Methods and device for LCD photocuring 3D printing light equalizing optimization compensation

A technology of 3D printing and compensation method, applied in the field of 3D printing, can solve problems such as the success or failure of printing, insufficient light source intensity and need to be adjusted, and uneven exposure of light-curing 3D printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

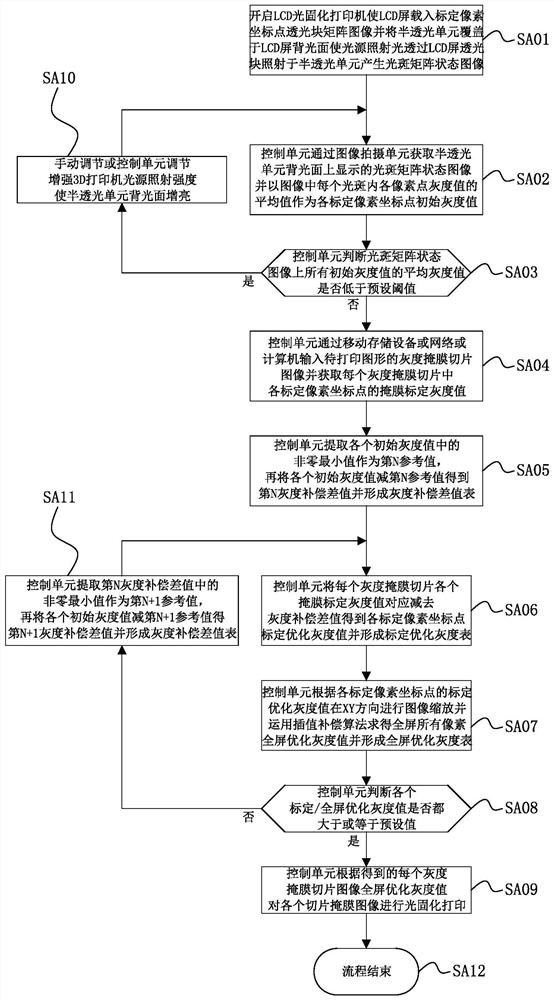

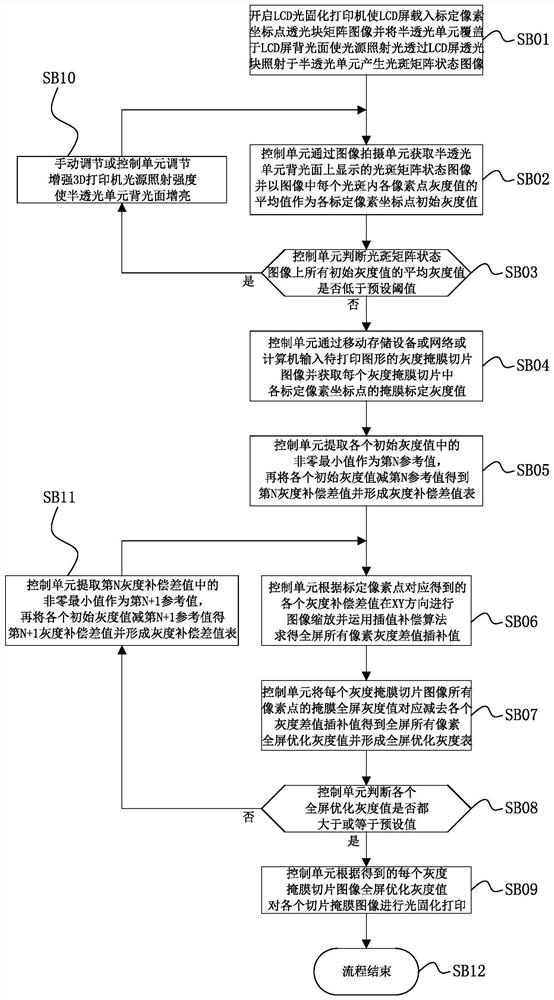

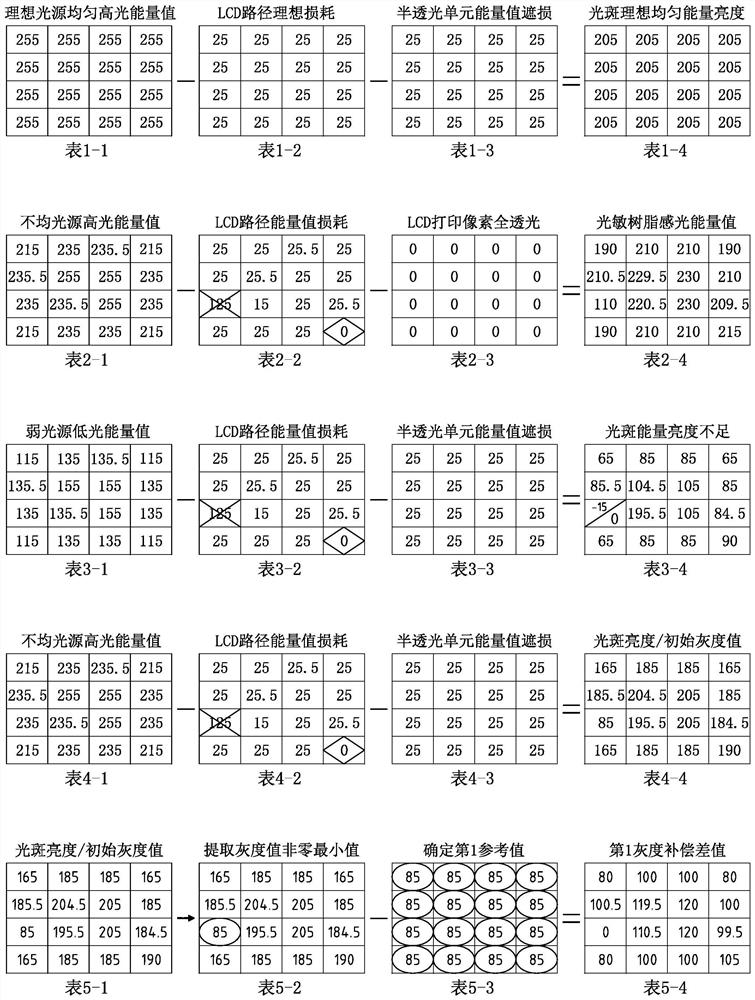

[0124] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0125] Current LCD light-curing 3D printers usually use a single light source or a matrix light source. Due to the service life of the lamp bead itself, manufacturing errors, manufacturing precision limitations of optical devices, and the energy loss of the LCD path, the energy value of the irradiated light at each point on the plane when the ultraviolet light source penetrates the mask pixel to irradiate the photosensitive curing reaction material Inconsistency, uneven exposure; and when there are dead pixels on the LCD screen, if the pre-stored gray value of the LCD screen is too small or the illumination intensity of the light source is not enough, there will also be problems of printing failure. Aiming at these problems, the present invention discloses six methods and a device for uniform light optimization and compensation of LCD photocuring 3D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com