A kind of non-woven fiber material and its production process for medical health protection

A fiber material, medical and health technology, applied in the direction of fiber chemical characteristics, non-woven fabrics, textiles and papermaking, etc., can solve the problems that are difficult to meet the use requirements, hygroscopicity and antibacterial properties are not very good, and achieve light weight and elasticity Good, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

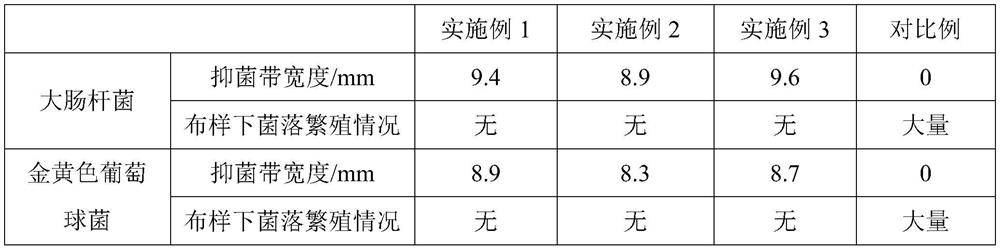

Examples

Embodiment 1

[0046] A non-woven fiber material used for medical and health protection, wherein the non-woven fiber material is modified polypropylene fiber.

[0047] The modified polypropylene fiber is obtained by modifying polypropylene with surface functional coral powder, and the mass ratio of surface functional coral powder to polypropylene is 1:20.

[0048] The diameter of the modified polypropylene fiber is 5-50 μm.

[0049] The preparation method of the surface functional coral powder is:

[0050] Step 1, firstly polish the coral sand into fine coral powder, then subject the fine coral powder to amination treatment to obtain coral powder amino treatment;

[0051] In step 2, the coral powder amino treatment substance is used to carry out grafting reaction with luteolin to obtain surface functional coral powder.

[0052] In the step 1, the coral sand is firstly ground to obtain 1-100 μm coral coarse powder, and then polished into 10-50 nm coral fine powder.

[0053] In the step 1, th...

Embodiment 2

[0082] A non-woven fiber material used for medical and health protection, wherein the non-woven fiber material is modified polypropylene fiber.

[0083] The modified polypropylene fiber is obtained by modifying polypropylene with surface functional coral powder, and the mass ratio of surface functional coral powder to polypropylene is 1:15.

[0084] The diameter of the modified polypropylene fiber is 5-50 μm.

[0085] The preparation method of the surface functional coral powder is:

[0086] Step 1, firstly polish the coral sand into fine coral powder, then subject the fine coral powder to amination treatment to obtain coral powder amino treatment;

[0087] In step 2, the coral powder amino treatment substance is used to carry out grafting reaction with luteolin to obtain surface functional coral powder.

[0088] In the step 1, the coral sand is firstly ground to obtain 1-100 μm coral coarse powder, and then polished into 10-50 nm coral fine powder.

[0089] In the step 1, ...

Embodiment 3

[0118] A non-woven fiber material used for medical and health protection, wherein the non-woven fiber material is modified polypropylene fiber.

[0119] The modified polypropylene fiber is obtained by modifying polypropylene with surface functional coral powder, and the mass ratio of surface functional coral powder to polypropylene is 1:35.

[0120] The diameter of the modified polypropylene fiber is 5-50 μm.

[0121] The preparation method of the surface functional coral powder is:

[0122] Step 1, firstly polish the coral sand into fine coral powder, then subject the fine coral powder to amination treatment to obtain coral powder amino treatment;

[0123] In step 2, the coral powder amino treatment substance is used to carry out grafting reaction with luteolin to obtain surface functional coral powder.

[0124] In the step 1, the coral sand is firstly ground to obtain 1-100 μm coral coarse powder, and then polished into 10-50 nm coral fine powder.

[0125] In the step 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com