Fixed-length cutting device for angular panel

A cutting device and plate technology, applied in metal processing and other directions, can solve problems such as insufficient product identity, potential safety hazards, and inability to fundamentally solve the problems of worker safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

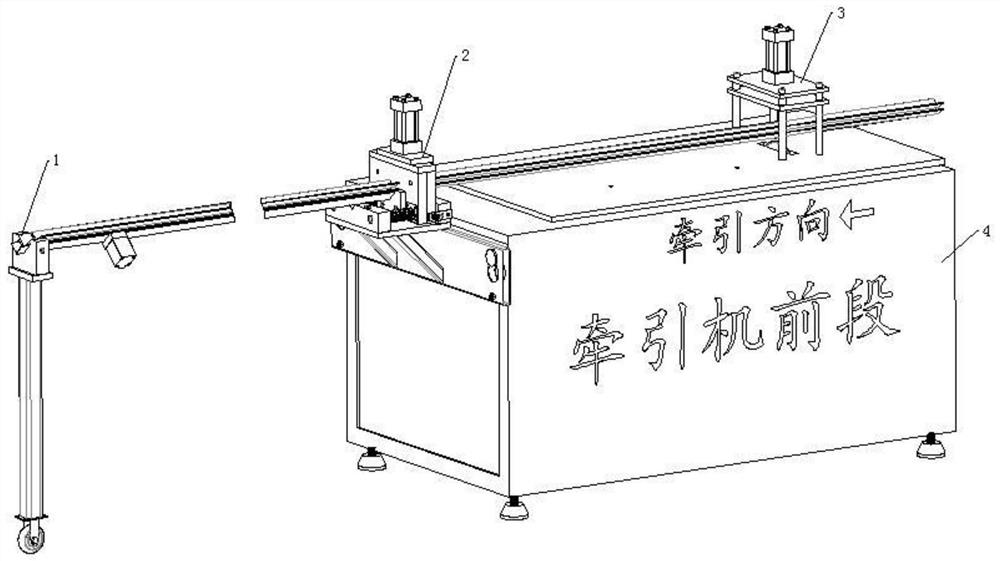

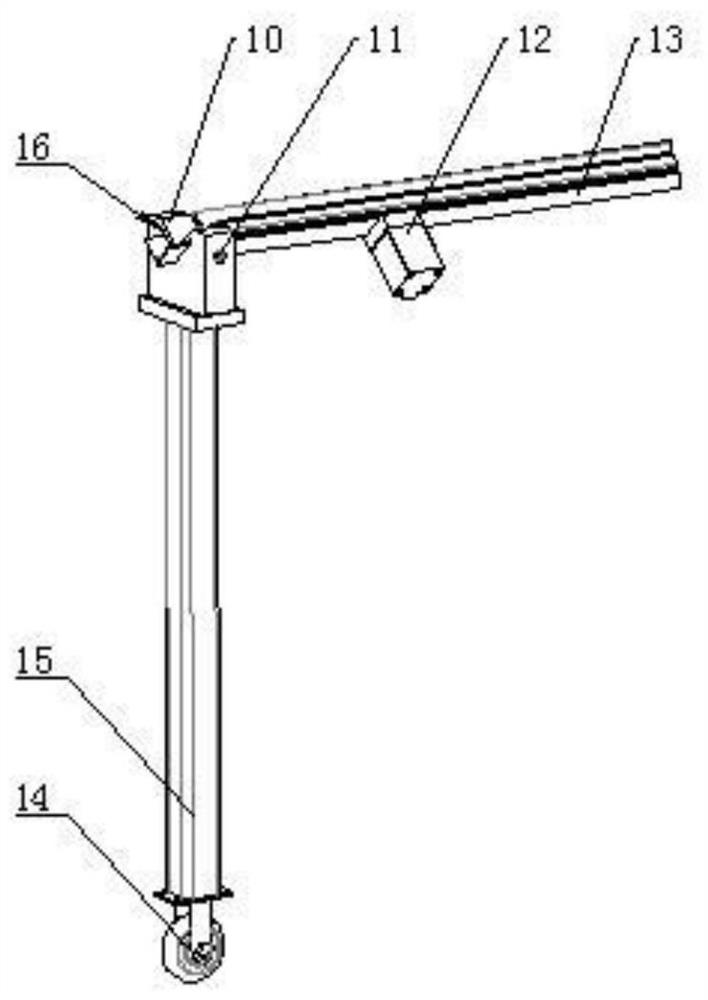

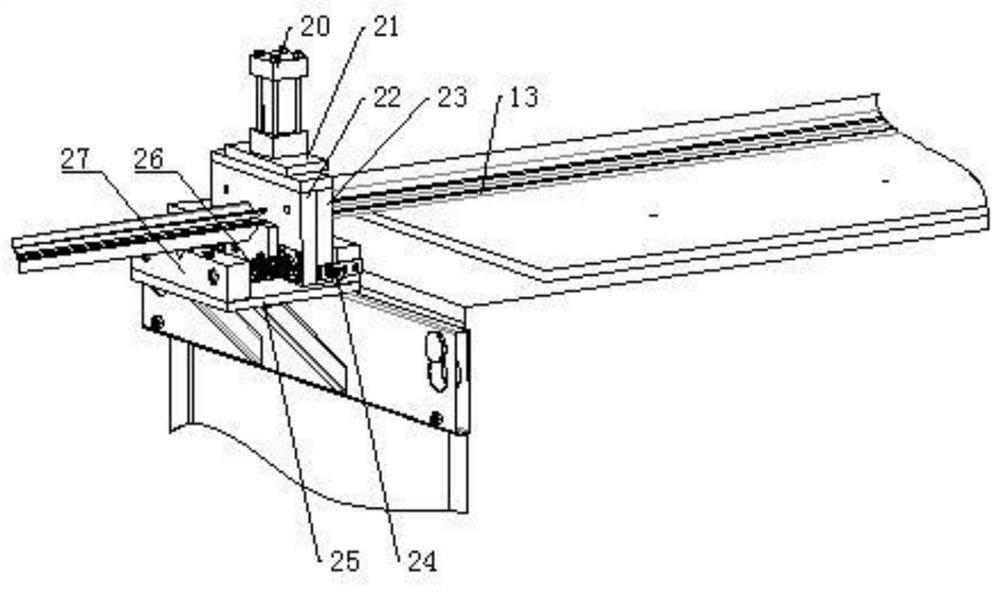

[0033] The fixed-length cutting device for angle-shaped plates includes a workbench 4. The workbench is installed at the downstream position of the extrusion process. The extruded plates are introduced from one side of the workbench and exported from the other side of the workbench. The workbench A cutting assembly 3 is installed in the table, and the innovation of the present invention is that a cutting assembly 2 and a length-fixing assembly 1 are installed in sequence at the downstream position of the cutting head assembly, and the cutting assembly and the length-fixing assembly are arranged at intervals. The gap between them is the fixed length of the plate to be cut, and the cutting assembly is used to cut the fixed length of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com