Five-gear planetary automatic transmission

An automatic transmission and planetary technology, applied in vehicle gearboxes, transmission components, transmission devices, etc., can solve the problems of increased volume and weight of gearboxes, high manufacturing and maintenance costs, slow response to speed changes, etc., to reduce energy consumption , compact structure, strong impact and vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

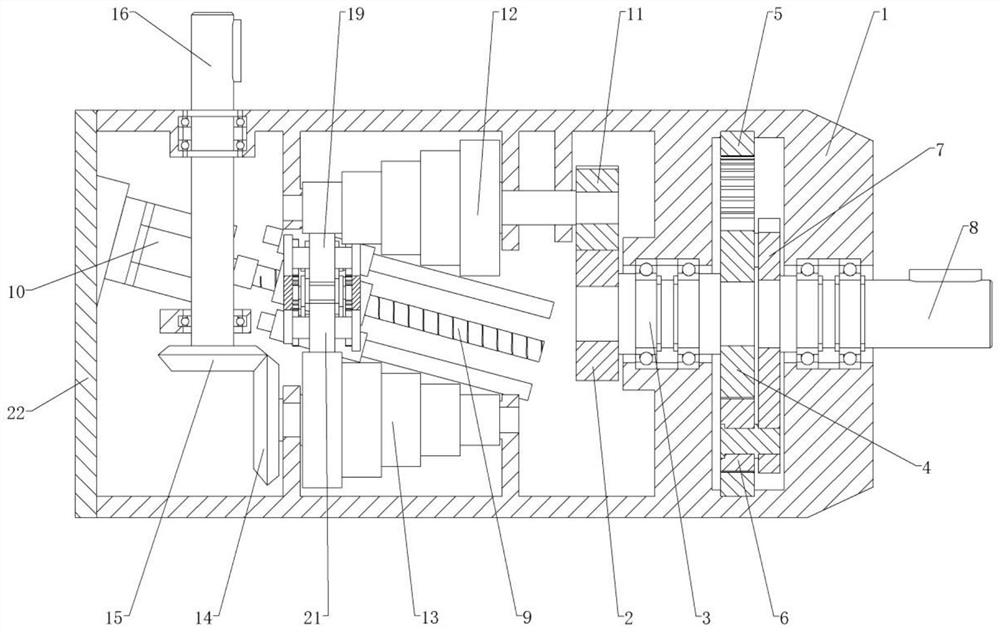

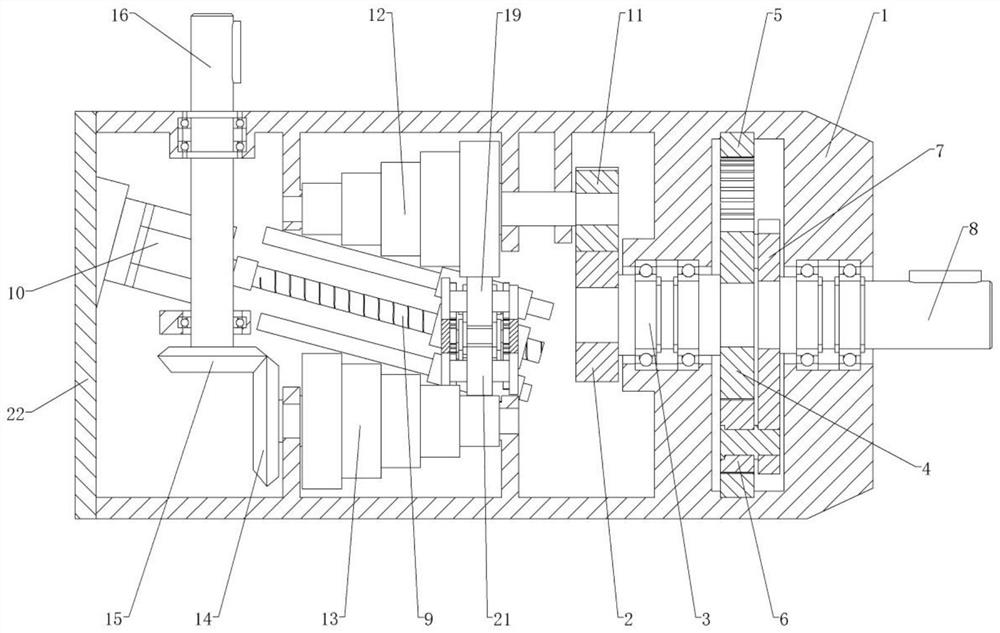

[0027]The present invention will be further described below with reference to the accompanying drawings and specific examples, and illustrative of the invention, but is not intended to limit the invention.

[0028]Such asFigure 1 to 8As shown, a five-dimensional planetary automatic transmission includes housing 1, fourth gear 2, central axis 3, central gear 4, internal gear 5, planetary gear 6, planet carrier 7, output shaft 8, thread rod 9, motor 10, the third gear 11, the second gear tower 12, the first gear column 13, the second cone gear 14, the first cone gear 15, the input shaft 16, the slider 17, the first holding rod 18, the driven gear 19, The driven sub-gear 19.1, the second holding rod 20, the drive gear 20.1, the drive gear 21, the drive sub-gear 21.1, the sealing cover 22, the retaining sheet 23, and the electric push rod 24, characterized in that the outer casing 1 is the support body, the input shaft 16 is rotated by the rotation of the outer casing 1 and drives the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com