Sympodial bamboo felling method

A regional and step 3 technology, applied in the field of clumping bamboo cutting, can solve the problems of restricting the development of bamboo industry, difficult management mode, difficult selection of cutting operations, etc., and achieve the effect of ideal effect, high economic effect and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

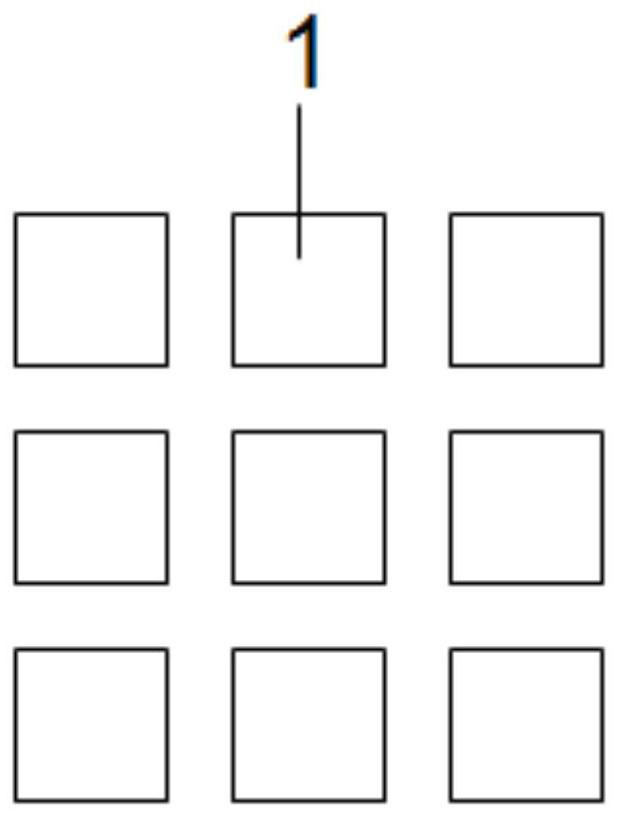

[0050] 1 / 2 clump logging method, such as figure 2 shown.

[0051] Step 1: Determine the harvesting area and harvesting time;

[0052] The felling area includes N clumps distributed in an array, 1≤N≤1000, the distance between adjacent clumps is 3 meters, and 10 clustered bamboos grow in each clump;

[0053] The harvesting time is from the beginning of winter to the vernal equinox of the next year;

[0054] Step 2: Planning the transportation route;

[0055] Step 3: carry out logging operations;

[0056] Cut down 1 / 2 of the clustered bamboo in each cluster in the felling area, and use the remaining clustered bamboo as a provenance to provide nutrients for the germination of the felled bamboo shoots and the growth of new bamboos;

[0057]The right side of the N clumps 1 is harvested, that is, in each clump, the right part is the felled cluster bamboo 3, and the left side is the remaining cluster bamboo 2.

[0058] Step 4: Clean up the logging site.

[0059] Before felling,...

Embodiment 2

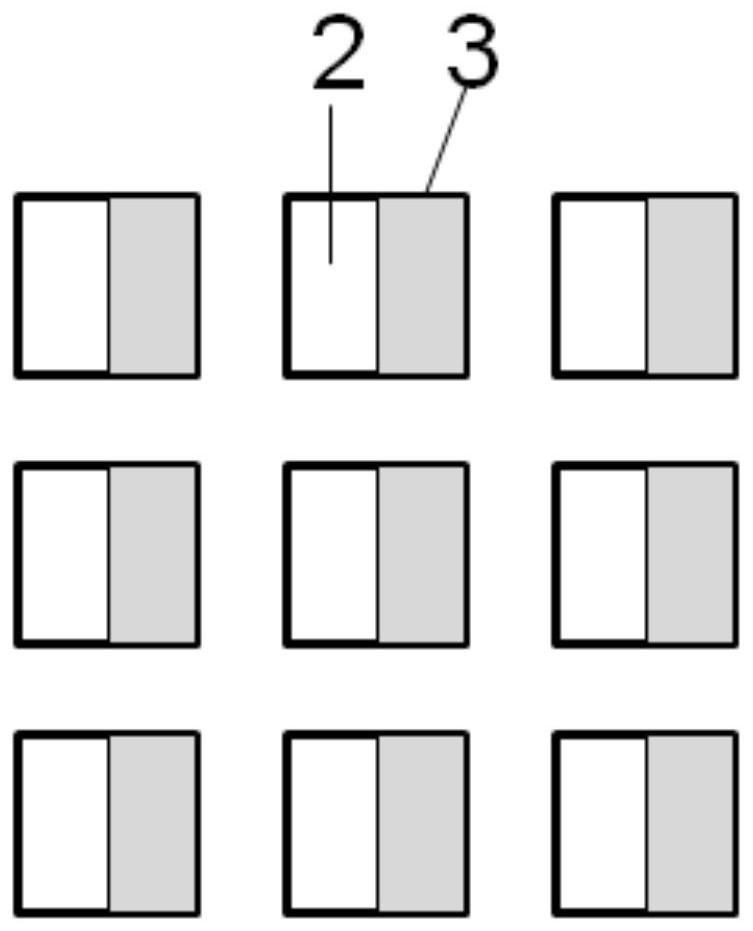

[0061] 1 / 3 clump harvesting methods such as image 3 shown.

[0062] Step 1: Determine the harvesting area and harvesting time;

[0063] The felling area includes N clumps distributed in an array, 1≤N≤1000, the distance between adjacent clumps is 3 meters, and 6 clumps of bamboo grow in each clump;

[0064] The harvesting time is from the beginning of winter to the vernal equinox of the next year;

[0065] Step 2: Planning the transportation route;

[0066] Step 3: carry out logging operation;

[0067] Cut down 1 / 3 of the clustered bamboo in each cluster in the felling area, and use the remaining clustered bamboo as a provenance to provide nutrients for the germination of the felled bamboo shoots and the growth of new bamboos;

[0068] The right side of the N clumps 1 is harvested, that is, in each clump, the right part is the felled cluster bamboo 3, and the left side is the remaining cluster bamboo 2;

[0069] Step 4: Clean up the logging site.

[0070] Before felling,...

Embodiment 3

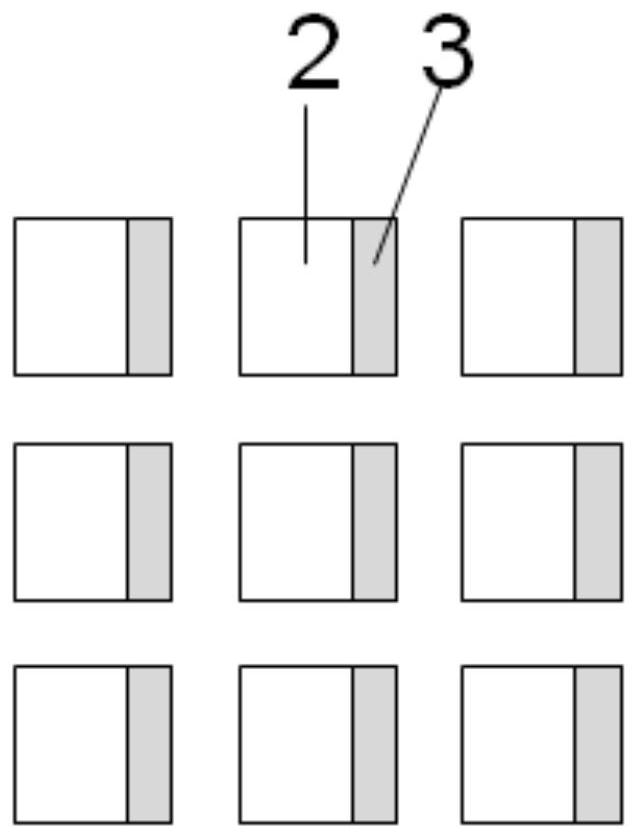

[0072] A whole bush harvesting method, such as Figure 4 shown.

[0073] Step 1: Determine the harvesting area and harvesting time;

[0074] The felling area is divided into a plurality of vertical felling units 5, and for reducing soil erosion in forest land, adjacent cutting units are separated by 30 meters of width 4 (the average plant height of dragon bamboo is 15 meters, and width 4 is twice the height of bamboo, i.e. 30 meters) ;

[0075] The harvesting time is from the beginning of winter to the vernal equinox of the next year;

[0076] Step 2: Planning the transportation route;

[0077] Step 3: carry out logging operation;

[0078] All the clumps of bamboo in the felling area will be felled;

[0079] Step 4: Clean up the logging site.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com