Green and energy-saving fabricated building wall and construction method thereof

A building wall and assembly technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of little effect of indoor temperature, damage, waste of resources, etc., achieve convenient and fast assembly and disassembly, promote circulation, and build The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

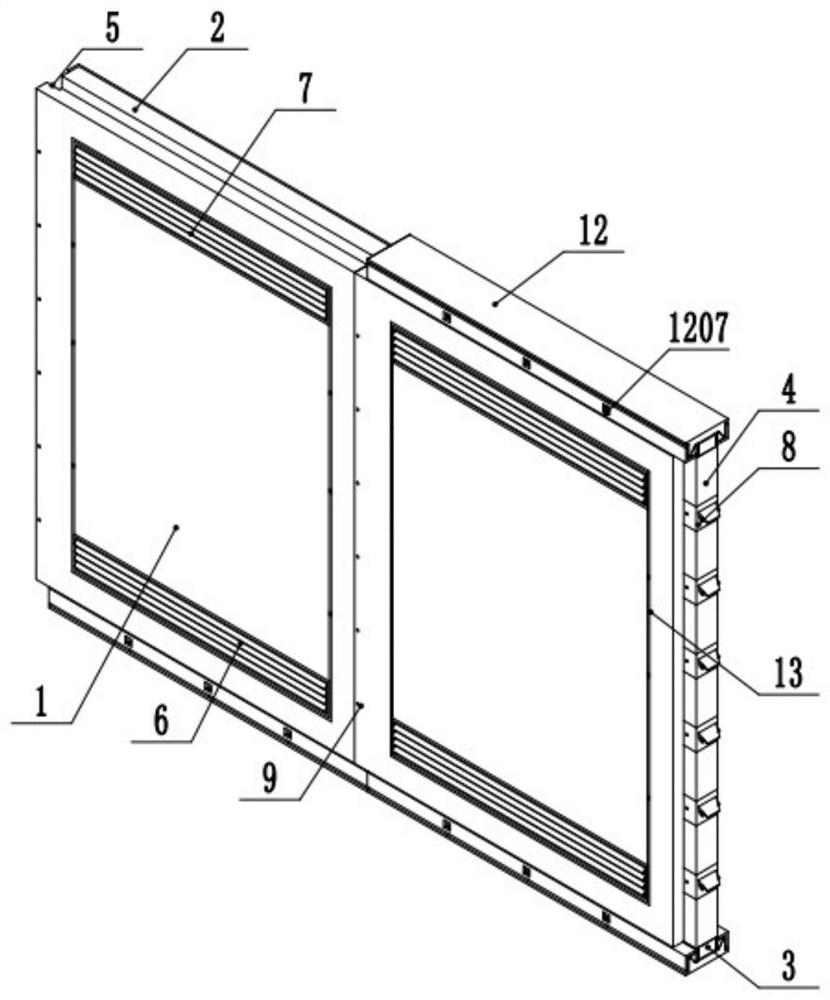

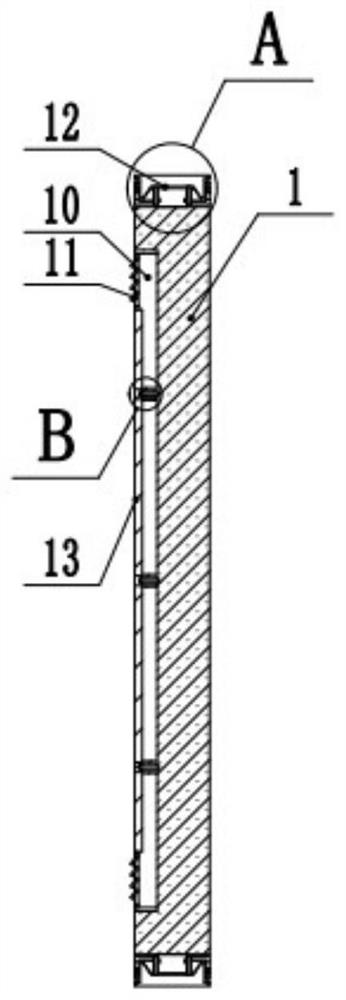

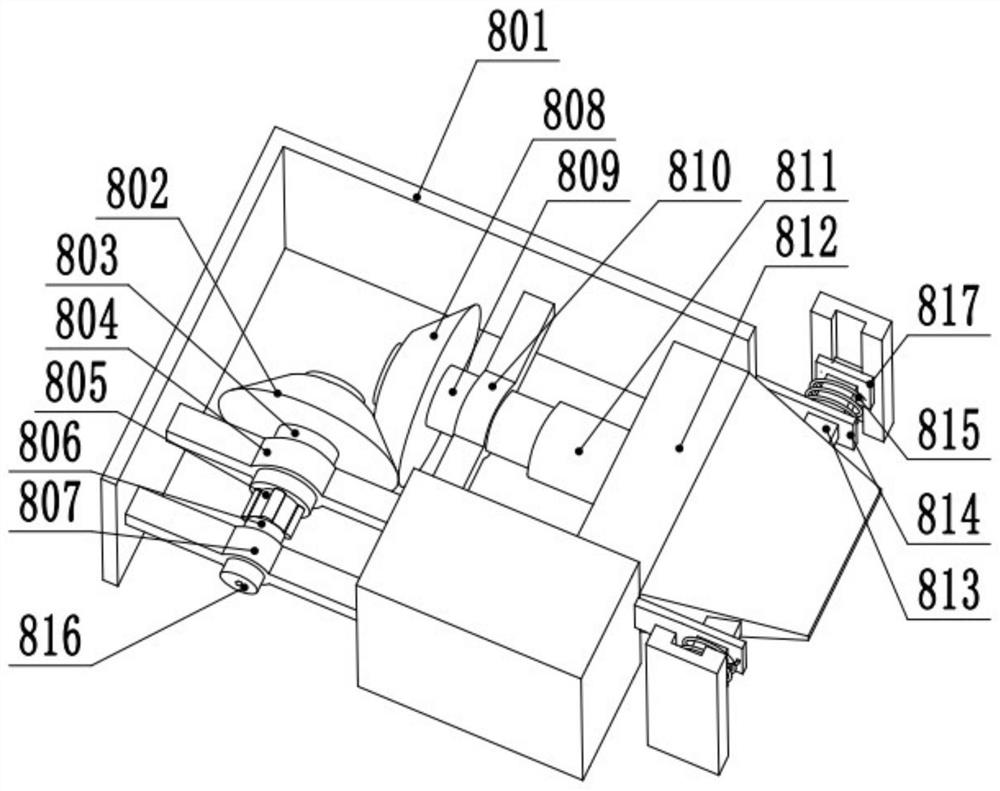

[0032] Such as figure 1As shown in and , the wall body 1 comprising a rectangular structure, the top of the wall body 1 is provided with an equal-length fillet 1 2, the bottom is provided with an equal-length fillet 2 3, the left side is provided with grooves 5 at intervals, and the right side Protrusions 4 and slot mechanisms 8 are alternately provided, and the first molding 2, the second molding 3, the bumps 4 and the grooves 5 are integrally cast and formed with the main body of the wall 1, and the shape of the slot mechanism 8 and the protrusions 4 The same, and both are matched with the telescopic connection of the left groove 5, and a horizontal groove is respectively provided at the top and bottom symmetrical positions of the groove 5, which is used to splice a plurality of wall main bodies 1; The upper and lower sides of the second 3 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com