Refined oil decolorizing tower

A decolorization tower and refined oil technology, which is applied in the field of refined oil decolorization tower technology, can solve the problems of uneven clay and oil, high cost, etc., and achieve the effects of improving stirring efficiency, increasing tumbling degree, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

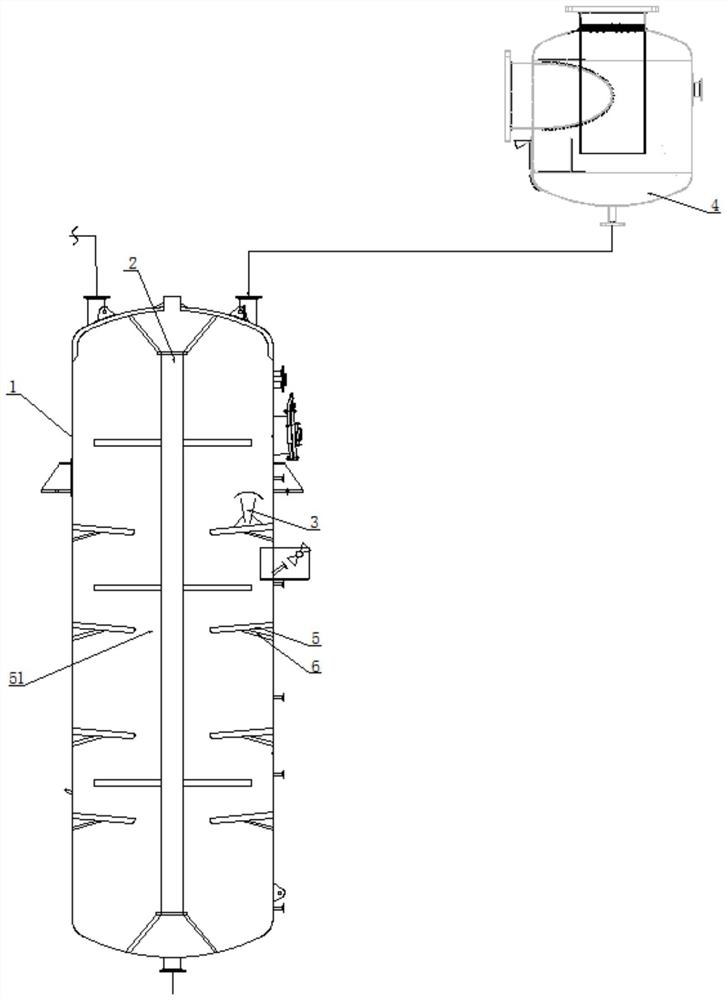

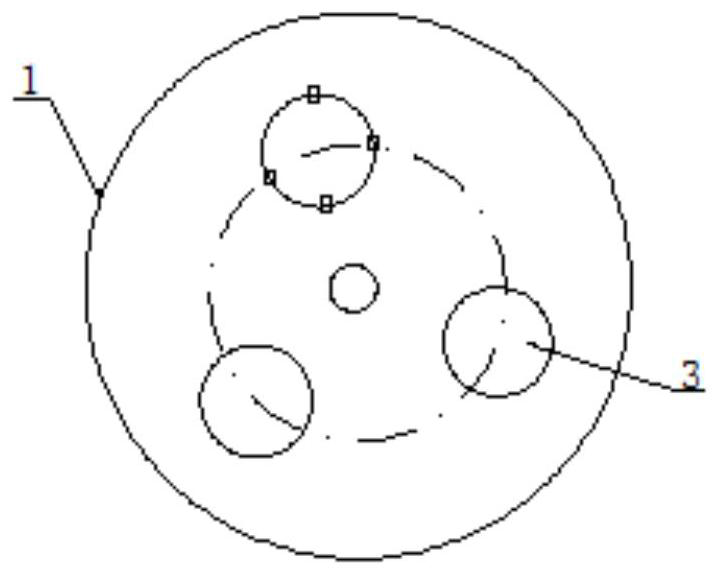

[0025] A kind of refined oil decolorization tower that the embodiment 1 of the present invention provides, comprises decolorization tower body 1, please refer to figure 1 As shown, the decolorization tower body 1 is provided with an agitator 2 inside. The stirrer 2 is arranged vertically. The agitator 2 and the decolorization tower body 1 are on the same axial line.

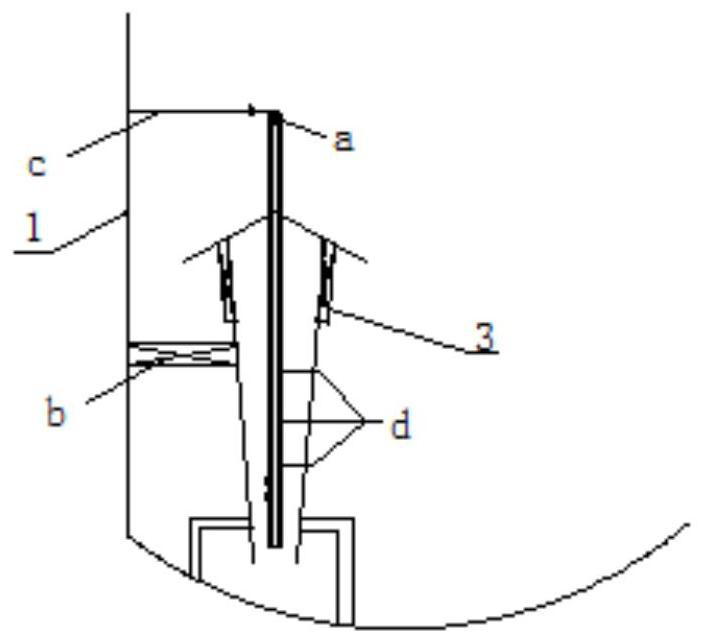

[0026] When in use, the original steam stirring coil is removed, and the agitator is installed from the top of the tower for mechanical agitation; because the agitator is added, the load bearing of the flange is increased, and the weld seam needs to be supported inside and outside; 100 high * 300 A total of 6 triangular flat irons with length * 5 thickness are evenly distributed and fully welded on the new flange and upper top cover; 6 SS304 flat iron supports are prefabricated and welded from the inside. The thickness of the flat iron is not less than 5mm; the width is not low At 100, one every 90 degrees, a t...

Embodiment 2

[0029] A kind of refined oil decolorization tower provided by embodiment 2 of the present invention comprises a decolorization tower body 1, please refer to figure 1 As shown, the decolorization tower body 1 is provided with an agitator 2 inside. The stirrer 2 is arranged vertically. The agitator 2 and the decolorization tower body 1 are on the same axial line.

[0030] When in use, the original steam stirring coil is removed, and the agitator is installed from the top of the tower for mechanical agitation; because the agitator is added, the load bearing of the flange is increased, and the weld seam needs to be supported inside and outside; 100 high * 300 A total of 6 triangular flat irons with length * 5 thickness are evenly distributed and fully welded on the new flange and upper top cover; 6 SS304 flat iron supports are prefabricated and welded from the inside. The thickness of the flat iron is not less than 5mm; the width is not low At 100, one every 90 degrees, a total ...

Embodiment 3

[0034] A kind of refined oil decolorization tower provided by embodiment 3 of the present invention comprises a decolorization tower body 1, please refer to figure 1 As shown, the decolorization tower body 1 is provided with an agitator 2 inside. The stirrer 2 is arranged vertically. The agitator 2 and the decolorization tower body 1 are on the same axial line.

[0035] When in use, the original steam stirring coil is removed, and the agitator is installed from the top of the tower for mechanical agitation; because the agitator is added, the load bearing of the flange is increased, and the weld seam needs to be supported inside and outside; 100 high * 300 A total of 6 triangular flat irons with length * 5 thickness are evenly distributed and fully welded on the new flange and upper top cover; 6 SS304 flat iron supports are prefabricated and welded from the inside. The thickness of the flat iron is not less than 5mm; the width is not low At 100, one every 90 degrees, a total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com