Installing structure of forced side feeding machine of double-screw extruder

A twin-screw extruder and installation structure technology, which is applied in the field of twin-screw extruders, can solve problems such as difficulty in assembly and maintenance of gearboxes, difficulty in installation and positioning adjustment of side feeding barrels, and spraying of materials at the inlet of side feeding barrels. , to achieve the effect of saving assembly and maintenance time, convenient installation and operation, and simple assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

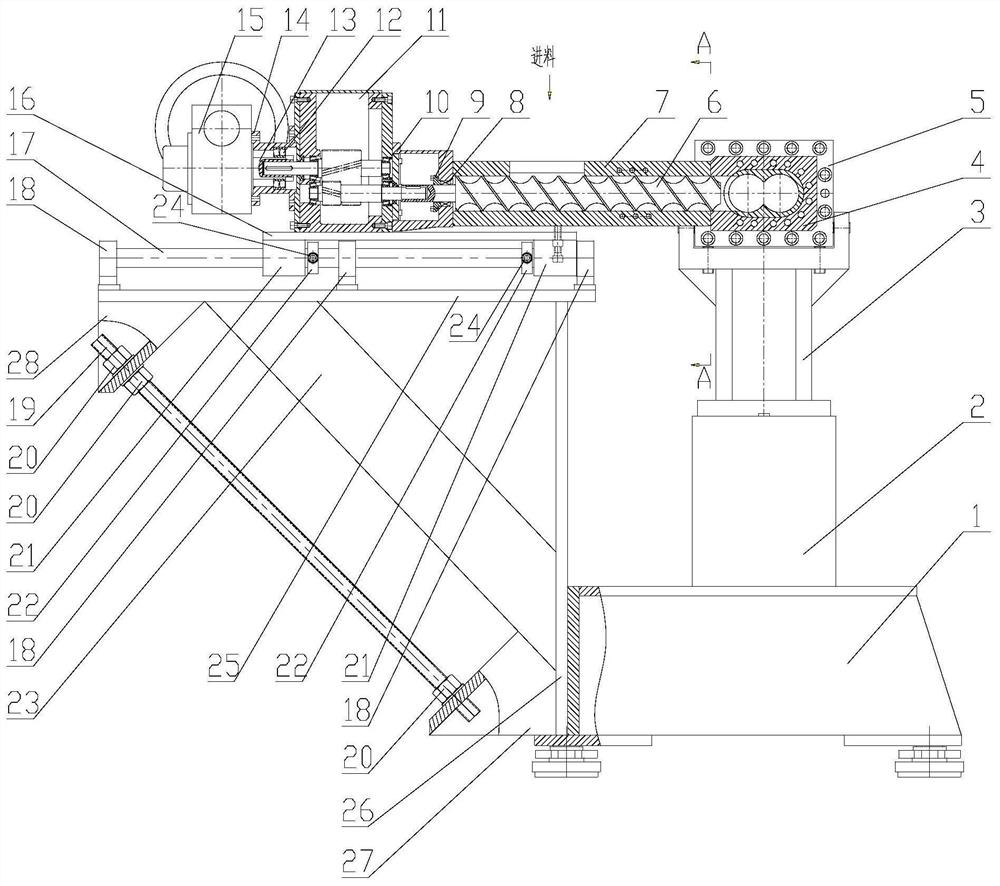

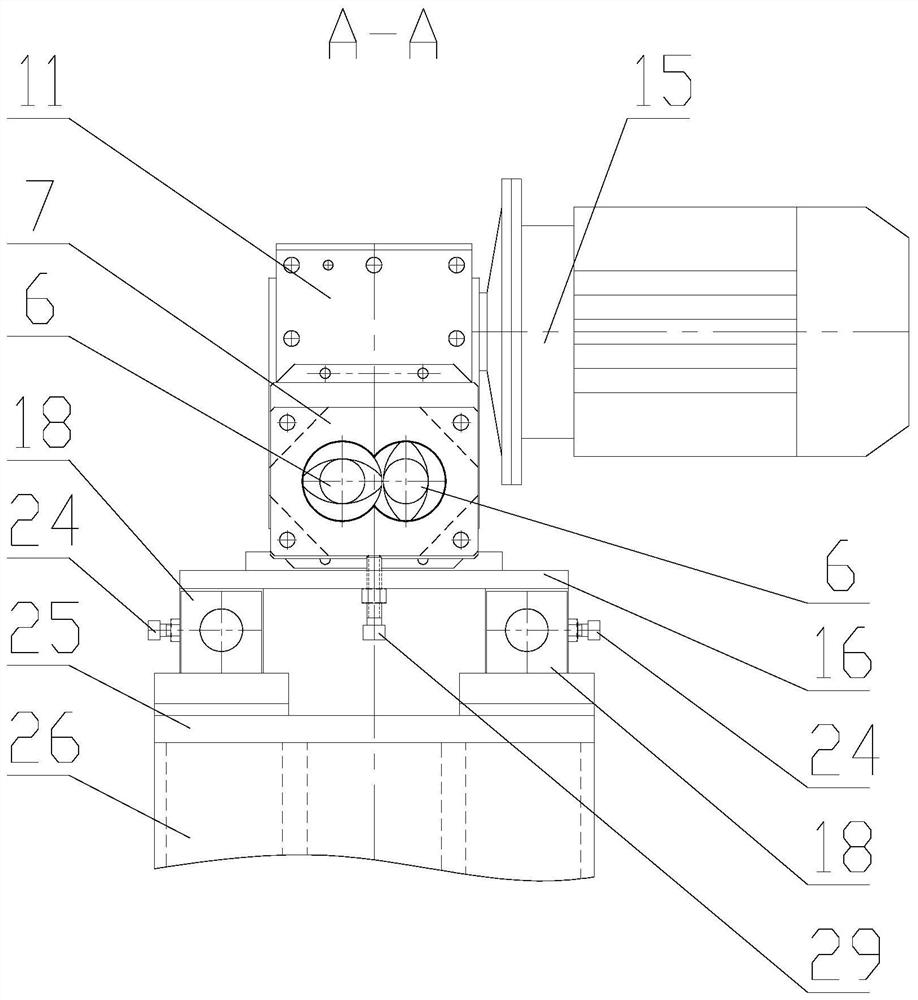

[0035] The present invention will be further explained below in conjunction with the accompanying drawings.

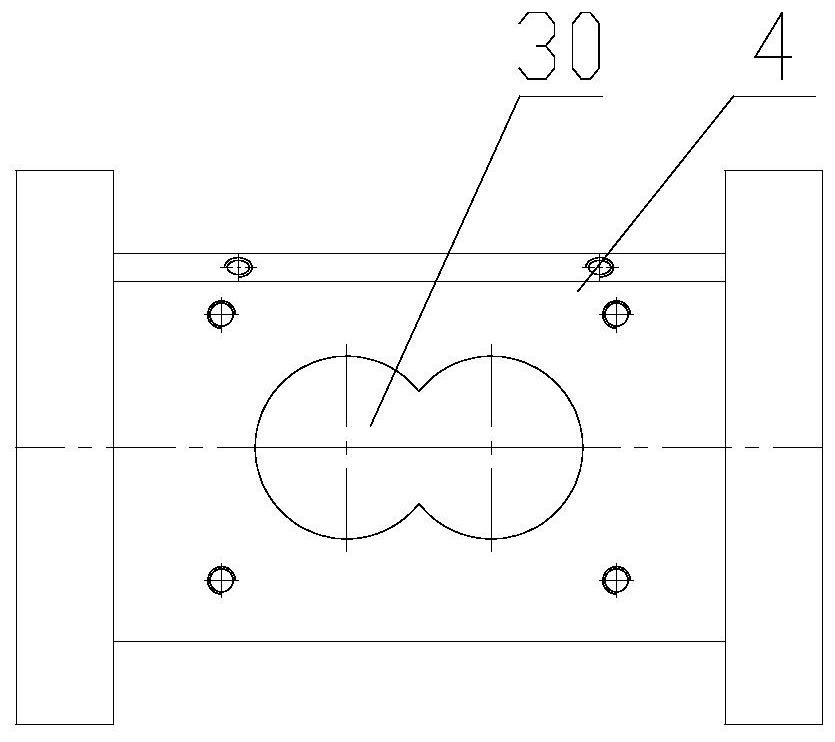

[0036] Such as figure 1 , 2 Shown in and 3, a kind of twin-screw extruder forced side feeder installation structure of the present invention comprises a forced side feeder, and the forced side feeder consists of a side feeding cylinder 7, a pair of intermeshed side feeders The screw rod 6, the connecting body 10, the gear box 11, the connecting flange 14 and the reduction motor 15 are combined. The side feed barrel 7 of the forced side feeder is connected to the side feed port 30 of the side feed barrel 4 of the twin-screw extruder.

[0037] Such as image 3 and 4 As shown, the side feeding cylinder flange II5 of the side feeding cylinder 4 is installed above the cylinder support 3, the lower part of the cylinder support 3 is installed on the upper part of the support base 2, and the lower part of the support base 2 is connected to the twin-screw The upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com