Vacuum food processor convenient to clean

A food processing machine and vacuum technology, which is applied in the field of food processing, can solve the problems of complicated cleaning, many vacuum pipelines, and the cup lid cannot be soaked and washed, and achieve the effects of simplifying the vacuuming pipeline, improving the vacuuming efficiency, and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

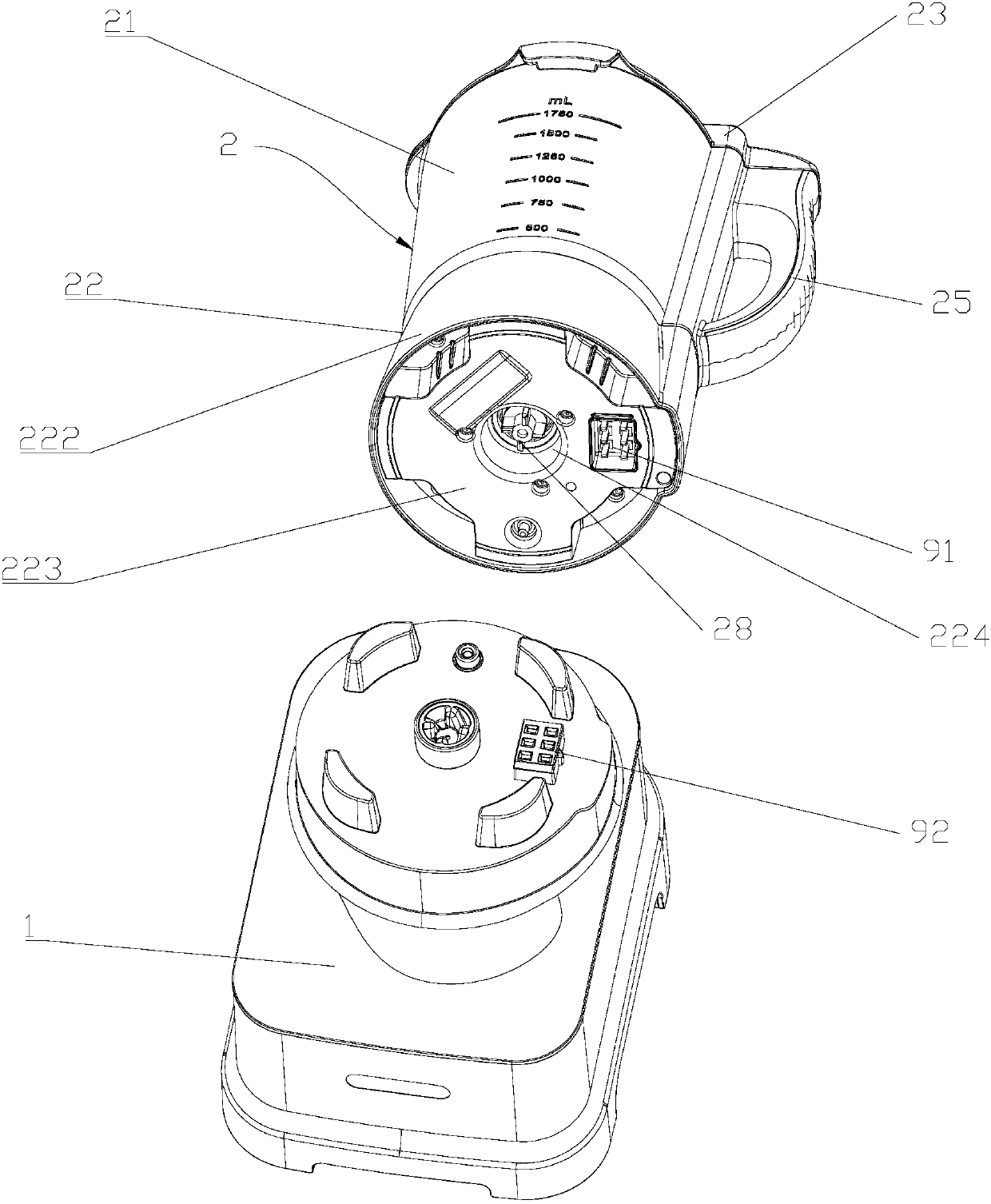

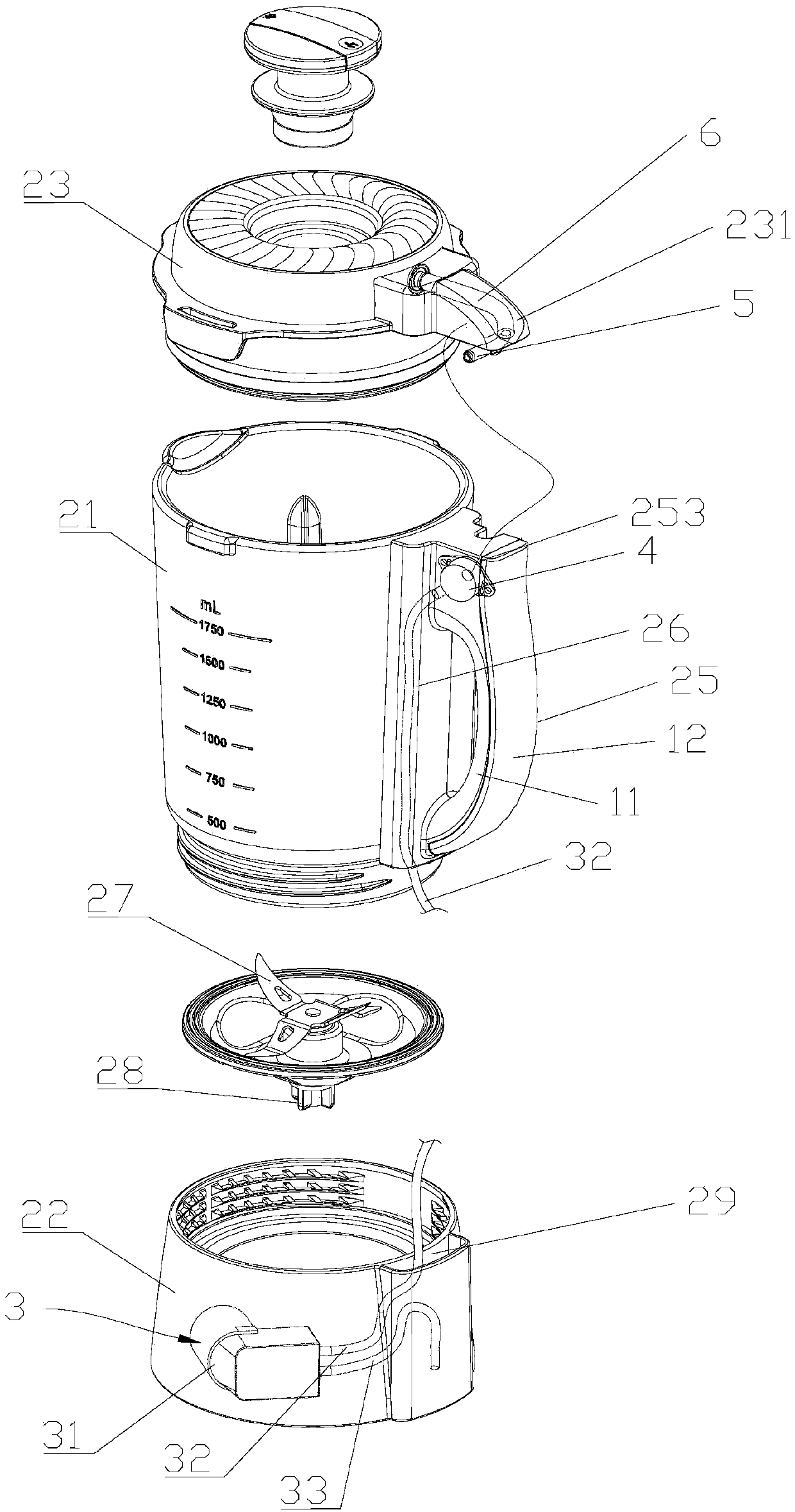

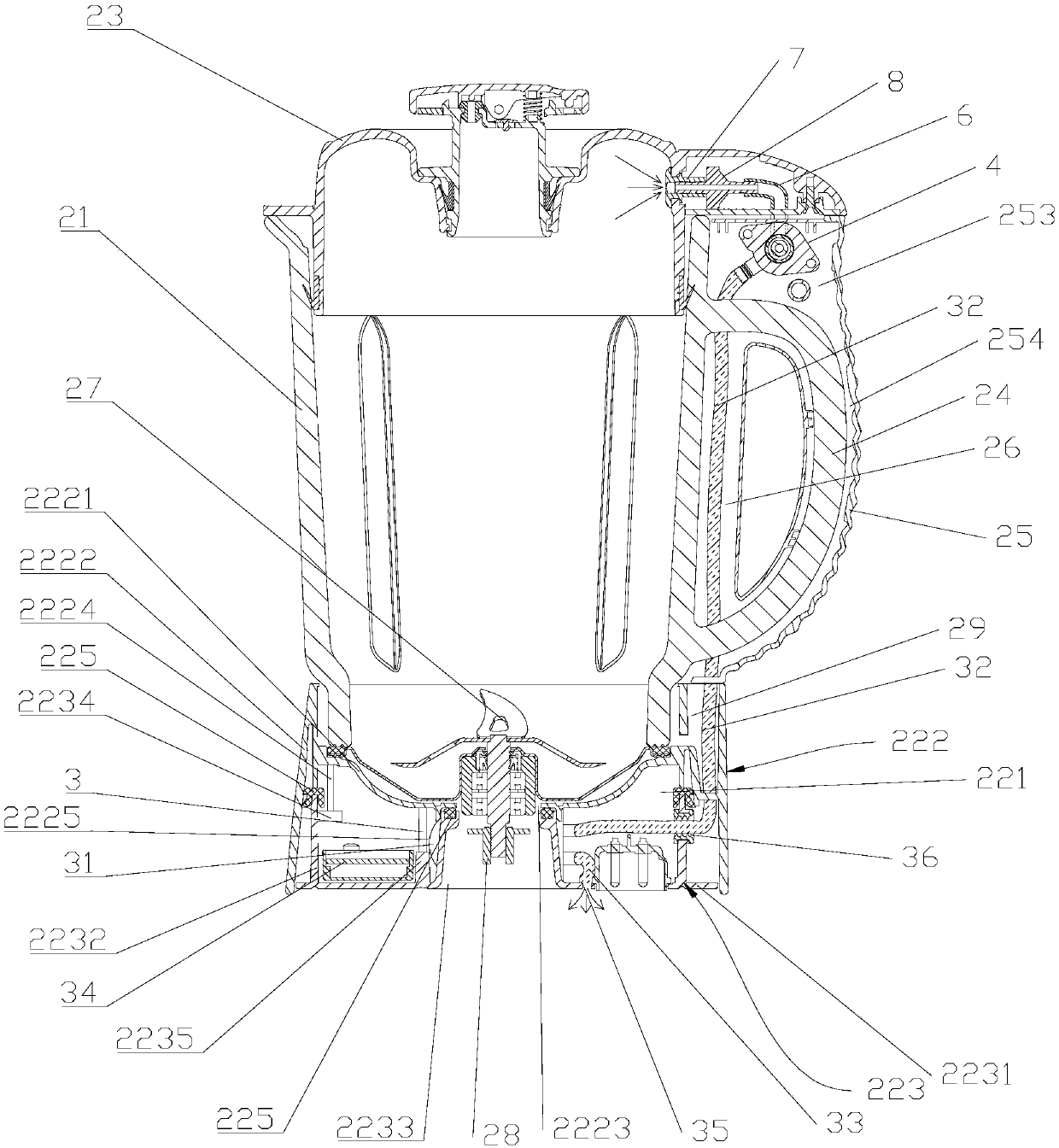

[0036] Such as Figure 1 to Figure 3 As shown, the vacuum food processor of this embodiment includes a machine base 1 , a stirring cup 2 and a vacuum device 3 . The base 1 is provided with a motor and a main circuit board (not shown). The stirring cup 2 is located above the machine base 1. The stirring cup 2 includes a cup body 21, a cup holder 22 and a cup cover 23. The cup body 21 is a glass cup body, the cup holder 22 is a plastic cup holder, and the cup cover 23 is a plastic cup cover. The body 21 has an upper opening and a lower opening. The cup holder 22 is threadedly connected to the lower opening of the cup body 21. The cup cover 23 is disassembled and installed on the upper opening of the cup body 21. The cup cover 23 is provided with a communication hole communicating with the inside of the cup body 21. One side of the cup body 21 is provided with a handle 24, the handle 24 is integrally formed with the cup body 21, the handle 24 is provided with a handle cover 25, ...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 lies in the structure of the handle cover, combined with Figure 4 to Figure 6 As shown, the handle cover 25 of this embodiment includes a left handle cover 251 and a right handle cover 252, the left handle cover 251 and the right handle cover 252 are snapped together to form the handle cover 25, and the upper end of the handle cover 25 is provided with a first adapter mounting cavity 253, the first adapter 4 is located in the first adapter installation cavity 253, the upper part of the left handle cover 251 and the upper part of the right handle cover 252 enclose the aforementioned first adapter installation cavity 253, the lower part of the left handle cover 251 and the lower part of the right handle cover 252 The handle cavity 254 for accommodating the handle 24 is formed by enclosing it, so that the first adapter mounting cavity 253 is arranged above the handle cavity 254, on the one hand, avoiding interference ...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the sealed cavity structure of the cup holder, combined with Figure 7 As shown, the air pump 31 of this embodiment is placed in the sealed cavity 221, so that the height requirement for the sealed cavity 221 is relatively low, and the height of the sealed cavity 221 will not be too large to cause the overall imbalance of the mixing cup. The air pump 31 includes a pump body 311 and motor 312, the suction pipe 32 and the exhaust pipe 33 are all connected to the pump body 311, the air pump circuit board 34 is electrically connected to the motor 312, and the air pump circuit board 34 is also located in the sealed cavity 221, the pump body 311 is connected to the motor 312 Being fixed in an L shape makes the fixing positions of the pump body 311 and the motor 312 in the sealing chamber 221 reasonable and compact, and also makes the piping system take up less space and the piping stroke is effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com