Method for hoisting fabricated light steel keel steel mesh mold lightweight wall

A technology of light steel keel and light wall, which is applied in the direction of transportation and packaging, load hanging components, cranes, etc., can solve the problems that the stability needs to be further improved, so as to improve the stability and safety, and improve the firmness of the structure , Improve the effect of transportation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

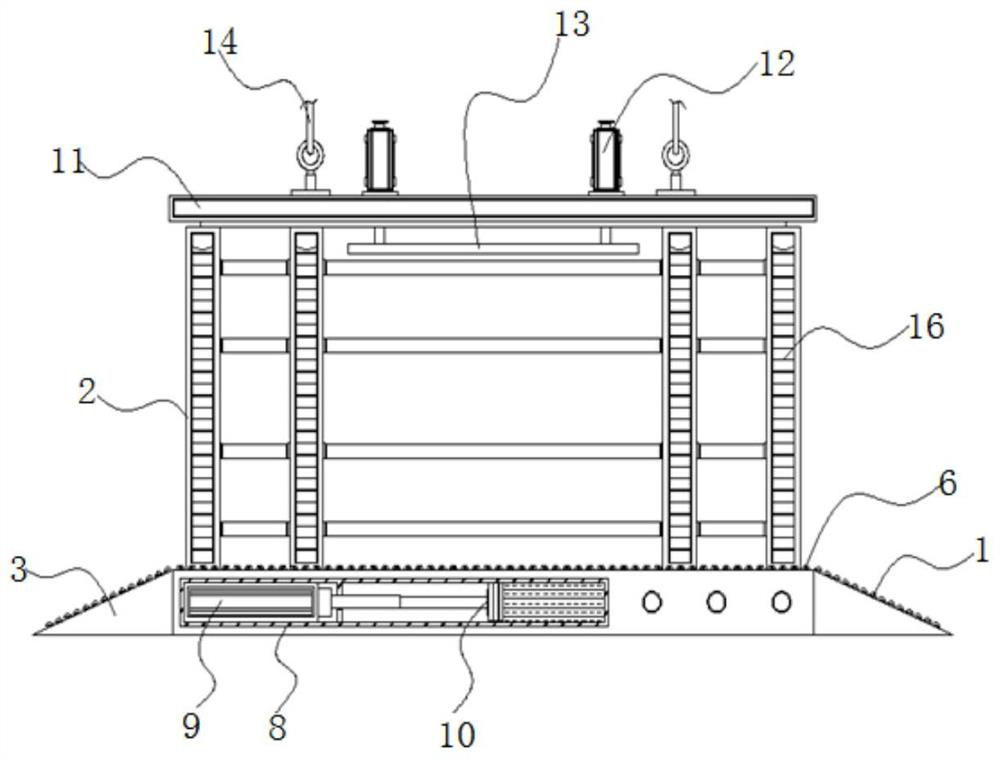

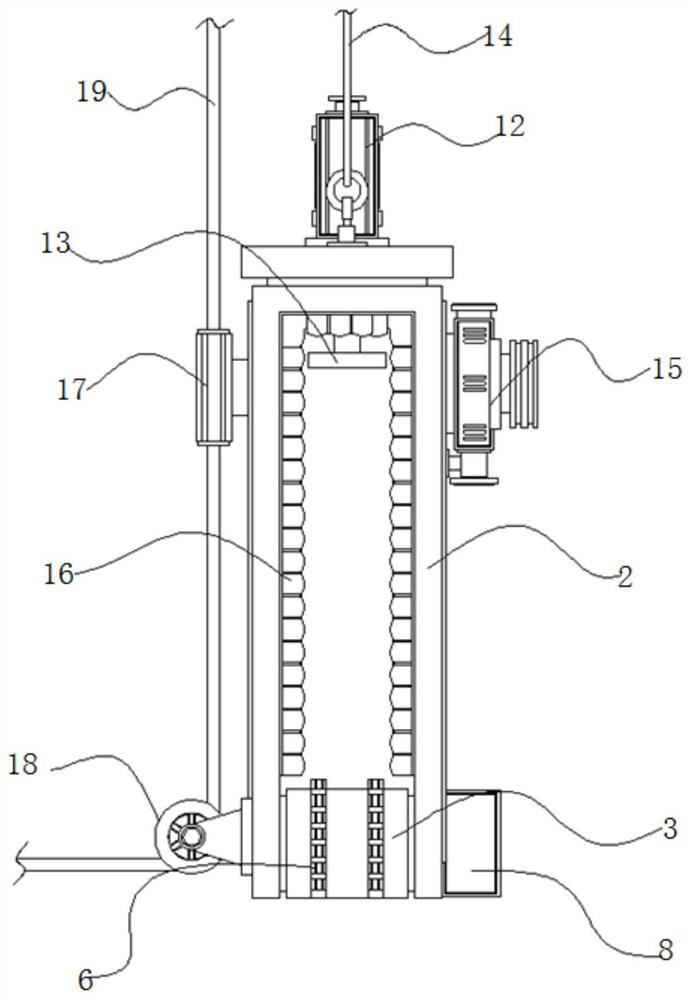

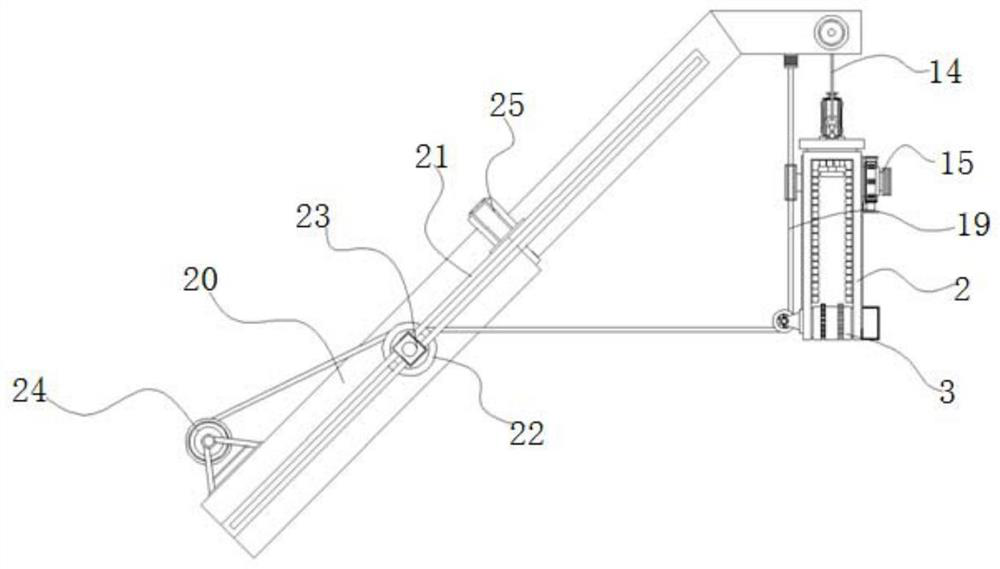

[0036] Such as Figure 1-Figure 3 As shown, a prefabricated wall hoisting device with a stable structure in this embodiment includes a hoisting arm 20, a hoisting frame and a balance assembly, wherein the hoisting frame is used to support and fix the prefabricated wall, and the hoisting frame is used to support and fix the prefabricated wall. The cable 14 and the lifting arm 20 form a lifting structure, and the balance assembly includes a stable steel cable 19, a stable pipe 17, an adjustment roller 18, a vertical roller 22 and a steel cable reel drum 24, and the stable pipe 17 and the adjustment roller 18 are aligned vertically. Correspondingly installed on the same side of the lifting frame up and down, the vertical roller 22 can be slidably installed on the side of the lifting arm 20 along the length direction of the lifting arm 20, and one end of the stabilizing steel cable 19 passes through the stabilizing pipe 17 to be connected with the lifting arm 20, and the other end ...

Embodiment 2

[0038] A prefabricated wall hoisting device with a stable structure in this embodiment is basically the same as in Embodiment 1. Specifically, a slide rail 21 is provided on the side of the lifting arm 20 in this embodiment, and vertical rollers 22 are installed on the slide rail. 21 and is connected with the first servo motor 23. The vertical roller 22 forms a sliding structure between the first servo motor 23 and the slide rail 21, and the first servo motor 23 drives the vertical roller 22 to move along the slide rail 21, so that the vertical roller 22 is always in line with the adjustment roller 18 and the stabilizing tube 17 A right-angled structure is formed, and the operation and control are relatively simple. The right-angle position of the right-angled stabilizing steel cable 19 will rise and fall together with the wall fittings, so that the wall fittings are always kept horizontal when transported in the air, which is conducive to improving the stability of the wall f...

Embodiment 3

[0040] A prefabricated wall hoisting device with a stable structure in this embodiment is basically the same in structure as in Embodiment 2, the main difference is that the stable steel cables 19 include two, which respectively pass through the lifting arm 20 in two The vertical rollers 22 on the opposite side are connected with the steel cable reel drum 24, that is, both sides of the hoisting frame are connected with the lifting arm 20 through a stable steel cable 19, which is conducive to further improving the structural firmness of the overall device and the stability of the wall hoisting sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com