A kind of manufacture technology of graphene composite sponge

A graphene composite and production process technology, applied in the field of sponge production, can solve problems such as the inability to detect the user's sleeping posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

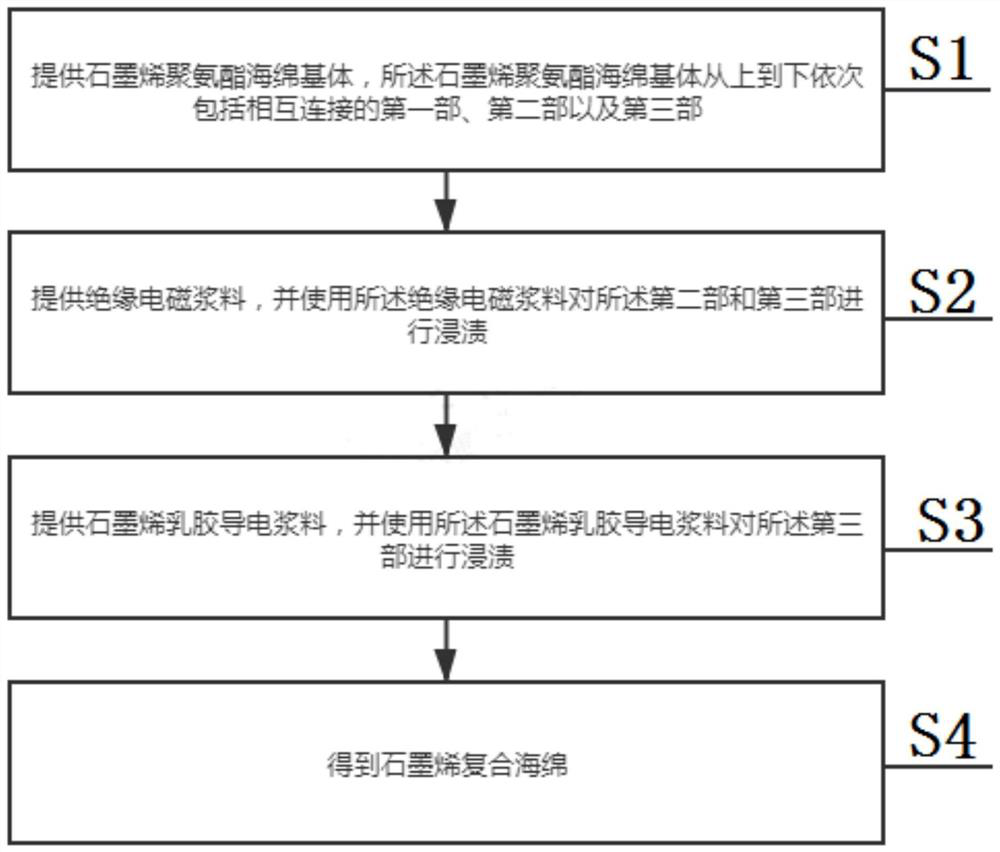

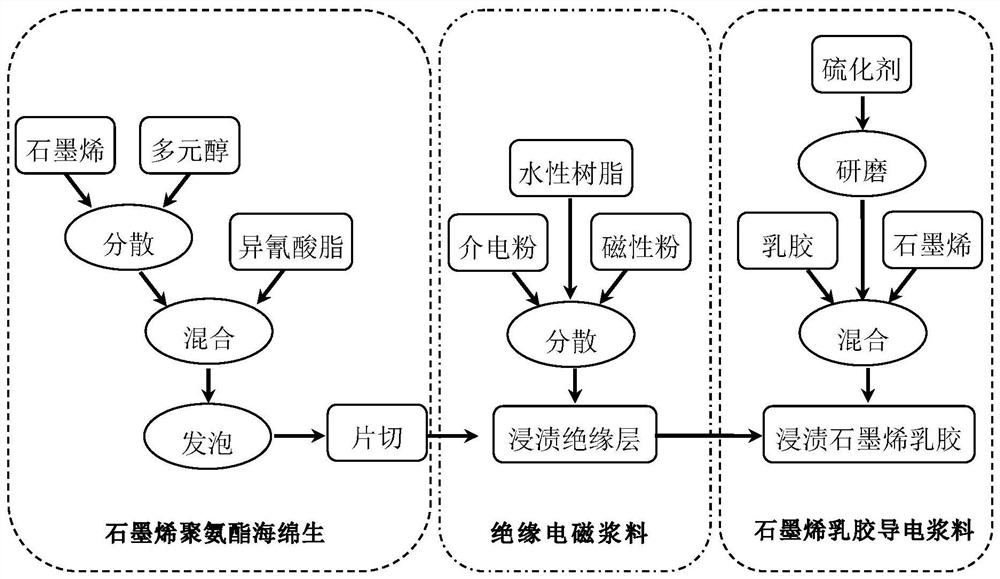

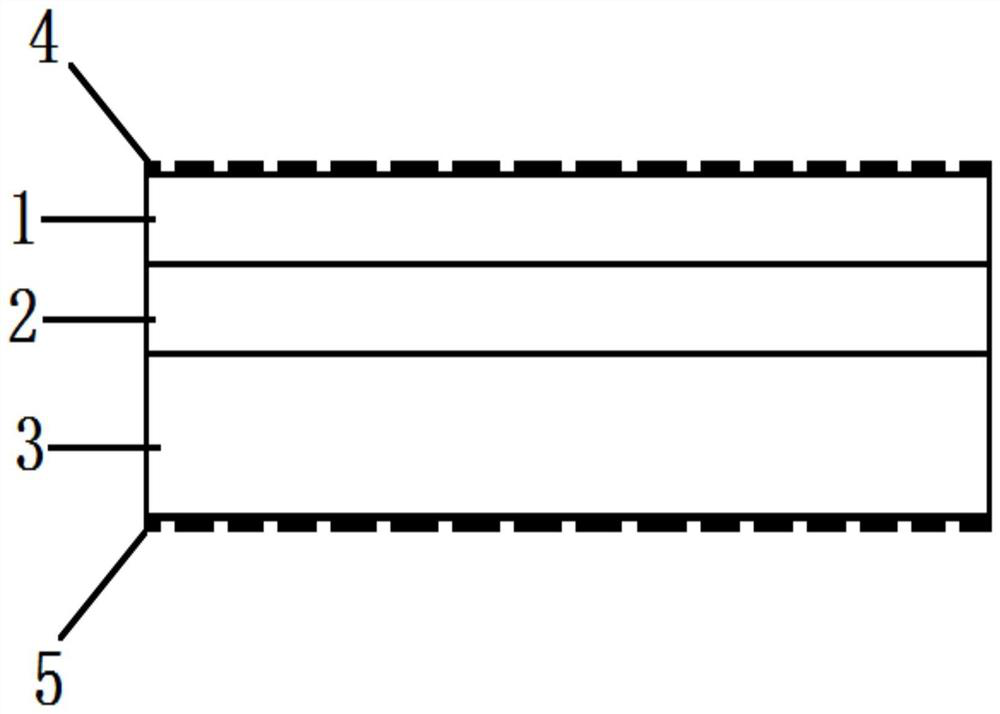

Method used

Image

Examples

Embodiment 1

[0097] Production of graphene polyurethane sponge matrix:

[0098] a. Heat nano-graphene and carbon nanotubes and polyether polyols with a hydroxyl value of 300mgKOH / g to 7% by weight in a reactor to stir and disperse evenly, and the weight ratio of graphene to carbon nanotubes is 10 :1. The carbon content of multilayer graphene is greater than 97.5%, and the specific surface area is 120m 2 / g, the average aspect ratio of carbon nanotubes is greater than 1000.

[0099] b. Using a three-roll machine with a diameter greater than 150mm to circulate and disperse the graphene polyol slurry to obtain a graphene polyol slurry with an average particle size of graphene less than 20 μm.

[0100] C, add foaming agent, surfactant, cell opener and catalyst in graphene polyol slurry, get component A after mixing; Foaming agent is water, and surfactant is silicone oil, and cell opener is formazan Base siloxane, catalyst is T9, and the weight ratio of described foaming agent, surfactant, c...

Embodiment 2

[0117] Production of graphene polyurethane sponge matrix:

[0118] a. Heat nanographene and carbon nanotubes and polyether polyols with a hydroxyl value of 300mgKOH / g to 8% by weight in a reactor to stir and disperse evenly, and the weight ratio of graphene to carbon nanotubes is 10 : 1.5. The carbon content of multilayer graphene is greater than 97.5%, and the specific surface area is 120m 2 / g, the average aspect ratio of carbon nanotubes is greater than 1000.

[0119] b. Using a three-roll machine with a diameter greater than 150mm to circulate and disperse the graphene polyol slurry to obtain a graphene polyol slurry with an average particle size of graphene less than 20 μm.

[0120] C, add foaming agent, surfactant, cell opener and catalyst in graphene polyol slurry, get component A after mixing; Foaming agent is water, and surfactant is silicone oil, and cell opener is formazan Base siloxane, catalyst is T9, and the weight ratio of described foaming agent, surfactant,...

Embodiment 3

[0132] Production of graphene polyurethane sponge matrix:

[0133] a. Heat nano-graphene and carbon nanotubes and polyether polyols with a hydroxyl value of 280mgKOH / g to 10% by weight in a reactor to stir and disperse evenly, and the weight ratio of graphene to carbon nanotubes is 10 :1. The carbon content of multilayer graphene is greater than 97.5%, and the specific surface area is 150m 2 / g, the average aspect ratio of carbon nanotubes is greater than 1000.

[0134] b. Using a three-roll machine with a diameter greater than 150mm to circulate and disperse the graphene polyol slurry to obtain a graphene polyol slurry with an average particle size of graphene less than 20 μm.

[0135]C, add foaming agent, surfactant, cell opener and catalyst in graphene polyol slurry, get component A after mixing; Foaming agent is water, and surfactant is silicone oil, and cell opener is formazan Base siloxane, catalyst is A33, and the weight ratio of described foaming agent, surfactant, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com