Manufacturing method of digital 3D printing soft elastic tooth protector

A 3D printing and manufacturing method technology, applied in the field of oral digitalization, can solve problems such as weak retention force, cumbersome production process, unsatisfactory protection performance and comfort of mouthguards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] An embodiment of the present invention provides a method for manufacturing a digital 3D printed soft elastic mouthguard, which is realized through the following steps:

[0036] Step 1: Obtain the user's intraoral optical impression;

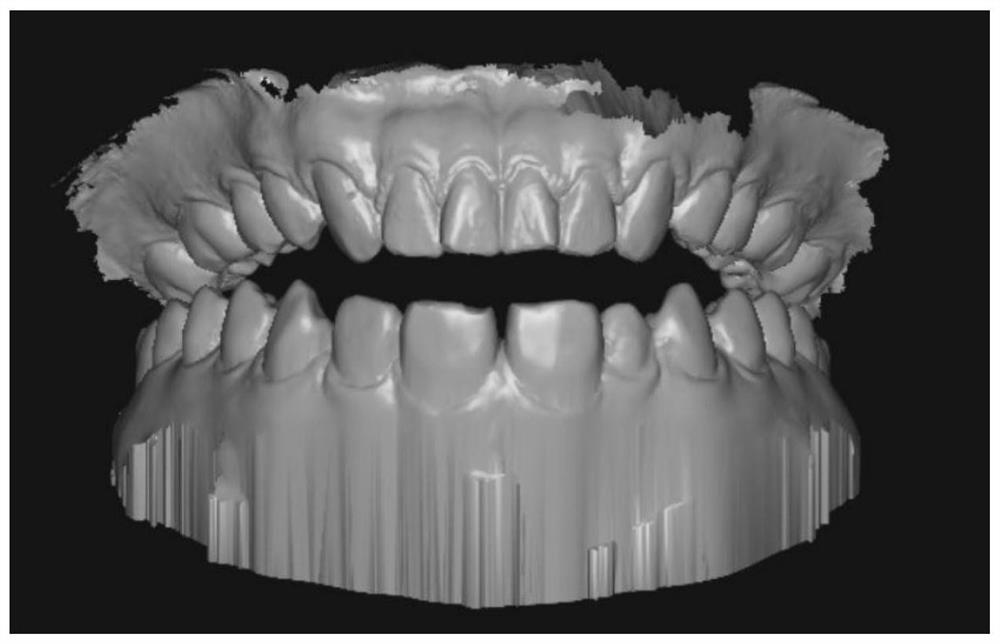

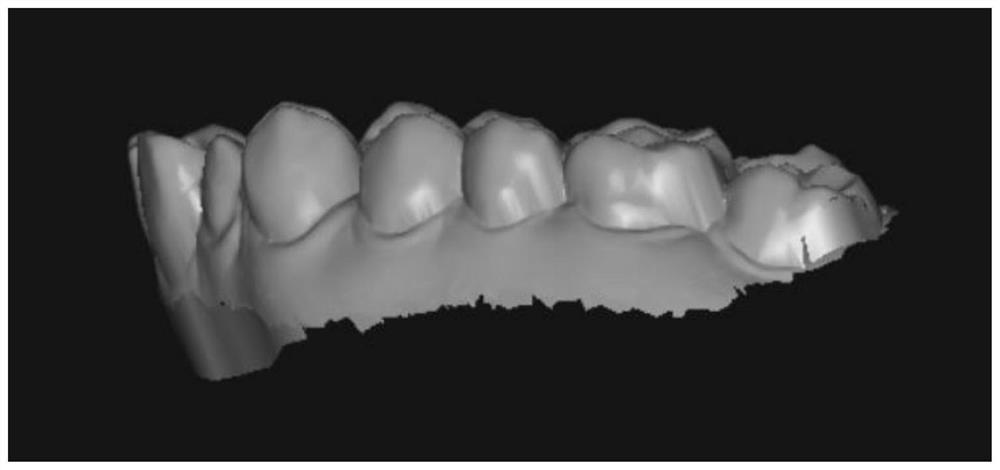

[0037] Specifically, as figure 1 As shown, the mucosal morphology of the upper and lower jaw dentition, maxillary lip-buccal gingival edge to lip-buccal mucosal refraction line, and 15 mm above the palatal gingival edge of the user’s mouth was obtained by a digital intraoral scanner, and the upper and lower jaws were determined according to the mucosal shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com