Anti-collision film preparation system and method

A preparation system and anti-collision technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of time-consuming clamping, difficult clamping and fixing of anti-collision film, complicated clamping process, etc. , to achieve the effect of reducing clamping time, enhancing market competitiveness and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

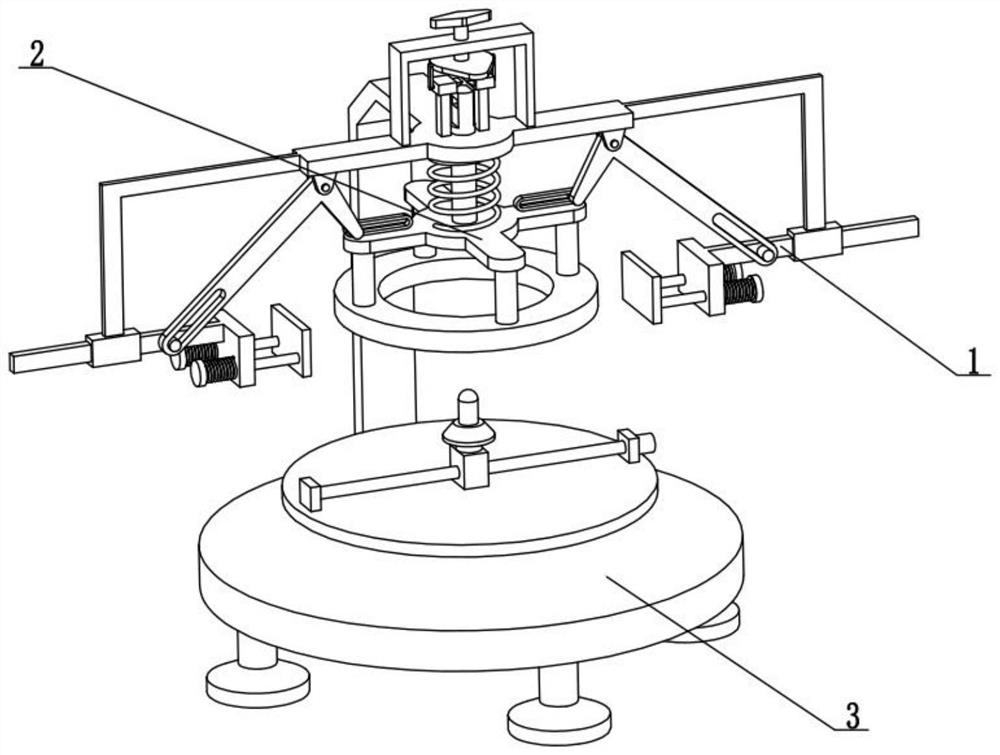

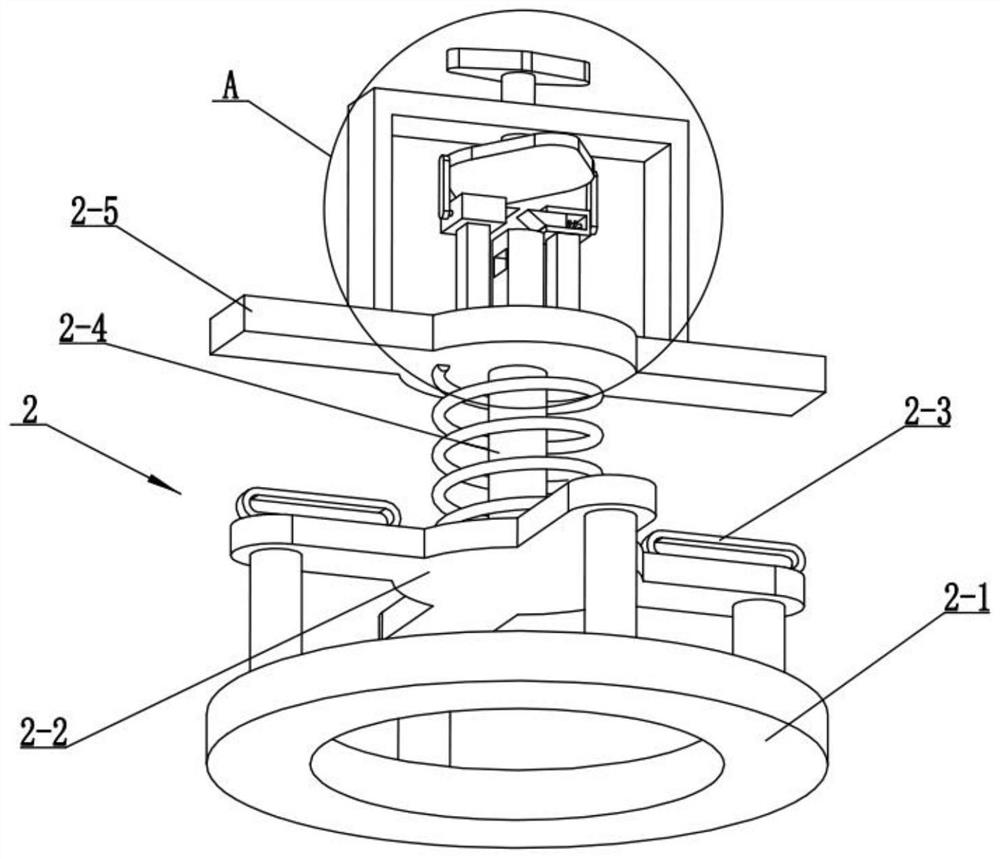

[0027] The following describes this embodiment in conjunction with the drawings. The present invention relates to the technical field of anti-collision film preparation, and more specifically, an anti-collision film preparation system, including an anti-collision film clamping mechanism 1, a telescopic fixing mechanism 2 and a processing and preparation mechanism 3. The telescopic fixing mechanism 2 is connected to the processing and preparation mechanism 3 , two anti-collision film clamping mechanisms 1 are respectively connected to the left and right sides of the telescopic fixing mechanism 2 , and the telescopic fixing mechanism 2 is located directly above the edge banding moving mechanism 3 .

[0028] Put the anti-collision film on the telescopic fixing mechanism 2, and use the telescopic fixing mechanism 2 to drive the two anti-collision film clamping mechanisms 1 to clamp and fix the anti-collision film to complete the fast clamping. The operation is simple, the operation ...

specific Embodiment approach 2

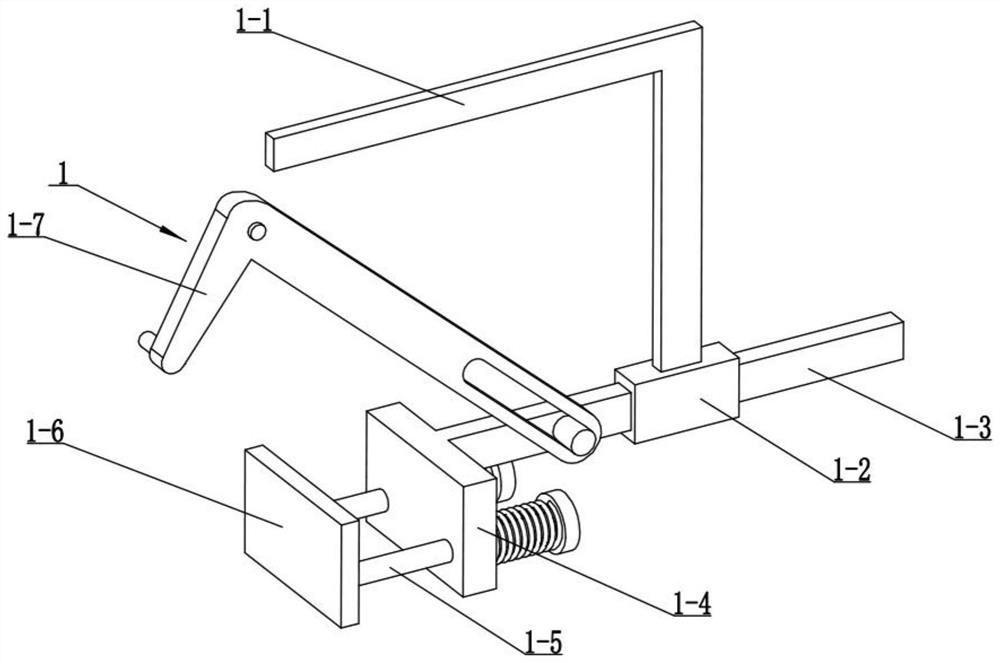

[0030] The present embodiment will be described below in conjunction with the drawings. This embodiment will further explain the first embodiment. The anti-collision film clamping mechanism 1 includes clamping slide bars 1-3, force vertical plates 1-4, and protective slide bars 1-4. 5 and the clamping side plate 1-6, the clamping side plate 1-6 is fixedly connected to the two protective slide bars 1-5, and the two protective slide bars 1-5 are both slidably connected to the stressed vertical plate 1-4 , the two protective slide bars 1-5 are equipped with return tension springs, and the two ends of each return tension spring are respectively fixedly connected to the protection slide bars 1-5 and the stressed vertical plates 1-4, and the stressed vertical plates 1-4 is fixedly connected to the inner end of clamping slide bar 1-3.

[0031] When two clamping side plates 1-6 were clamping the both sides of the anti-collision film, when the two clamping side plates 1-6 contacted the...

specific Embodiment approach 3

[0033] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the second embodiment. The anti-collision film clamping mechanism 1 also includes a right-angle boom 1-1, a horizontal slideway 1-2 and a clamping arm 1. -7, the horizontal slideway 1-2 is fixedly connected to the bottom end of the right-angle boom 1-1, the clamping slide bar 1-3 is slidably connected in the horizontal slideway 1-2, and the bottom end of the clamping arm 1-7 is clamped Slidingly connected on the clamping slide bar 1-3.

[0034] When the two clamping arms 1-7 are driven and the two clamping slide bars 1-3 slide in the two horizontal slideways 1-2, the two clamping side plates 1-6 can be close to each other to avoid collision Both sides of the film are clamped, and at the same time, the two horizontal slideways 1-2 can ensure that the two clamping slide bars 1-3 are always sliding and clamping in the horizontal direction at the same hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com