Wood peeling processing equipment for furniture production

A kind of processing equipment and wood technology, which is applied in the field of wood peeling processing equipment for furniture production, can solve the problems of easily hurting hands, easily damaging wood, and affecting peeling efficiency, so as to reduce the hazard, reduce the time of manual cutting, and realize The effect of automatically cutting wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

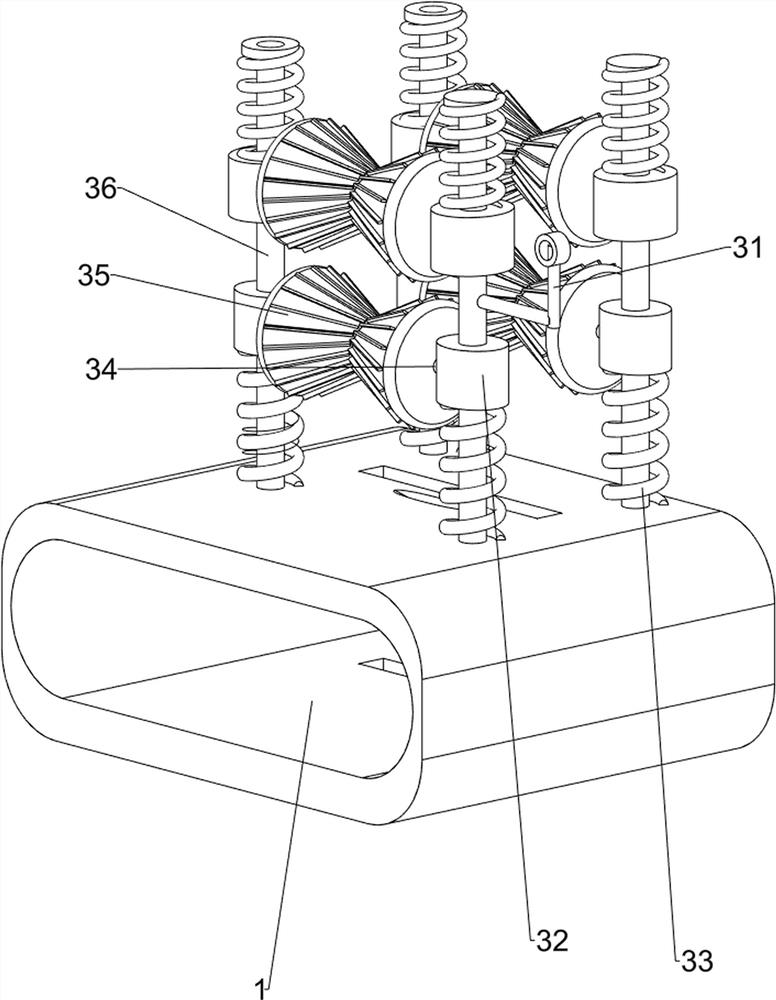

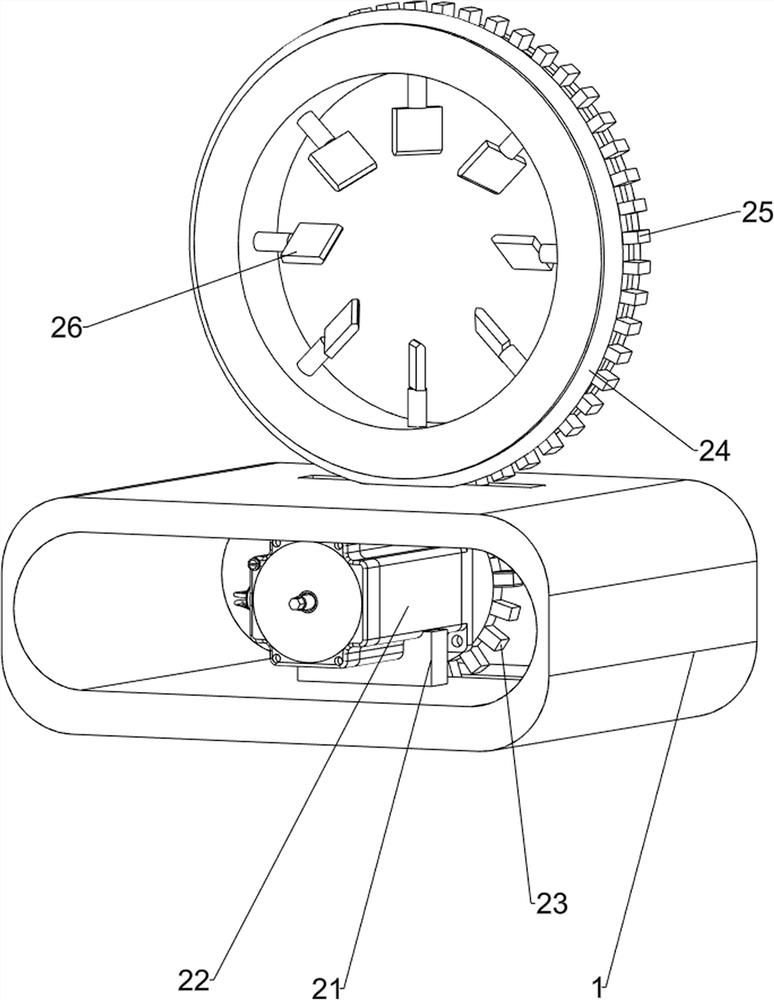

[0022] A wood peeling processing equipment for furniture production, such as Figure 1-3 As shown, it includes a first support frame 1, a rotary peeling mechanism 2 and an auxiliary peeling mechanism 3. The first support frame 1 on the front side is provided with a rotary peeling mechanism 2, and the top of the first support frame 1 on the front side is provided with There is an auxiliary peeling mechanism3.

[0023] When people need to peel wood, this kind of wood peeling processing equipment for furniture production can be used. First, the user needs to hold a piece of wood and place it in the part of the rotary peeling mechanism 2, then start the rotary peeling mechanism 2, and rotate The 2 parts of the peeling mechanism will peel the wood. When peeling the thicker furniture wood, the wood placed in the 2 parts of the rotary peeling mechanism will make the 3 parts of the auxiliary peeling mechanism move back, thereby assisting the rotary peeling. The 2 parts of the skin me...

Embodiment 2

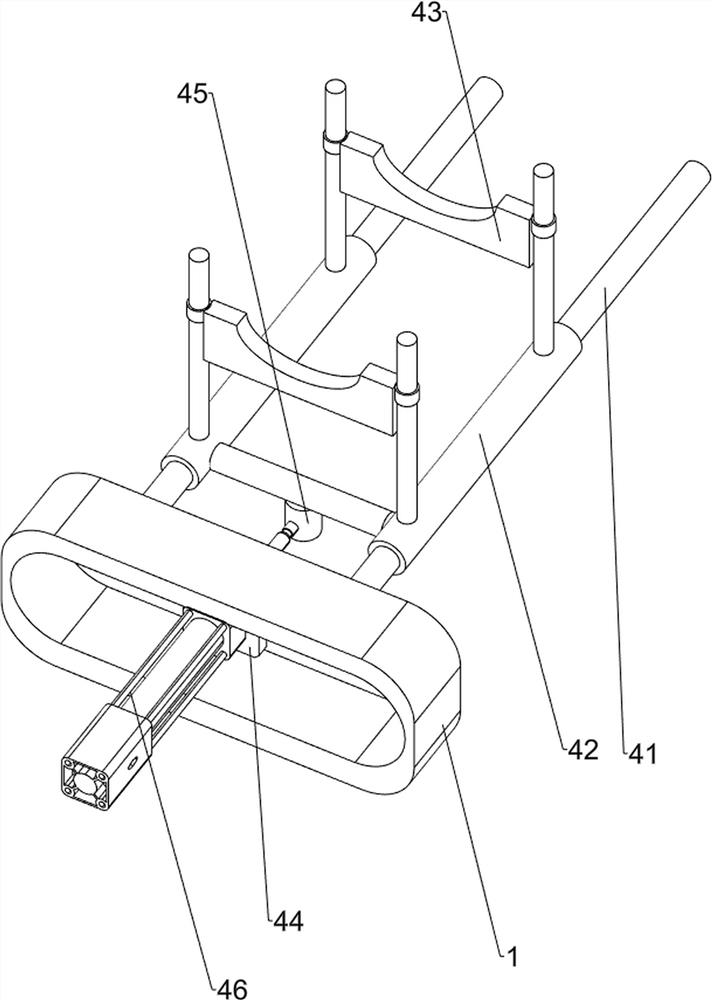

[0025] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, it also includes a feeding mechanism 4, and the feeding mechanism 4 includes a second support frame 41, a second sliding sleeve 42, a concave frame 43, a first fixed block 44, a second fixed block 45 and a cylinder 46, front and rear A second support frame 41 is provided between the first support frames 1 on both sides, and a second sliding sleeve 42 is slidably provided between the rear sides of the two second support frames 41. The tops of the front and rear sides of the second sliding sleeve 42 are A concave frame 43 is provided, and a first fixed block 44 is arranged on the upper side of the first support frame 1 inner wall on the rear side, and a cylinder 46 is installed on the first fixed block 44, and a second fixed block 45 is provided on the telescopic rod of the cylinder 46. , the second fixing block 45 is connected with the second sliding sleeve 42 .

[0026] The user puts the wood on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com