Concrete flow control system

A flow control, concrete technology, applied in the direction of unloading devices, etc., can solve the problems of waste, uncontrollable concrete speed and volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

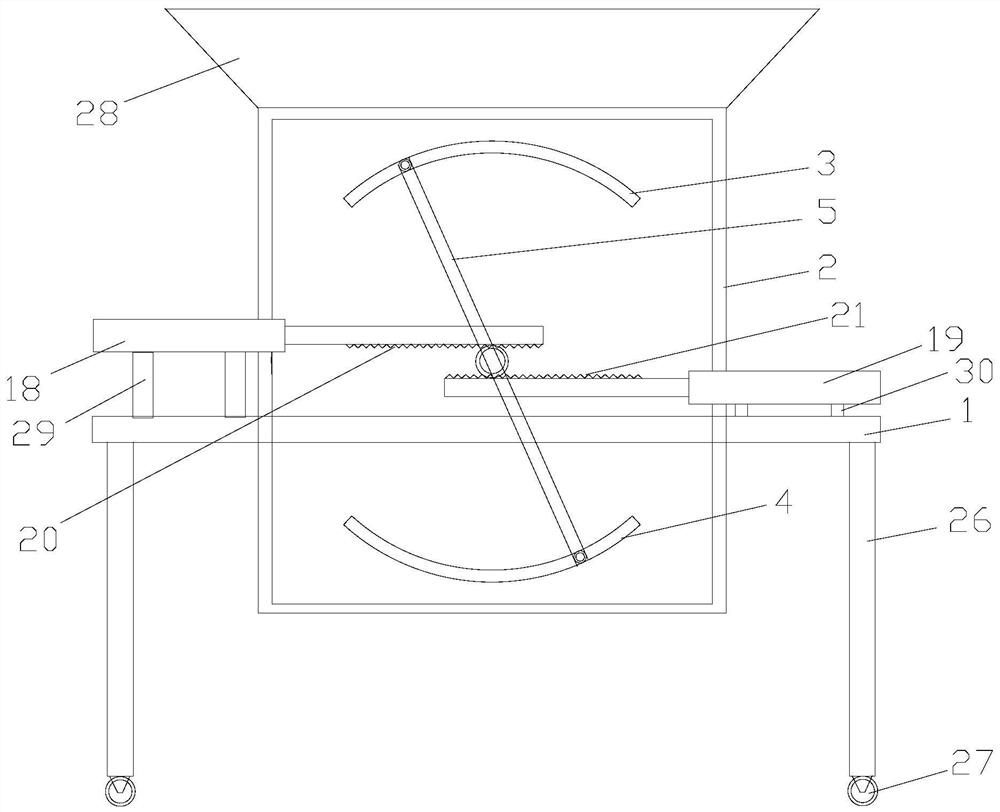

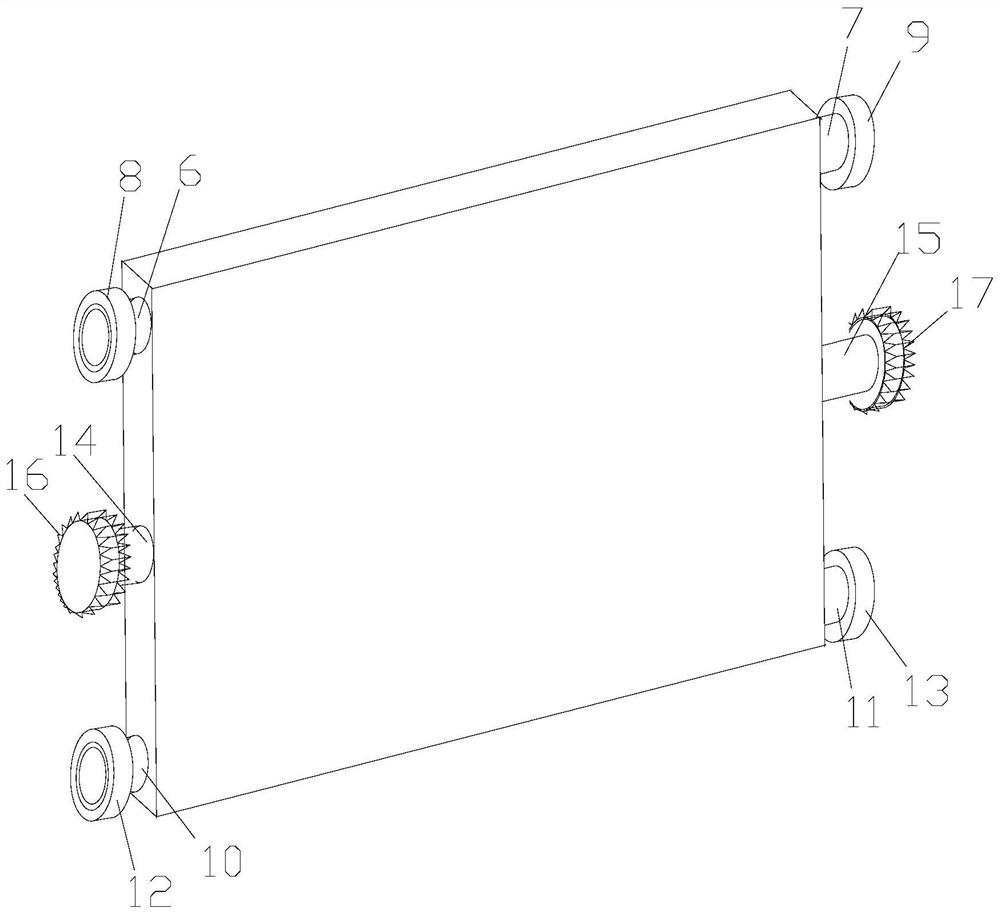

[0019] like figure 1 and figure 2 , this embodiment provides a concrete flow control system, including a support plate 1, a flow limiting box 2, an upper chute 3, a lower chute 4, a flow limiting plate 5, a first connecting column 6, a second connecting column 7, a first One bearing 8, the second bearing 9, the third connecting column 10, the fourth connecting column 11, the third bearing 12, the fourth bearing 13, the fifth connecting column 14, the sixth connecting column 15, the first connecting gear 16, the Two connecting gears 17, the first cylinder 18, the second cylinder 19, the first rack 20, the second rack 21, the third cylinder 22, the fourth cylinder 23, the third rack 24, the fourth rack 25, support Pin 26, universal wheel 27, feed hopper 28, high support frame 29, low support frame 30; Wherein the 3rd cylinder 22, the 4th cylinder 23, the 3rd rack 24, the 4th rack 25 and the first cylinder 18 , the second cylinder 19 , the first rack 20 , and the second rack 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com