Portable automatic vacuum test bench

A vacuum test and portable technology, which is applied in portable laboratories, laboratory stools/lab tables, laboratory appliances, etc., can solve the problems of inconvenient and portable installation methods, and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

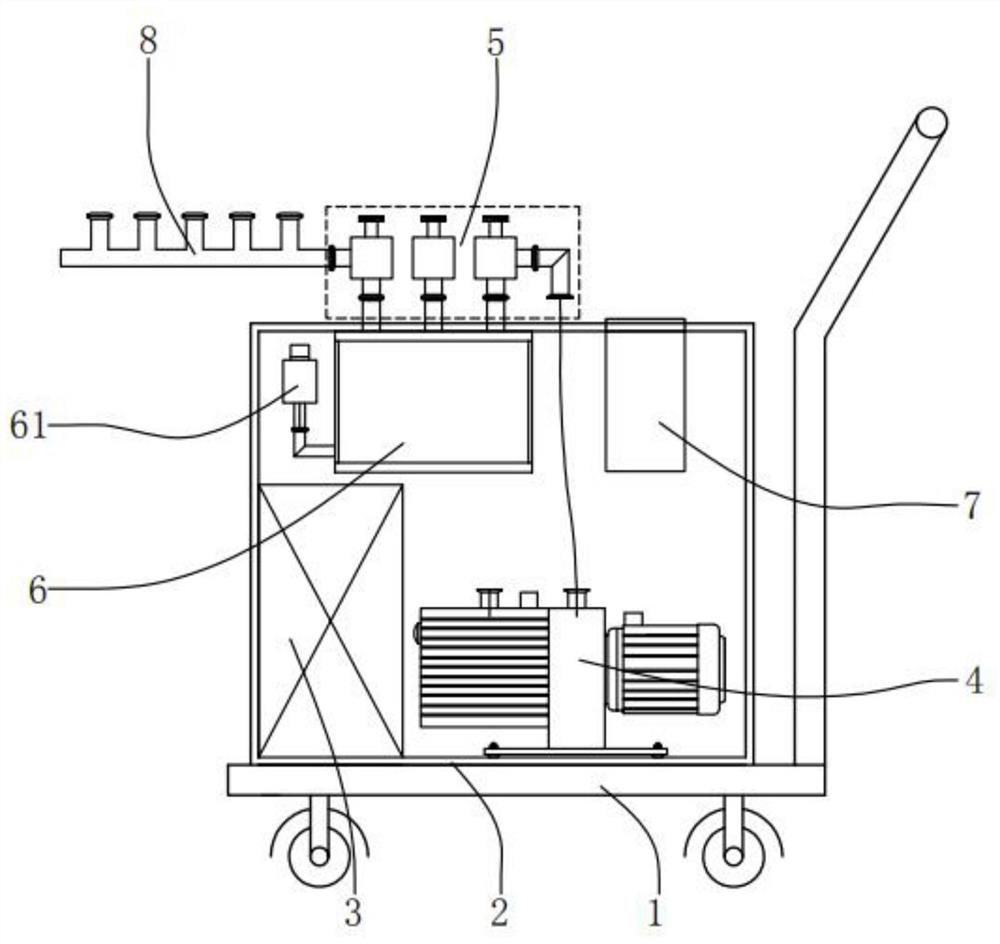

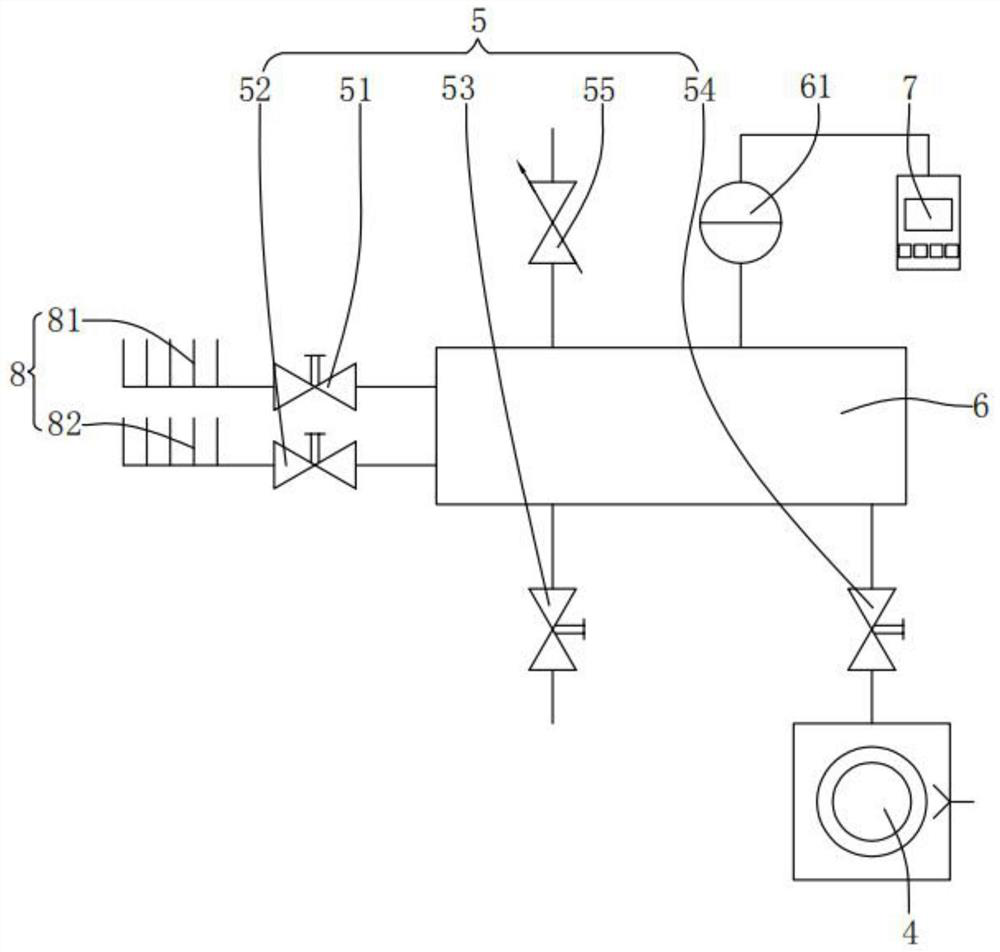

[0030] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 The structural representation of the first embodiment of the portable automatic vacuum test bench provided by the present invention; figure 2 for figure 1 The system diagram of the portable automated vacuum test bench shown; image 3 for figure 1 Overall exterior view shown. A portable automatic vacuum test bench includes: a trolley 1; a mounting frame 2, the bottom of which is fixed on the top of the trolley 1; a tool locker 3, the tool locker 3 is arranged on the The inner side of the mounting frame 2; the vacuum pump 4, the bottom of the vacuum pump 4 is fixed on the bottom of the inner wall of the mounting frame 2; the valve group 5, the valve group 5 is arranged on the top of the mounting frame 2, the valve Group 5 includes a first manual valve 51, a second manual valve 52, a third manual valve 53, a fourth manual valve 54 and a fine-tuning valve 55; a vacuum buffer chamber 6, the surface of wh...

no. 2 example

[0047] see Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , based on the portable automated vacuum test bench provided in the first embodiment of the present application, the second embodiment of the present application proposes another portable automated vacuum test bench. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0048] Specifically, the difference of the portable automated vacuum test bench provided in the second embodiment of the present application is that the portable automated vacuum test bench also includes: the bottom of the mounting frame 2 is provided with universal wheels 21, and the mounting frame The outer surface of 2 is respectively provided with a power control panel 22, a vacuum gauge control panel 23 and a molecular pump control panel 24, the top of the inner wall of the mounting frame 2 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com