Superfineatomized all-weather low-viscosity multipurpose water-based blended water and preparation method thereof

An all-weather, multi-purpose technology used in coatings to solve problems such as high construction viscosity, complex formulations, and suboptimal testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

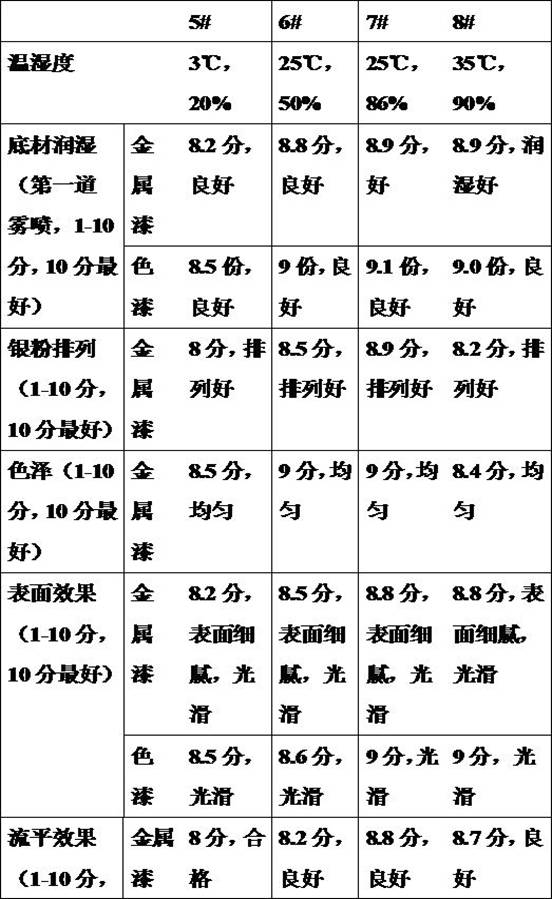

Examples

Embodiment 1

[0028] An ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water, the preparation method is:

[0029] e1: Add rheological additives, deionized water, and dispersants in the additives in the formula amount in sequence, and stir at 500-800r / min at high speed for 20 minutes;

[0030] e2: Add formula amount of co-solvent to e1, 300-600 r / min, stir for 5 minutes; then add substrate wetting agent, 300-600 r / min, stir for 5 minutes;

[0031] e3: Add the thickener of formula quantity, under 500-800 r / min, stir 10 minutes; Then add resin, under 500-800 r / min, stir 10 minutes;

[0032] e4: Finally, add n-amyl alcohol in the prescribed amount, 300-600 r / min, and stir for 20 minutes to obtain ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water.

[0033]The amount of each substance is: 25 parts of resin, 8 parts of n-amyl alcohol, 4 parts of polypropylene glycol, 3 parts of dipropylene glycol methyl ether, 0.5 part of disper...

Embodiment 2

[0038] An ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water, the preparation method is:

[0039] e1: Add rheological additives, deionized water, and dispersants in the additives in the formula amount in sequence, and stir at 500-800r / min at high speed for 20 minutes;

[0040] e2: Add formula amount of co-solvent to e1, 300-600 r / min, stir for 5 minutes; then add substrate wetting agent, 300-600 r / min, stir for 5 minutes;

[0041] e3: Add the thickener of formula quantity, under 500-800 r / min, stir 10 minutes; Then add resin, under 500-800 r / min, stir 10 minutes;

[0042] e4: Finally, add n-amyl alcohol in the prescribed amount, 300-600 r / min, and stir for 20 minutes to obtain ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water.

[0043] The raw materials used and the amount used are: the following components (weight ratio): 20 parts of resin, 5 parts of n-pentanol, 4 parts of polypropylene glycol, 0.5 parts...

Embodiment 3

[0048] An ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water, the preparation method is:

[0049] e1: Add rheological additives, deionized water, and dispersants in the additives in the formula amount in sequence, and stir at 500-800r / min at high speed for 20 minutes;

[0050] e2: Add formula amount of co-solvent to e1, 300-600 r / min, stir for 5 minutes; then add substrate wetting agent, 300-600 r / min, stir for 5 minutes;

[0051] e3: add resin afterwards, under 500-800 r / min, stir for 10 minutes;

[0052] e4: Finally, add n-amyl alcohol in the prescribed amount, 300-600 r / min, and stir for 20 minutes to obtain ultra-fine atomized all-weather low-viscosity multi-purpose water-based blended water.

[0053] Wherein the raw materials and consumption used in embodiment 3 are (weight ratio): 20 parts of resin, 5 parts of n-amyl alcohol, 2.5 parts of polypropylene glycol, 1 part of dispersant, 0.4 part of substrate wetting agent, 1.5 parts of hect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com