Soluble ball seat

A ball seat and cross technology, applied in the field of soluble ball seats, can solve the problems of harsh dissolution conditions, small fluid channel diameter, and many dissolved residues, etc., and achieve the effect of solving many dissolved residues and not easy to accidentally set.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

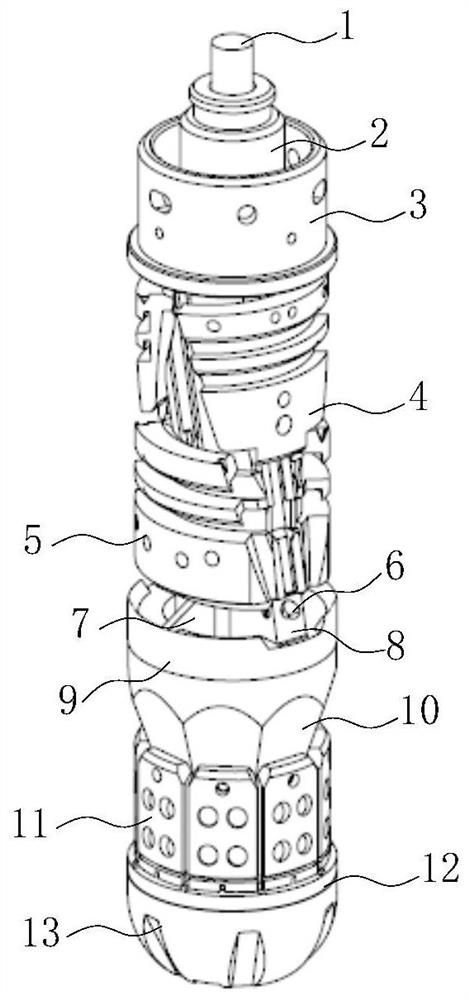

[0032] See attached figure 1 , a kind of soluble ball seat of the present invention comprises:

[0033] connecting rod 1;

[0034] A cross wing 2 coaxially arranged with the connecting rod 1, the inner surface of the cross wing 2 is threadedly connected with the rod portion near the upper end of the connecting rod 1;

[0035] The pusher connector 3 coaxially arranged outside the cross wing 2, the pusher connector 3 and the cross wing 2 are slidably fitted, and the symmetrical two sides of the lower part of the cross wing 2 are separated from the pusher connector 3 side walls protrude;

[0036] The ring-shaped ball seat body located outside the cross wing 2 and the push cylinder connector 3, the ring-shaped ball seat body includes four split petals with the same structure, the upper size of each split petal is smaller than the lower size, and the oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com