Connecting device and connecting structure for high-voltage battery modules in electric automobile

A technology for electric vehicles and high-voltage batteries, applied in battery pack parts, structural parts, circuits, etc., can solve problems such as difficulty in routing low-voltage lines and high-voltage lines of battery modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

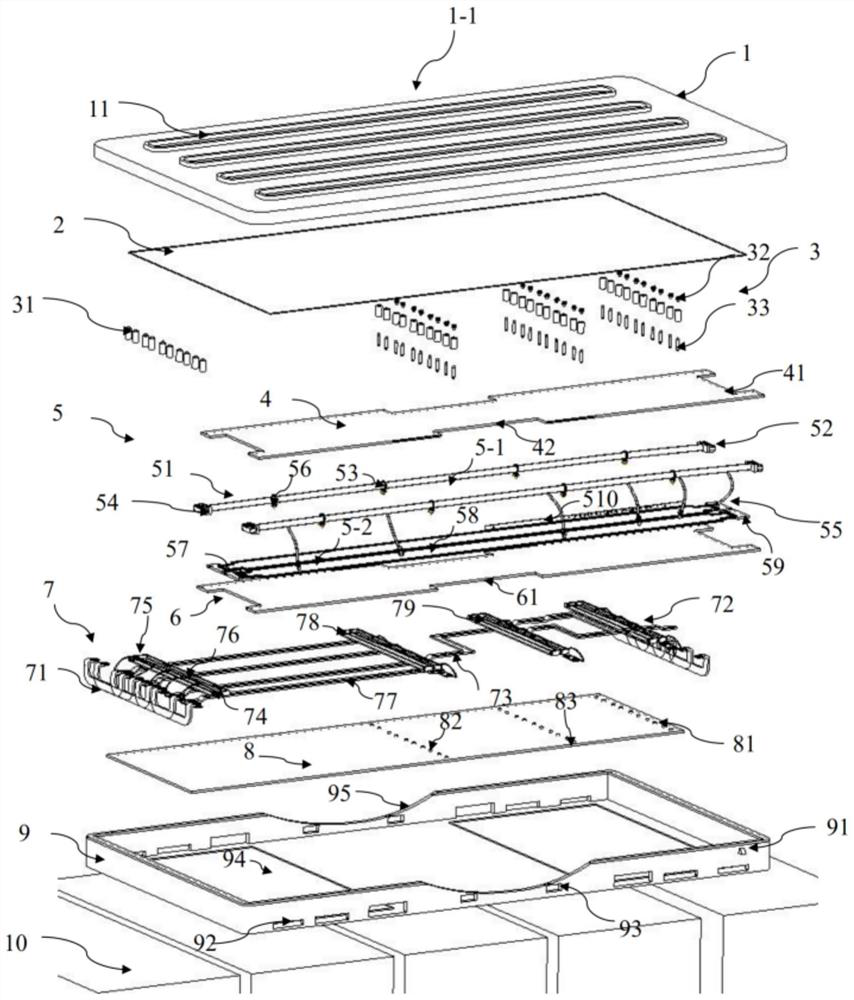

[0056] Such as figure 1 Shown is an electric vehicle high-voltage battery module connecting device 1-1 according to an embodiment of the present invention, comprising: an upper cover plate 1 of the device, a low-voltage connecting module 5, a high-voltage copper bar connecting module 7, and a lower cover plate 9 of the device. The upper cover plate 1 of the device and the lower cover plate 9 of the device are connected to form a device shell, and the low-voltage connection module 5 and the high-voltage copper bar connection module 7 are housed in the device shell;

[0057] The low-voltage connection module 5 includes a low-voltage wire harness assembly 5-1 electrically connected to the low-voltage circuit of the battery module 10, and a flexible circuit board assembly 5-2 electrically connected to the battery management system of the electric vehicle;

[0058] The high-voltage copper bar connection module 7 includes a high-voltage copper bar electrically connected to the high...

Embodiment 2

[0074] Such as Figure 1 to Figure 24 As shown, a connection device 1-1 for a high-voltage battery module of an electric vehicle in the present invention includes: an upper cover plate 1 of the device, a low-voltage connection module 5, a high-voltage copper bar connection module 7, and a low-voltage connection module arranged above the low-voltage connection module 5. The upper partition plate 4 of the module, the lower partition plate 6 of the low-voltage module arranged below the low-voltage connection module 5, and the lower cover plate 9 of the device, the upper cover plate 1 of the device and the lower cover plate 9 of the device are connected to form a device shell, The low-voltage connection module 5 and the high-voltage copper bar connection module 7 are accommodated in the device shell, and the low-voltage connection module 5 and the upper partition plate 4 of the low-voltage module are metal plates;

[0075] The low-voltage connection module 5 includes a low-voltage...

Embodiment 3

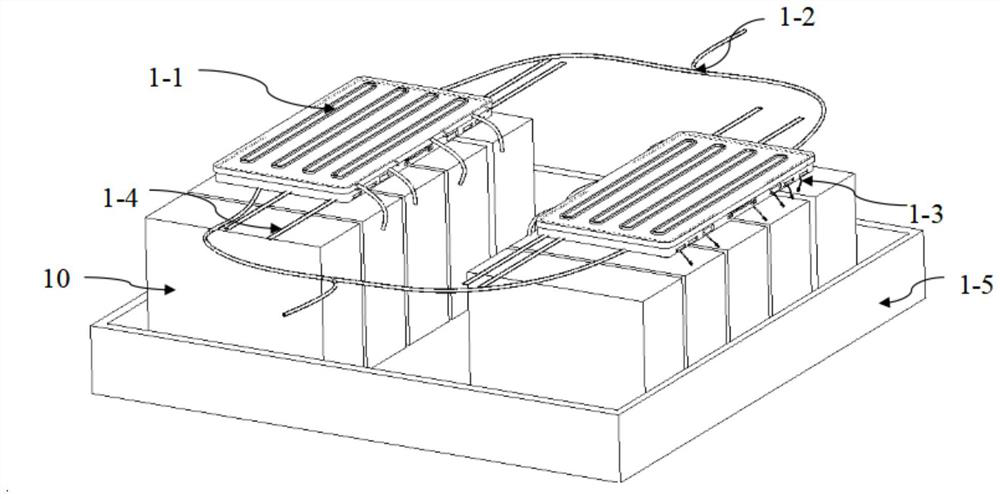

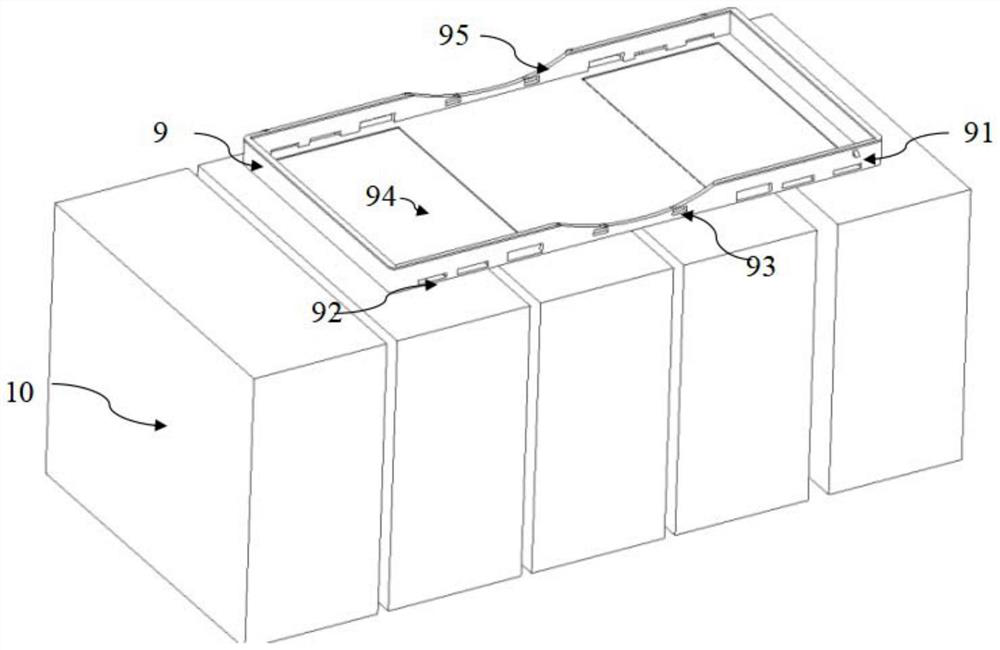

[0108] An embodiment of the present invention is a high-voltage battery module connection structure for an electric vehicle, including a high-voltage battery module connection device 1-1 for an electric vehicle, and a plurality of battery modules 10;

[0109] Electric vehicle high-voltage battery module connection device 1-1, including: device upper cover 1, low-voltage connection module 5, high-voltage copper bar connection module 7, and device lower cover 9, the device upper cover 1 and the device The lower cover plate 9 is connected to form a device casing, and the low-voltage connection module 5 and the high-voltage copper bar connection module 7 are accommodated in the device casing;

[0110] The low-voltage connection module 5 includes a low-voltage wire harness assembly 5-1 electrically connected to the low-voltage circuit of the battery module 10, and a flexible circuit board assembly 5-2 electrically connected to the battery management system of the electric vehicle; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com