Gas ejector

A technology of ejector and gas, which is applied in jet pumps, machines/engines, non-volume pumps, etc., to achieve the effects of improving ejector efficiency, improving versatility, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals.

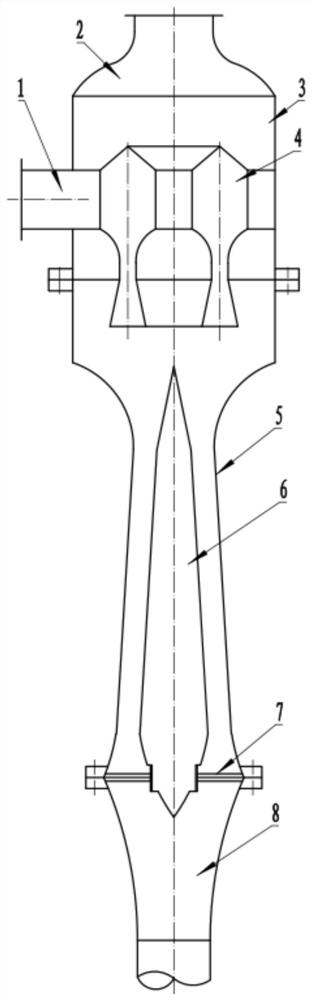

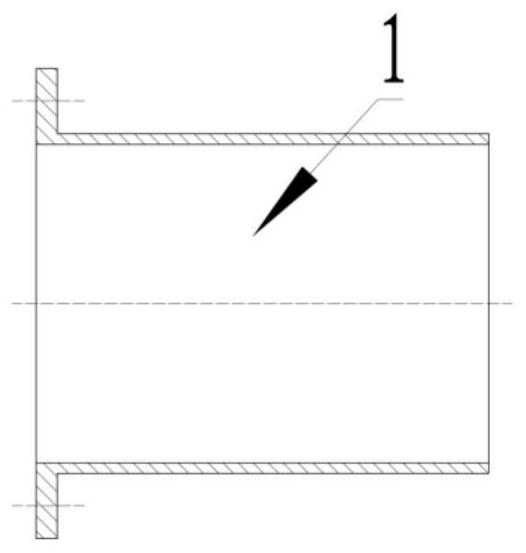

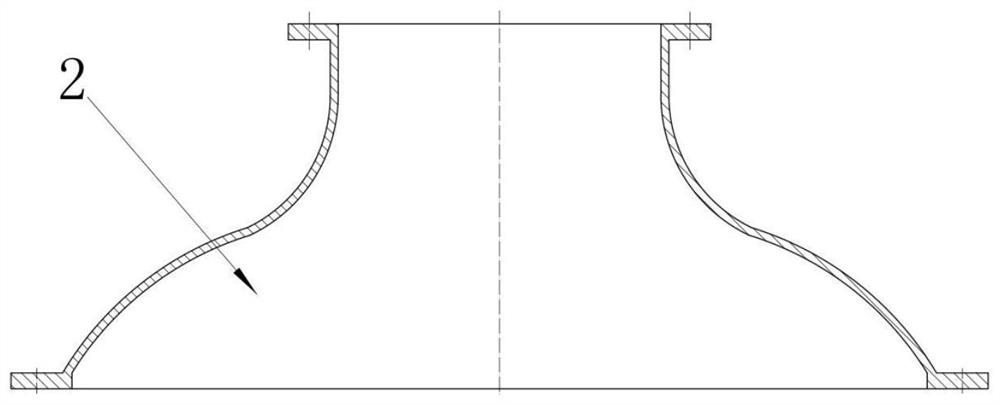

[0031] A gas ejector such as figure 1 As shown, it includes a suction chamber 3 , a diffuser outer cylinder 5 , an exhaust tailpipe 8 , an annular nozzle 4 and a diffuser cone 6 . The suction chamber 3, the diffuser outer cylinder 5, and the exhaust tail pipe 8 are sealed and communicated in sequence, and each pipe is arranged coaxially. The annular nozzle 4 is arranged in the suction chamber 3 and is coaxial with the suction chamber 3, combined with figure 2 with Figure 5 As shown, the annular nozzle 4 is communicated with the jet inlet pipe 1 extending out of the suction chamber 3, and the end of the annular nozzle 4 facing the exhaust tailpipe 8 is provided with an annular nozzle coaxial with its body, and part of the nozzles of the annular nozzle 4 Stretch into the diffuser oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com