Clamp for machining mold insert

A technology for processing molds and inserts, applied in workpiece clamping devices, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as inconvenience, and achieve the effect of improving efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

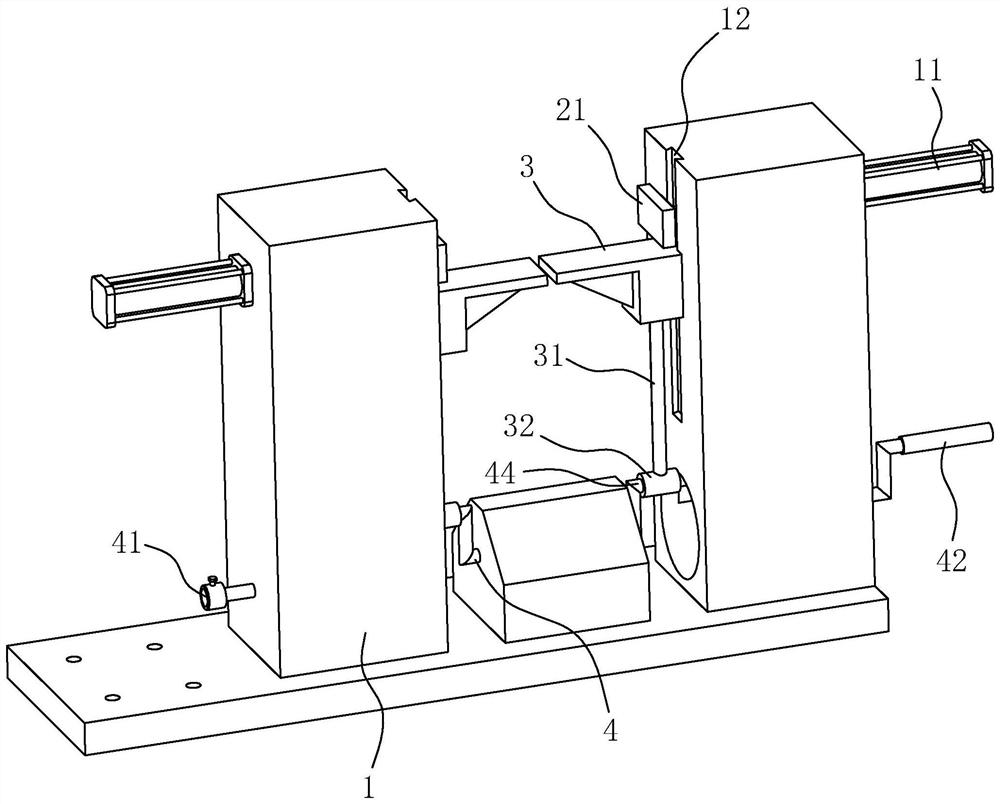

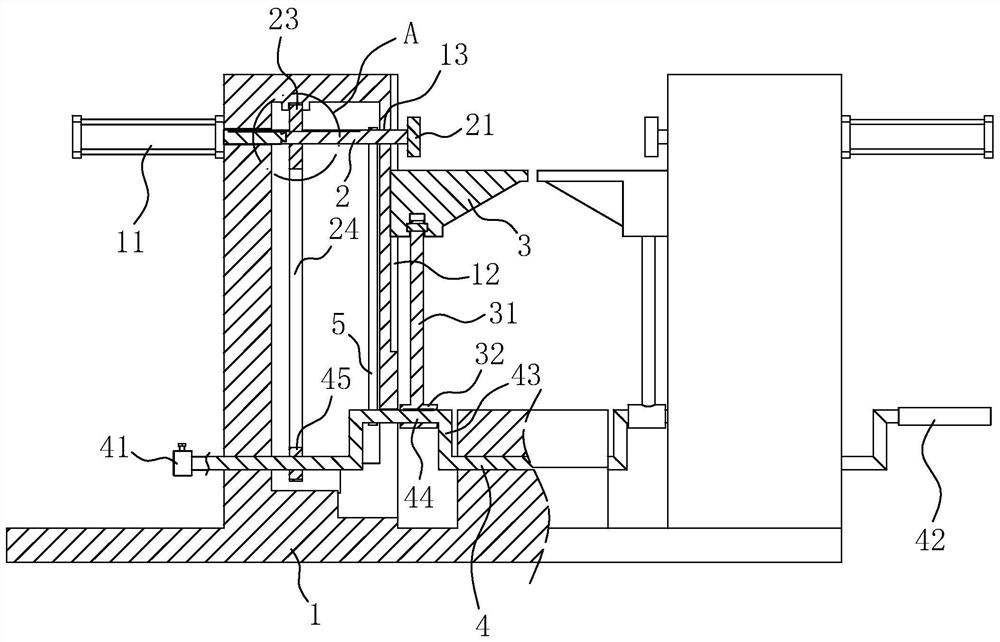

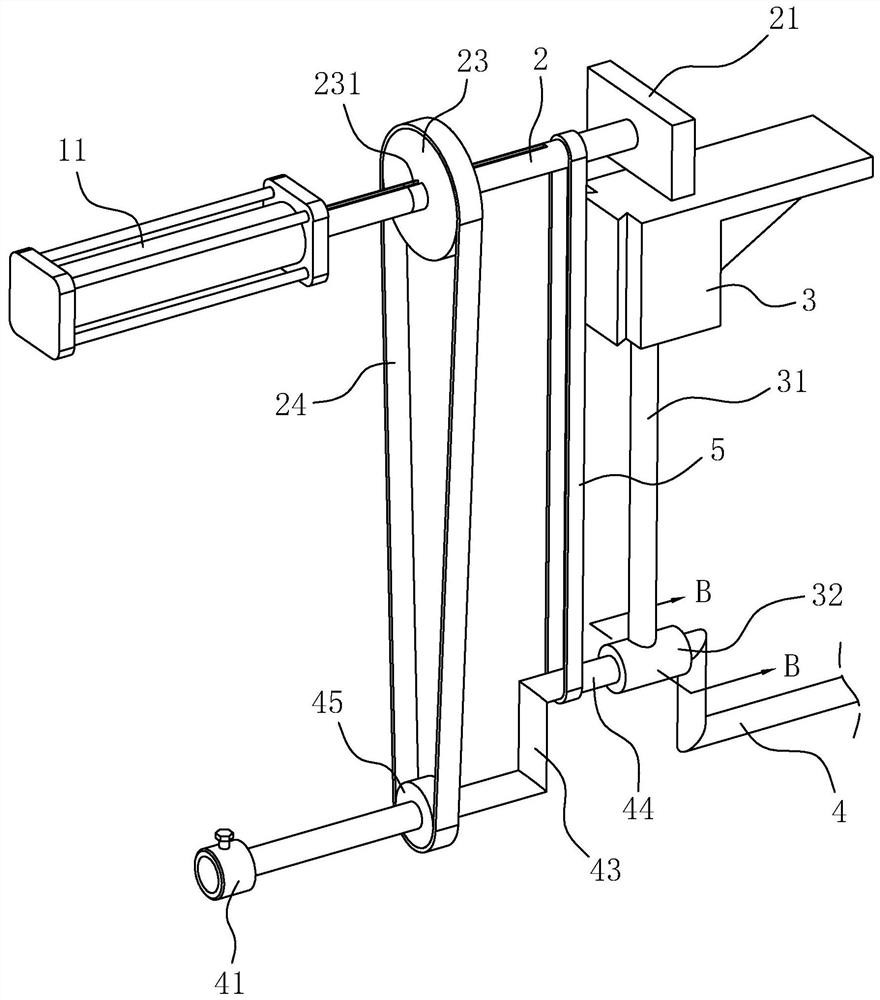

[0034] The following is attached Figure 1-5 The application is described in further detail.

[0035] The embodiment of the present application discloses a fixture for processing mold inserts. refer to figure 1 and figure 2 , the fixture used for processing mold inserts includes a base 1, on which there are two cylinders 11, and two sliding rods 2 driven and slid by the two cylinders 11 respectively, the axial direction and sliding direction of the sliding rods 2 are all along the horizontal direction, the axes of the two sliders 2 coincide. The end of the slide bar 2 facing away from the cylinder 11 is fixed with a clamping block 21, and when the cylinder 11 drives the slide bar 2 to slide, the clamping block 21 plays the role of clamping and loosening the insert. The base 1 is slidably provided with two support blocks 3 along the vertical direction, and the two support blocks 3 are located directly below the two clamping blocks 21 respectively, and the support blocks 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com