Automatic feeding, cutting and shaping system

An automatic feeding and silo technology, which is applied to other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems that automatic feeding and continuous automatic processing cannot be realized in the cutting of cans, so as to achieve good market returns and increase Processing production efficiency and the effect of solving hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

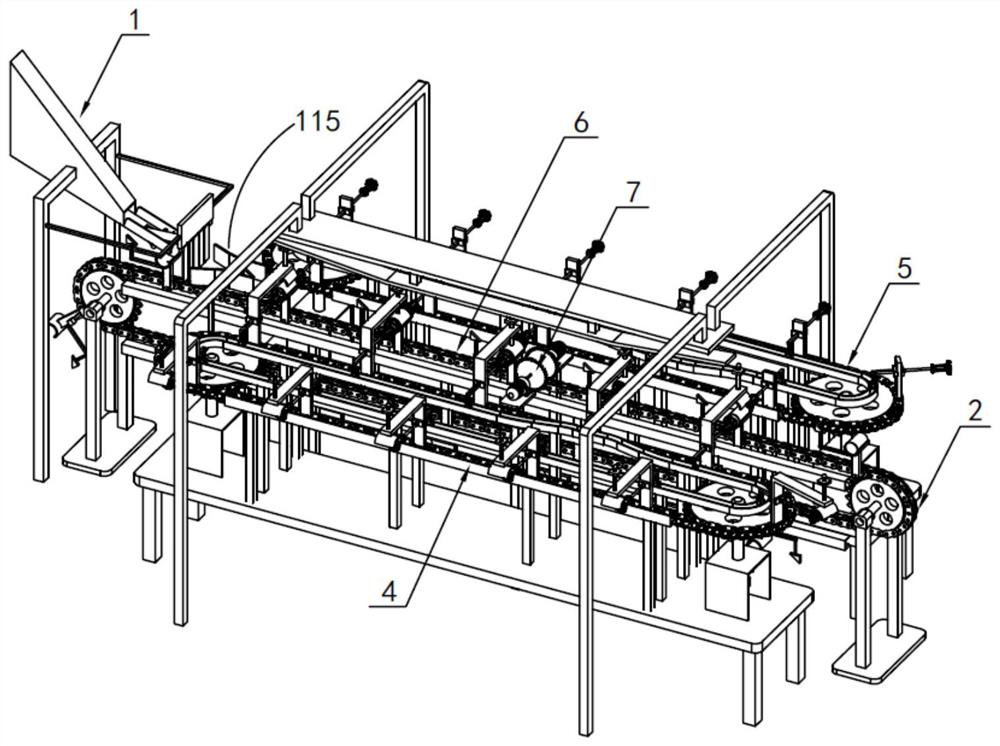

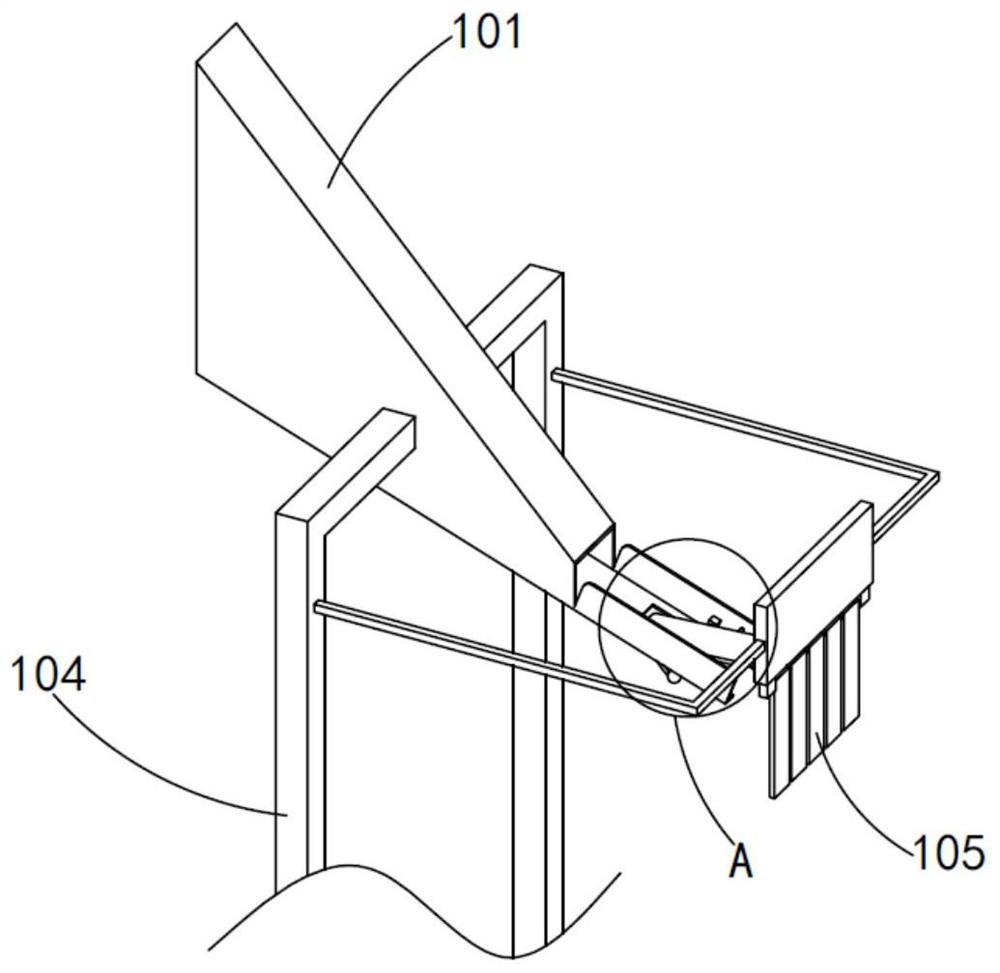

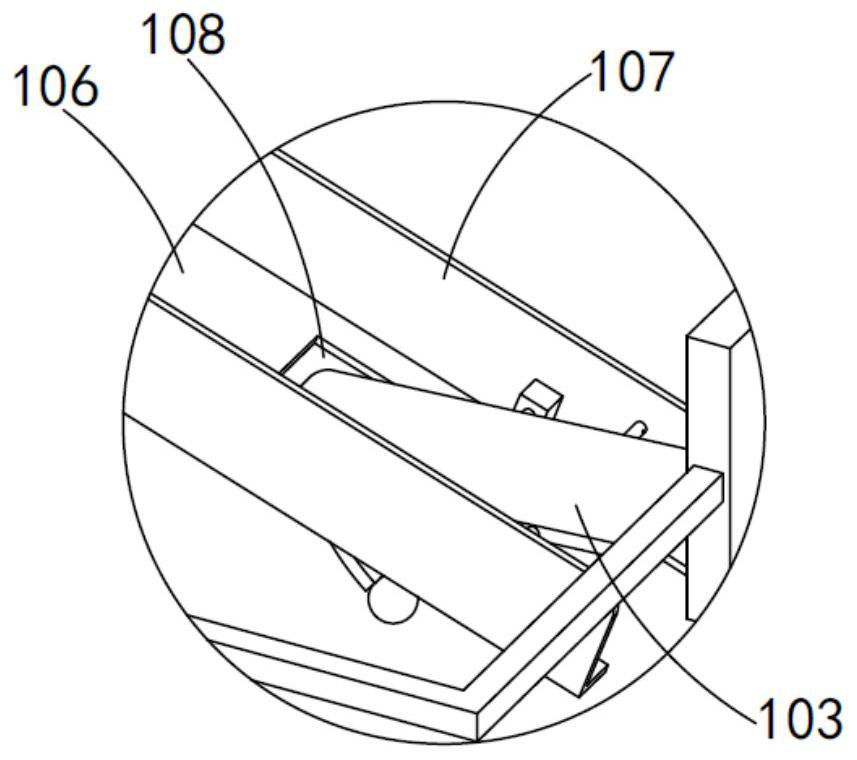

[0046] Such as Figure 1 to Figure 18 As shown, an automatic feeding cutting shaping system includes a feeding device 1, and the feeding device 1 includes a feeding bin 101, and the bottom of the feeding bin 101 is provided with a discharge channel 102, and the discharge channel 102 There is a material turning assembly 103 on the top, and a No. 1 rotary device 2 is provided below the feeding device 1. A number of equidistant bearing mechanisms 3 are arranged on the No. 1 rotary device 2. The carrier mechanism 3 includes a push Component 301 and a supporting component 302, the pushing component 301 is used to push the turning component 103 under the drive of the No. 1 rotary device 2 to transfer the pop-top cans output from the upper bin 101 to the supporting component 302 individually, The two sides of the moving path of the carrying mechanism 3 are respectively provided with a No. 2 turning device 4 and a No. 3 turning device 5. The No. 2 turning device 4 is provided with a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com