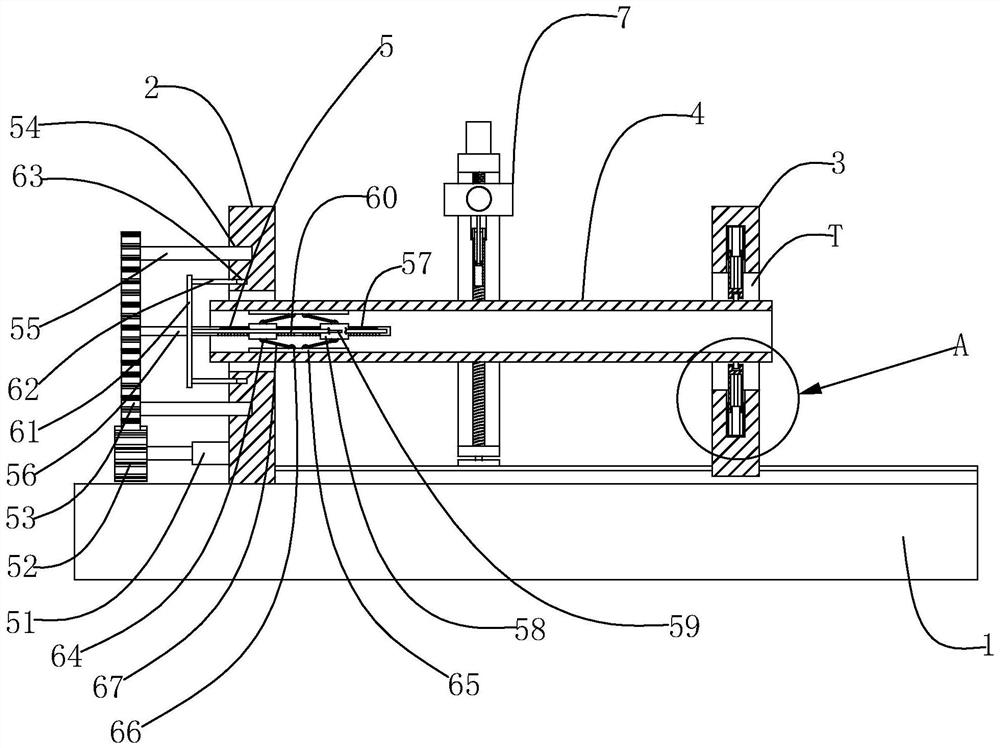

[0030]The invention discloses a numerically controlled fixture system for numerically controlled machine tools, comprising a numerically controlled machine tool platform 1, a first support plate 2 fixedly installed on the numerically controlled machine tool platform 1, movably installed on the numerically controlled machine tool platform 1 and connected with the first support plate 2. The second support plate 3 arranged in parallel. The first support plate 2 and the second support plate 3 are provided with a through hole T, and a tubular workpiece 4 is erected between the two through holes T. In the specific embodiment of the present invention In 1, an inner hole clamping device 5 for clamping a tubular workpiece 4 is installed on the CNC machine tool platform 1, and the inner hole clamping mechanism 5 includes an inner hole clamping device installed on the first support plate 2 and the output end is horizontally arranged. The first servo motor 51, the first driving gear 52 fix...

Embodiment 2

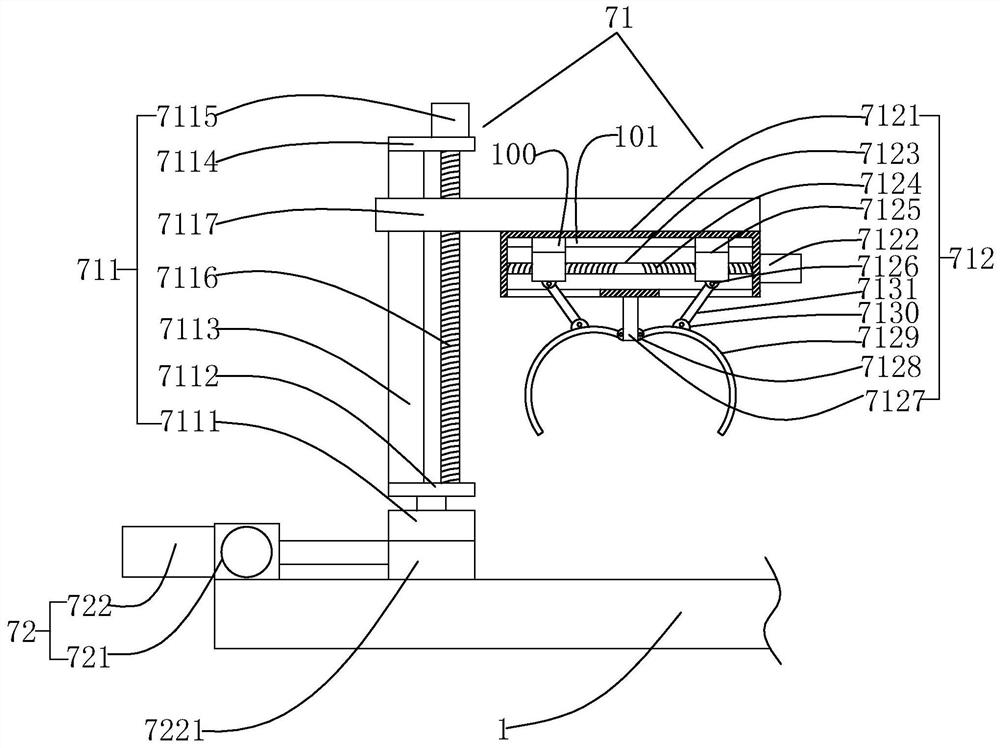

[0034] In Embodiment 2 of the present invention, the CNC machine tool platform 1 is provided with a loading and unloading device 7 for loading the tubular workpiece 4 into the through holes T of the first support plate 2 and the second support plate 3. The device 7 includes a workpiece clamping mechanism 71 and a displacement mechanism 72 that drives the workpiece clamping mechanism 71 to move, and the displacement mechanism 72 includes a horizontal horizontal driving electric cylinder 721 installed on the platform 1 of the CNC machine tool and connected to the horizontal horizontal Drive the electric cylinder 721 to drive and connect the horizontal and vertical driving electric cylinder 722, the horizontal and longitudinal driving electric cylinder 721 is used to drive the horizontal and longitudinal driving electric cylinder 722 to reciprocate along the horizontal horizontal direction, the output of the horizontal and longitudinal driving electric cylinder 722 A base plate 72...

Embodiment 3

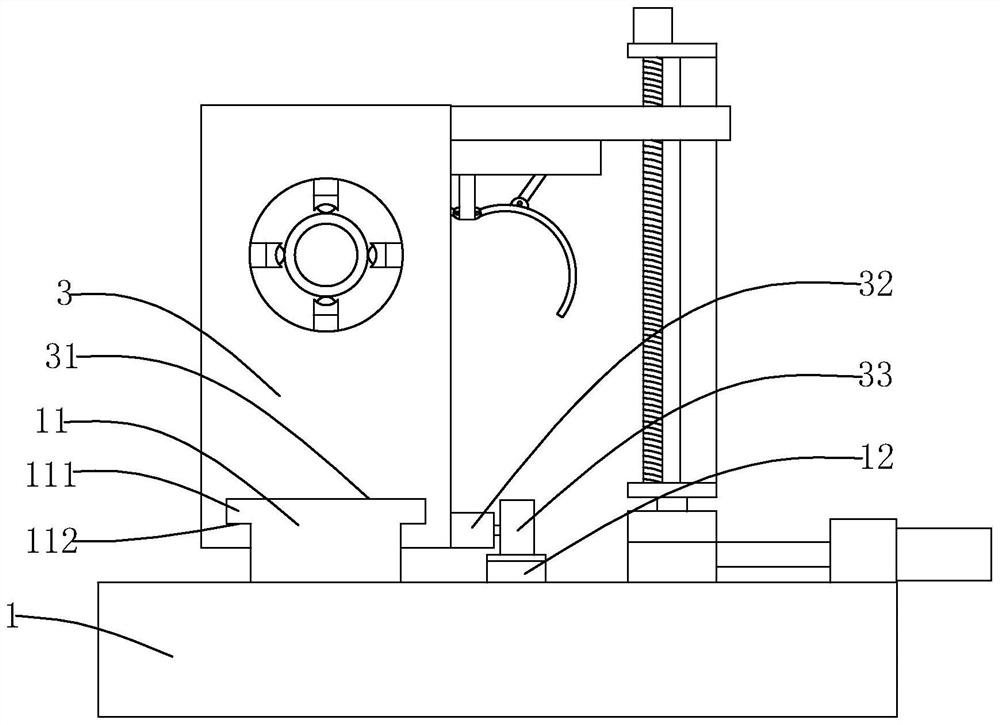

[0041] In Embodiment 3 of the present invention, the CNC machine tool platform 1 is provided with a linear guide rail 11 extending toward the first support plate 2, the second support plate 3 is slidably arranged on the linear guide rail 11, and the second support The plate 3 is provided with a through groove 31 which can be partially embedded into the linear guide rail 11. One side of the linear guide rail 11 is provided with a toothed linear guide rail 12 parallel to it and fixedly installed on the CNC machine platform 1. The second support A fifth servo motor 32 is fixedly installed on the side wall near the bottom of the plate 3, and the output end of the fifth servo motor 32 is fixedly sleeved with a second driving gear 33, and the second driving gear 33 and the toothed linear guide rail 12 tooth surface meshing.

[0042] In the specific embodiment 3 of the present invention, both sides of the top of the linear guide rail 11 are fixedly provided with stoppers 111 along it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com