Taper pipe inner wall grinding method

A technology of tube inner wall and taper, applied in grinding machine, grinding frame, grinding bed and other directions, can solve the problems of low grinding efficiency, high labor intensity, welding slag and rust spots, etc., to improve grinding efficiency and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments, not limited to this.

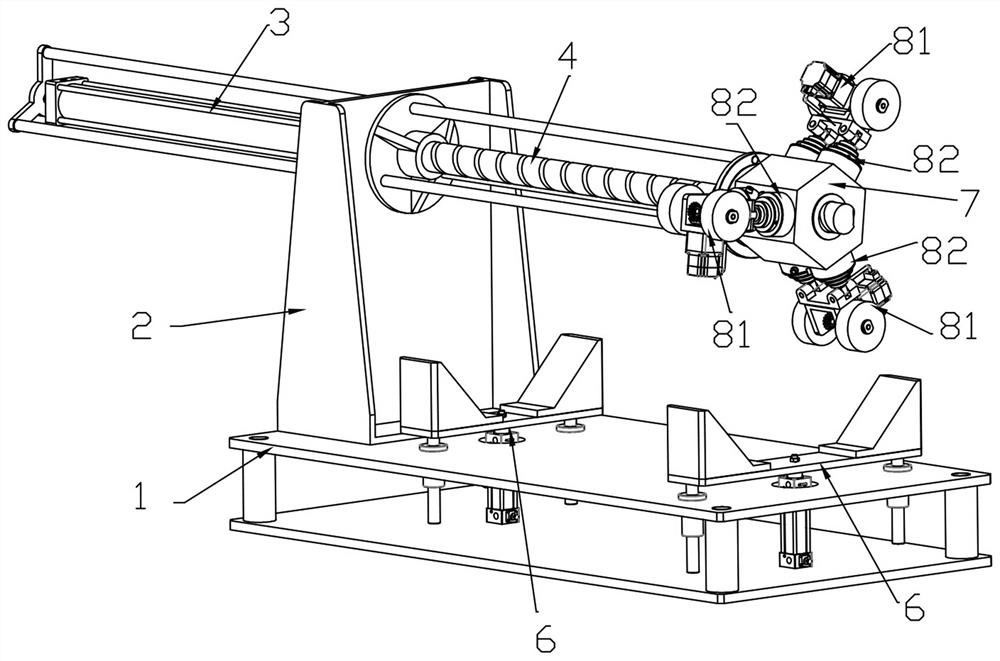

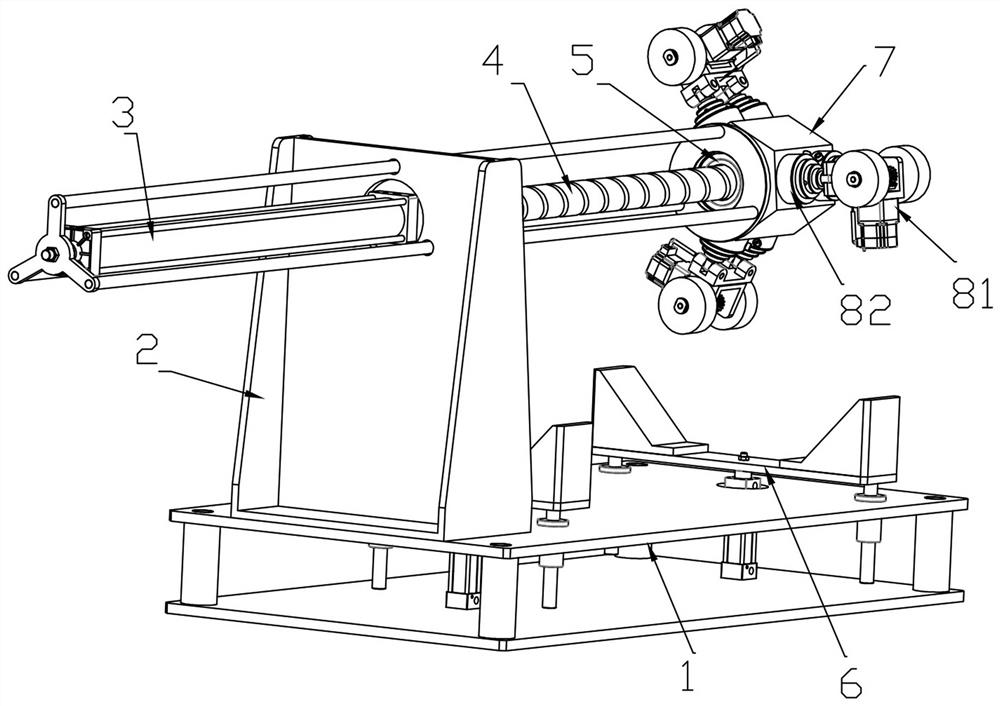

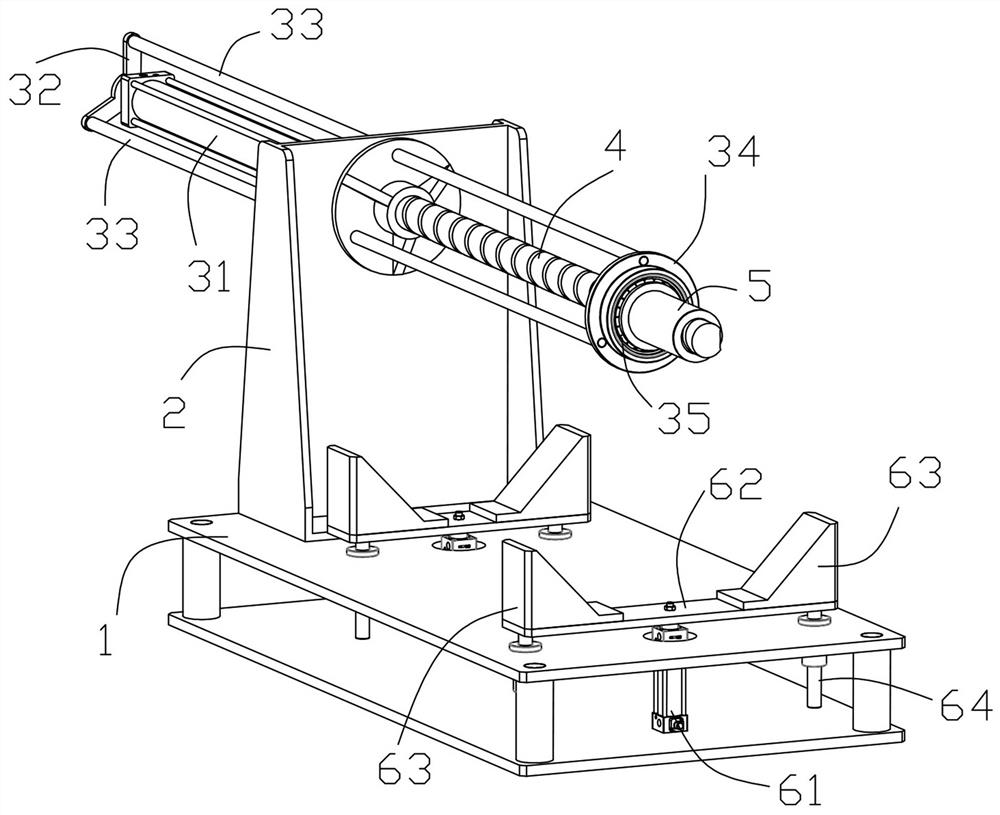

[0019]Such asFigure 1 to 5 As shown, the inner wall grinding method of the inner wall of the present embodiment, including the bottom frame 1, the supporting seat 2, the axial driving device 3, the screw 4, and the nut 5, the support seat 2 is fixed at one end of the chassis 1. Two support assemblies 6 are disposed side by side and the support assembly 6 for supporting the taper tube, the axial driving device 3 is provided on one side of the support seat 2, and one end of the screw 4 passes A mounting holder is fixed to the other side of the supporting seat 2, and the threaded angle of the screw 4 is larger than the threaded self-locking angle, the nut 5 threaded on the screw 4, and the nut is provided with a rotating shaft 7. The outer wall of the rotating shaft 7 is provided with three inner wall grinding apparatuses 8 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com