Self-skinning device for plastic foam box

A technology of foamed plastics and self-skinning, which is applied in the field of foamed plastics and can solve the problems of insufficient foaming degree of materials, limited stirring range of stirring rods, and reduced production quality of foamed plastic boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Figure 6 Shown:

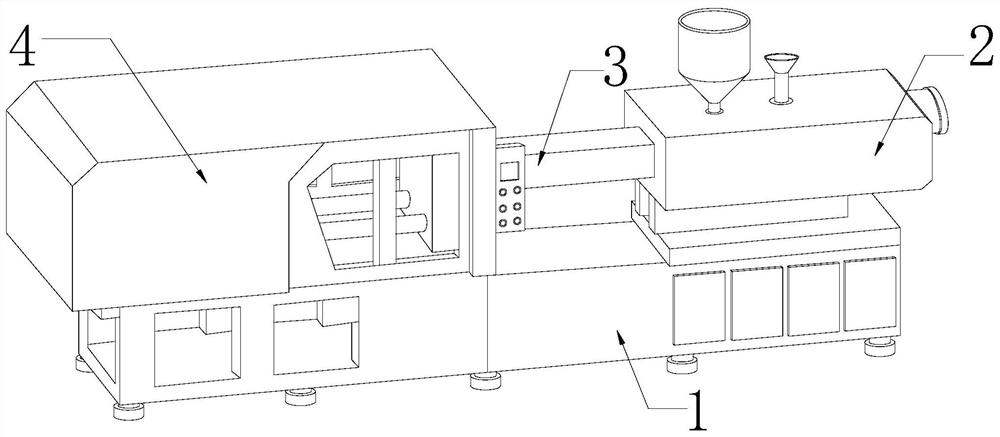

[0030] The invention provides a self-skinning equipment for a foamed plastic box, the structure of which includes a body 1, a mixer 2, a feeding pipe 3, and a mold 4. The mixer 2 is horizontally fixed on the top of the right end of the body 1, and the mold 4 is located On the left side of the device 2, the feed pipe 3 is installed between the mold 4 and the mixer 2.

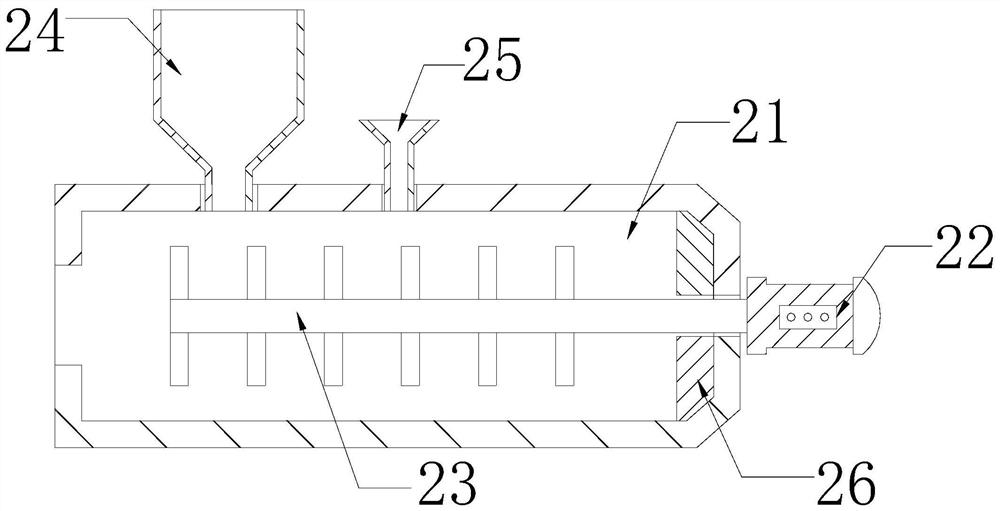

[0031] The mixer 2 is provided with a foaming chamber 21, a motor 22, a stirring rod 23, a hopper 24, a reagent tube 25, and a pushing mechanism 26. The foaming chamber 21 is located inside the mixer 2, and the motor 22 is horizontally fixed on In the middle part of the right end of the mixer 2, the stirring rod 23 is arranged in the middle part of the foaming cavity 21, and cooperates with the motor 22. The hopper 24 is vertically fixed on the top of the mixer 2, and the reagent tube 25 is located on the right side of the hopper 24. The pushing mechanis...

Embodiment 2

[0039] as attached Figure 7 to attach Figure 9 Shown:

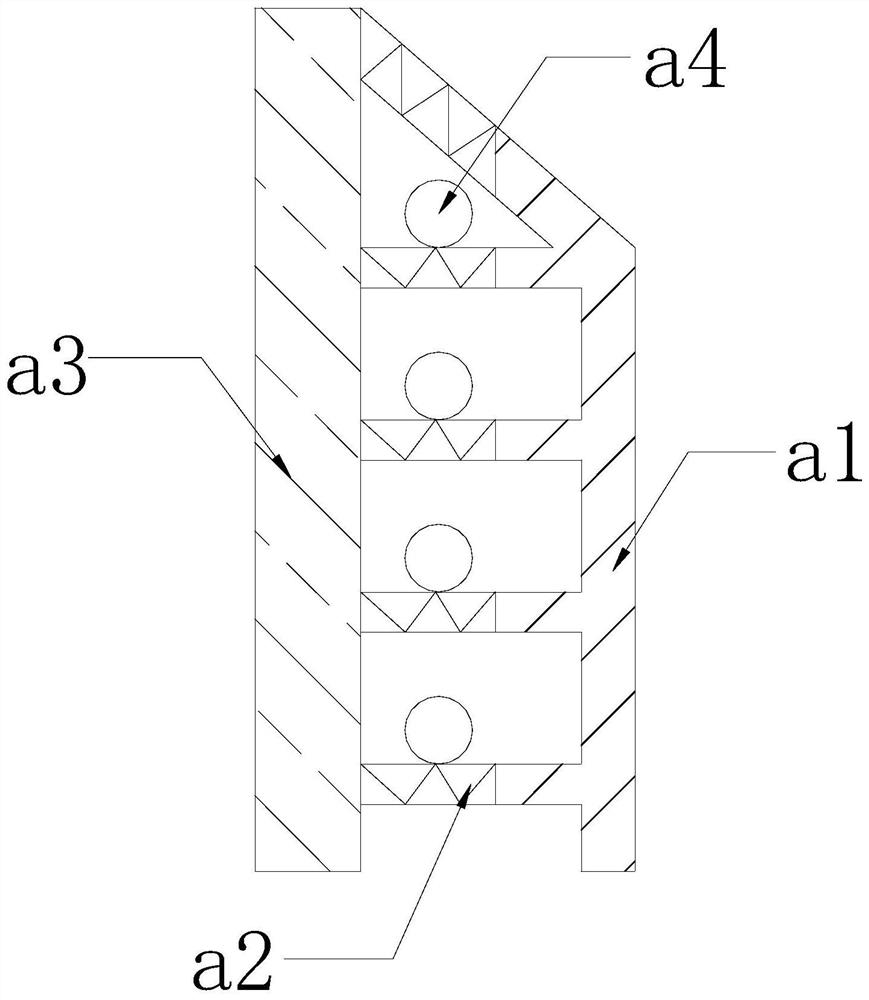

[0040] Wherein, the clearing block s4 is provided with a card groove e1, a drainage groove e2, a clearing plate e3, and a reset bar e4, and the locking groove e1 is recessed on the top of the clearing block s4, and the drainage groove e2 runs through the middle and left sides of the clearing block s4. Between the sides, and communicate with the card slot e1, the clearing plate e3 is set on the top of the card slot e1, the reset strip e4 is installed between the bottom surface of the clearing plate e3 and the inner wall of the card slot e1, and the drainage groove e2 The bottom surface of the left end is inclined, which can reduce resistance and friction, and is conducive to the flow and discharge of material fluid along the drainage groove e2, reducing material retention inside the drainage groove e2, further reducing the gravity of the push plate a3, and speeding up the moving speed of the push plate a3 .

[0041] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com