Automatic steel cutting and binding device

A cutting device and steel technology, applied in the engineering field, can solve problems such as single function and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

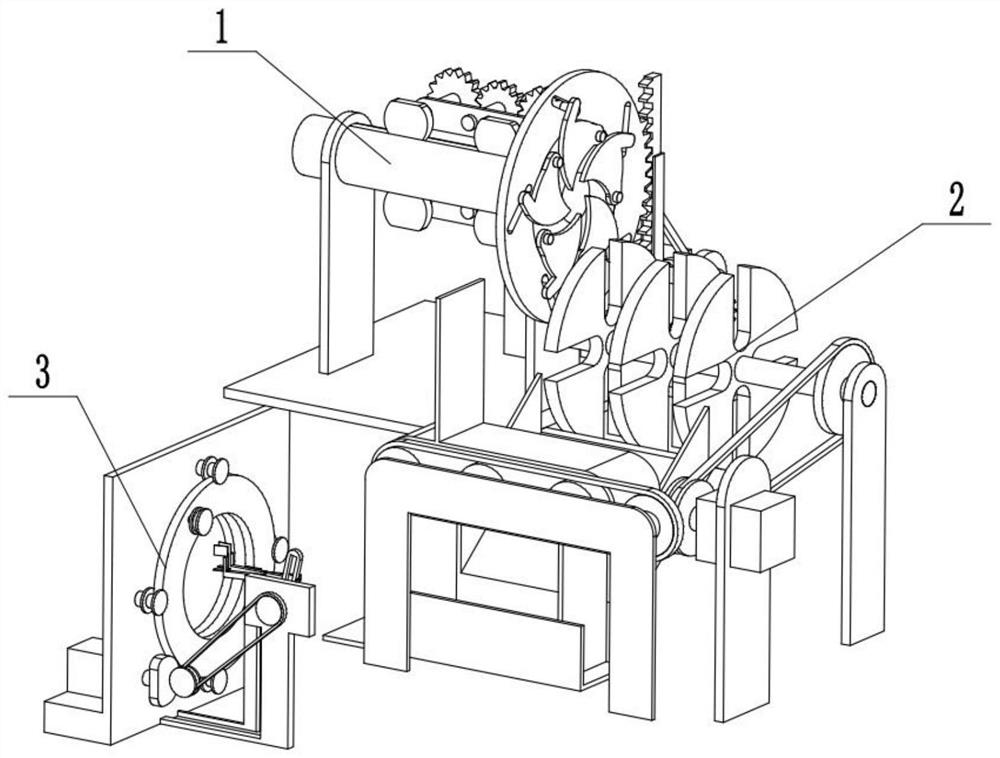

[0026]Bonded belowFigure 1-10In the present embodiment, an automatic steel cutting bundling device includes a cutting device 1, a transmission device 2, a bundled apparatus 3, and the cutting device 1 is connected to the transmission device 2, and the cutting device 1 is connected to the bundled apparatus 3.

specific Embodiment approach 2

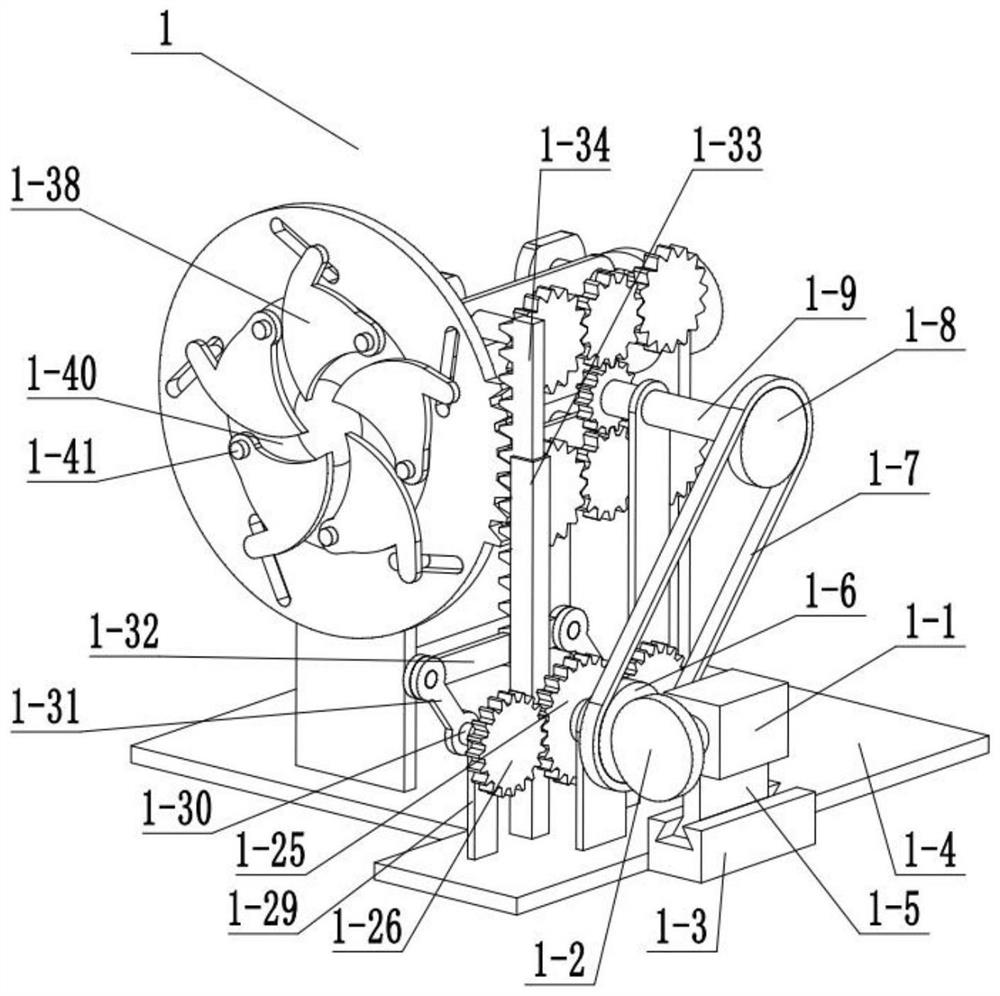

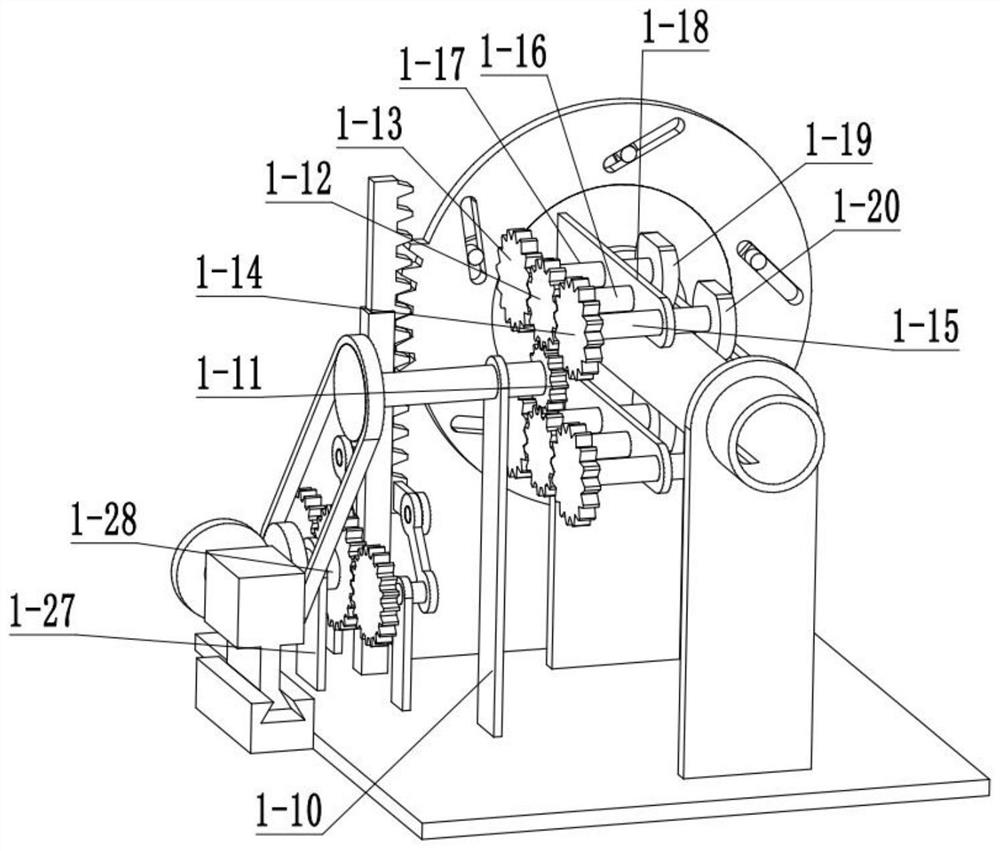

[0028]Bonded belowFigure 1-10In this embodiment, the present embodiment will further explain the embodiment, and the cutting device 1 includes a motor 1-1, a rotary one 1-2, a motor base 1-3, a base boss 1-4, a slider 1-5, Runner 2 1-6, belt 1-7, runner three 1-8, connecting rod 1-9, stent one 1-10, gear 1-11, gear 2 1-12, gear Three 1-13, gear four 1-14, connecting rod two 1-15, connecting rod three 1-16, connecting rod 4 1-17, bracket 2 1-18, half wheel 1-19, half turn wheel 2 1-20, transmission tube 1-21, slot 1-22, bracket three 1-23, bracket 4 1-25, gear six 1-26, bracket 5 1-27, connecting rod 5 1 -28, bracket six 1-29, connecting rod 6 1-30, function rod 1-31, long rod 1-33, straight tooth 1-34, functional disk 1-35, small slot 1 -36, small cylindrical 1-37, cutting blade 1-38, nozzle 1-39, inner disc 1-40, hinge column 1-41, motor one 1-1 and wheel 1-2 fixed connection, The motor 1-1 is fixed to the slider 1-5, the motor base 1-3 is slidable with the slider 1-5, and the moto...

specific Embodiment approach 3

[0031]Bonded belowFigure 1-10In the present embodiment, the present embodiment will further explain the embodiment, and the transmission device 2 includes a motor 2-1, a struts 2-2, a rotary four 2-3, a belt 2-4, a strut 2 2 -5, runner five 2-6, function long rod 2-7, turntable 2-8, card slot 2-9, slide 2-10, transmission inner column 2-11, transmission 3-12, transmission belt 2 -13, Function Board 2-14, belt three 2-15, collect box 2-16, pillar three 2-17, runner six 2-18, fixed column 2-19, motor 2-1 and pillar one 2- 2 fixed connection, motor 2-1 and rotary four 2-3 fixed connections, rotary four 2-3 with belt 2-4, belt 2-4 with the runner five 2-6, transfer Wheel 5 2-6 is fixedly connected to function long rod 2-7, and the function long rod 2-7 is rotated to the pillar 2-5, and the four turntables 2-8 are fixedly connected to the functional long rod 2-7, four cards Both the slots 2-9 are provided on the turntable 2-8, the transmission inner column 2-11 is rotated to the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com