Patents

Literature

36results about How to "Improve shipping accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

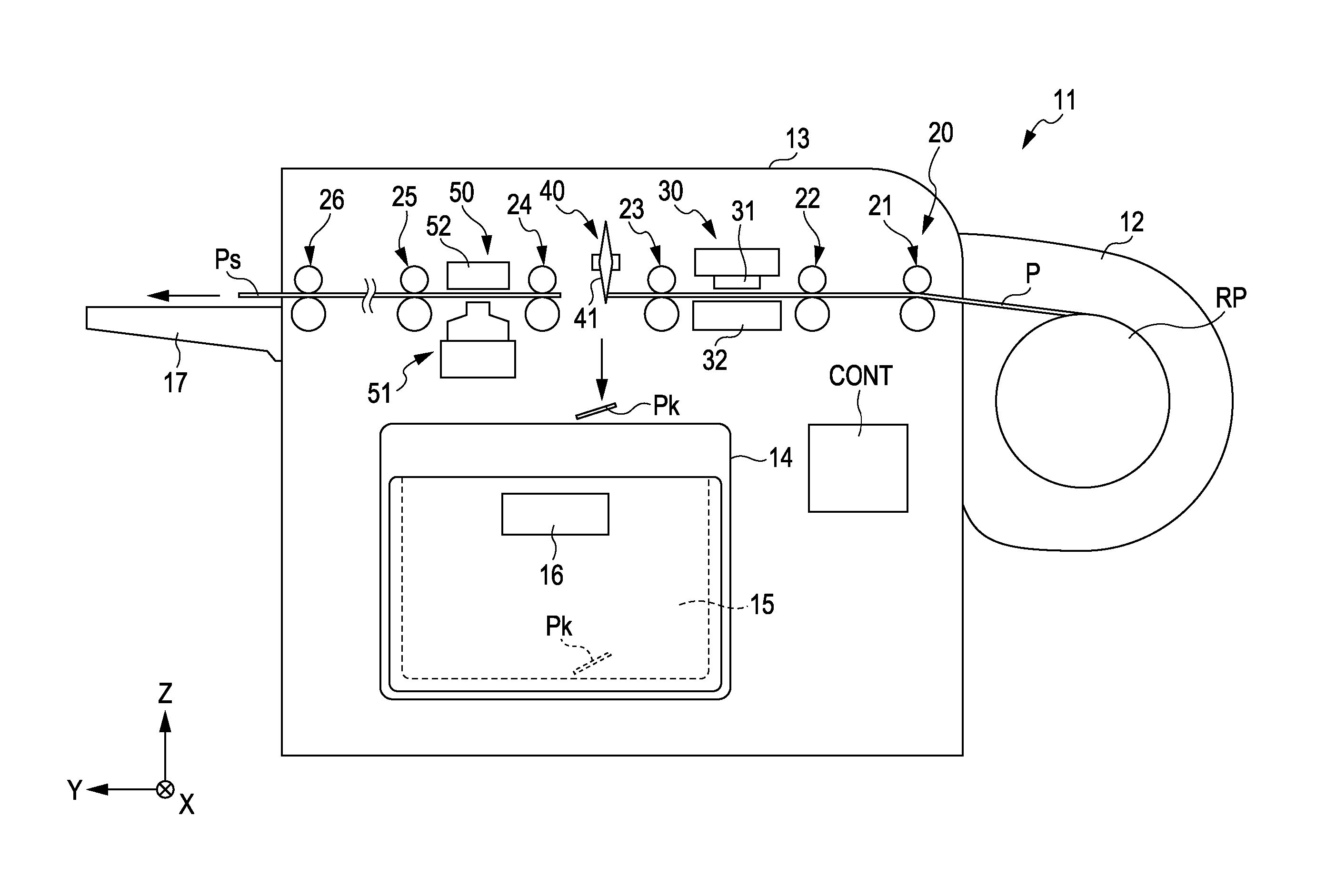

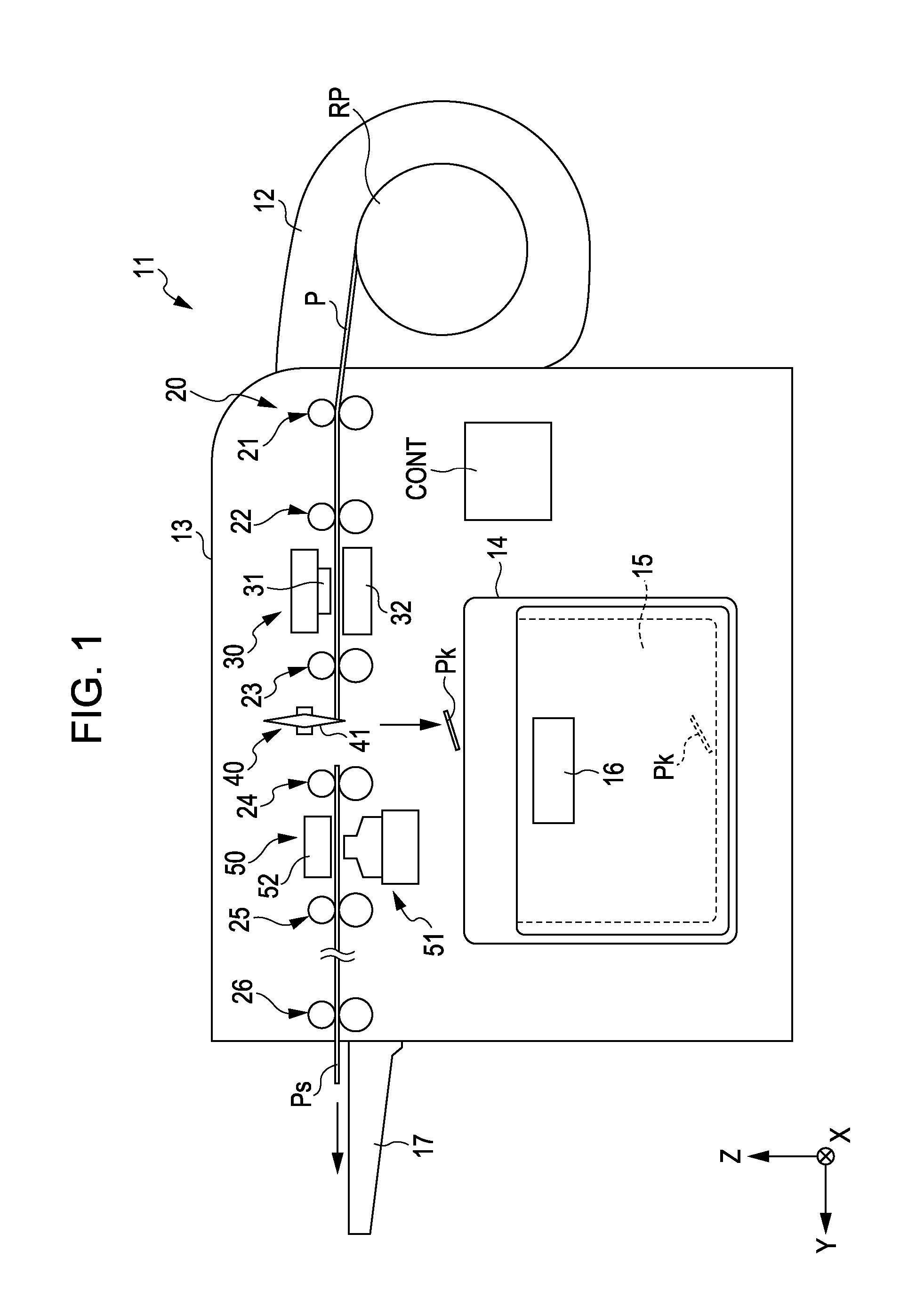

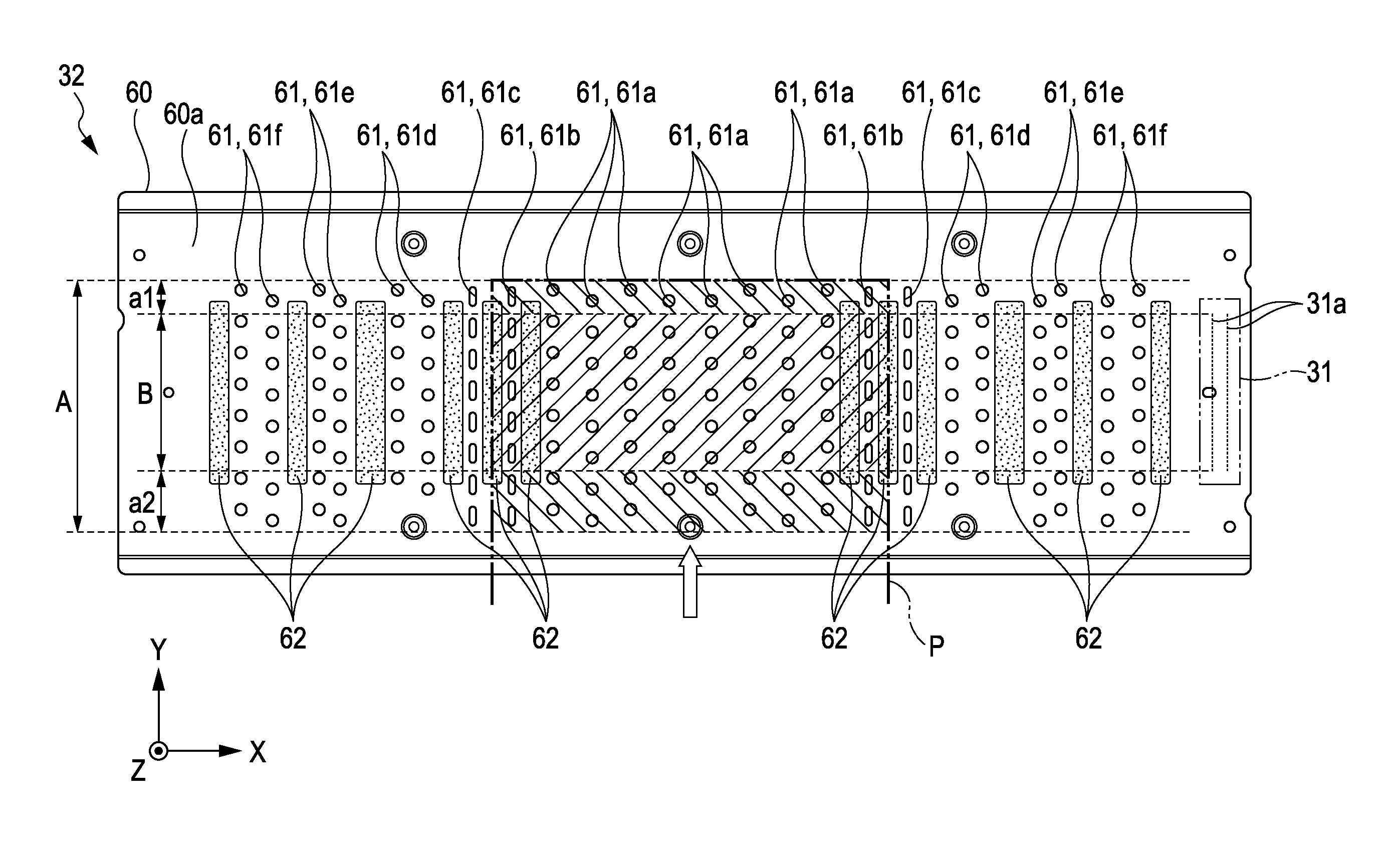

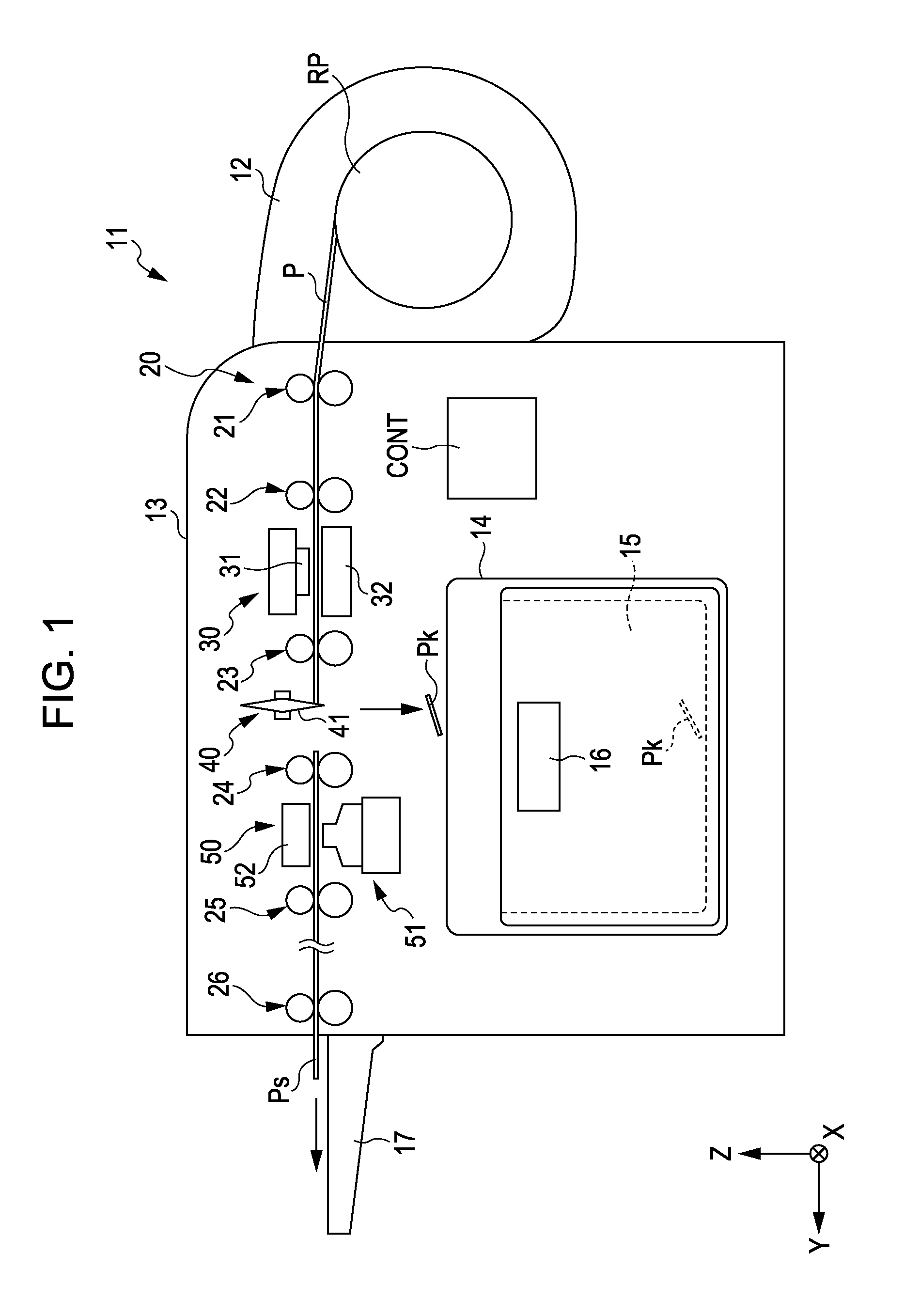

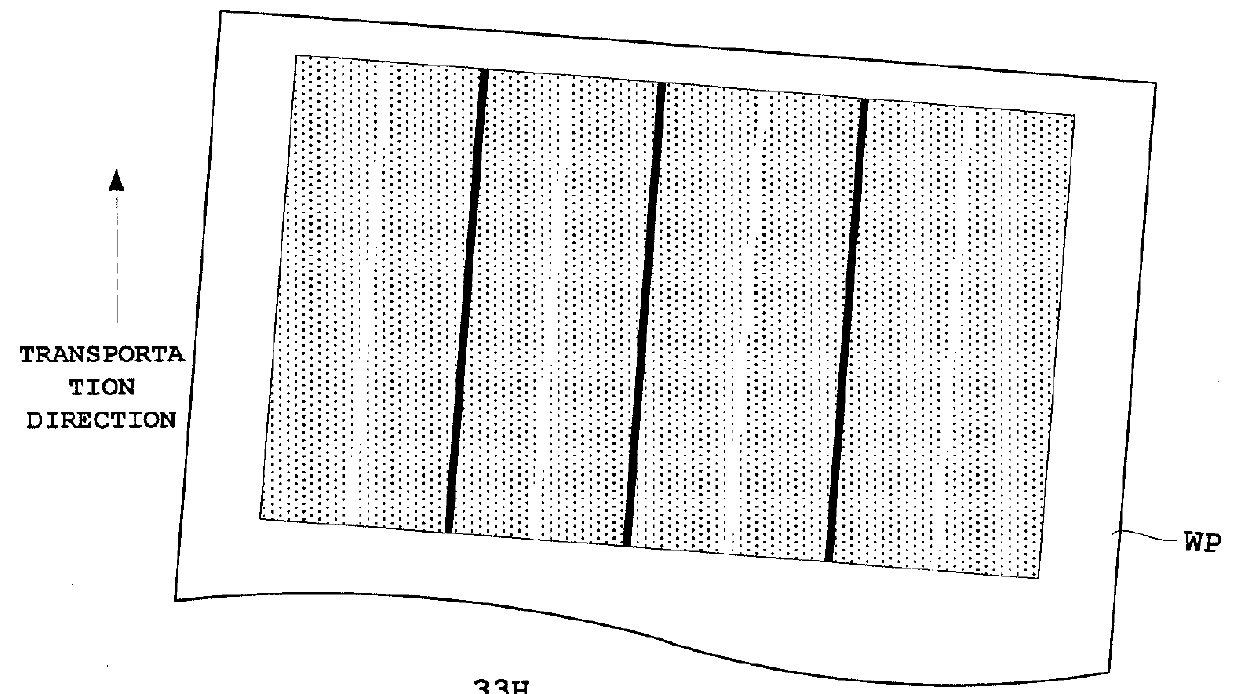

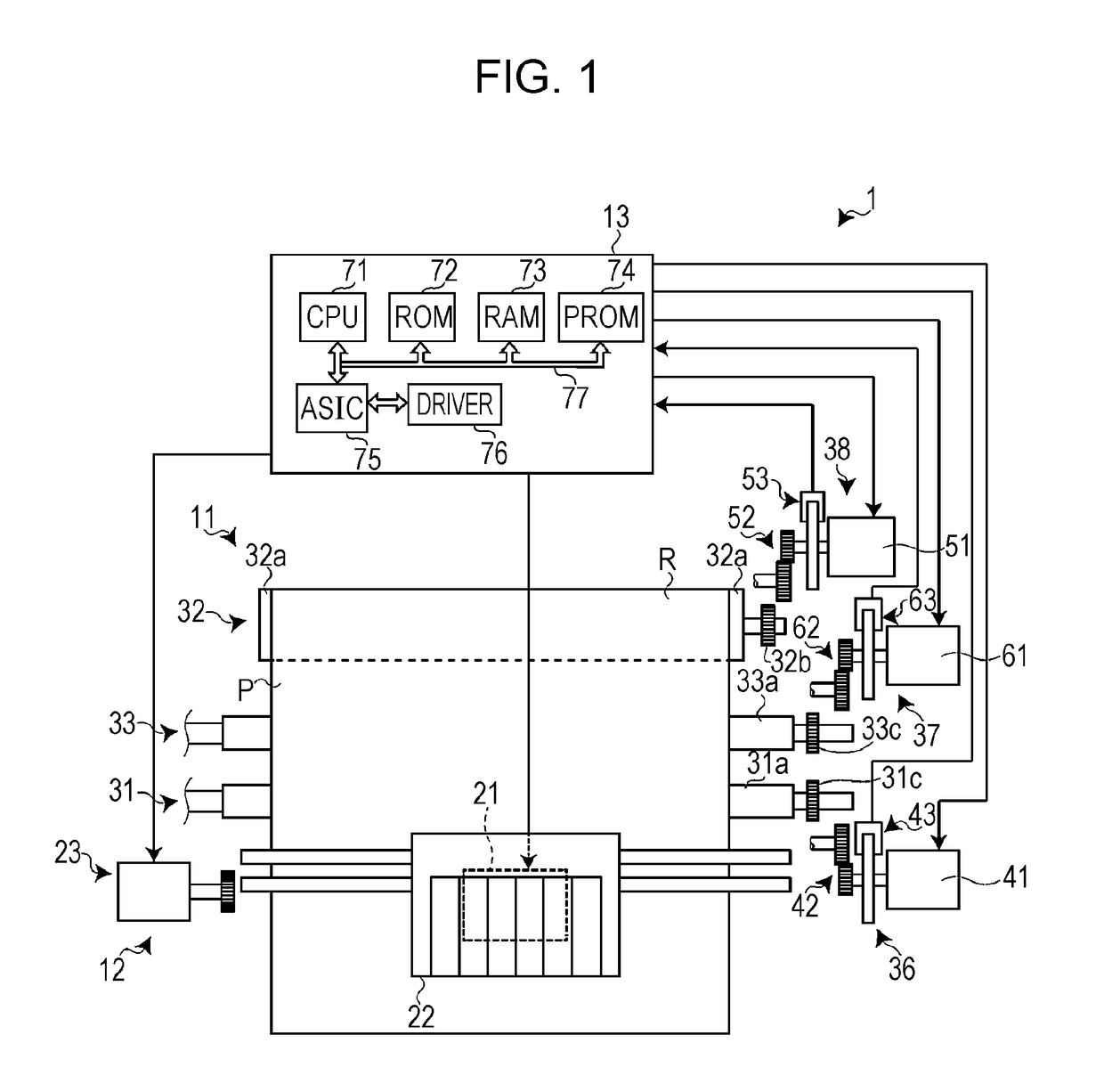

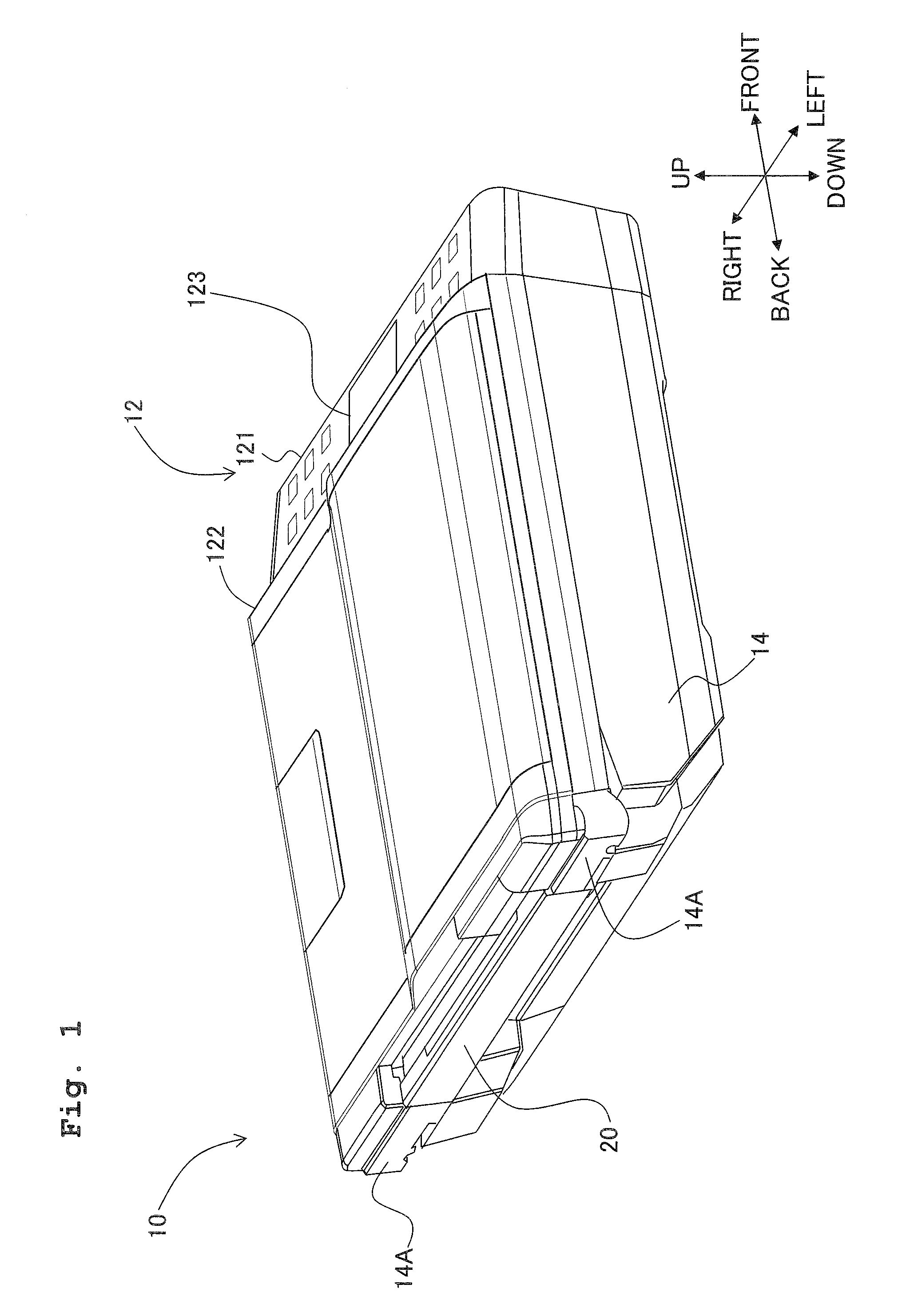

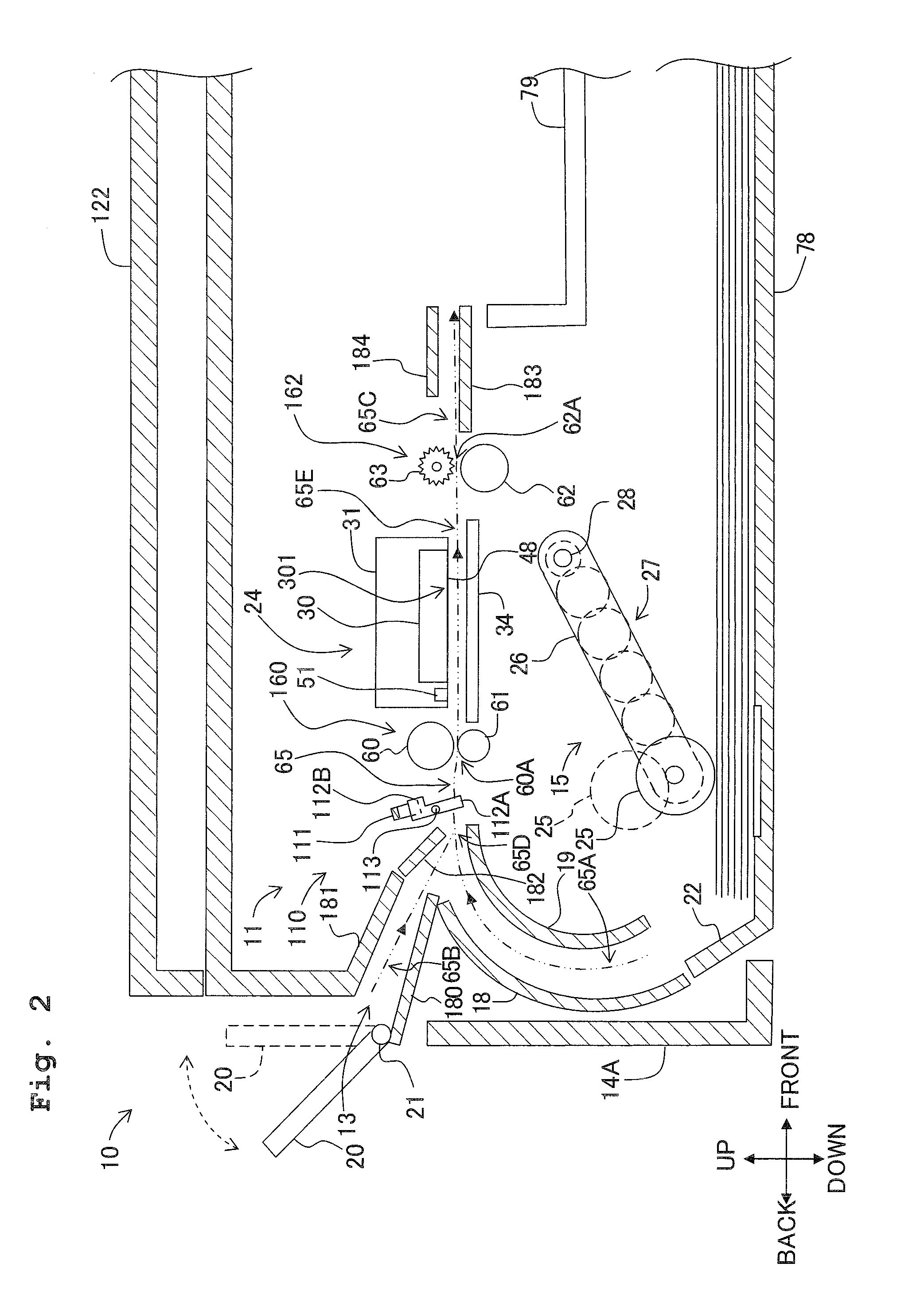

Recording apparatus

ActiveUS20120069076A1Improve flatnessSuppress printing qualityOther printing apparatusEngineeringRecording media

A recording apparatus includes a supporting member on which a plurality of suction holes for sucking a recording medium are formed on a supporting face for supporting the recording medium, a transportation device which transports the recording medium along the supporting face, a recording head which ejects fluid on the recording medium supported by the supporting face so as to perform printing, and a control device which makes the recording head execute the printing when a front end of the recording medium in the transportation direction reaches to a position at which the front end of the recording medium covers the suction holes formed at downstream-most positions in the transportation direction on the supporting face.

Owner:SEIKO EPSON CORP

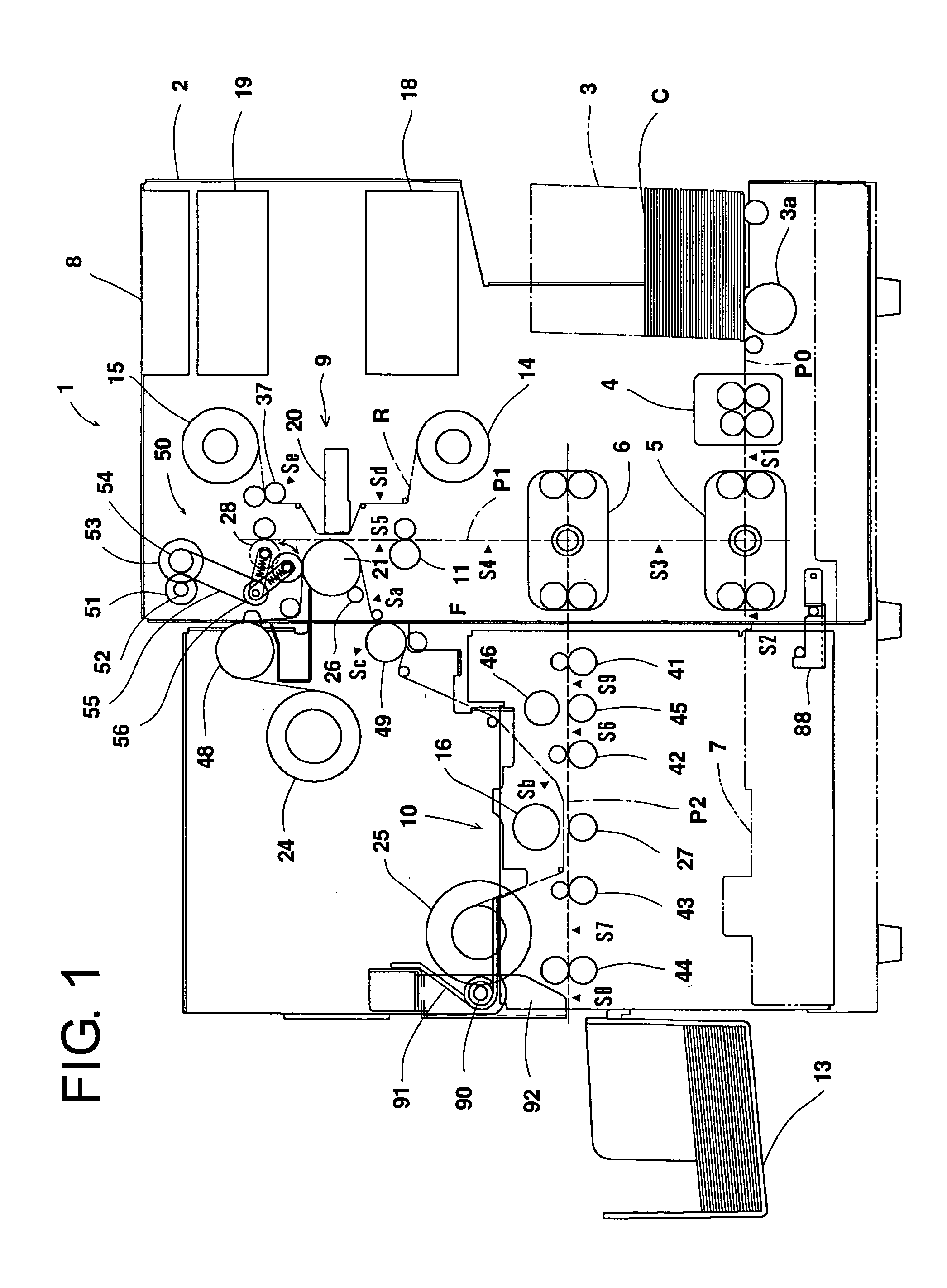

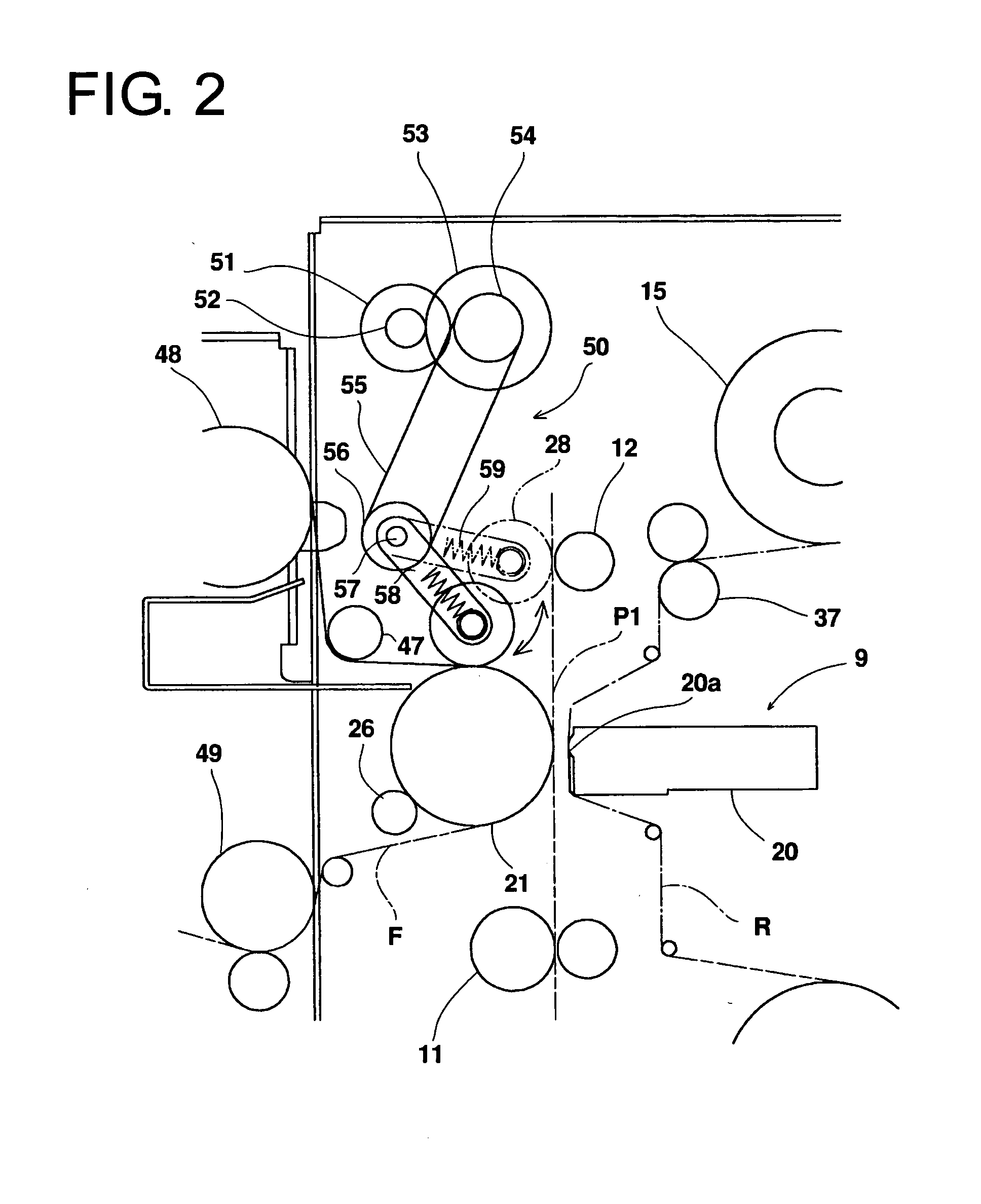

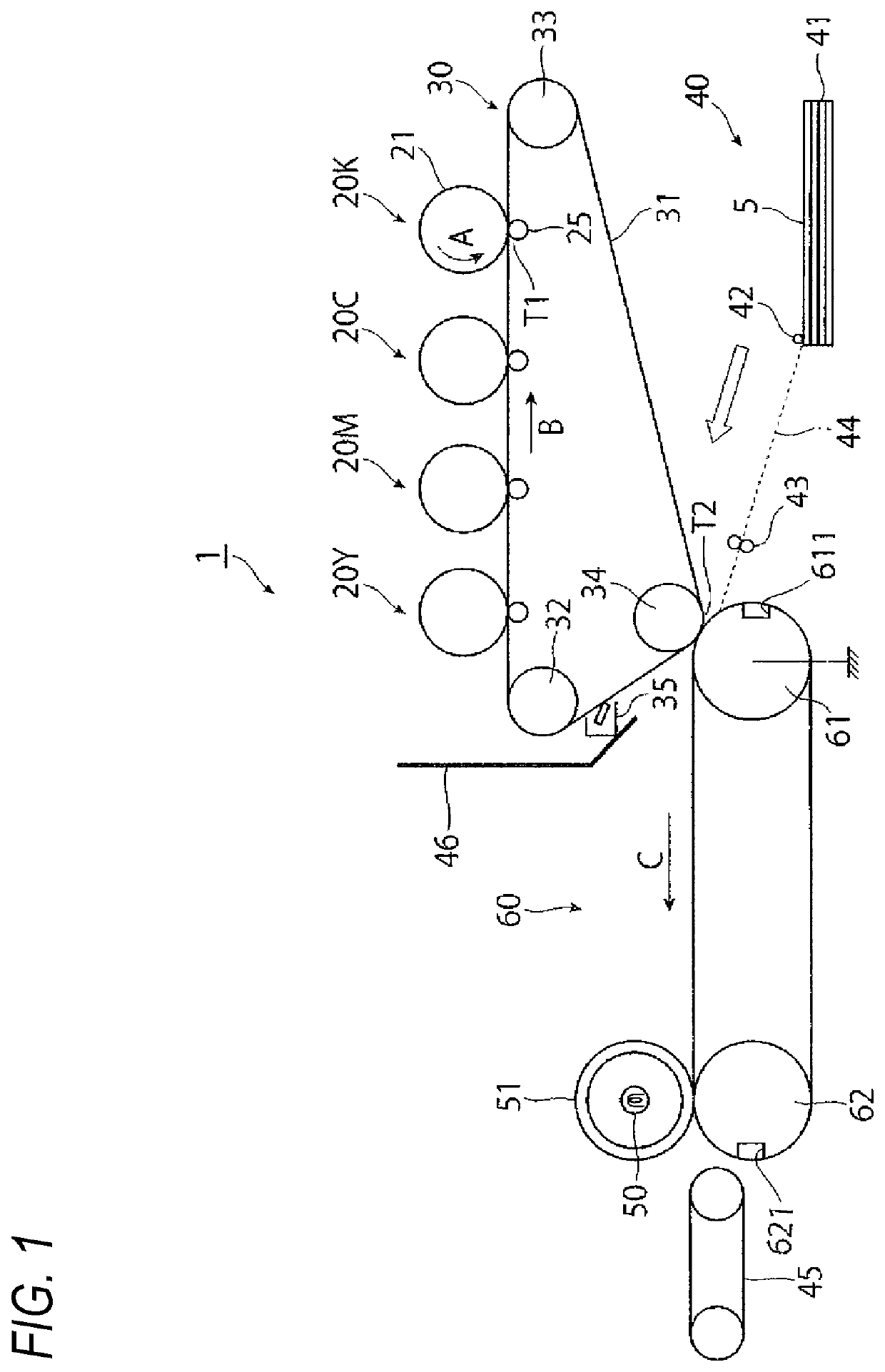

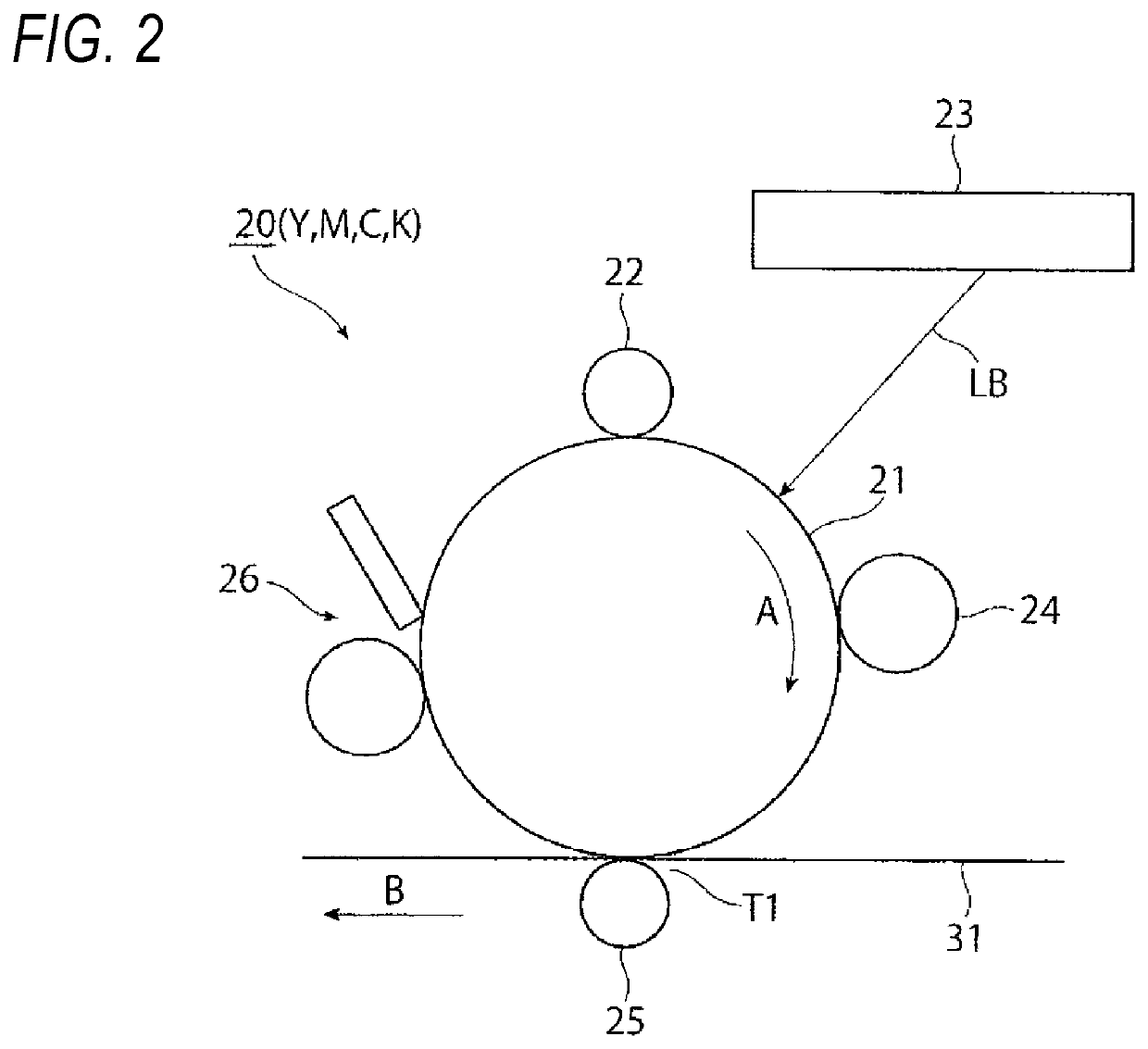

Printing apparatus

InactiveUS20050083395A1Improve accuracyLow costPrinting mechanismsRecording apparatusEngineeringRecording media

A printing apparatus includes a printing device for selectively forming an image on a recording medium and a transfer medium, and a platen roller arranged opposite to the printing device. A nipping roller is arranged for nipping the transfer medium with the platen roller, and a mode setting device is used for setting a direct mode for forming the image on the recording medium and a indirect mode for forming the image on the transfer medium. A moving device moves the nipping roller to contact with and separate from the platen roller according to the direct mode and the indirect mode set by the mode setting device.

Owner:NISCA KK

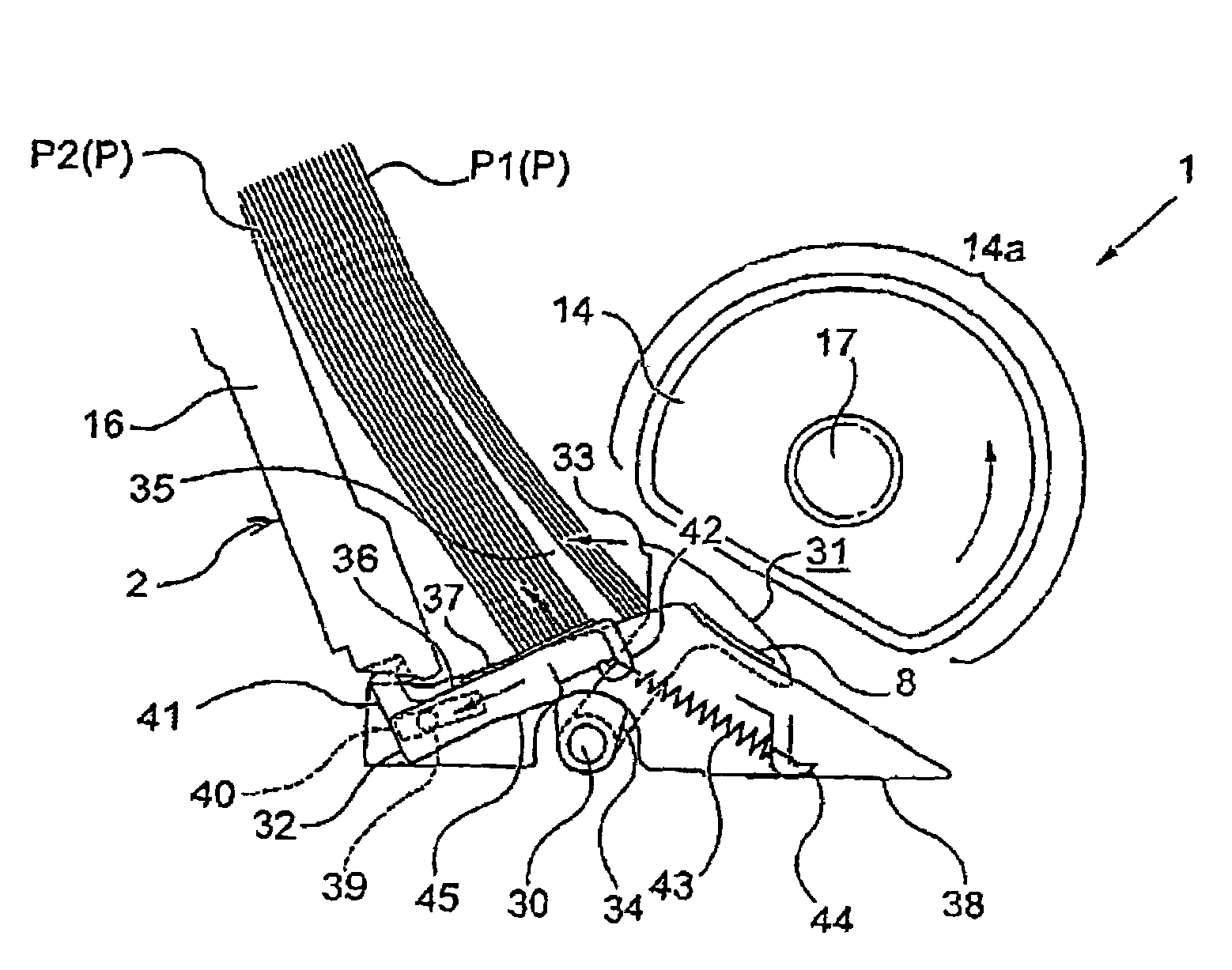

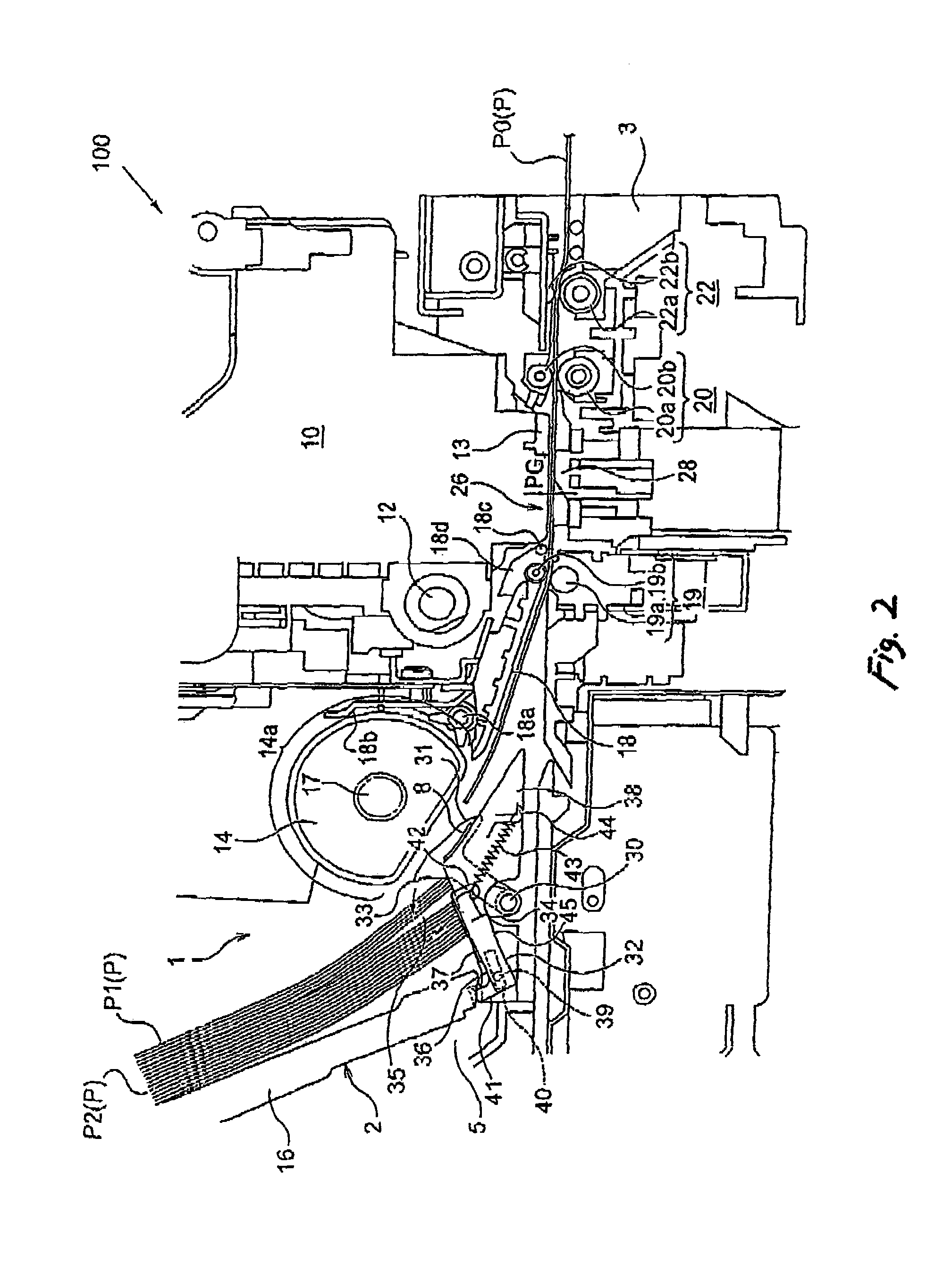

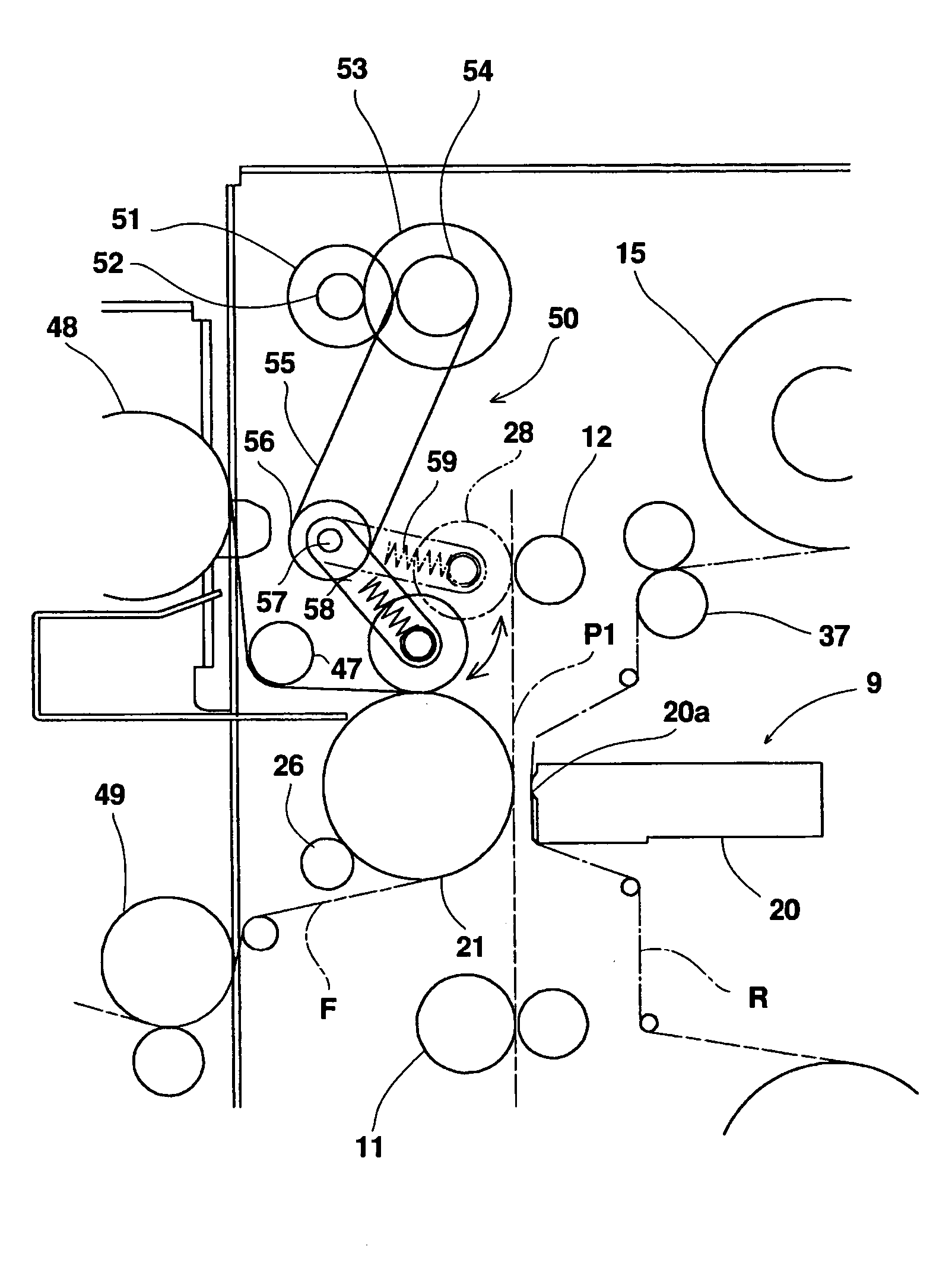

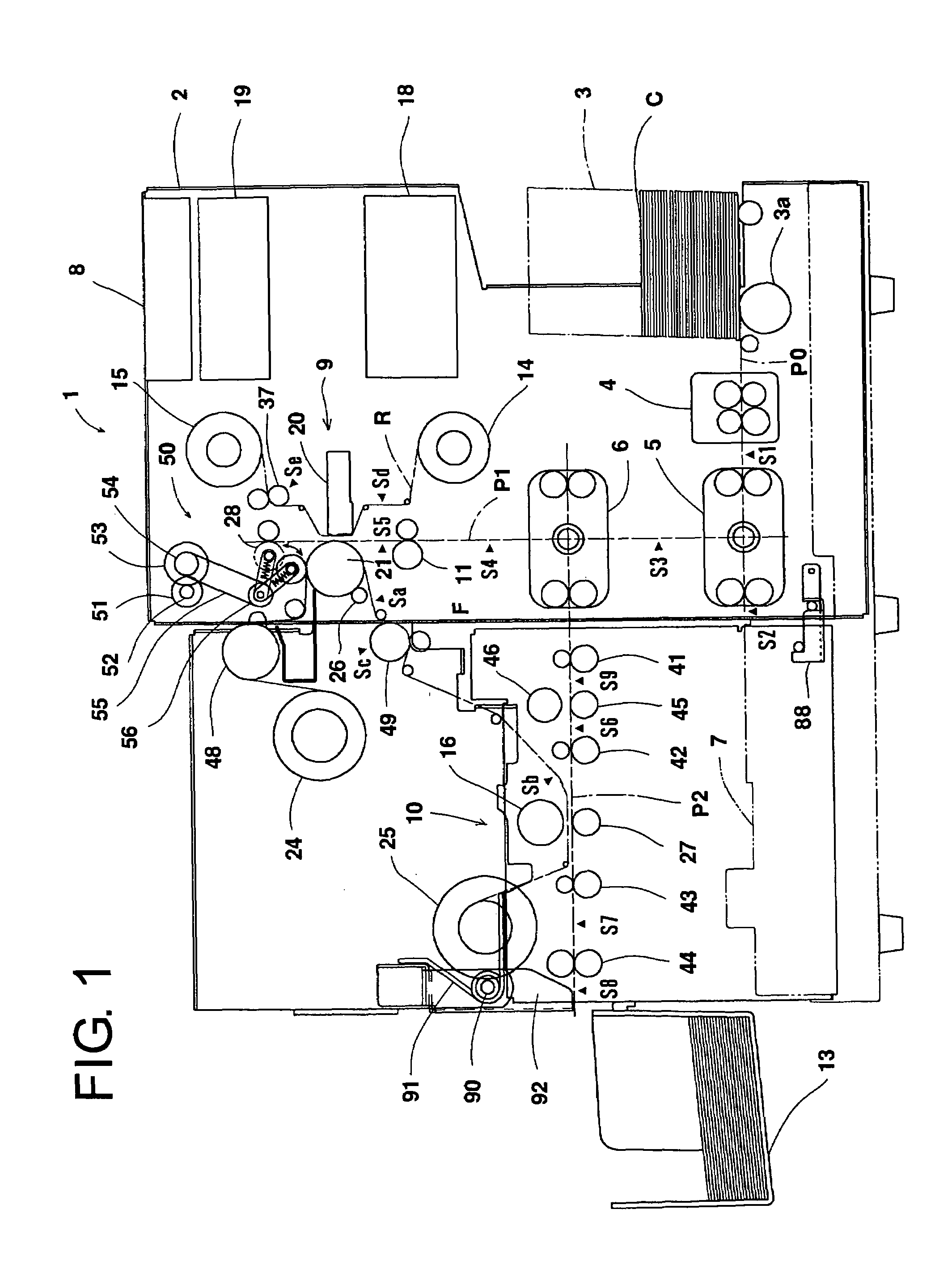

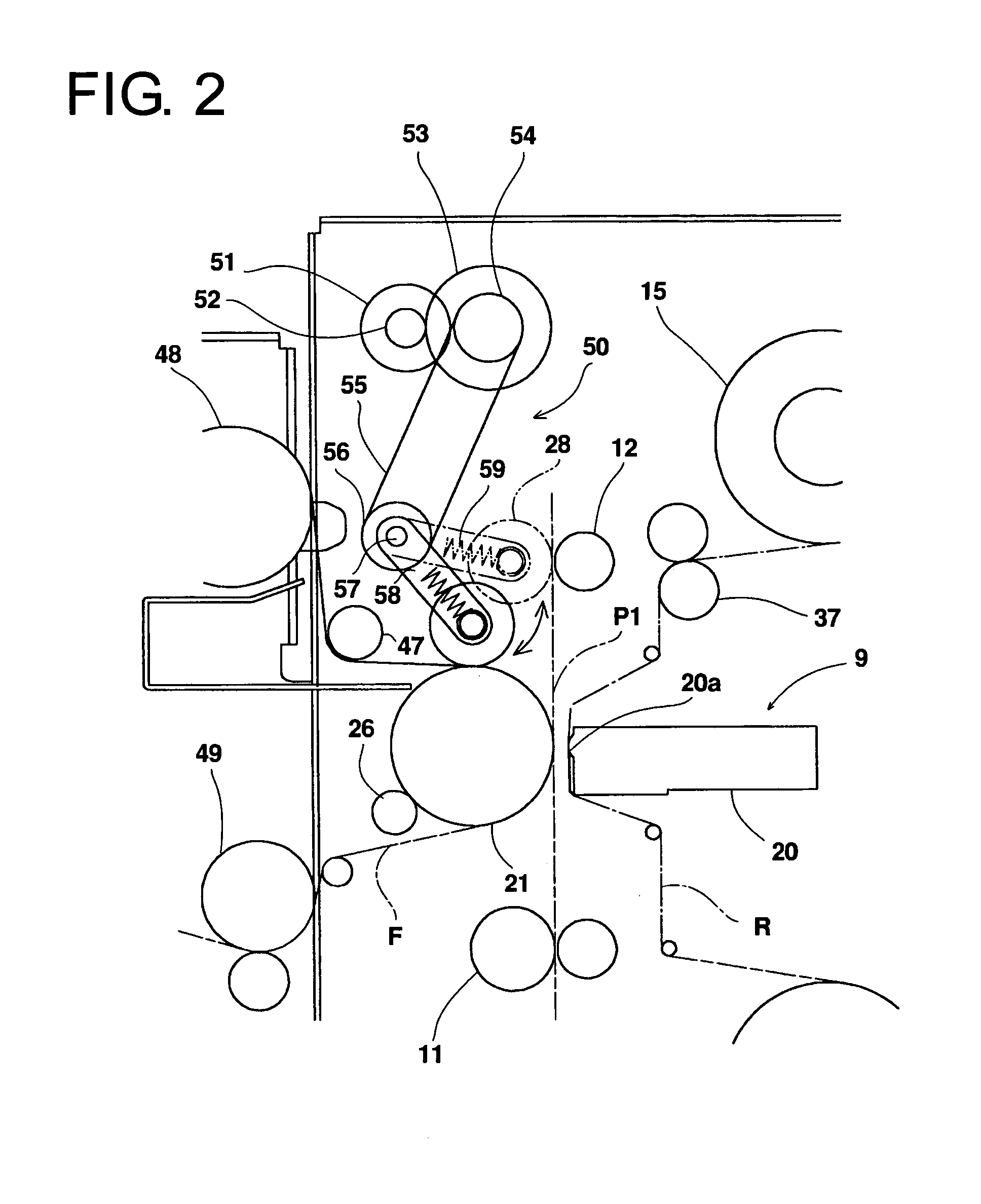

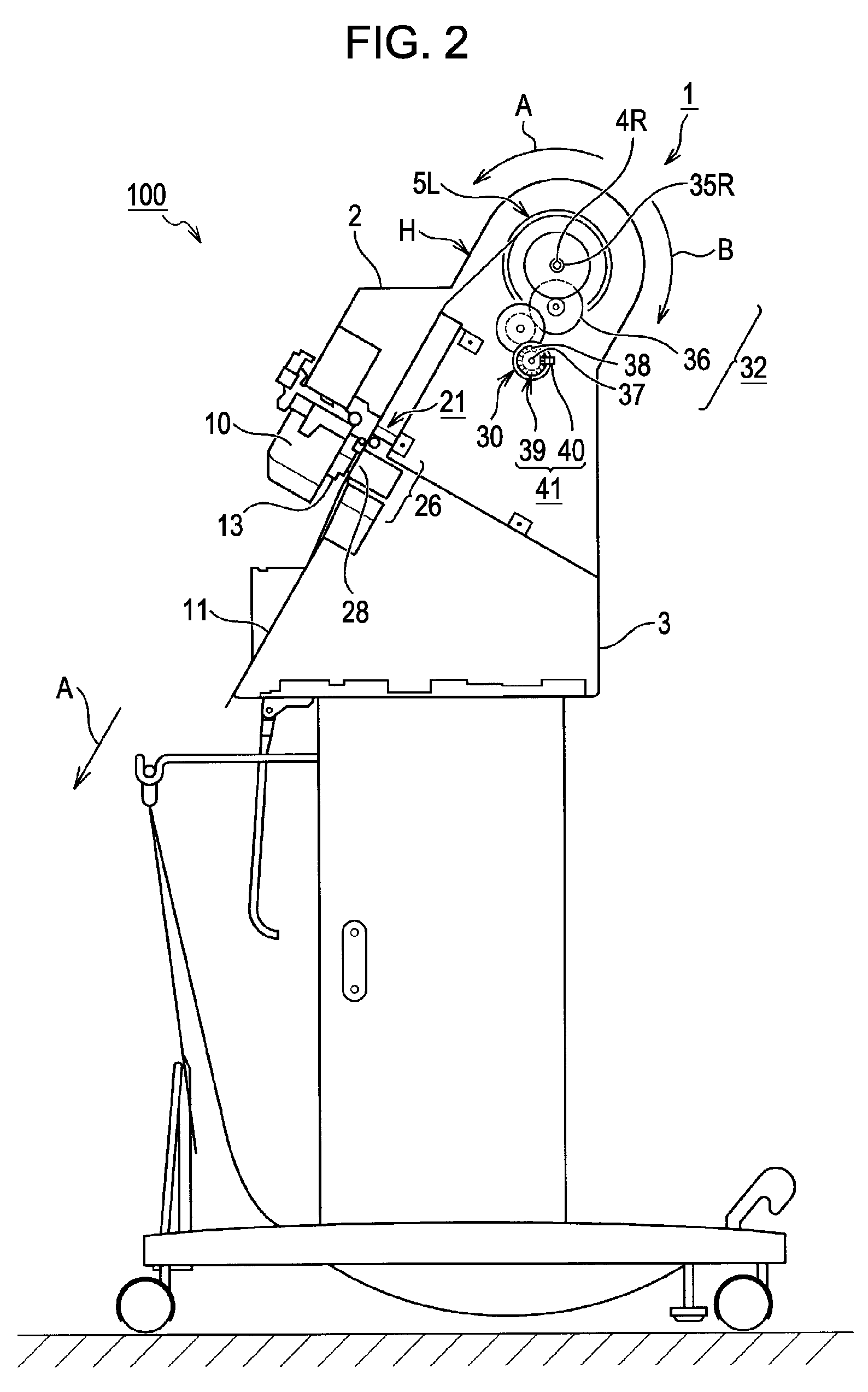

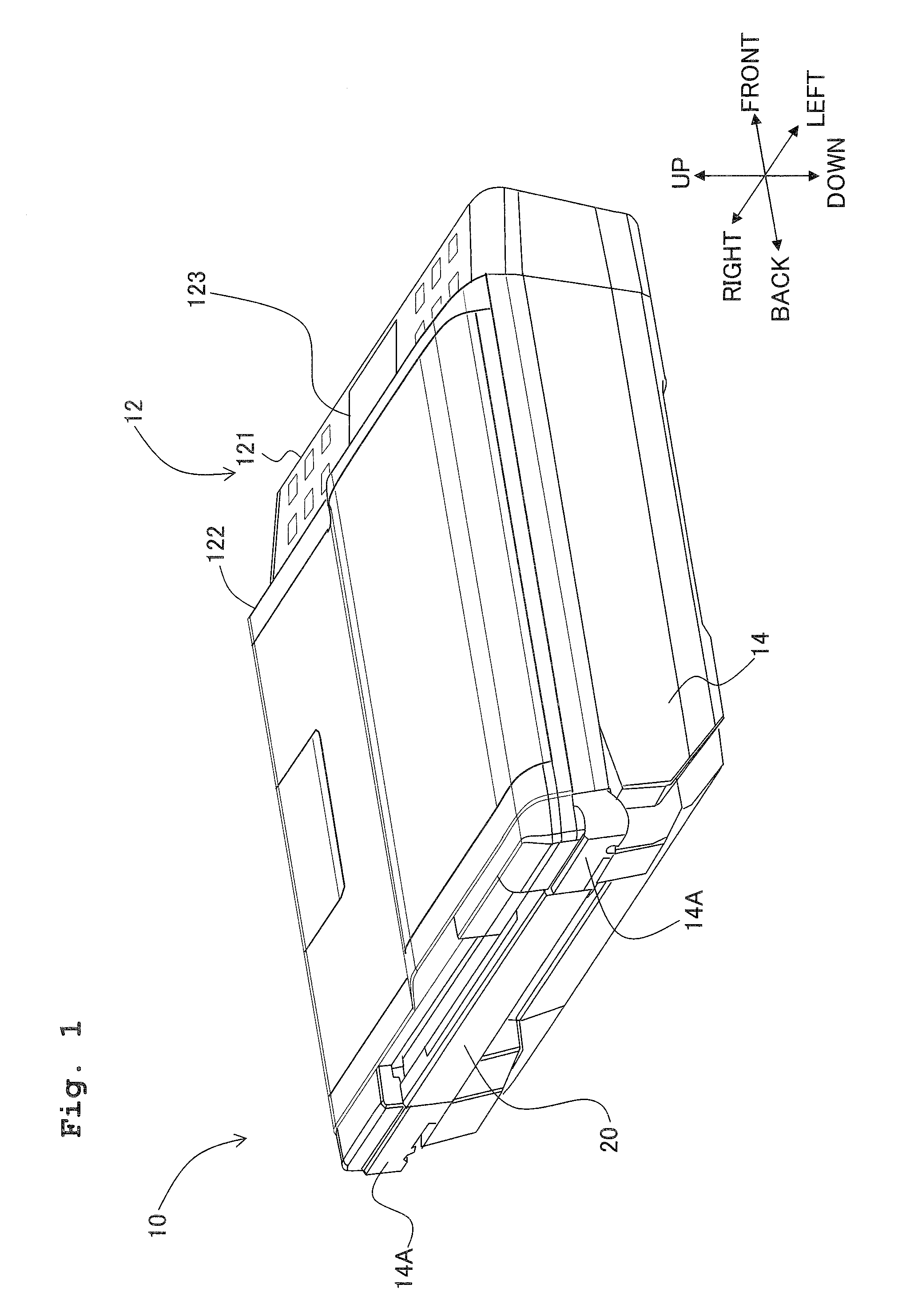

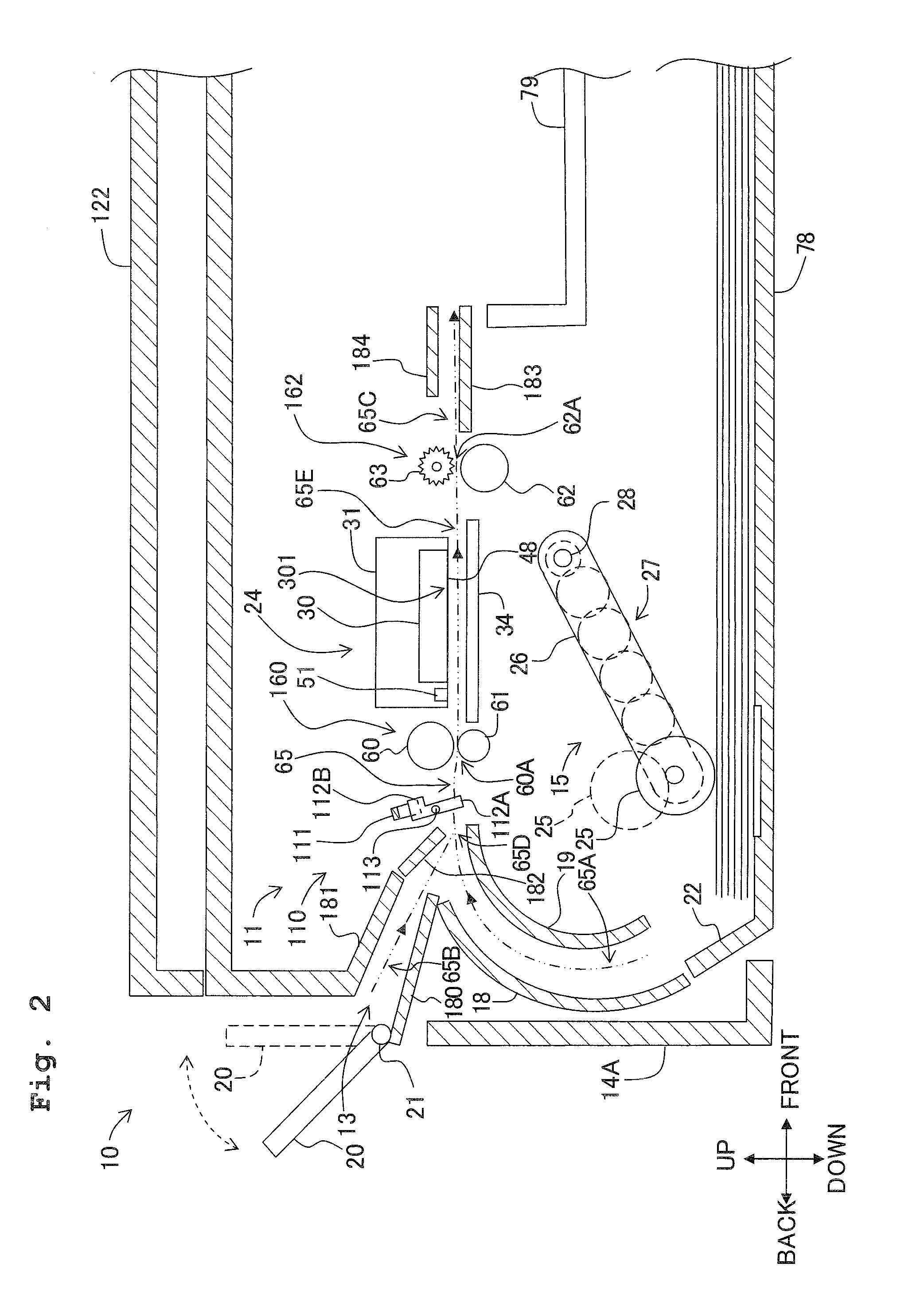

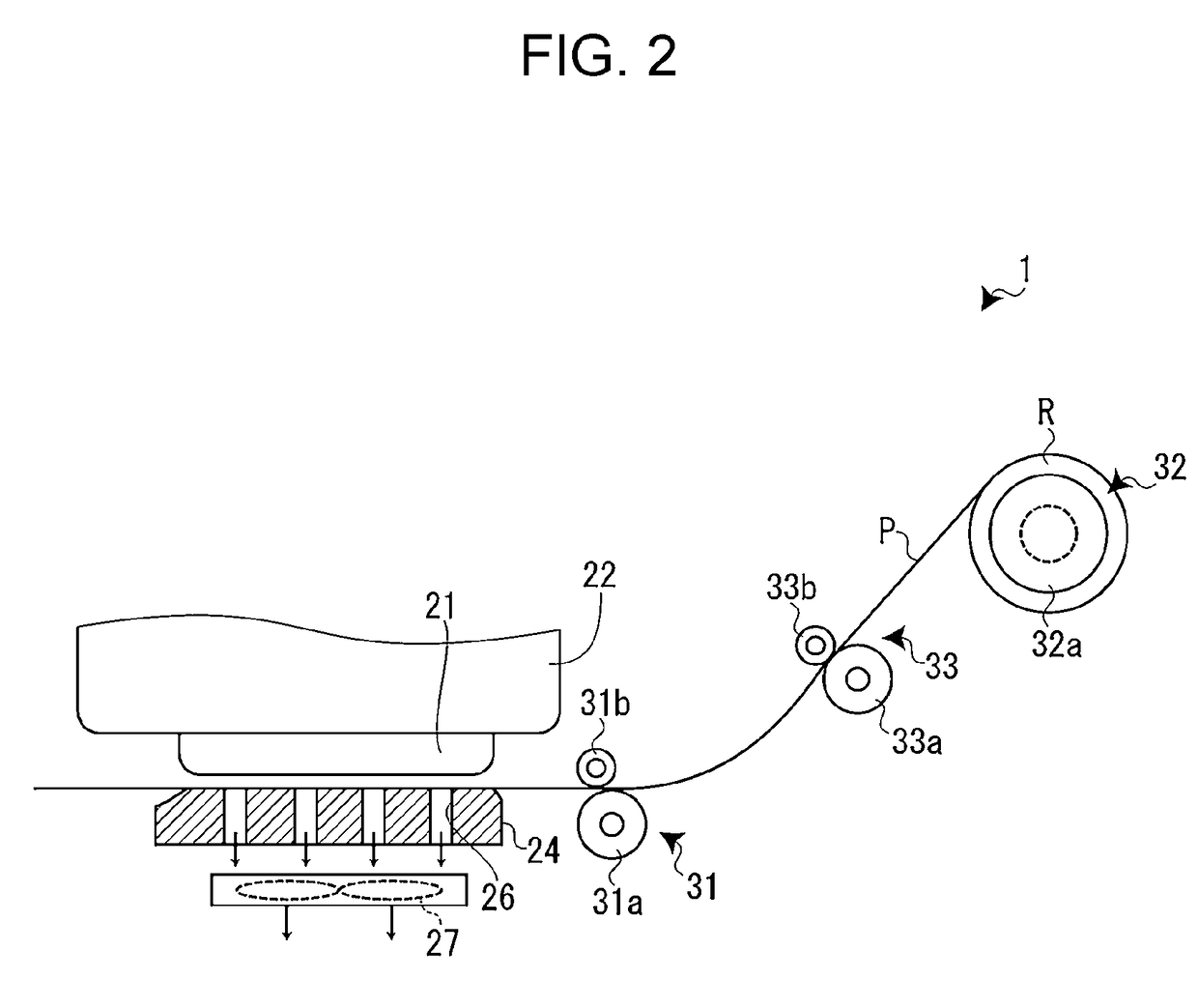

Returner incorporated in automatic feeder, and recording apparatus or liquid or liquid ejecting apparatus provided with the same

InactiveUS7422206B2Small sizeReliable returnElectrographic processes using charge patternPrintingLiquid jetMechanical engineering

Owner:SEIKO EPSON CORP

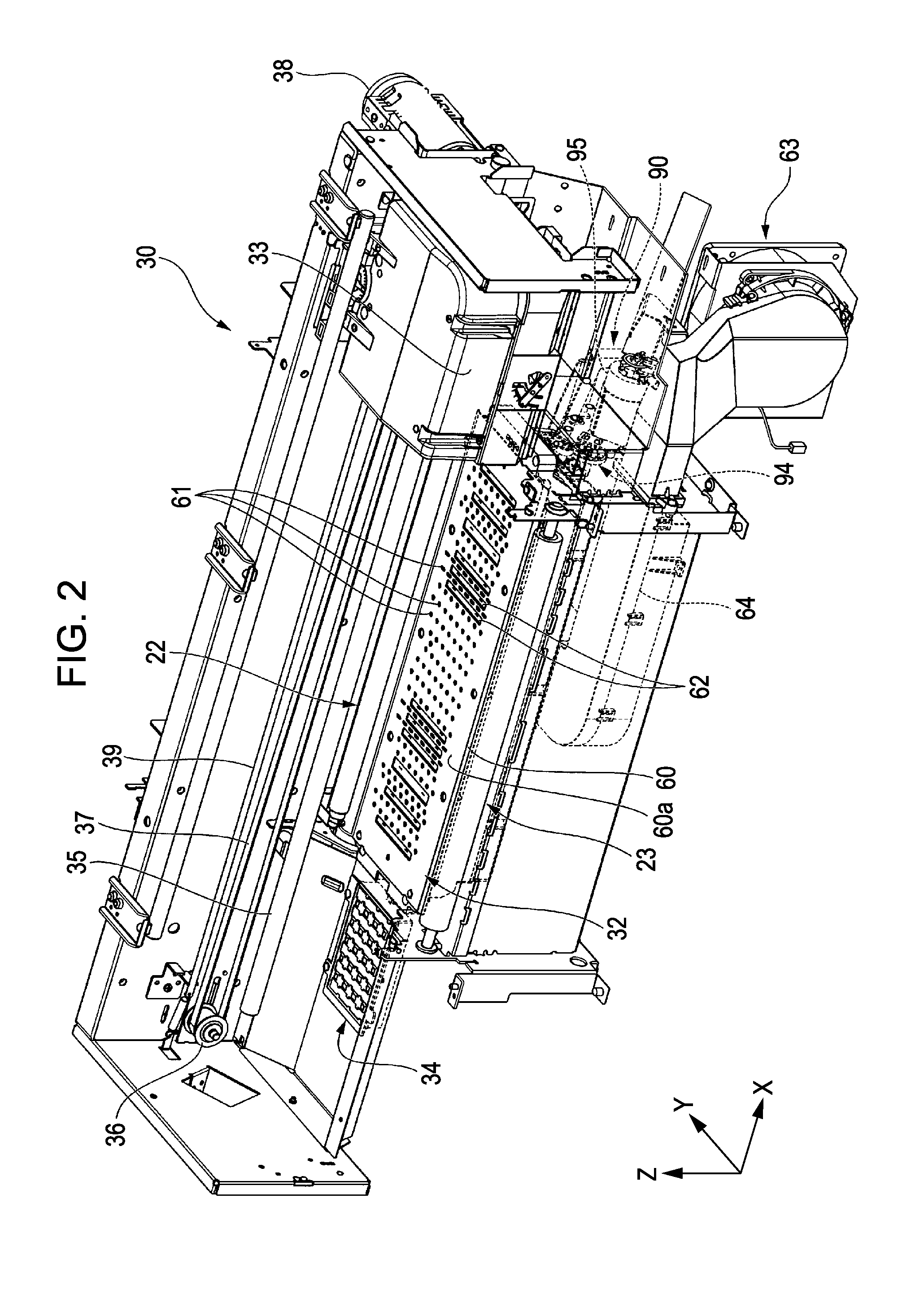

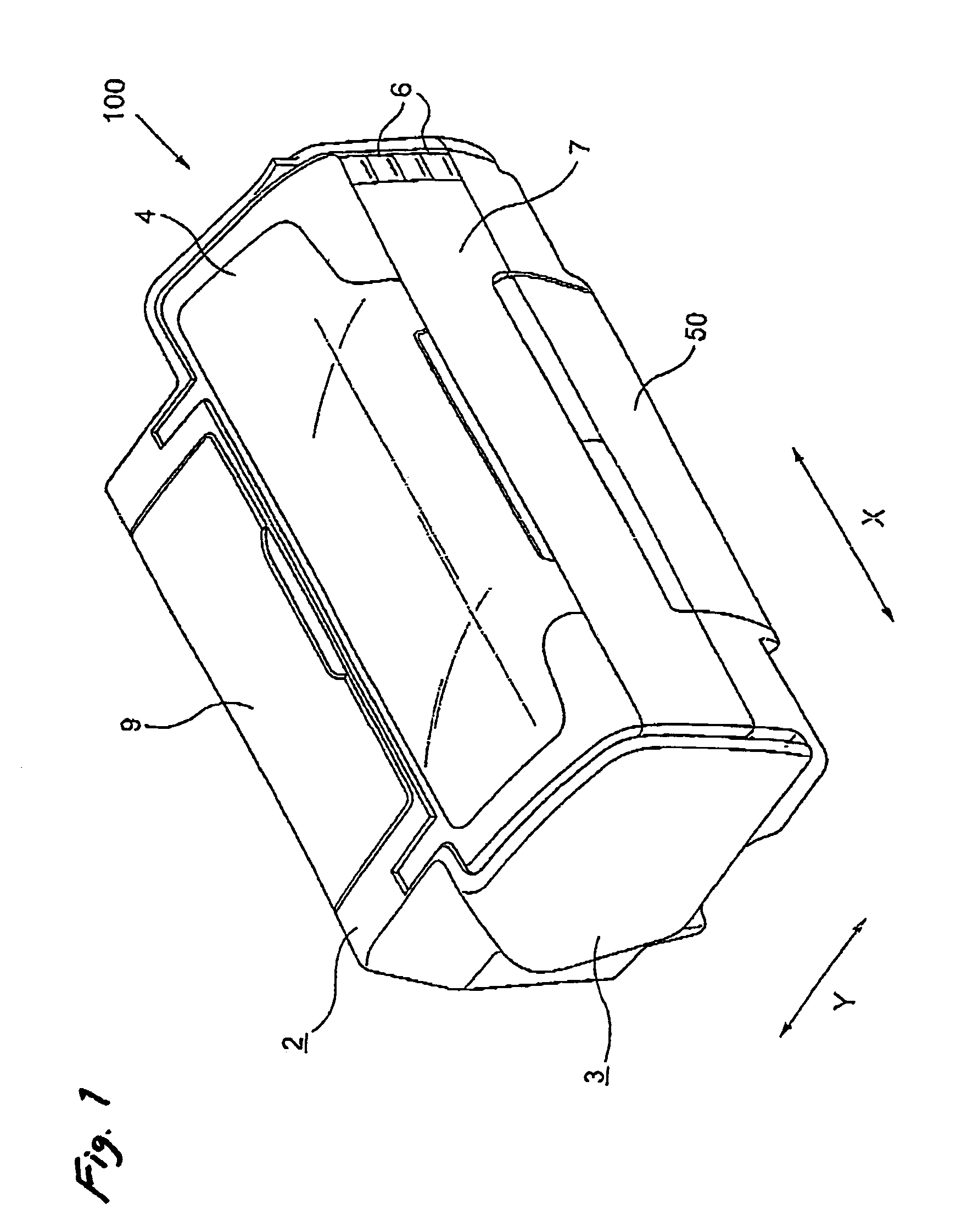

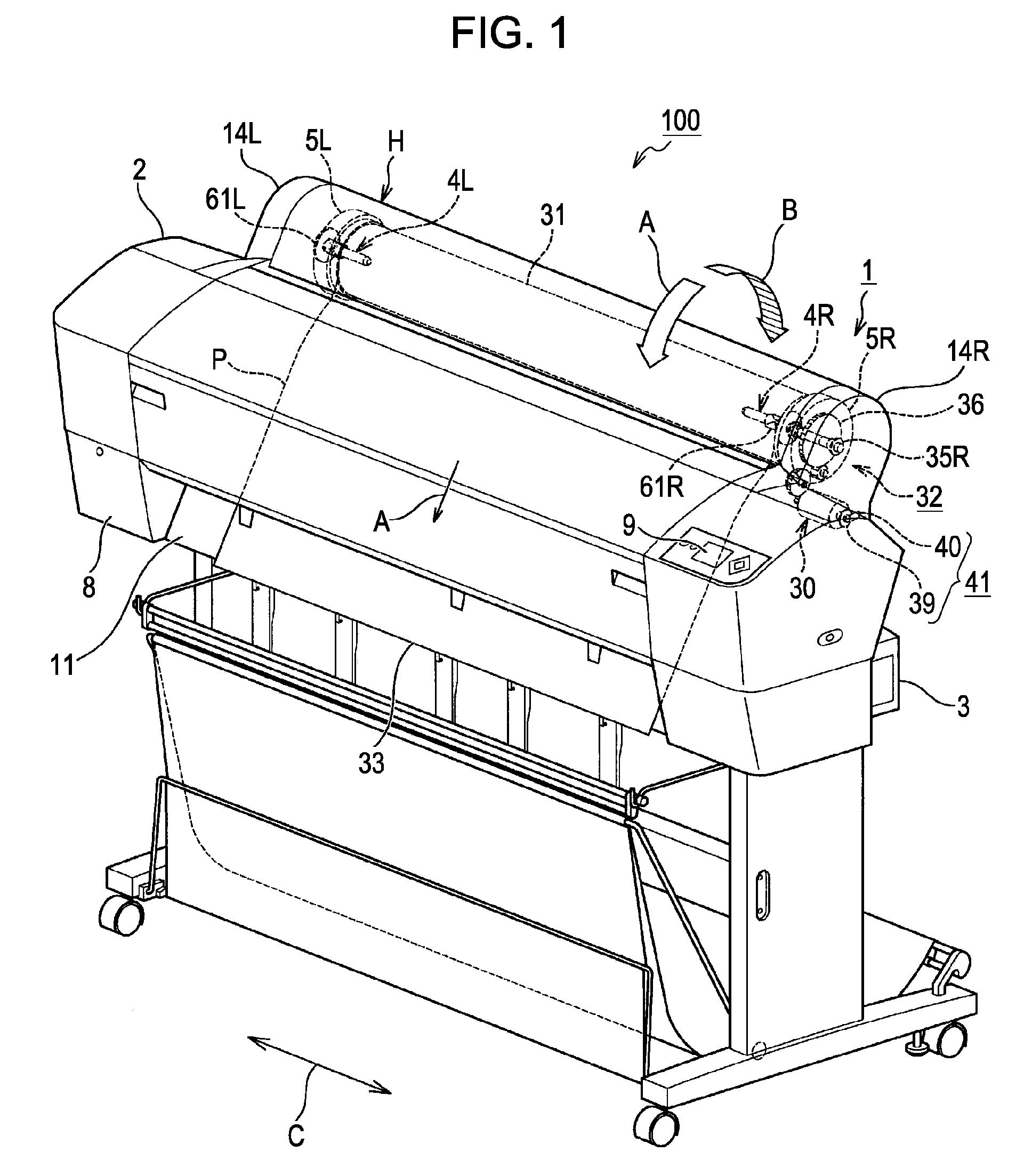

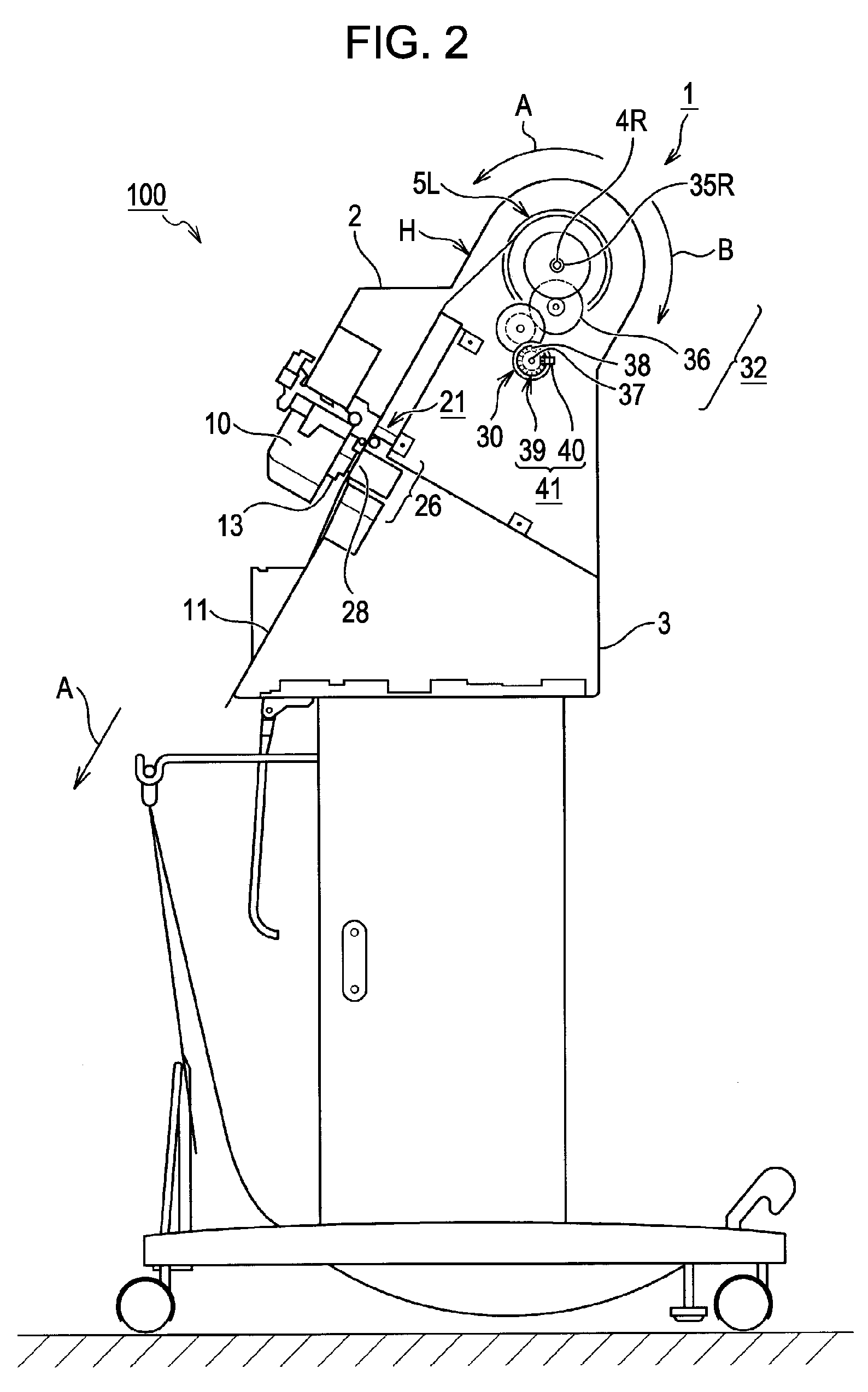

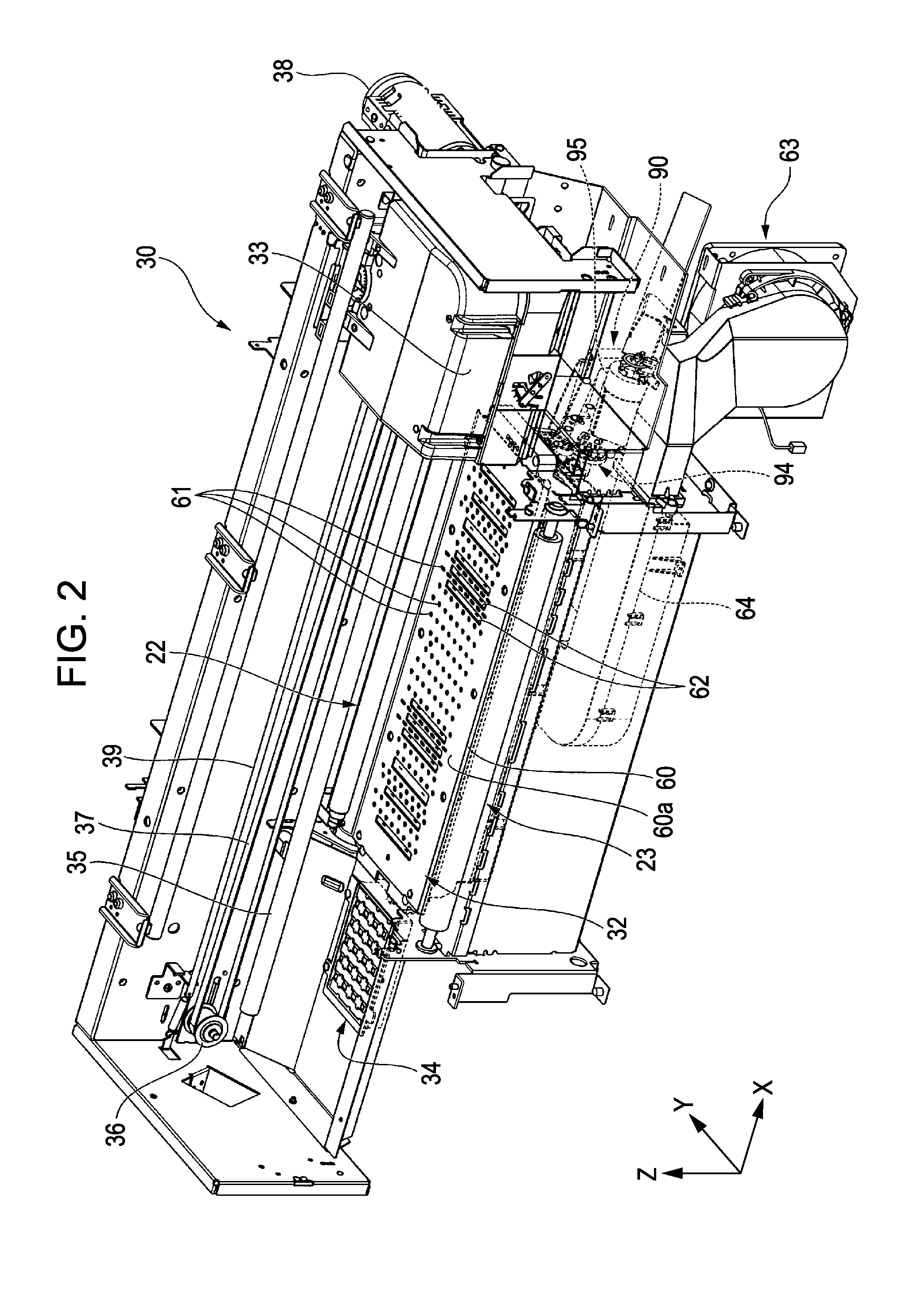

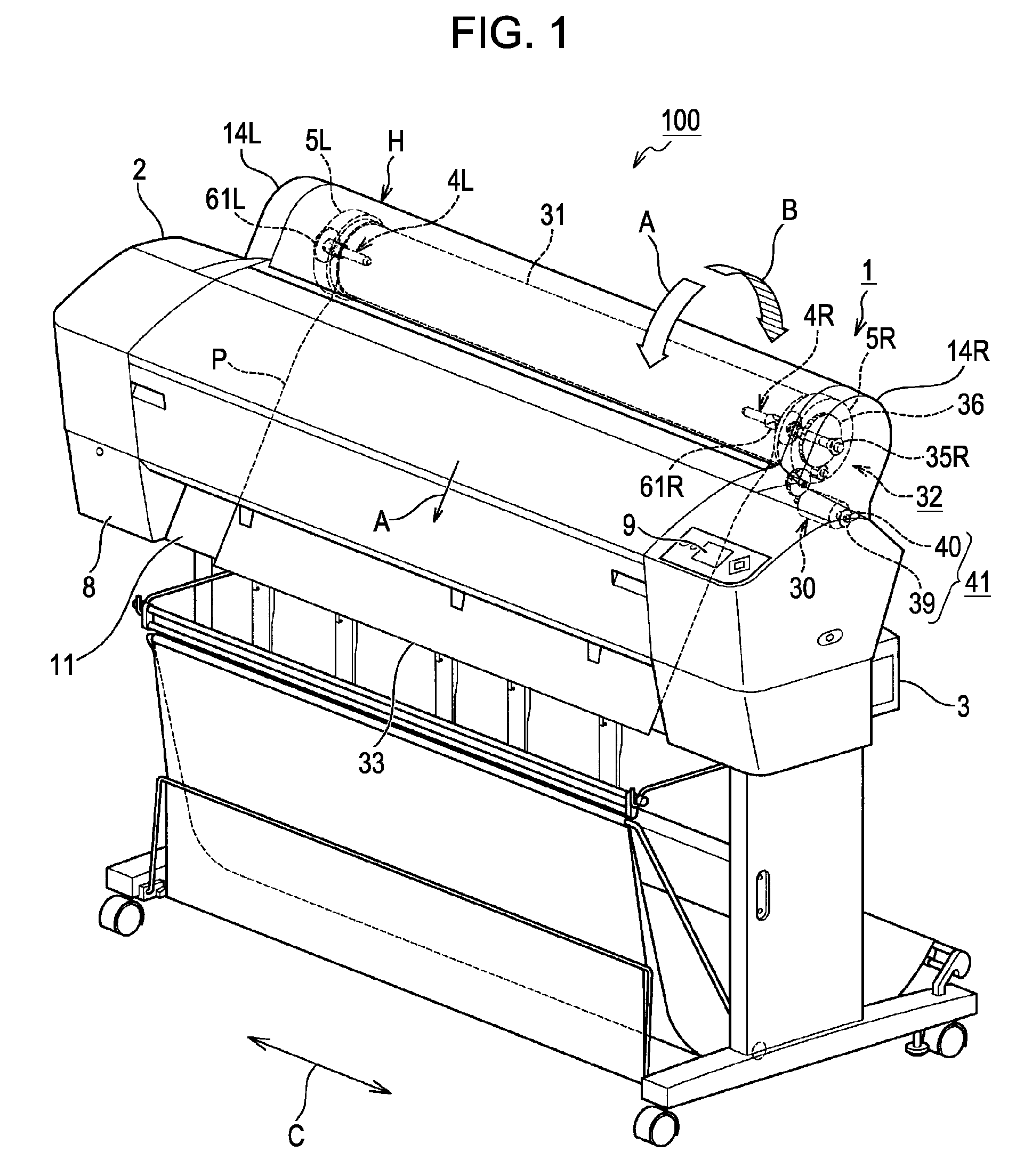

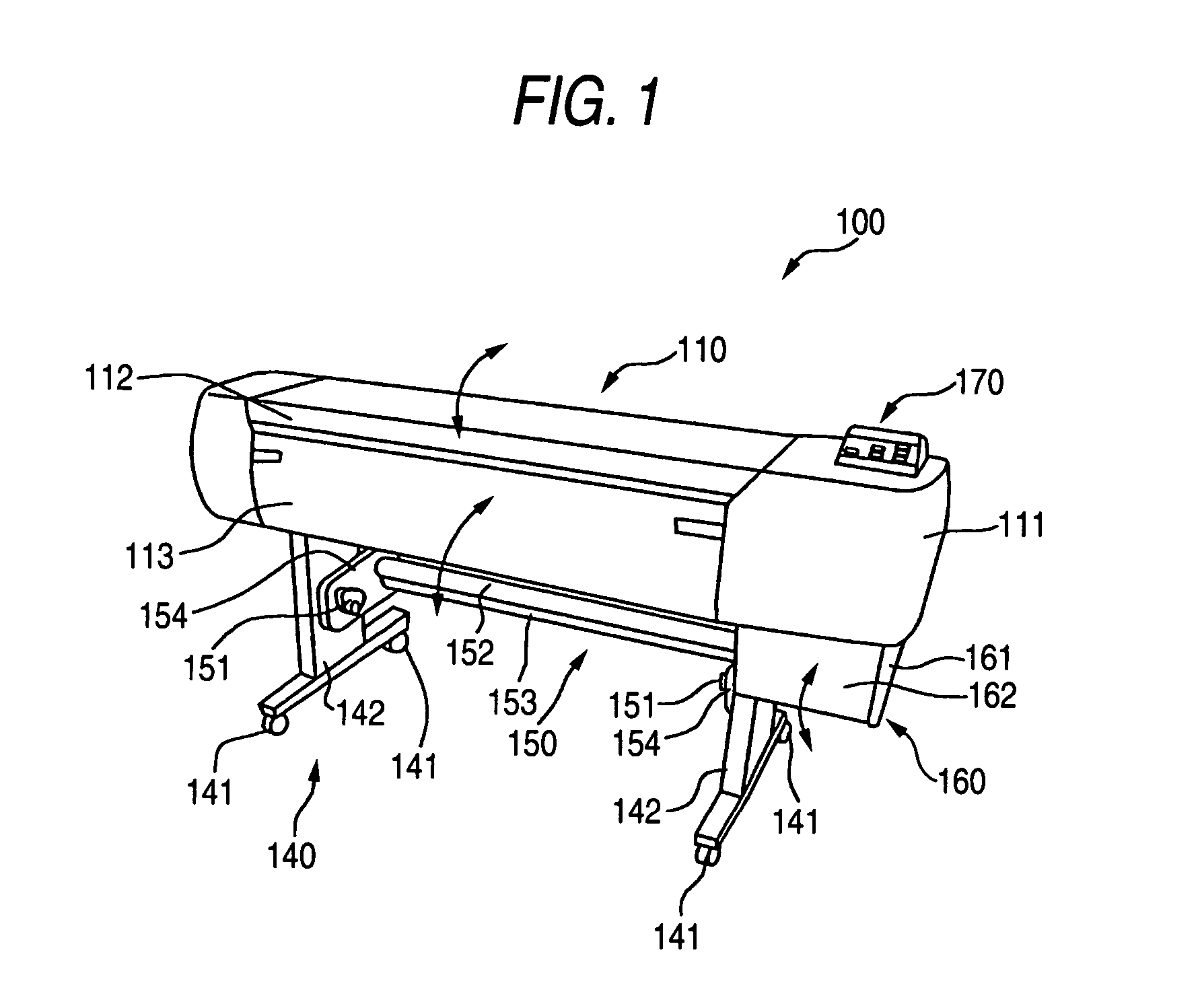

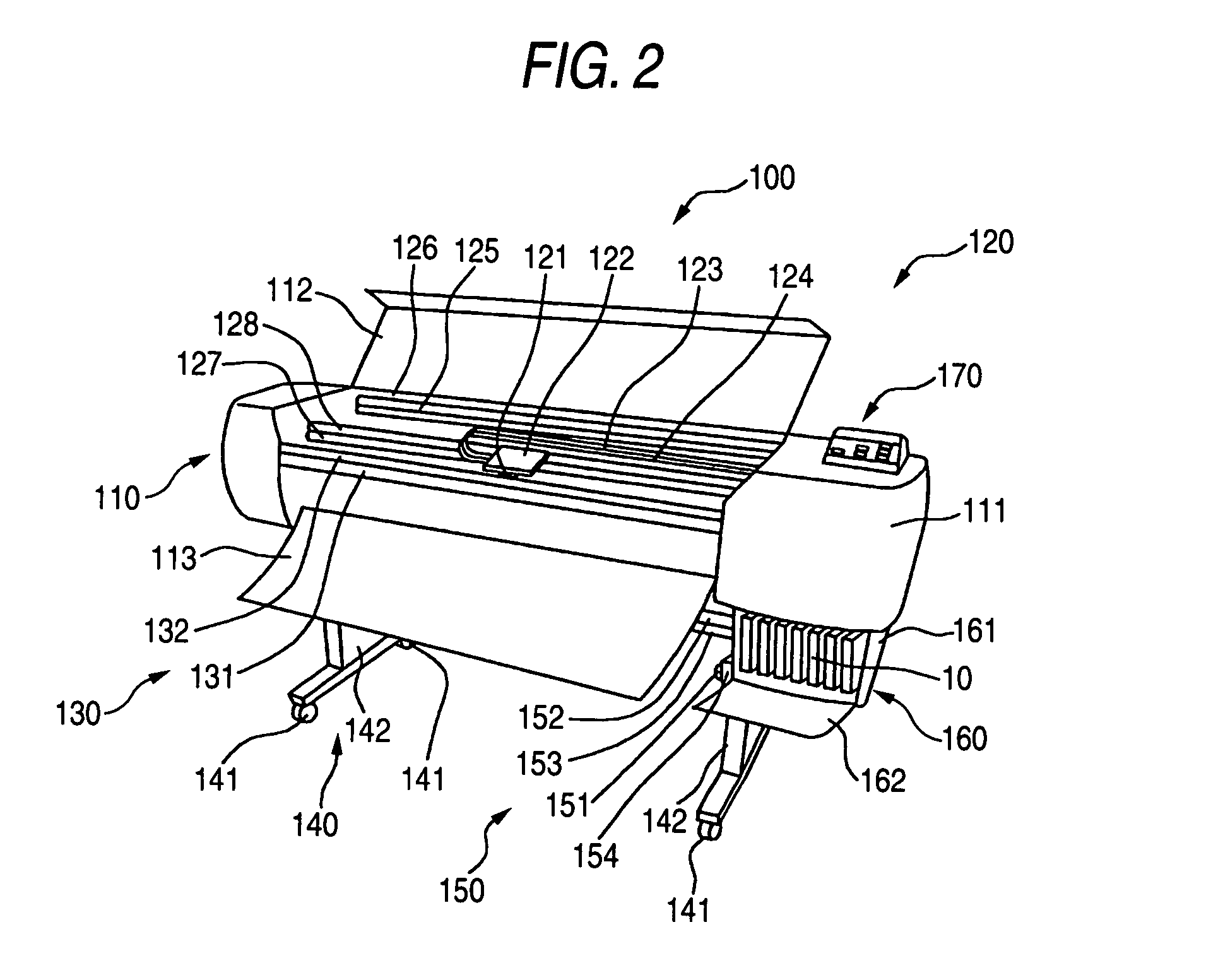

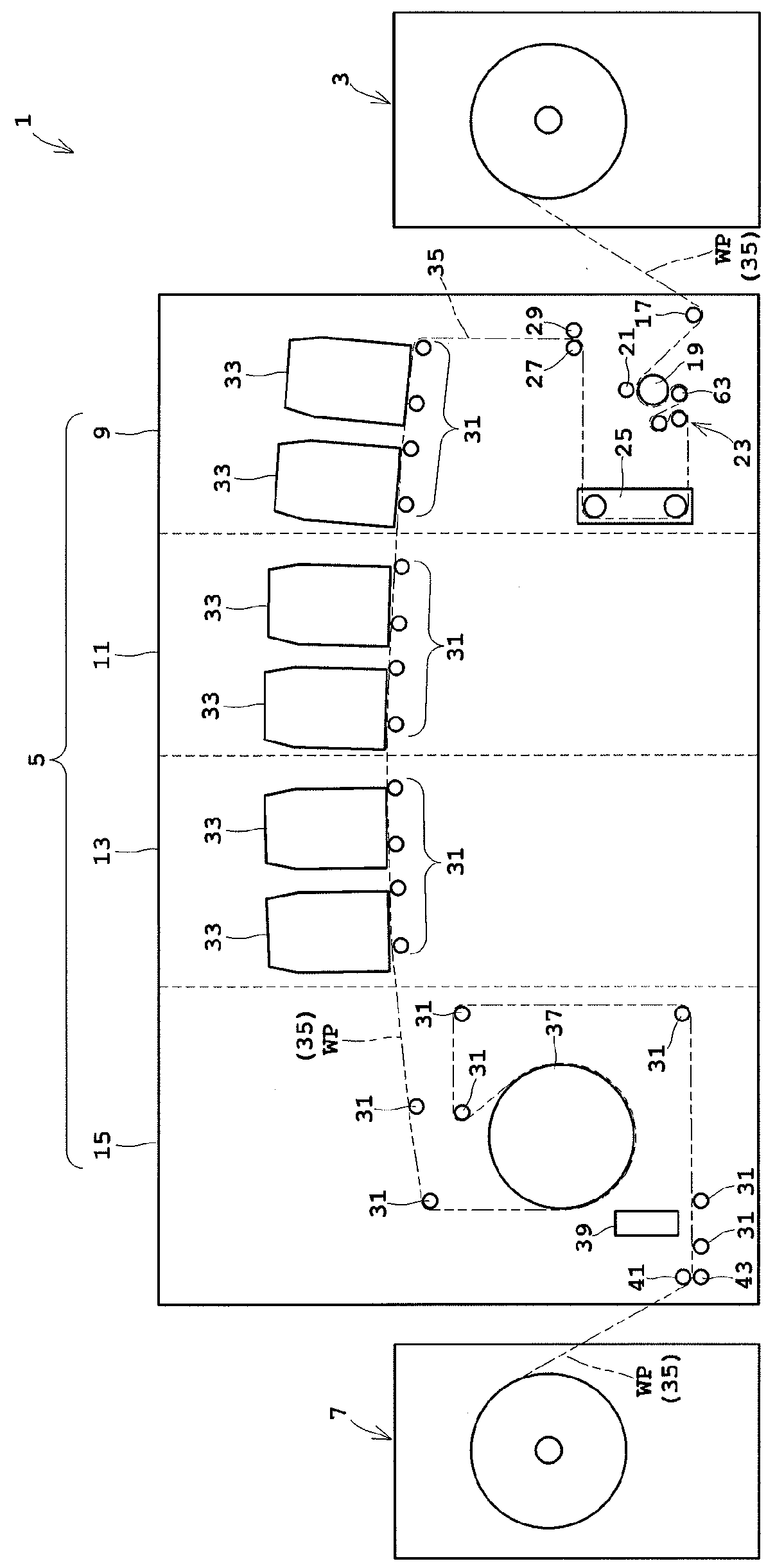

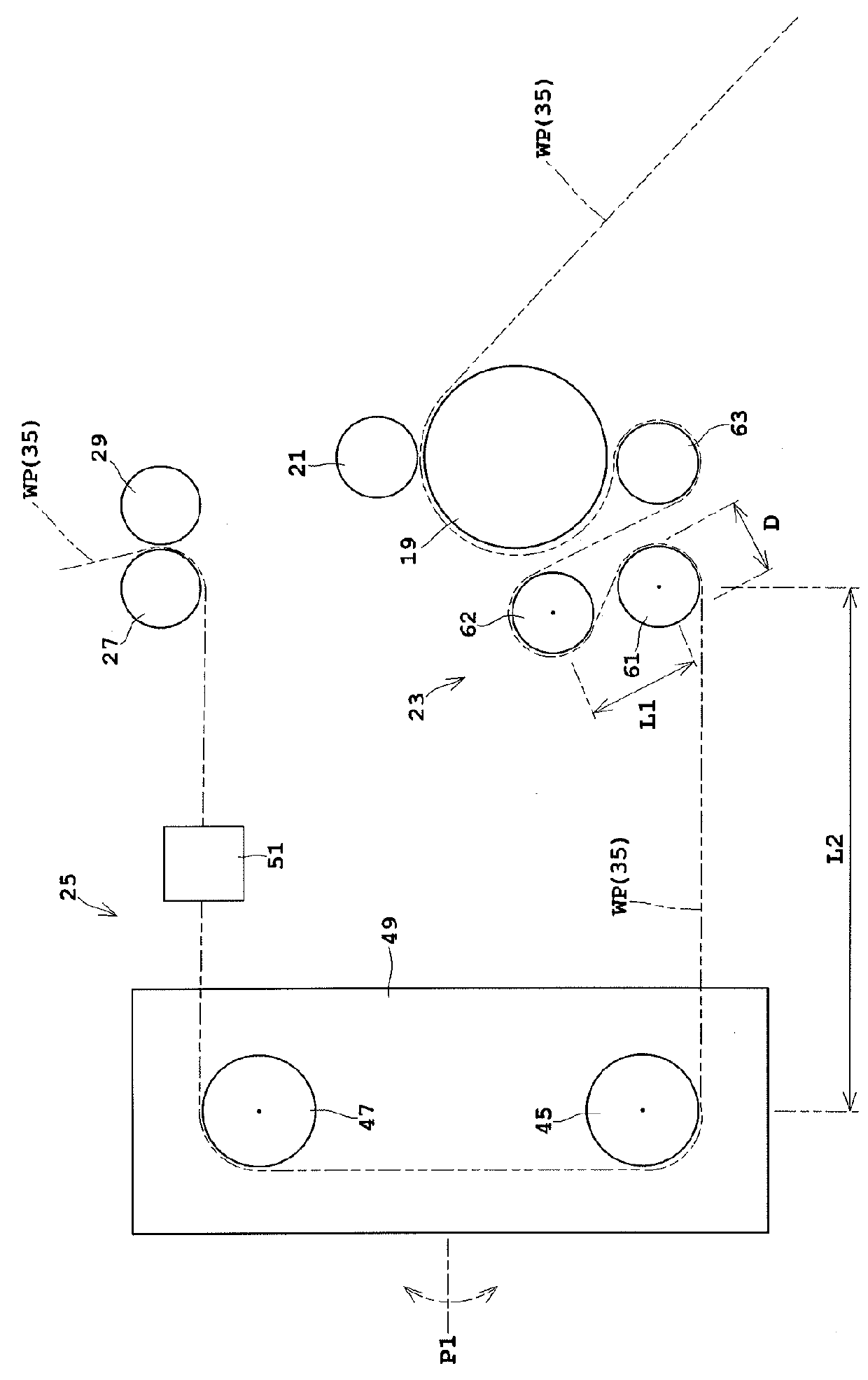

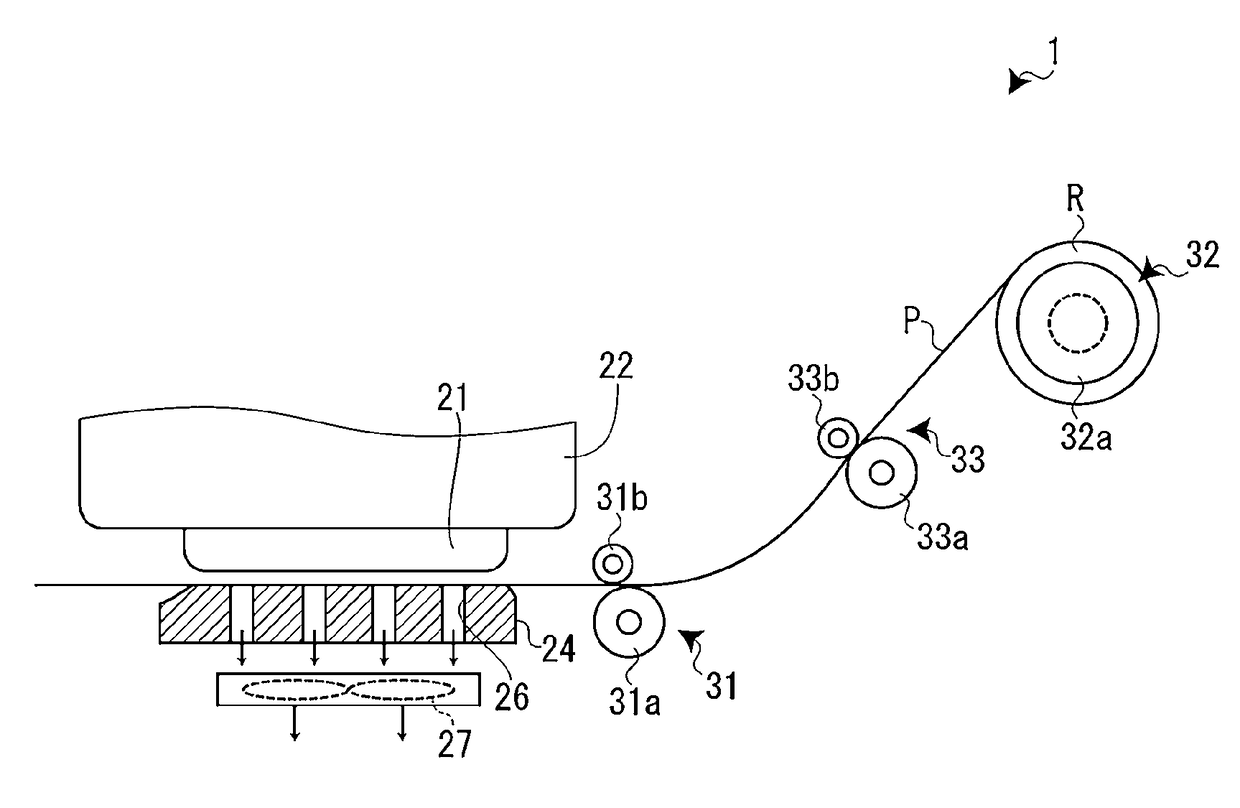

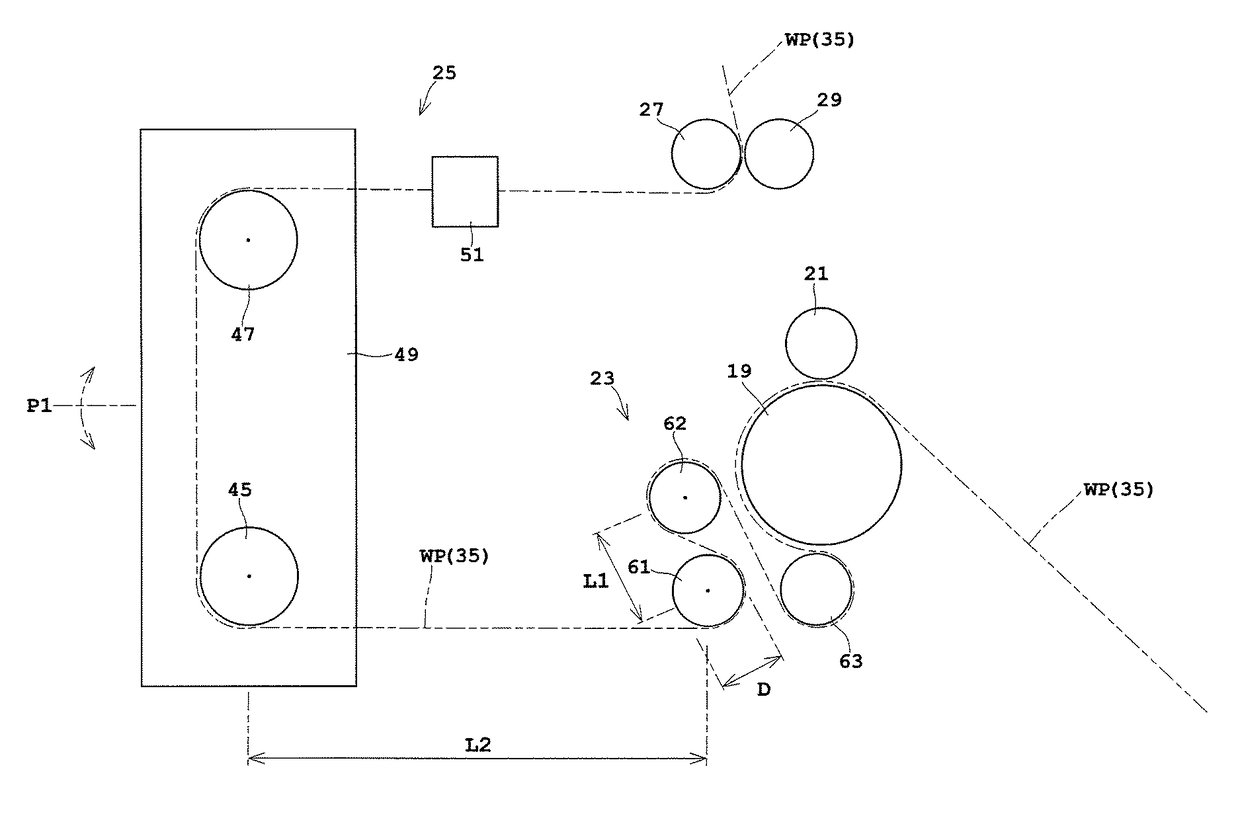

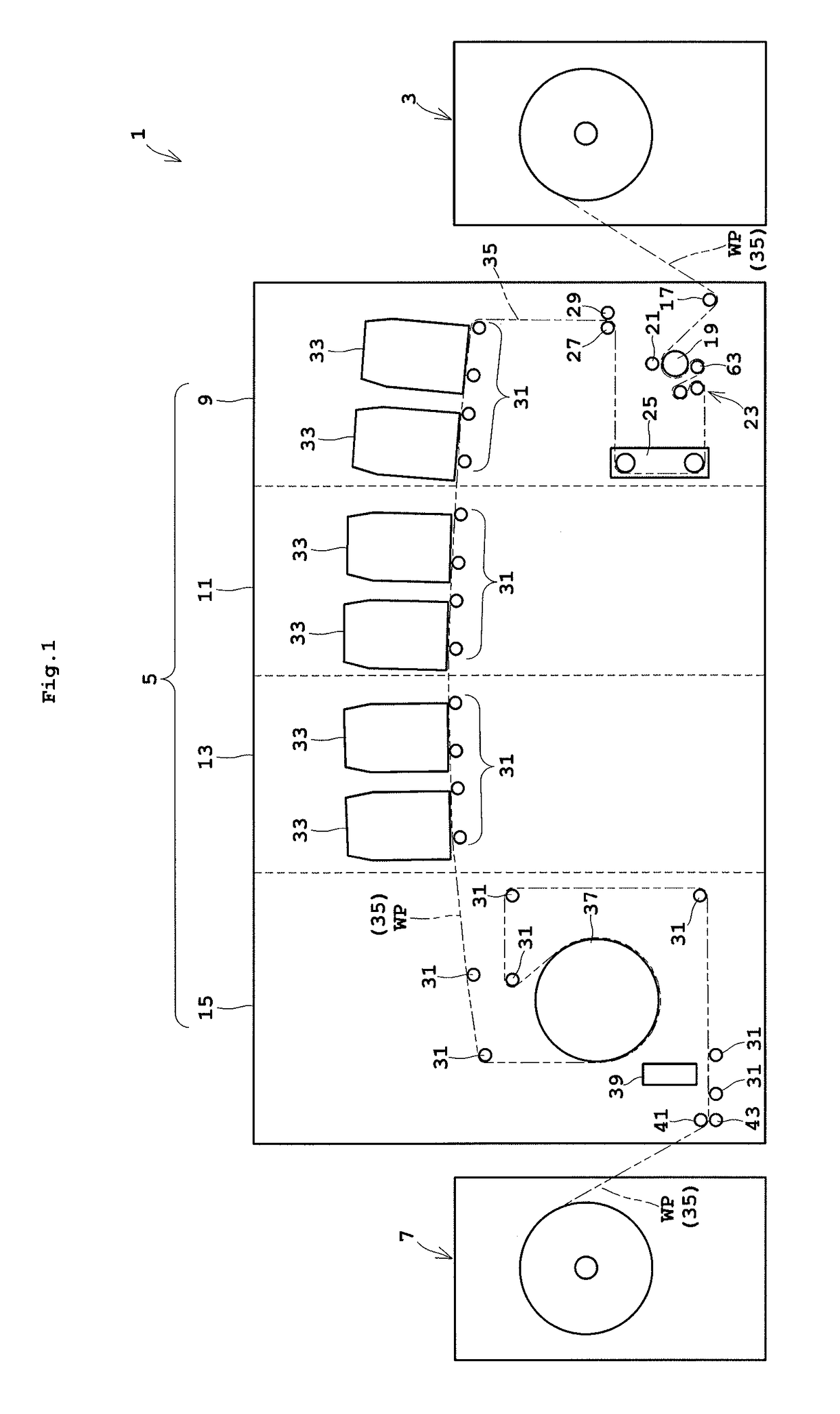

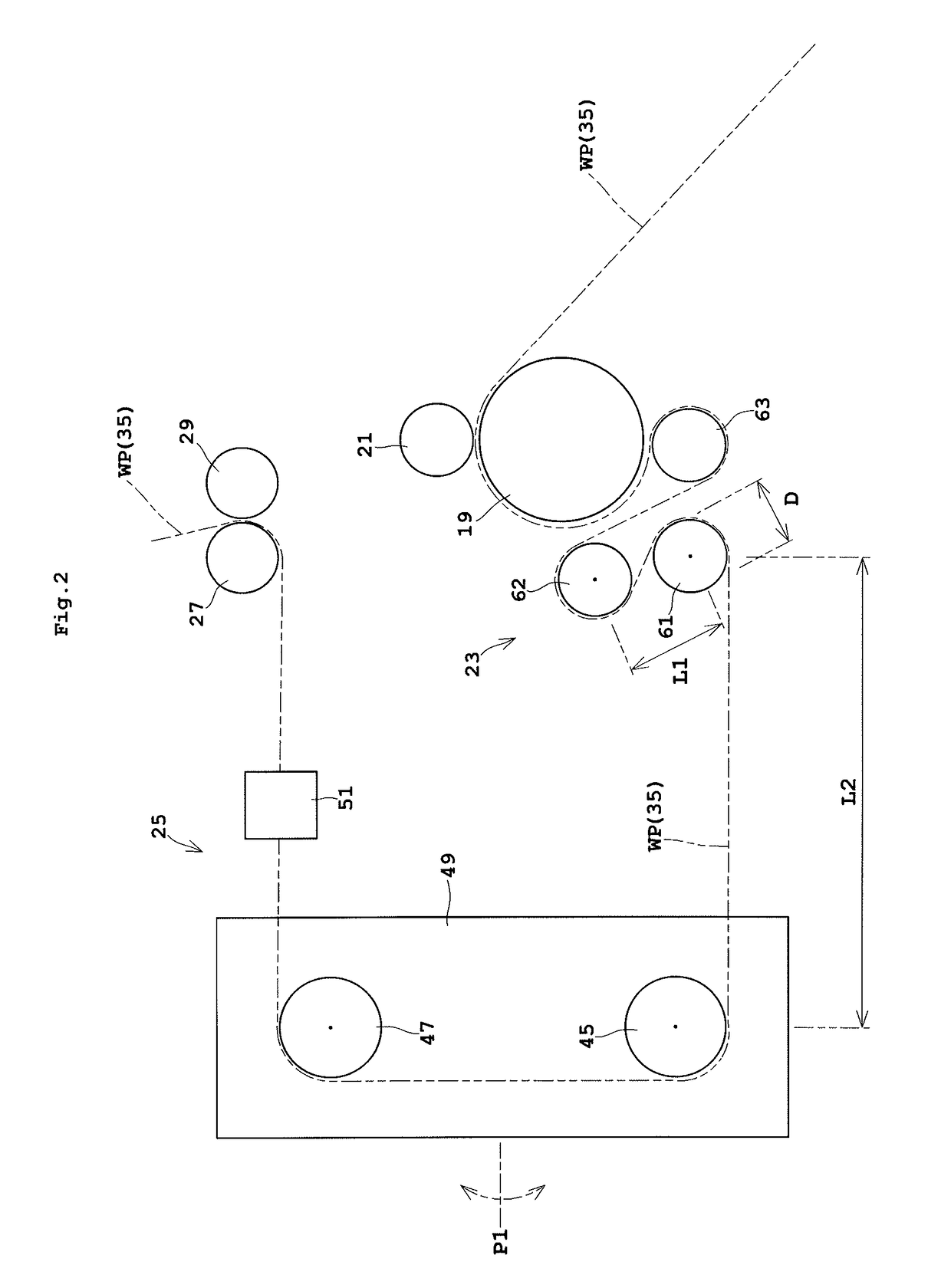

Transport device for transporting roll-shaped recording medium and recording apparatus

InactiveUS20090242603A1Reduce the number of partsSimple structureFilament handlingOther printing apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Printing apparatus

Owner:NISCA KK

Recording apparatus

ActiveUS8398200B2Suppress printing qualityPlanarityOther printing apparatusEngineeringRecording media

A recording apparatus includes a supporting member on which a plurality of suction holes for sucking a recording medium are formed on a supporting face for supporting the recording medium, a transportation device which transports the recording medium along the supporting face, a recording head which ejects fluid on the recording medium supported by the supporting face so as to perform printing, and a control device which makes the recording head execute the printing when a front end of the recording medium in the transportation direction reaches to a position at which the front end of the recording medium covers the suction holes formed at downstream-most positions in the transportation direction on the supporting face.

Owner:SEIKO EPSON CORP

Transport device for transporting roll-shaped recording medium and recording apparatus

InactiveUS8292213B2Reduce the number of partsSimple structureFilament handlingOther printing apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

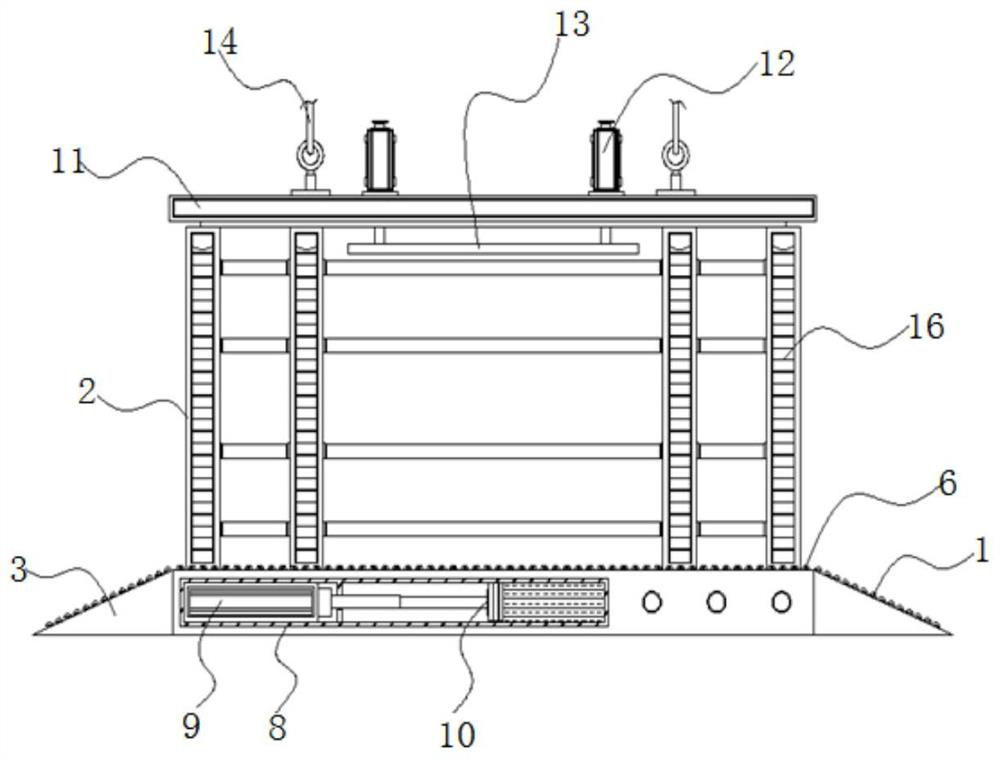

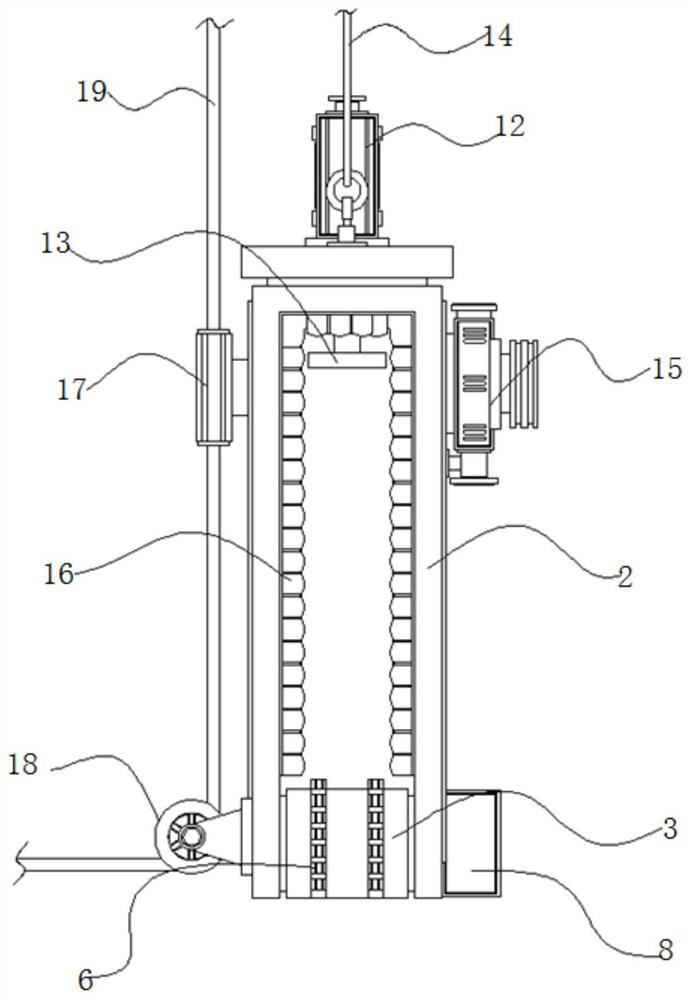

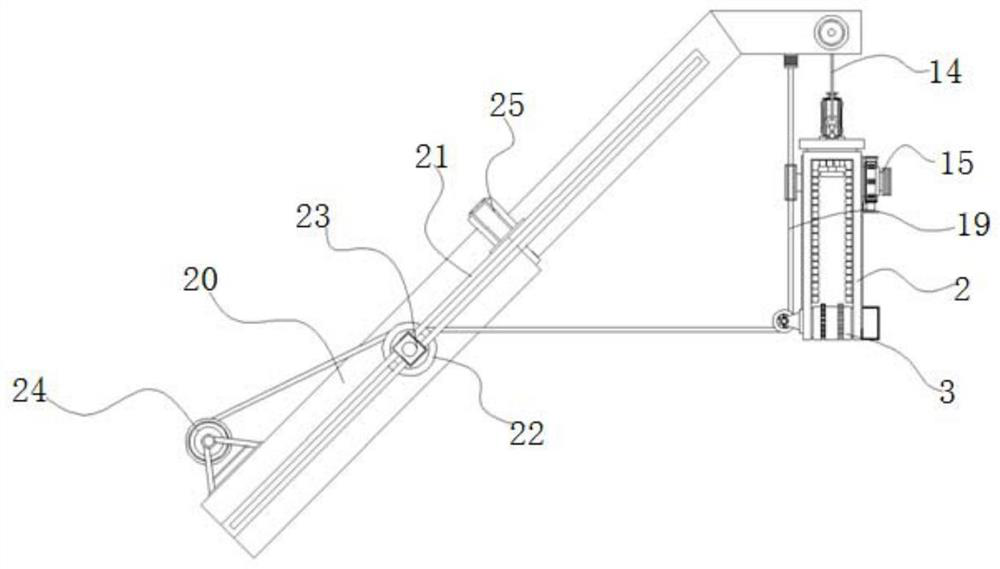

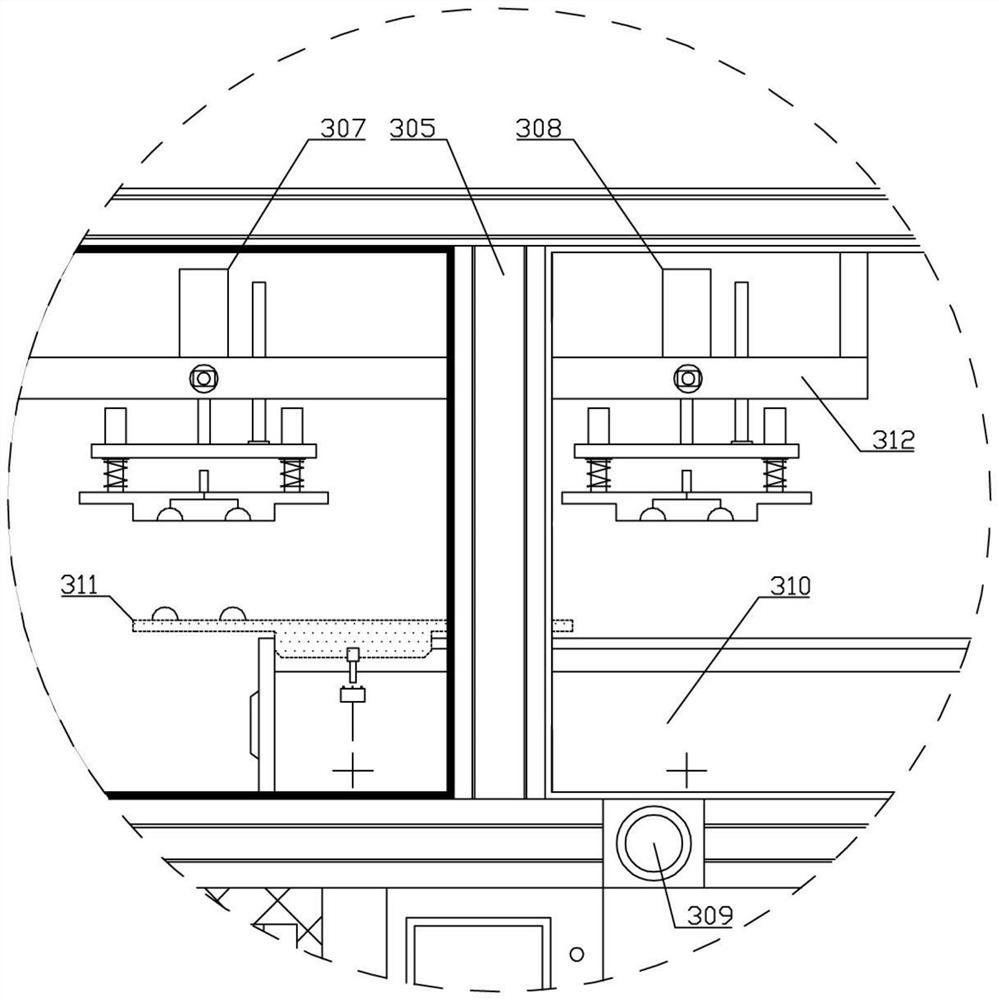

Method for hoisting fabricated light steel keel steel mesh mold lightweight wall

ActiveCN112875545AAvoid shakingImprove stabilityBuilding material handlingVibration suppression adjustmentsStructural engineeringMechanical engineering

The invention discloses a method for hoisting a fabricated light steel keel steel mesh mold lightweight wall, and relates to the technical field of fabricated building hoisting frames. According to the method for hoisting the fabricated light steel keel steel mesh mold lightweight wall, fabricated wall accessories are installed and supported on a hoisting frame, then the wall accessories are hoisted through hoisting arms and lifting steel cables, meanwhile, vertical rolling wheels are controlled to slide along the hoisting arms, so that the vertical rolling wheels, an adjusting rolling wheel in the lifting process and a stable steel rope always form a right angle shape, a steel rope winding barrel is controlled to rotate so that the stable steel rope can be always kept in a tightened state, and finally when the wall accessories reach a designated position, the wall accessories are taken down. By the adoption of the technical scheme, the stability of a wall in the whole hoisting process can be effectively improved, it is guaranteed that the wall accurately reaches the to-be-installed position, the hidden danger of hoisting installation is reduced, and the assembling efficiency is improved.

Owner:CHINA MCC17 GRP

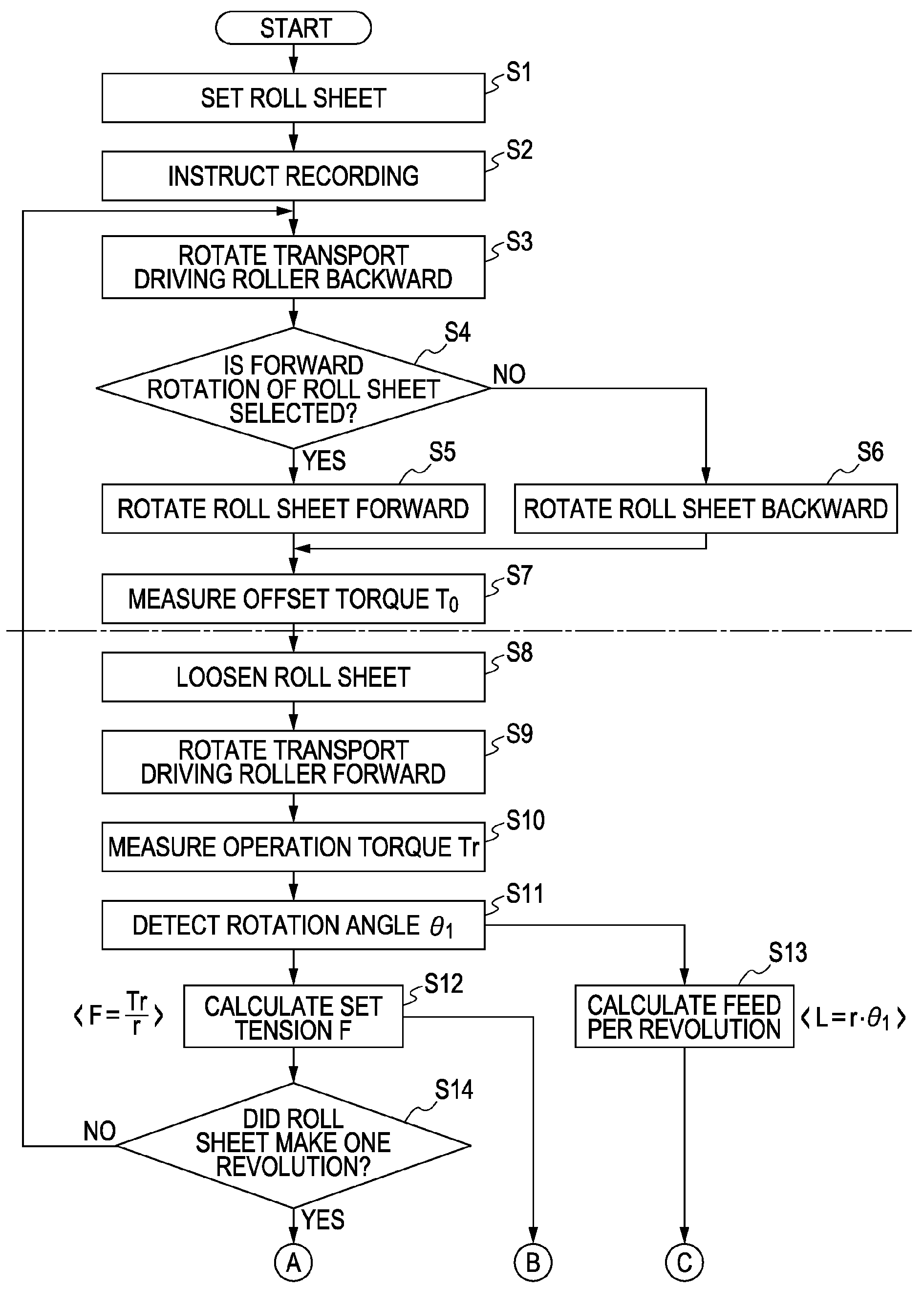

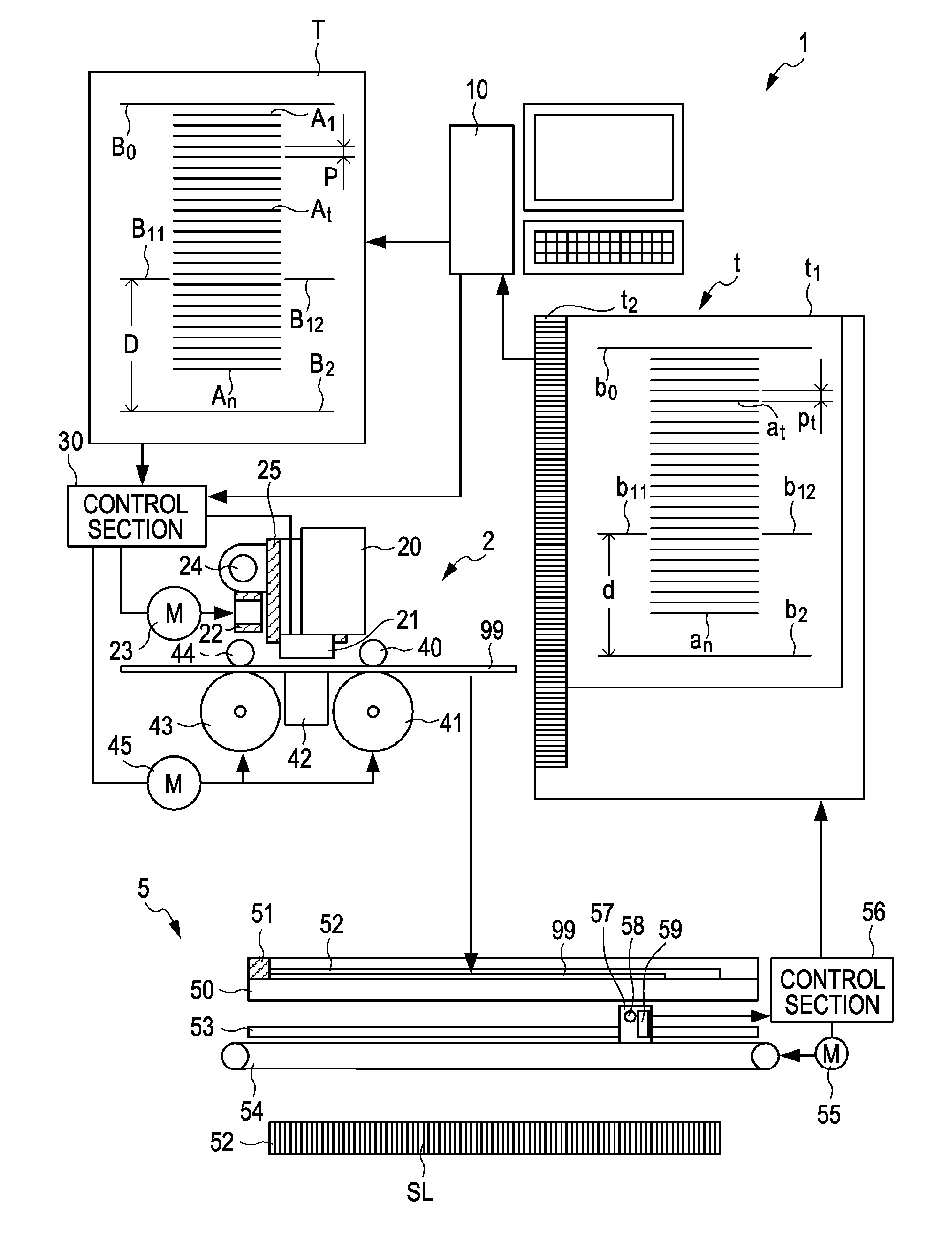

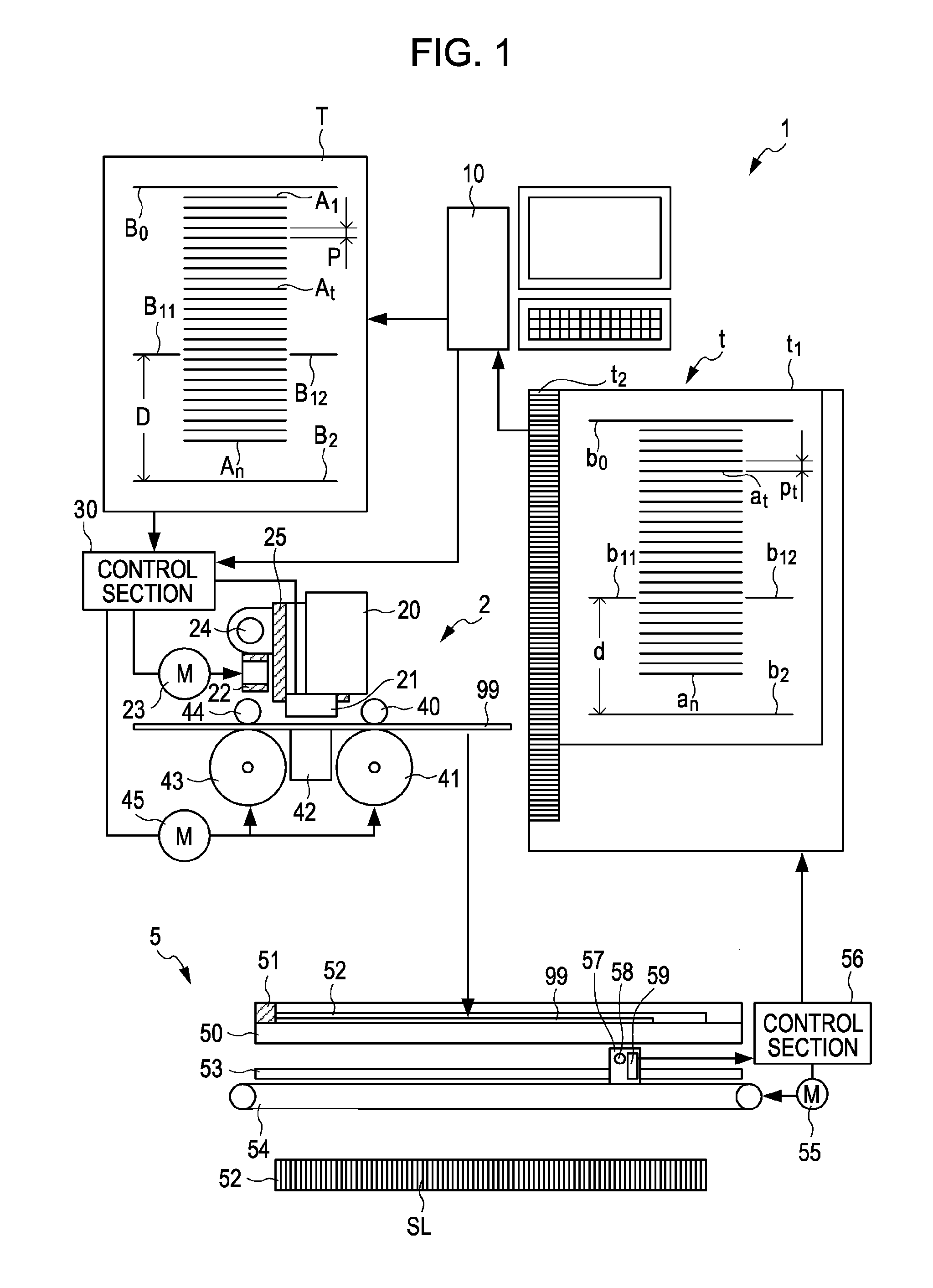

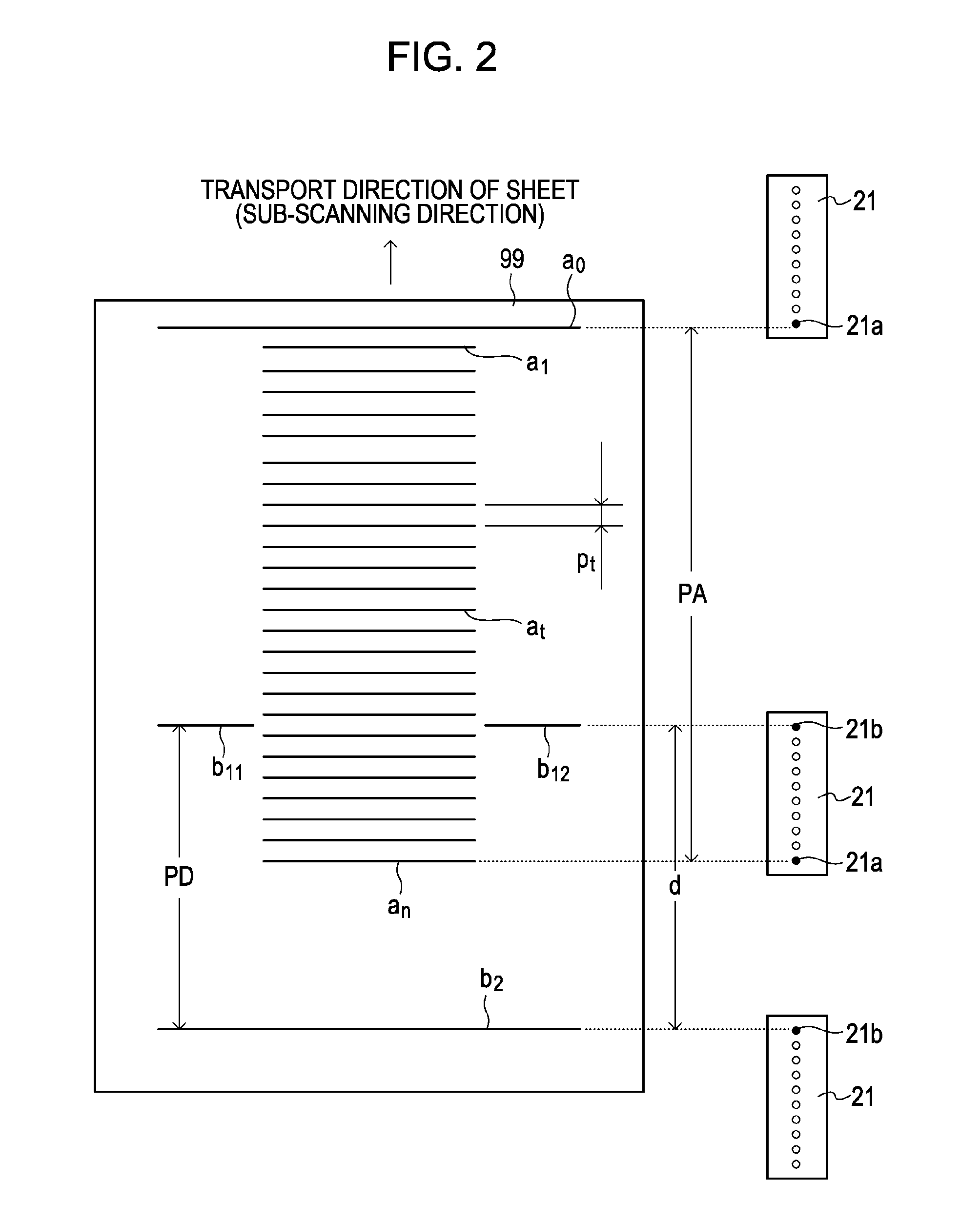

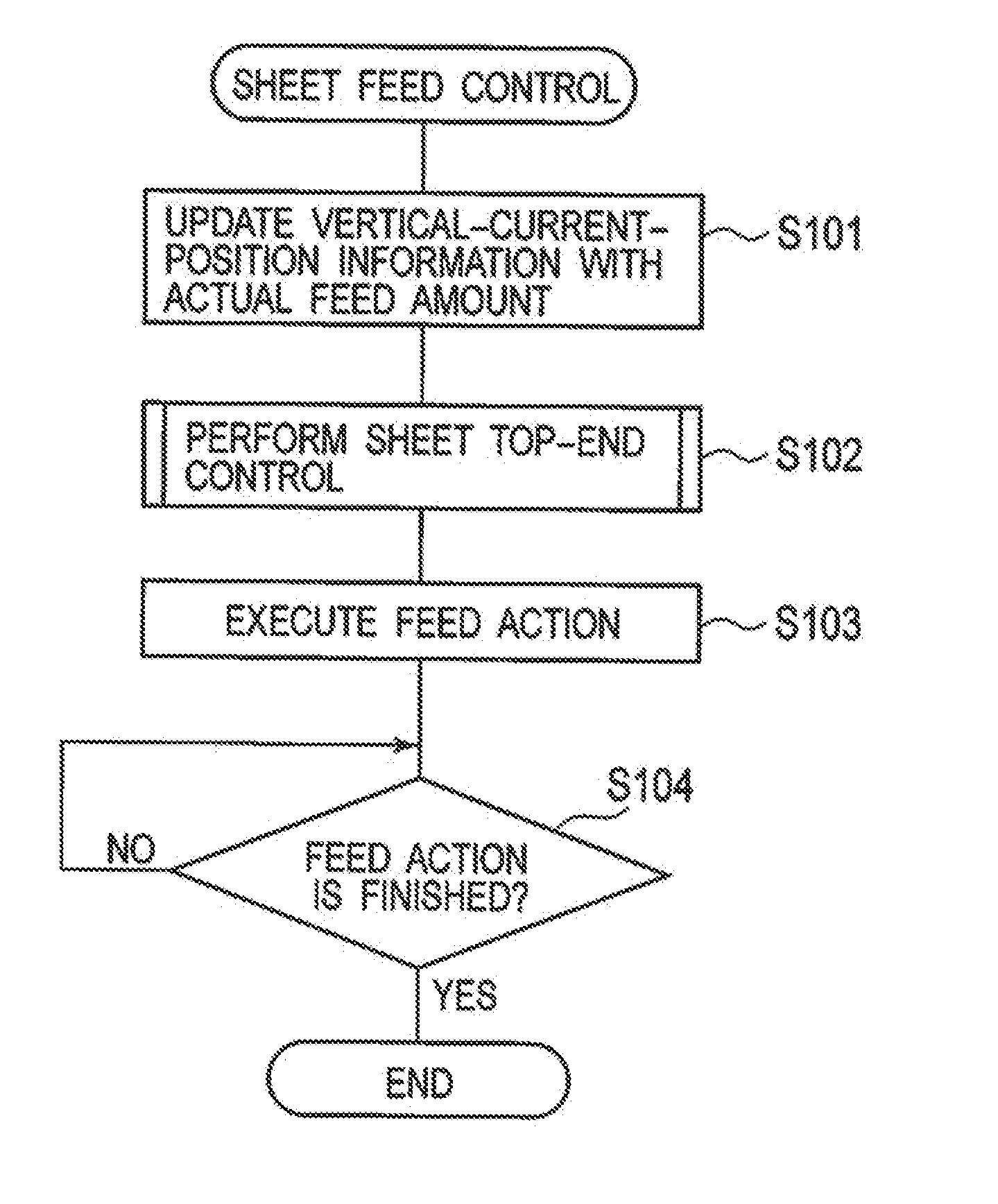

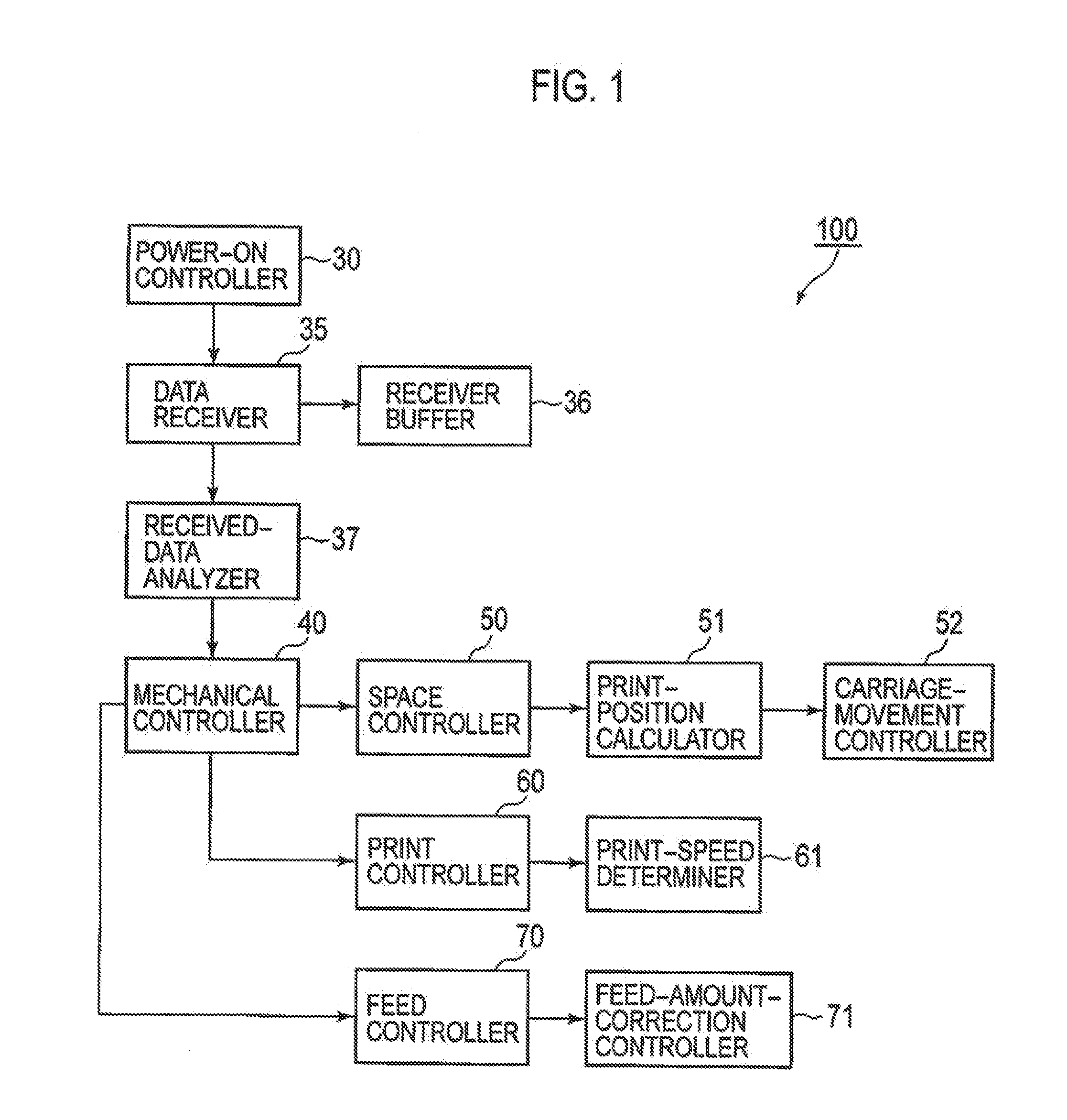

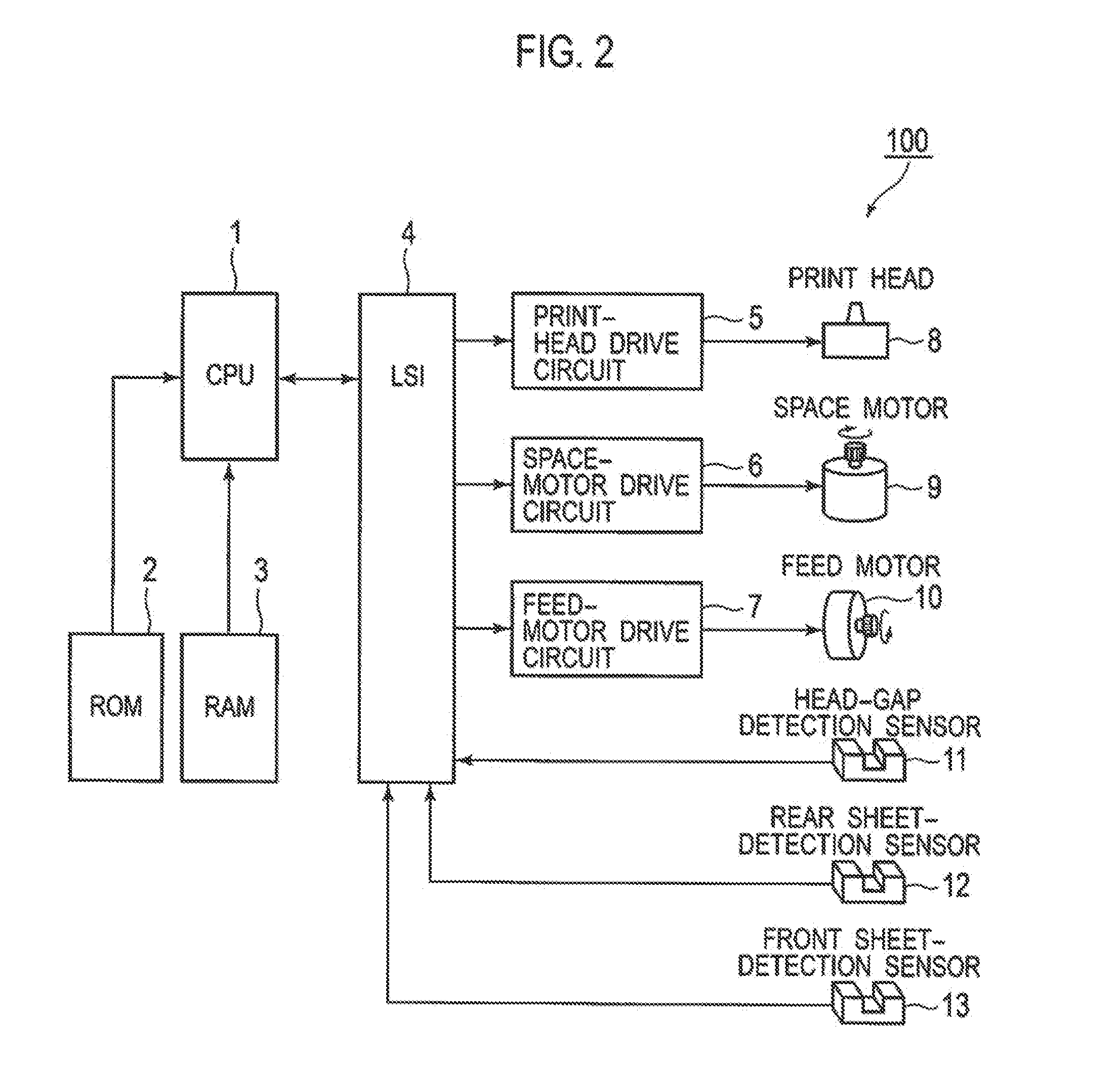

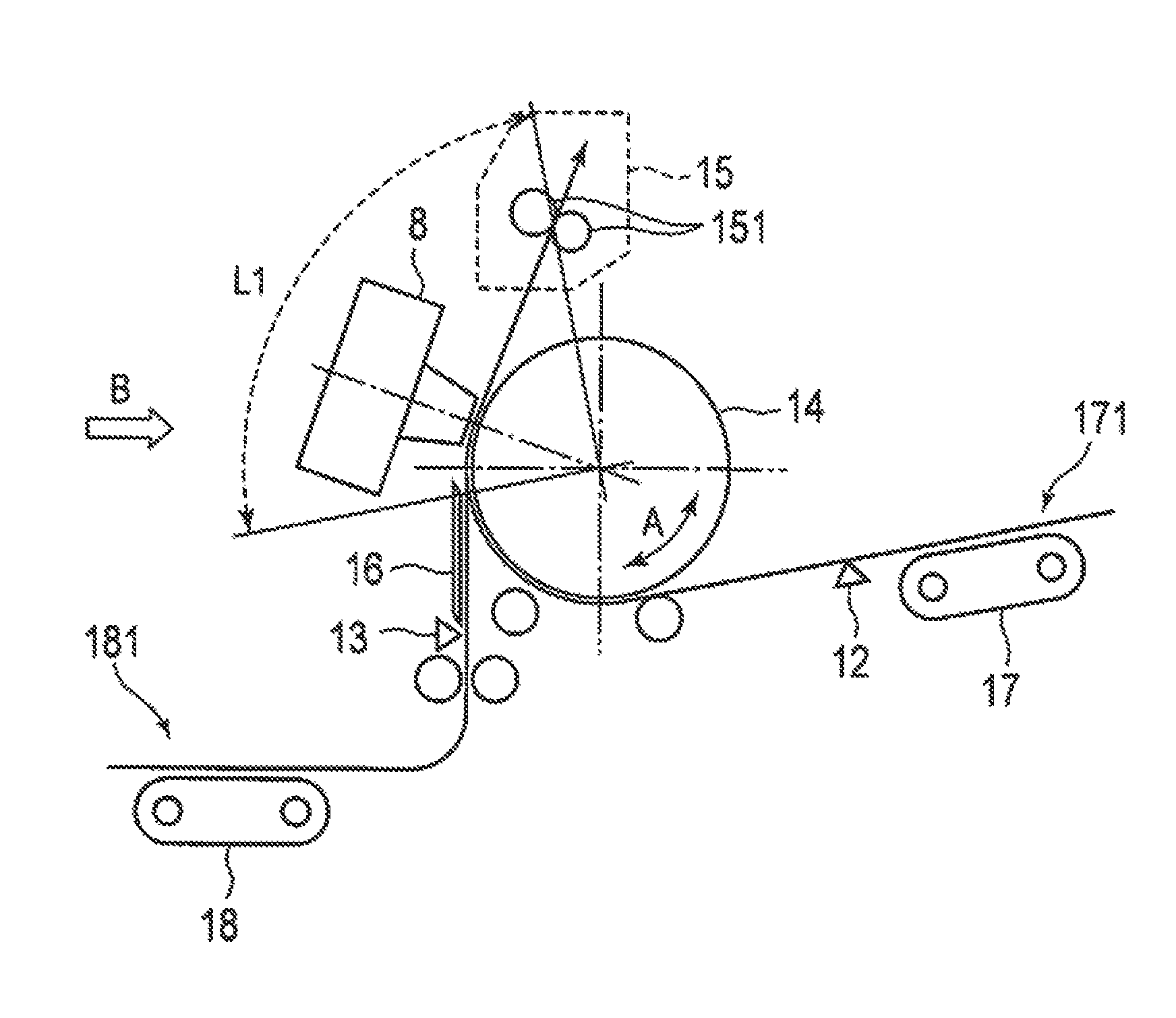

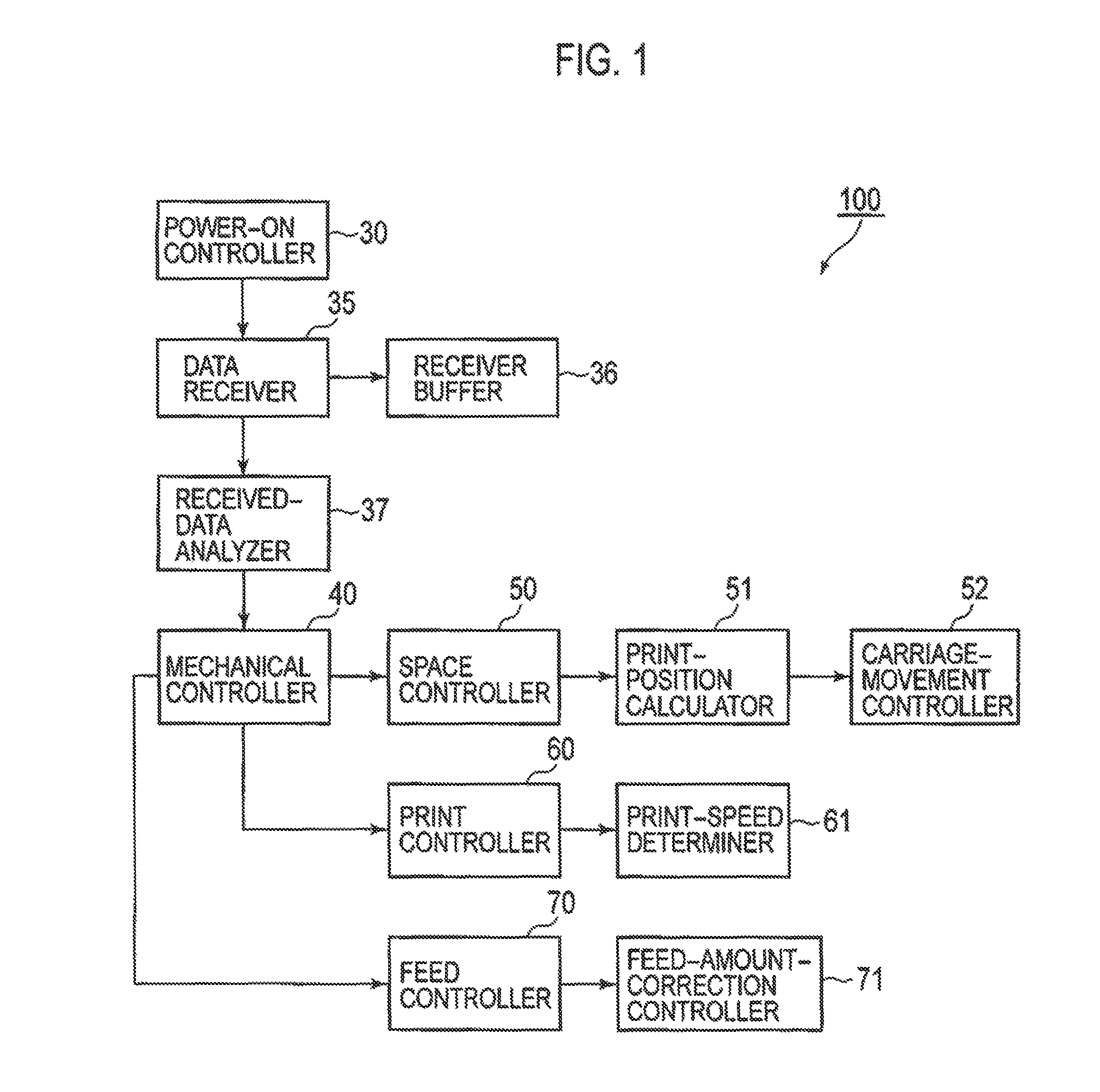

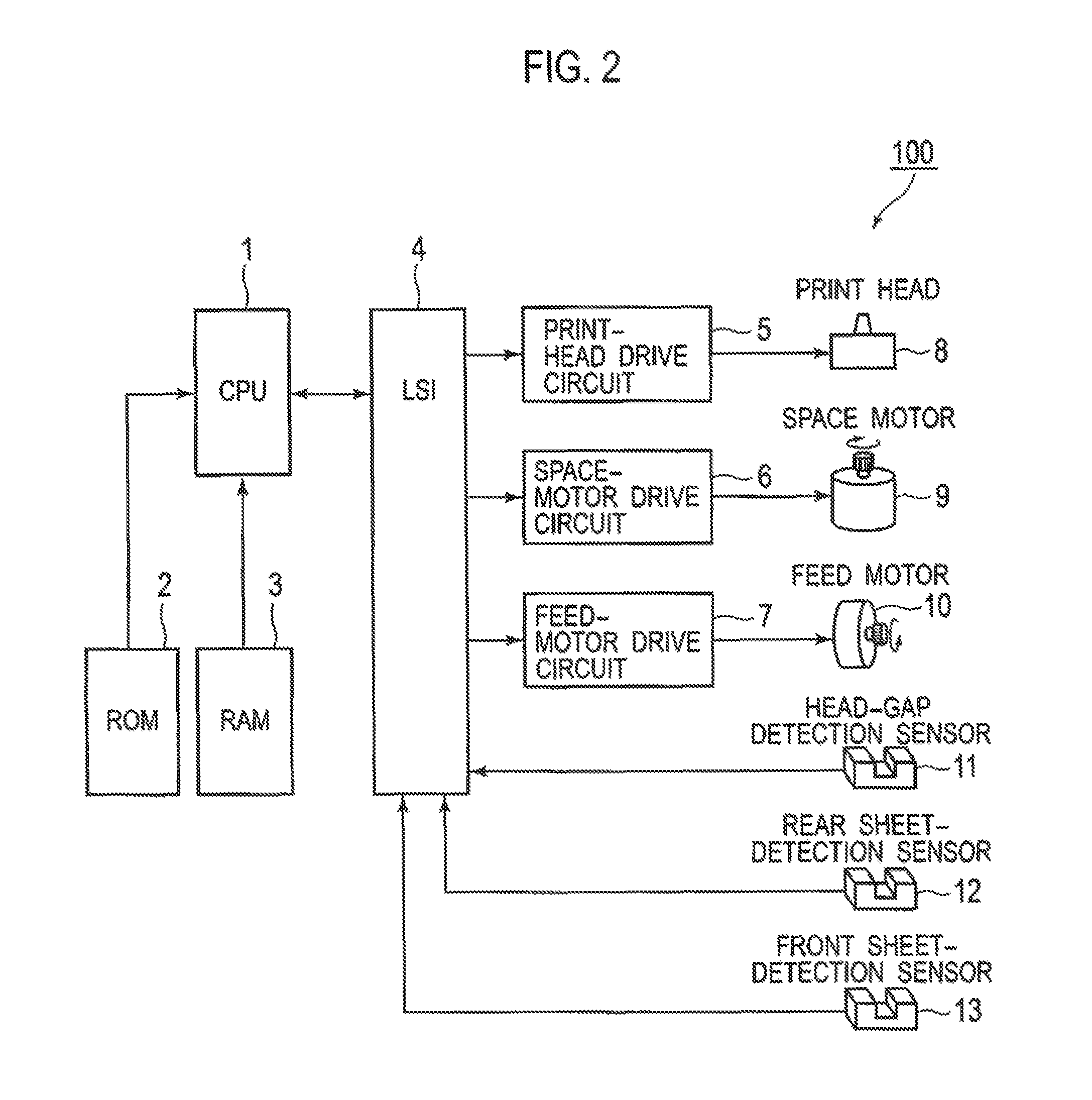

Transport adjustment method, transport adjustment system, and transport adjustment program

InactiveUS20120081447A1Increase transport accuracyImprove shipping accuracyOther printing apparatusNozzleTransport engineering

Owner:SEIKO EPSON CORP

Material conveying belt for cement automatic production line

PendingCN108455265AImprove shipping accuracyProtect the working environmentConveyorsCleaningProduction lineWorking environment

The invention provides a material conveying belt for a cement automatic production line. The material conveying belt comprises a conveying belt; the conveying belt is driven to work by a transmissionmotor arranged on one side; an arrangement plate is arranged on the conveying belt, and is positioned on the conveying belt; the position of the arrangement plate is adjusted through an adjusting cylinder arranged at the lower end; a baffle plate is arranged beside the arrangement plate; a stop cylinder is arranged at the upper end of the baffle plate; a material unloading groove is formed in an unloading end of the conveying belt; a contact sensor is arranged above the material unloading groove; and the contact sensor is associated with the transmission motor and the stop cylinder. The positions of materials on the conveying belt are adjusted through the arrangement plate; the transmission motor adjusts the speed of the conveying belt, and the baffle plate stops the materials advancing tocontrol the loading quantity of the conveying belt, so that the material conveying precision is improved; and dust generated in transportation is recovered through a dust sucking cover and a dust sucking fan, so that the working environment is protected.

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG

Print apparatus

InactiveUS20120163892A1Improve shipping accuracyImprove printing qualityOther printing apparatusTransport engineering

Owner:OKI DATA CORP

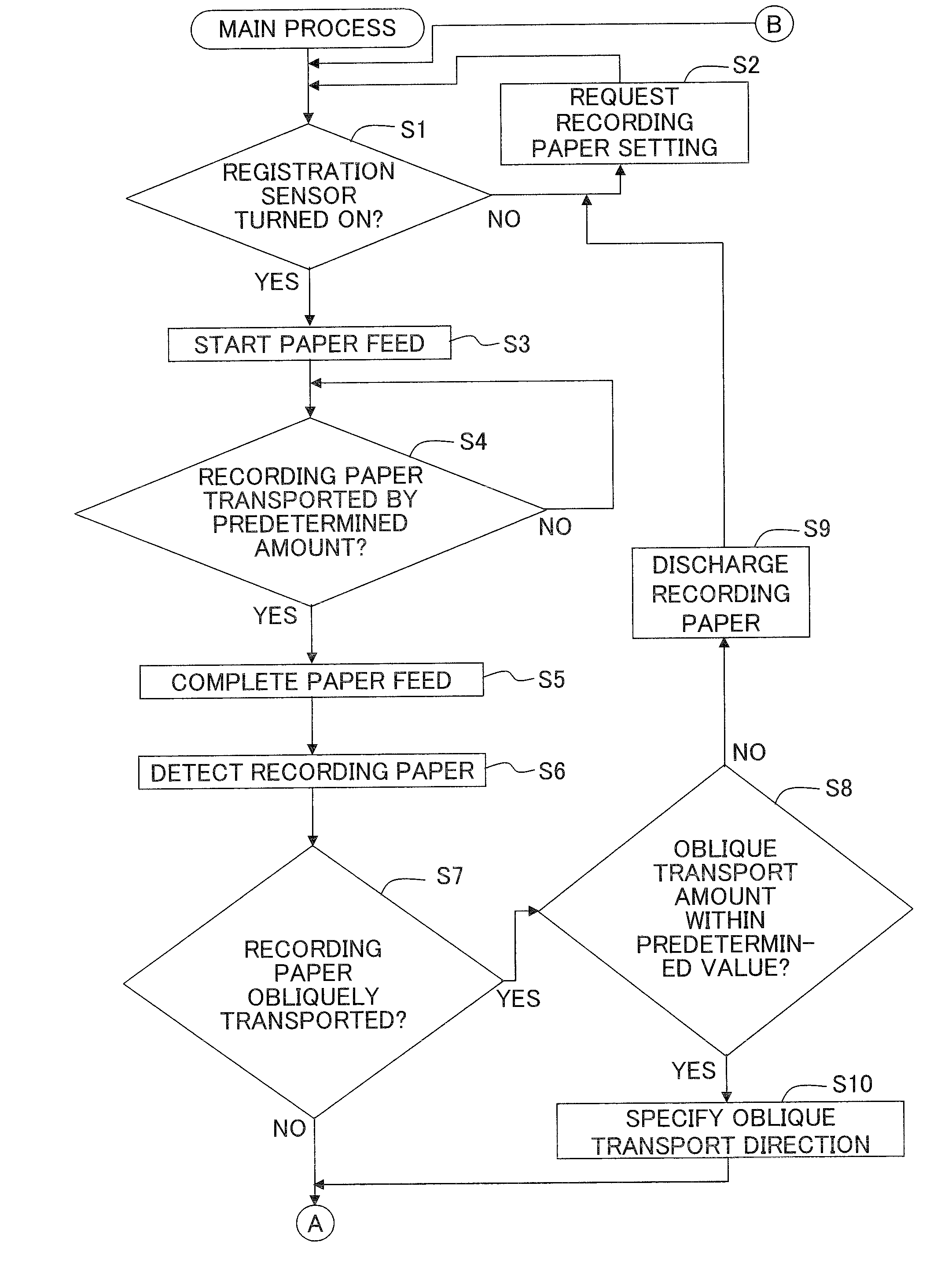

Image recording apparatus

ActiveUS20110293348A1Improve shipping accuracyQuality improvementOther printing apparatusImage recordingEngineering

An image recording apparatus includes: at least one roller pair which has a driving roller and a driven roller facing the driving roller and which rotates while interposing the recording medium therebetween to transport the recording medium in a first direction; a recording section which records an image on the recording medium transported by the roller pair; a position detecting section which detects a position of the recording medium with respect to the roller pair in a second direction perpendicular to the first direction before the recording section starts recording; a determining section which determines a rotation amount of the driving roller before the recording section starts the recording depending on the position in the second direction of the recording medium detected by the position detecting section; and a control unit which controls the driving roller based on the rotation amount determined by the determining section.

Owner:BROTHER KOGYO KK

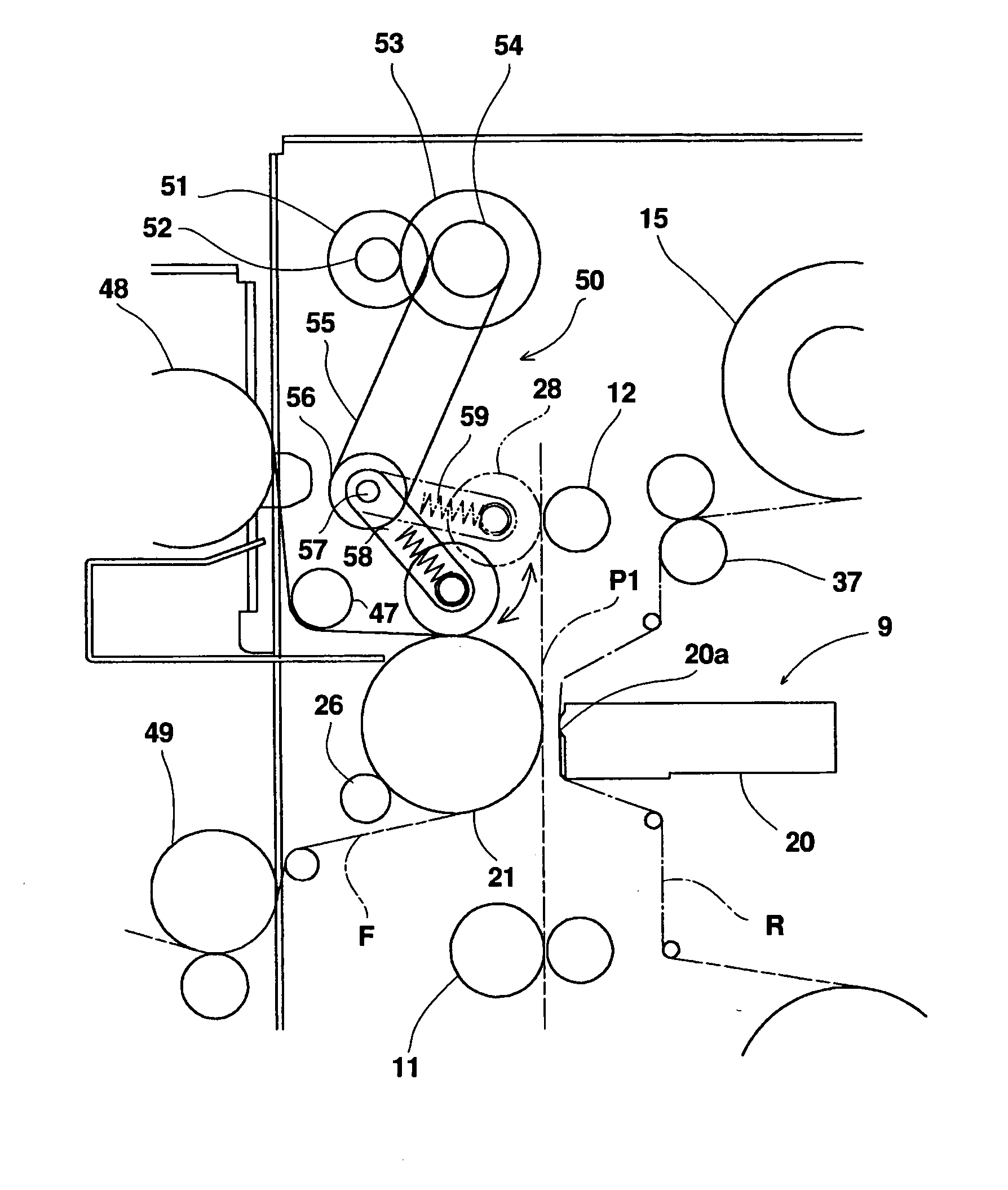

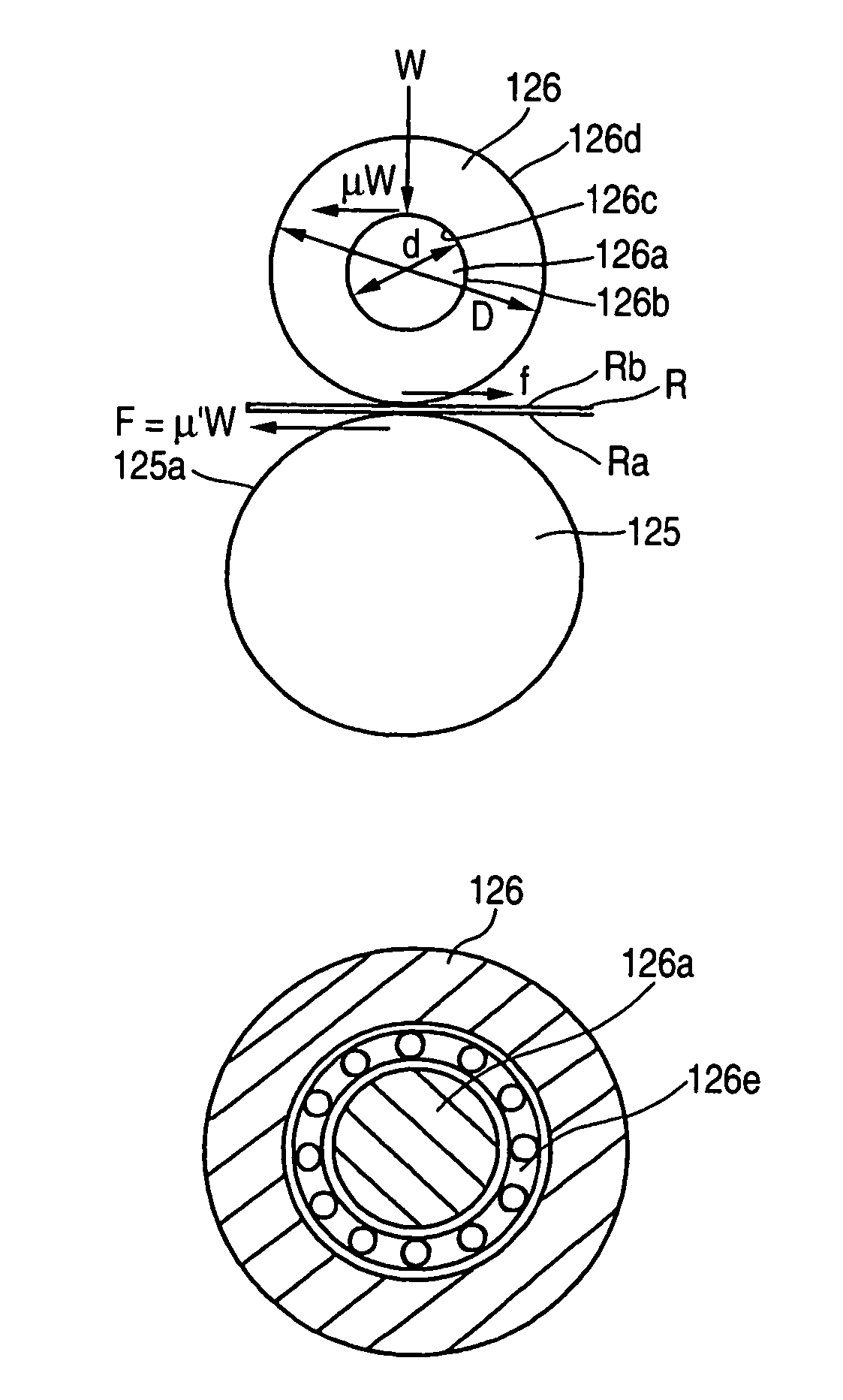

Medium transporting device and recording apparatus incorporating the same

ActiveUS6991328B2Constant and accurate transportingReduce forceLiquid surface applicatorsShaft and bearingsFriction lossLoad generation

A follower roller is brought into press contact with a driving roller by a load having a predetermined value, thereby being rotated in accordance with a rotation of the driving roller to transport the medium clamped therebetween in a first direction. The follower roller includes a shaft portion and a roller body provided so as to surround the shaft portion. The follower roller is configured such that a value of a ratio f / F is not greater than 0.03. Here, F is a force transporting the medium in the first direction which is generated by the load, and f is a resistance force generated in a second direction opposite to the first direction by a friction loss of the shaft portion of the follower roller which is generated by the load.

Owner:SEIKO EPSON CORP

Print apparatus

InactiveUS8882375B2Improve shipping accuracyImprove printing qualityOther printing apparatusTransport engineering

Owner:OKI DATA CORP

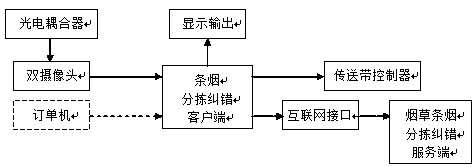

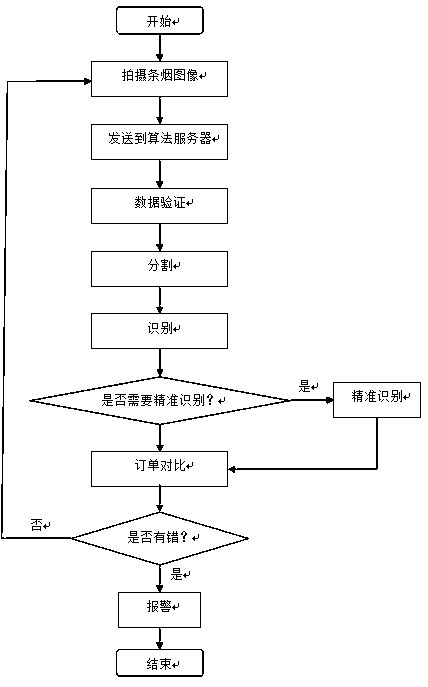

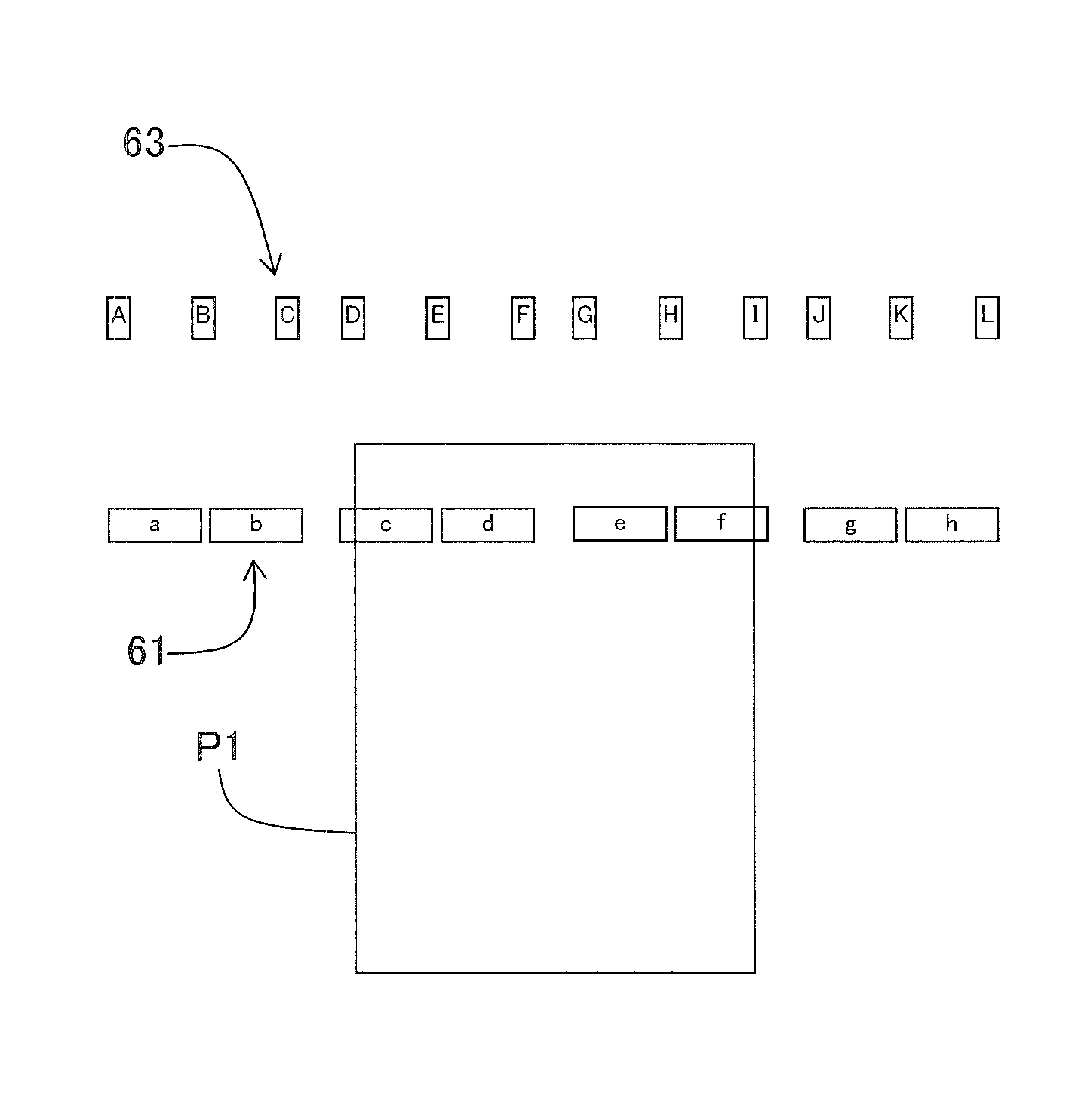

Intelligent error correcting system for cigarette sorting

InactiveCN110193465AImprove recognition rateImprove accuracyCharacter and pattern recognitionSortingThe InternetOutput device

The invention discloses an intelligent error correcting system for cigarette sorting. The system comprises a conveyor belt, a conveyor belt controller, a photoelectric coupler, a camera, an order machine, a cigarette sorting error correcting client, a display output device, an internet interface and a server; the intelligent error correcting system for cigarette sorting is realized through the image segmentation and depth learning recognition technology, and the technology mainly comprises the following steps that a training model is built; cigarettes are registered; the cigarette sorting error correcting client collects images and sends the images to a server; the server performs segmentation and recognition, and then, bar codes are sent back to the cigarette sorting error correcting client; the cigarette sorting error correcting client receives the bar codes returned by the server, compared with a current order, and if an abnormity is found, the system is shut down and an alarm is given. The system has the beneficial effects that the recognition rate is high, operation is easy, the interference eliminating performance is high, the delivery accuracy is improved, and the satisfaction degree of retailers is increased.

Owner:北京优创新港科技股份有限公司

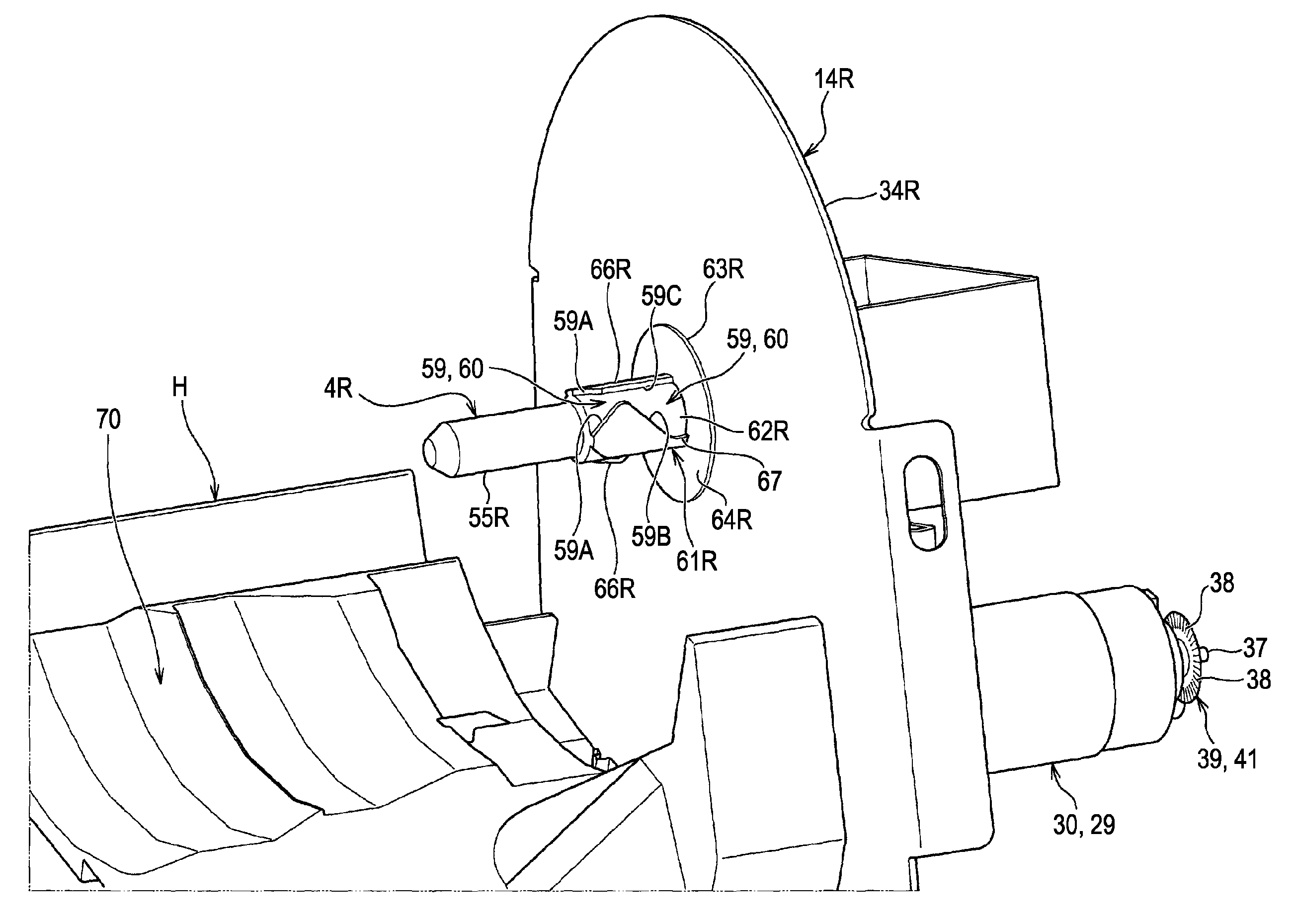

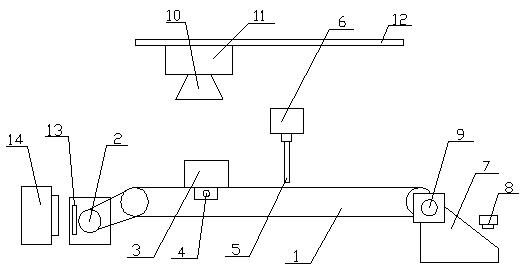

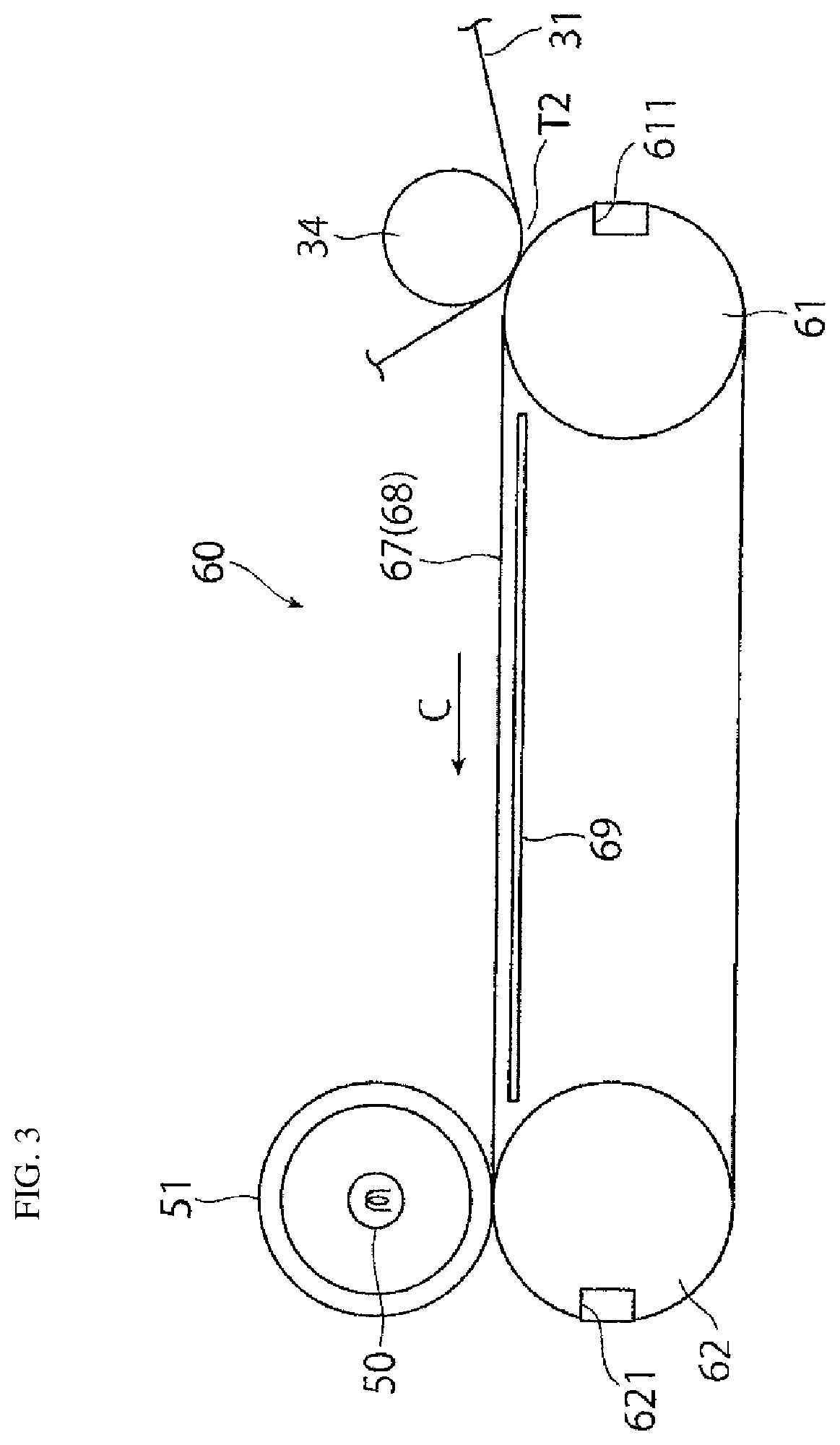

Medium transport device and printing apparatus provided therewith

ActiveUS20160052740A1Improve printing accuracyImprove shipping accuracyProjector film strip handlingFilament handlingTransport engineering

Provided is a medium transport device transporting a medium. The medium transport device includes a skew correcting mechanism disposed on a transport path for transporting a long medium, a first transport roller disposed on the transport path and transporting the medium, and a second transport roller transporting the medium to the first transport roller. The first transport roller is disposed upstream of the skew correcting mechanism. The second transport roller is disposed upstream of and next to the first transport roller. The second transport roller contacts one surface of the medium, and the first transport roller contacts the other surface of the medium.

Owner:DAINIPPON SCREEN MTG CO LTD

Sheet transport device and image forming apparatus

PendingUS20220184975A1Improve shipping accuracyElectrographic process apparatusOther printing apparatusPaper sheetEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

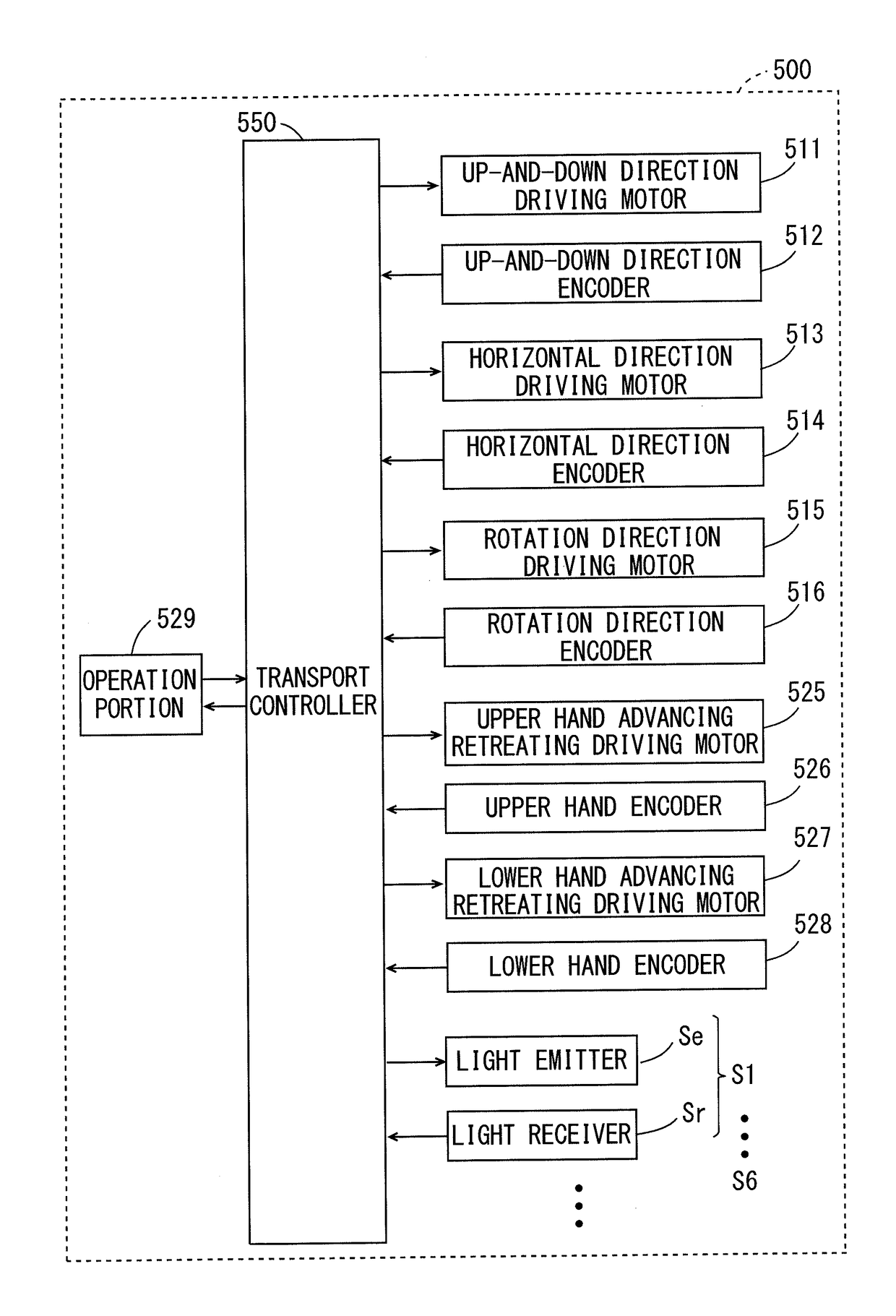

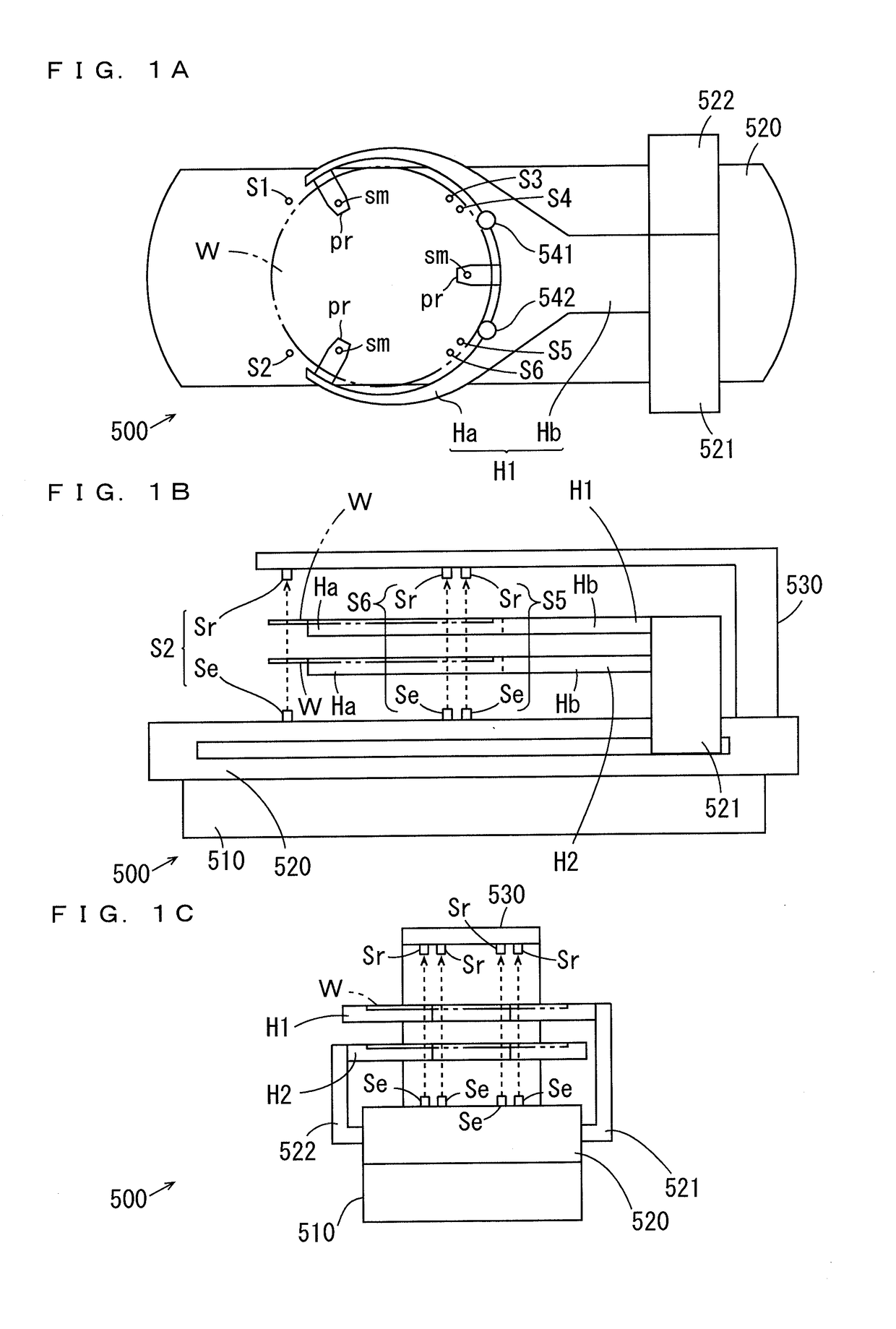

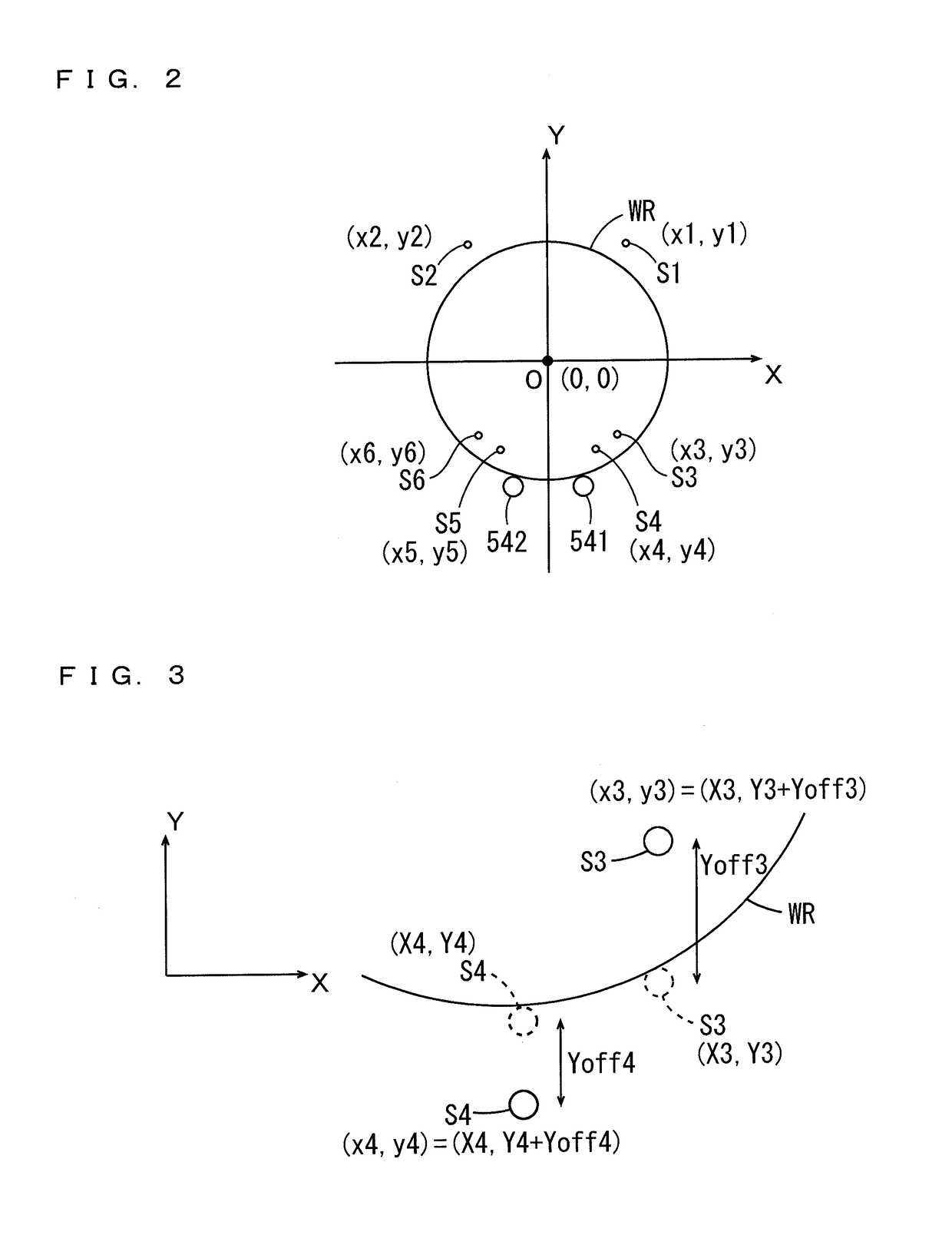

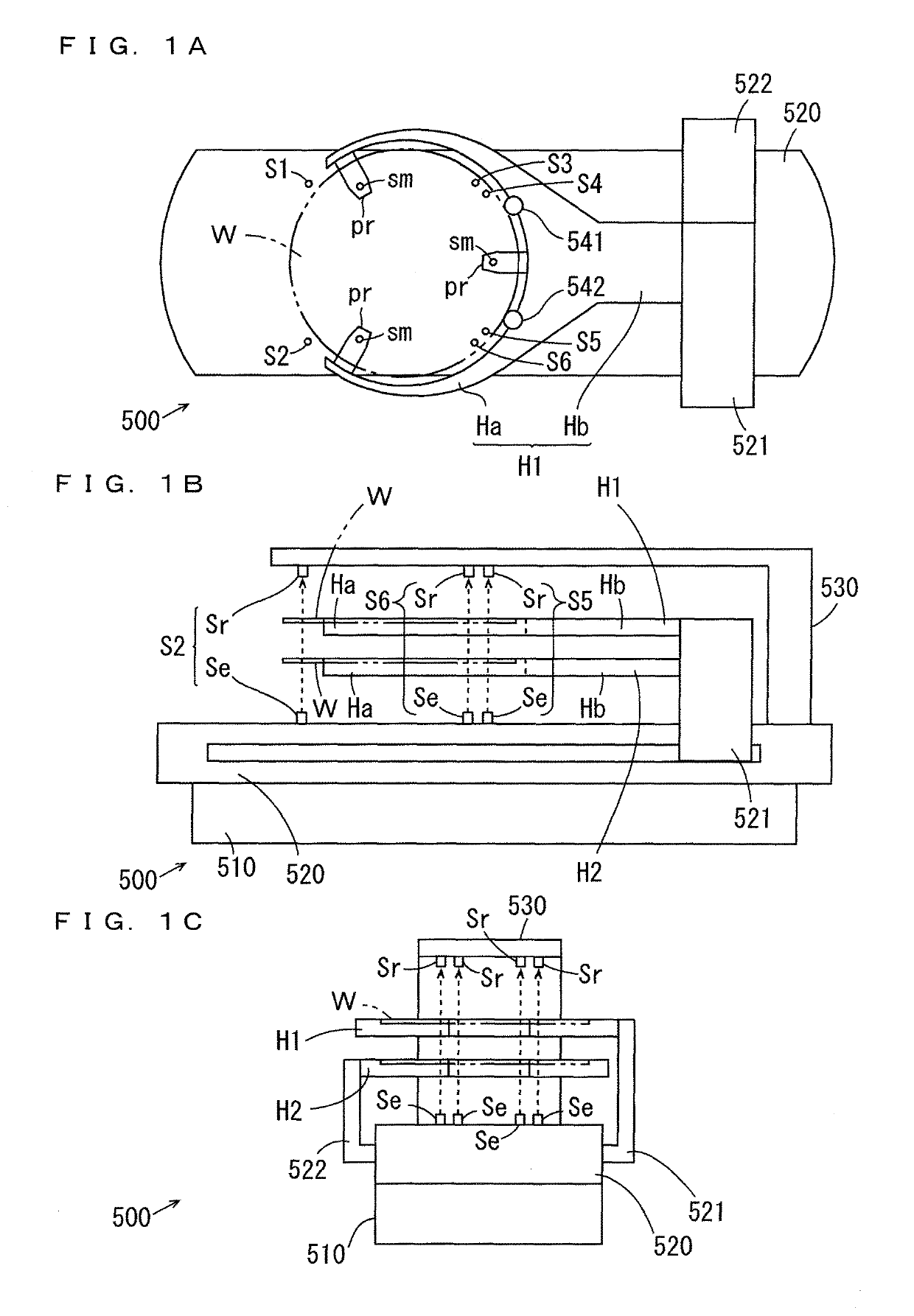

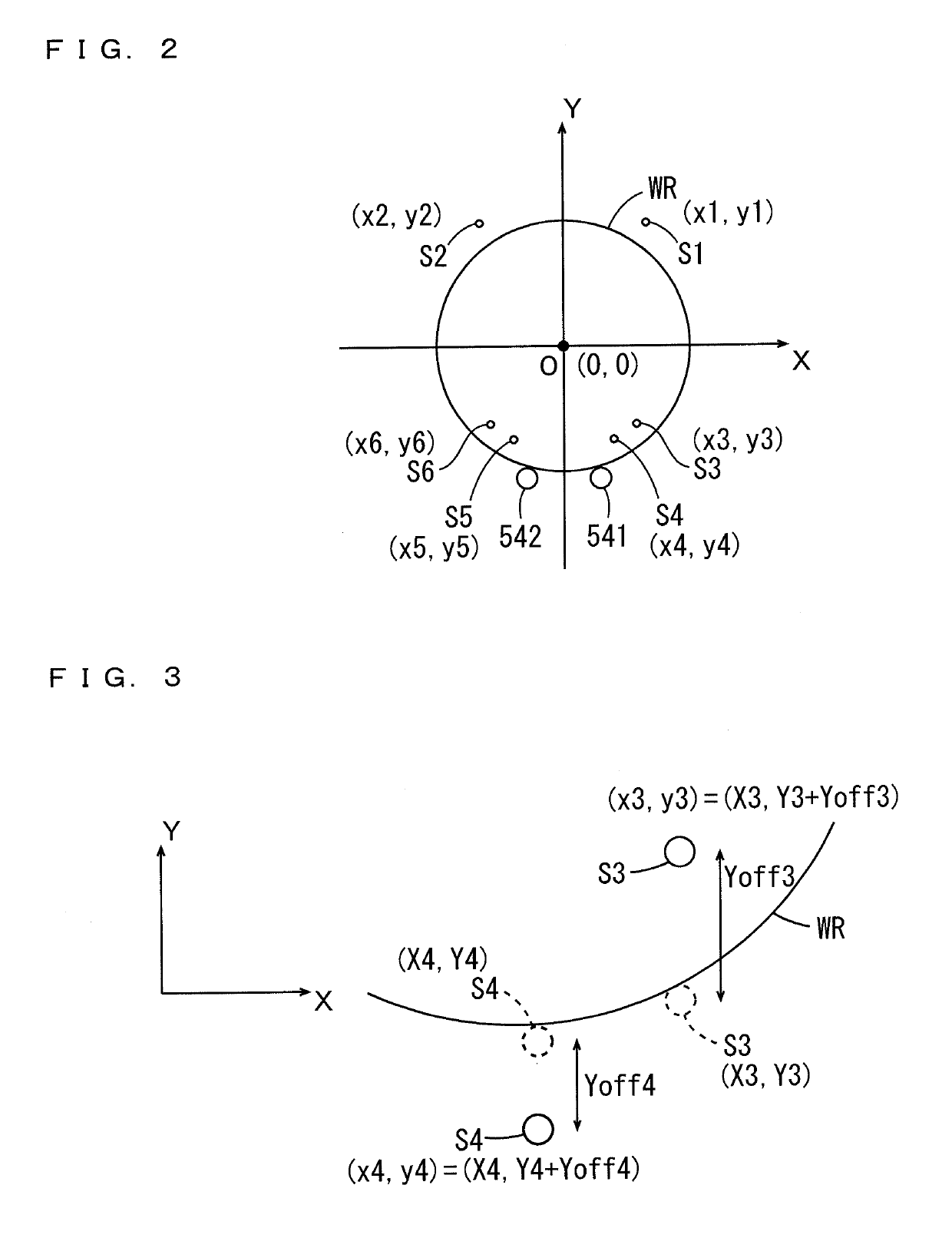

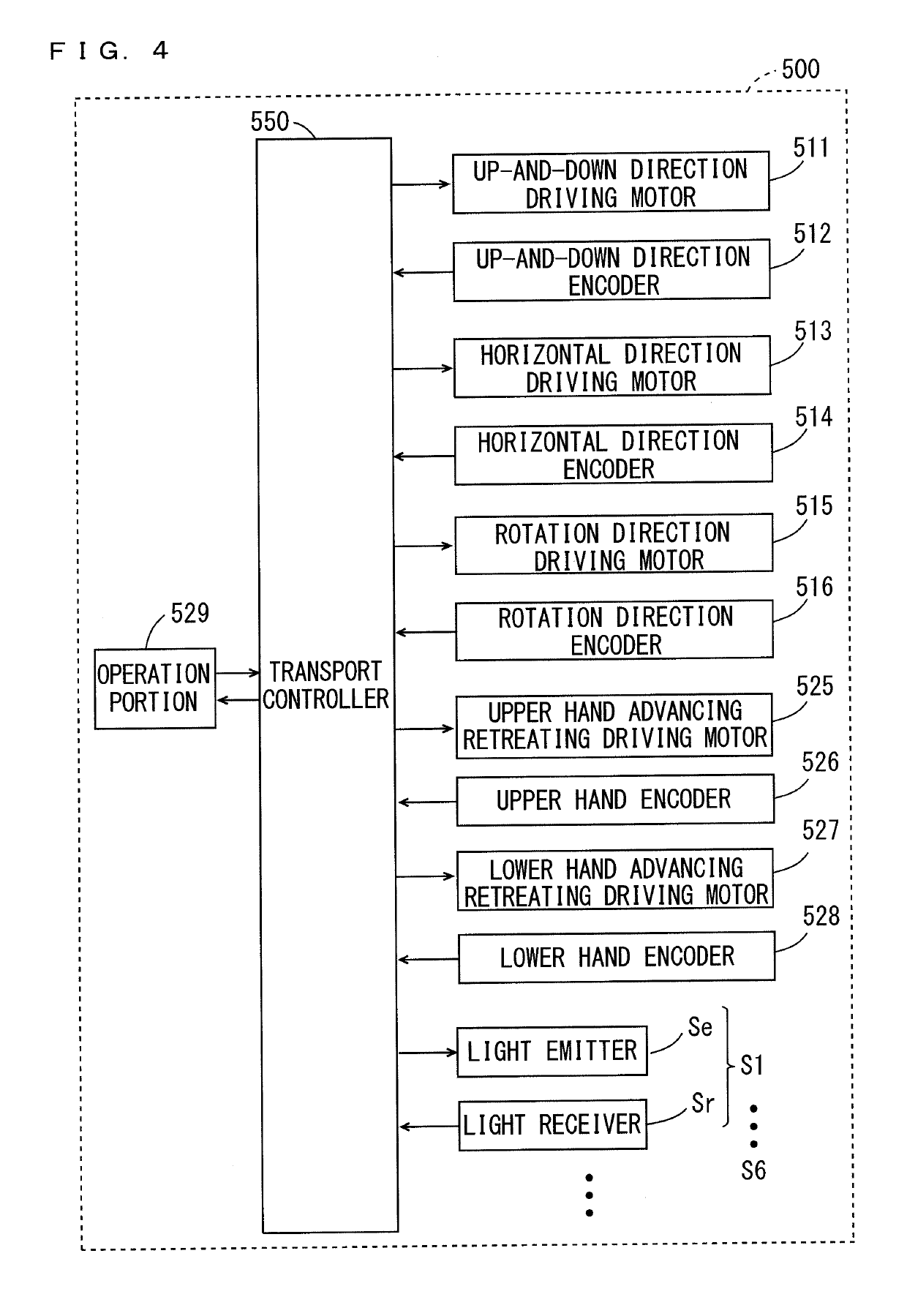

Substrate transport device, detection position calibration method and substrate processing apparatus

ActiveUS20180218935A1Improve shipping accuracyEasy to transportSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDrive motorComputer vision

During a detection position calibrating operation and a substrate transport operation, a detection coordinate calculator calculates detection coordinates of an outer periphery of a reference substrate or a substrate placed at a reference position on a hand. During the detection position calibrating operation, an offset calculator calculates offsets of a plurality of detectors based on detection coordinates and design coordinates. During the substrate transport operation, a detection coordinate corrector corrects the detection coordinates based on the offsets of the plurality of detectors, and a coordinate information corrector corrects coordinate information based on the corrected detection coordinates. A movement controller controls an up-and-down direction driving motor, a horizontal direction driving motor and a rotation direction driving motor and controls an upper hand advancing retreating driving motor and a lower hand advancing retreating driving motor, such that the substrate is transported from a reception position to a placement position based on the corrected coordinate information.

Owner:DAINIPPON SCREEN MTG CO LTD

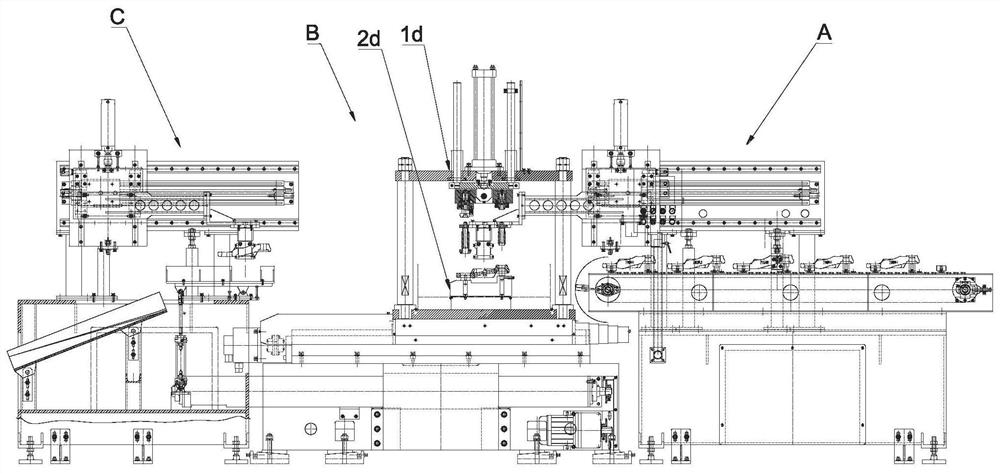

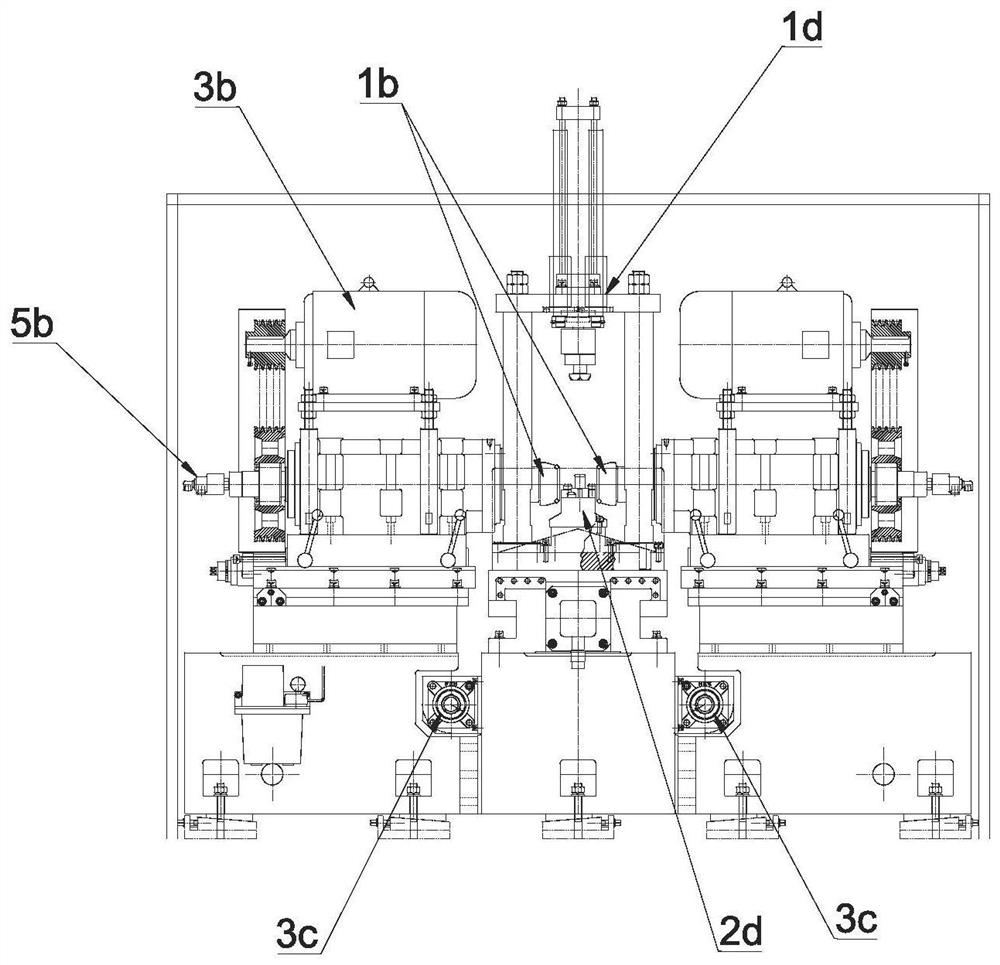

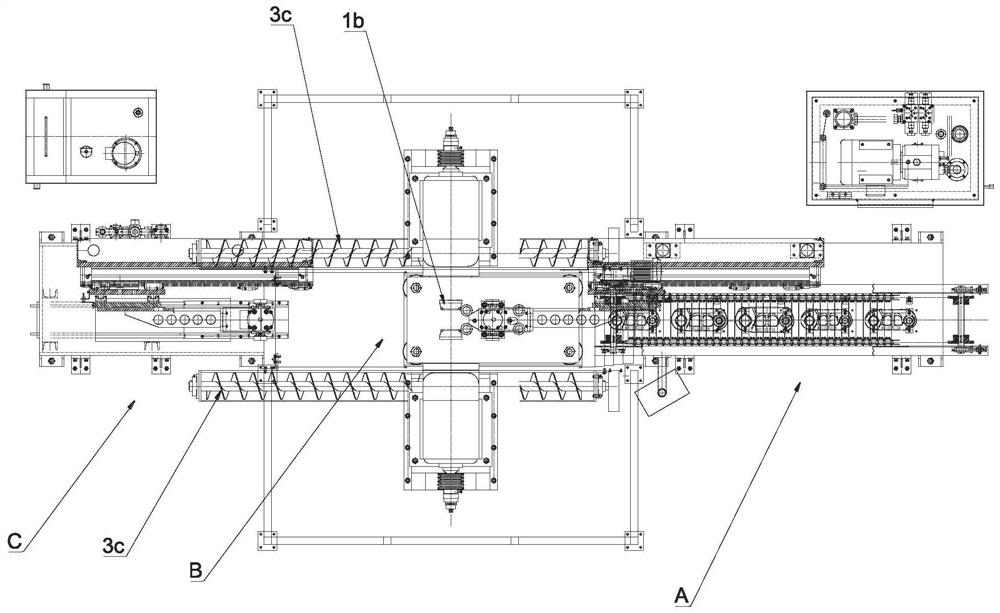

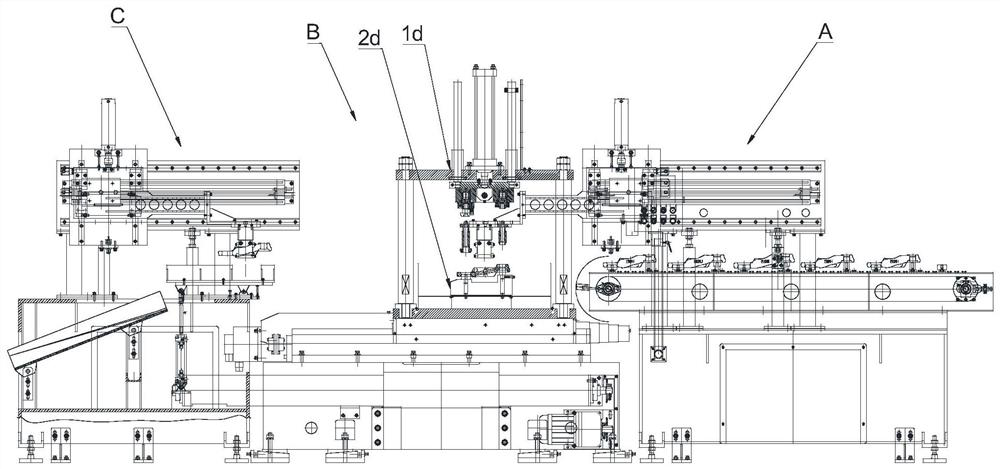

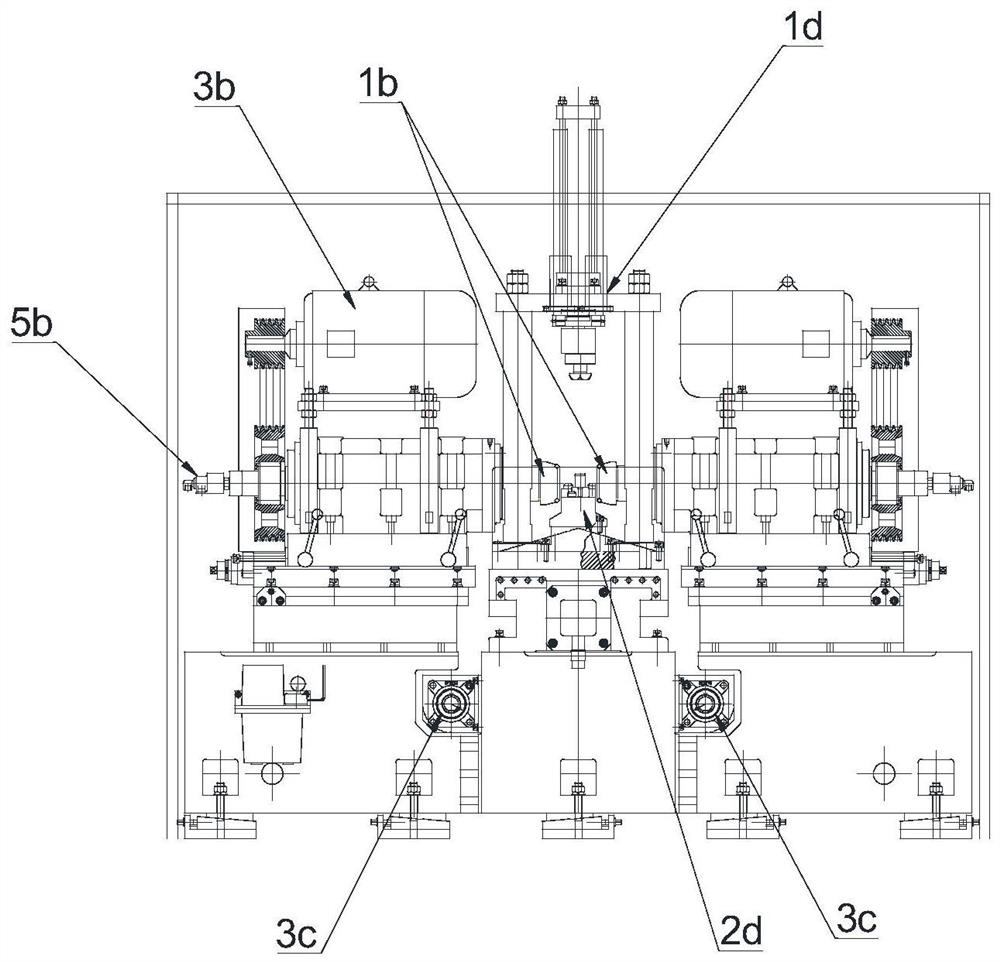

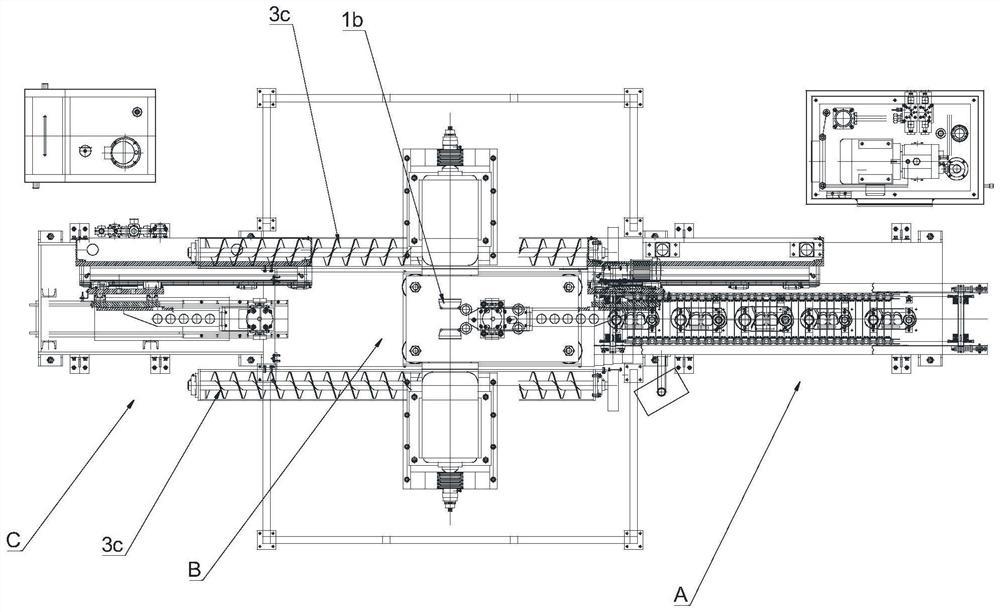

High-intelligence double-face milling production line for caterpillar track sections

ActiveCN112404534AAvoid offsetPrevent fallingWork clamping meansMilling equipment detailsMilling cutterTransfer mechanism

The invention discloses a high-intelligence double-face milling production line for caterpillar track sections. The high-intelligence double-face milling production line for the caterpillar track sections comprises a feeding module, a milling module and a discharging module, and a milling station is arranged in the milling module; the feeding module comprises a conveying mechanism and a feeding transferring mechanism; the conveying mechanism comprises a conveying belt and a conveying driving mechanism, and a plurality of positioning assemblies are arranged on the conveying belt; the discharging transferring mechanism comprises a discharging moving part, a discharging clamping assembly, a discharging clamping driving mechanism and a discharging transferring driving mechanism; A guide receiving mechanism comprises a supporting frame and a guide sliding rail, the guide sliding rail is obliquely arranged downwards from back to front, and the front end of the guide sliding rail correspondsto a receiving device; and the milling module comprises two milling cutters which are oppositely arranged and a milling driving mechanism for driving the two milling cutters to rotate. According to the high-intelligence double-face milling production line for the caterpillar track sections, full-automatic machining of double-face milling of the caterpillar track sections is achieved, feeding and discharging of workpieces do not need manual participation, manpower is saved, and the machining precision can be improved.

Owner:GUANGZHOU YUEYAN INTELLIGENT EQUIP CO LTD

Medium feeding apparatus and control method of medium feeding apparatus

InactiveUS20170274688A1Improve shipping accuracyImprove accuracyOther printing apparatusWebs handlingMechanical engineeringEngineering

Owner:SEIKO EPSON CORP

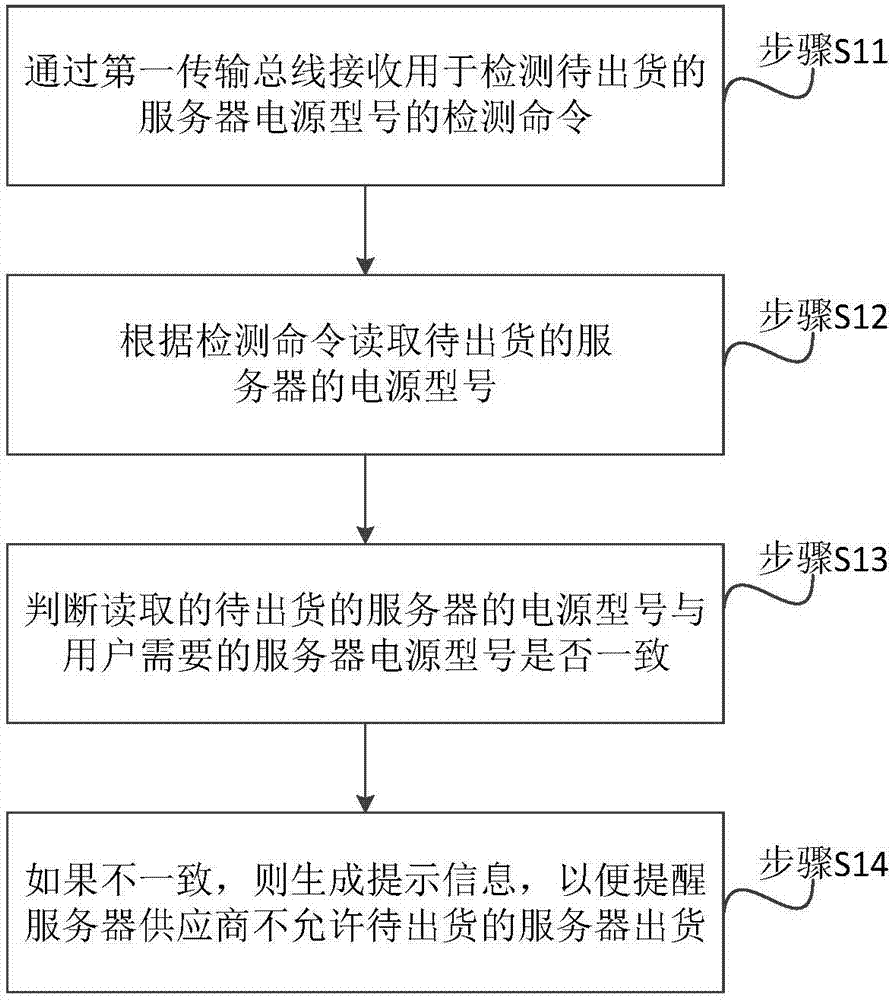

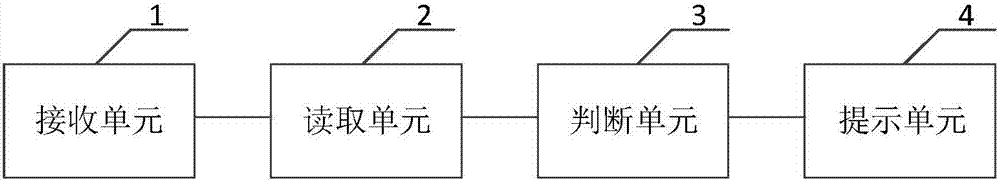

Server power source model detection method, system and device and storage medium

InactiveCN107577552AImprove shipping accuracyReduce returnsFault responseOperating systemSource model

The invention discloses a server power source model detection method. The method comprises the steps that a detection instruction for detecting a power source model of a server to be delivered is received through a first transmission bus, and according to the detection instruction, and the power source model of the sever to be delivered is read; whether or not the read to-be-delivered server powersource model is consistent with a server power source model needed by a user is judged; if the models are not consistent, a promoting message is generated so that a server provider can be promoted not to be allowed for delivering servers to be delivered. It can been seen that the power source model of the server to be delivered is strictly controlled, the delivery accuracy is greatly improved, the phenomenon that sales returning is caused due to the fact that the power source model is not qualified is reduced, and the user experience is improved. In addition, the method is applicable to various servers, and has the high replicability and development. The invention further provides a server power source model detection system and device and a storage medium which have the same advantages.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Substrate transport device, detection position calibration method and substrate processing apparatus

ActiveUS10395968B2Improve shipping accuracyEasy to transportSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDrive motorComputer vision

During a detection position calibrating operation and a substrate transport operation, a detection coordinate calculator calculates detection coordinates of an outer periphery of a reference substrate or a substrate placed at a reference position on a hand. During the detection position calibrating operation, an offset calculator calculates offsets of a plurality of detectors based on detection coordinates and design coordinates. During the substrate transport operation, a detection coordinate corrector corrects the detection coordinates based on the offsets of the plurality of detectors, and a coordinate information corrector corrects coordinate information based on the corrected detection coordinates. A movement controller controls an up-and-down direction driving motor, a horizontal direction driving motor and a rotation direction driving motor and controls an upper hand advancing retreating driving motor and a lower hand advancing retreating driving motor, such that the substrate is transported from a reception position to a placement position based on the corrected coordinate information.

Owner:DAINIPPON SCREEN MTG CO LTD

Image recording apparatus

ActiveUS8721206B2Improve shipping accuracyQuality improvementOther printing apparatusImage recordingRecording media

An image recording apparatus includes: at least one roller pair which has a driving roller and a driven roller facing the driving roller and which rotates while interposing the recording medium therebetween to transport the recording medium in a first direction; a recording section which records an image on the recording medium transported by the roller pair; a position detecting section which detects a position of the recording medium with respect to the roller pair in a second direction perpendicular to the first direction before the recording section starts recording; a determining section which determines a rotation amount of the driving roller before the recording section starts the recording depending on the position in the second direction of the recording medium detected by the position detecting section; and a control unit which controls the driving roller based on the rotation amount determined by the determining section.

Owner:BROTHER KOGYO KK

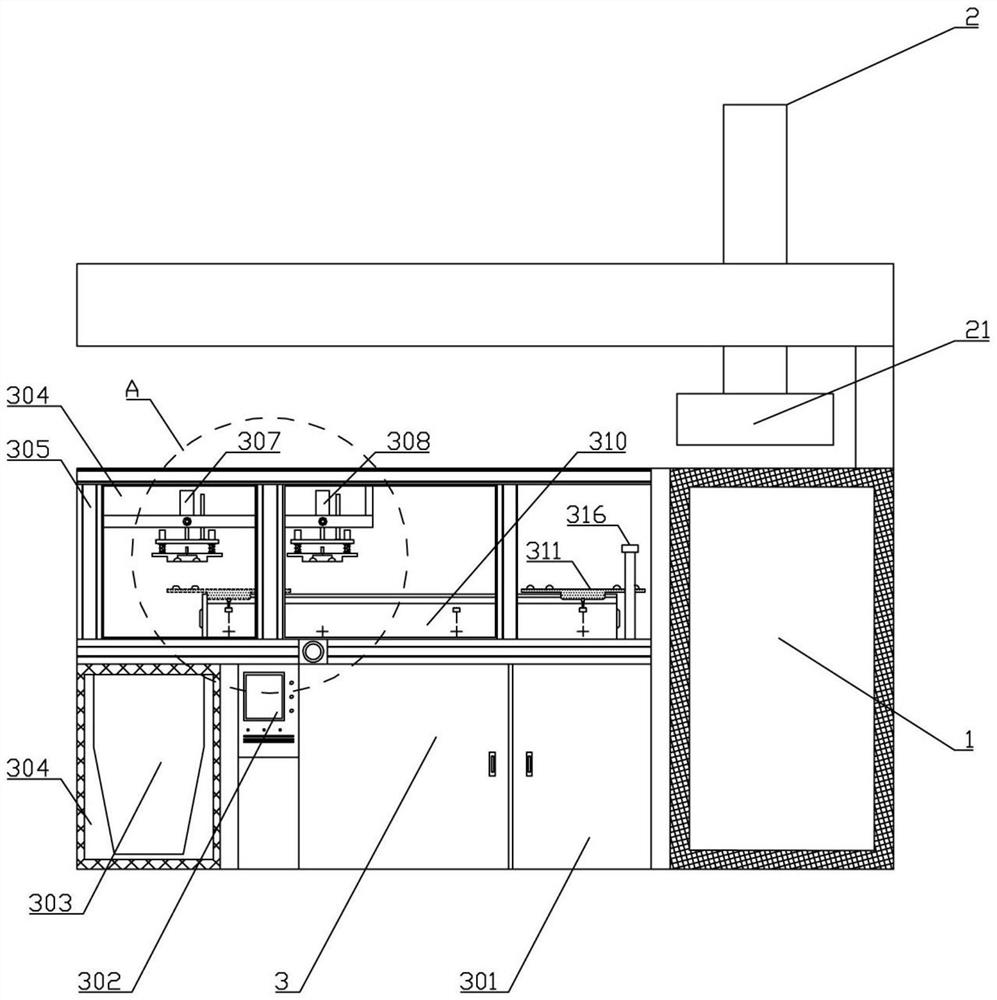

High-precision die assembly machine and die assembly process

The invention discloses a high-precision die assembly machine and a die assembly process. The die assembly machine comprises an injection molding machine, a manipulator and a die assembly machine, the injection molding machine is provided with a discharging port and a to-be-picked area, and the to-be-picked area is located in front of the discharging port. The manipulator is provided with a material taking device; the mold closing machine is divided into a feeding mold closing area and an unloading control area, the feeding mold closing area is arranged on the upper portion, the unloading control area is arranged on the lower portion, the feeding mold closing area is provided with a conveying mechanism, a mold closing left machine, a mold closing right machine, a material disc matched with the conveying mechanism and a feeding in-place sensor, and the conveying mechanism is located below the mold closing left machine and the mold closing right machine. The left mold closing machine and the right mold closing machine are symmetrically hoisted through a plurality of transverse supporting columns, the unloading control area is provided with an unloading box, the unloading box is in a funnel shape, the left mold closing machine is located over the unloading box, and the feeding in-place sensor is located at the starting end of the conveying mechanism.

Owner:KAILE TOYS CHONGQING

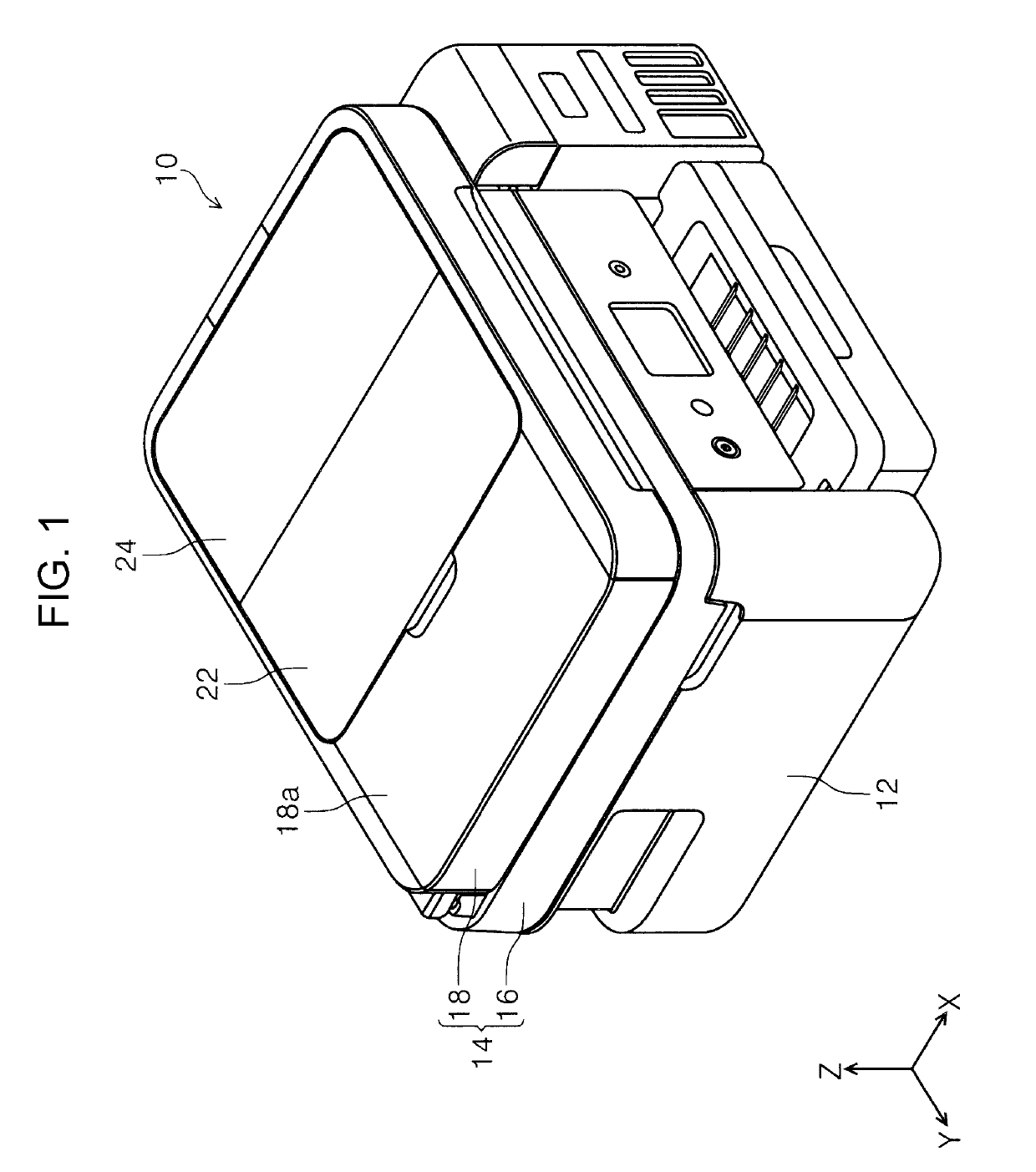

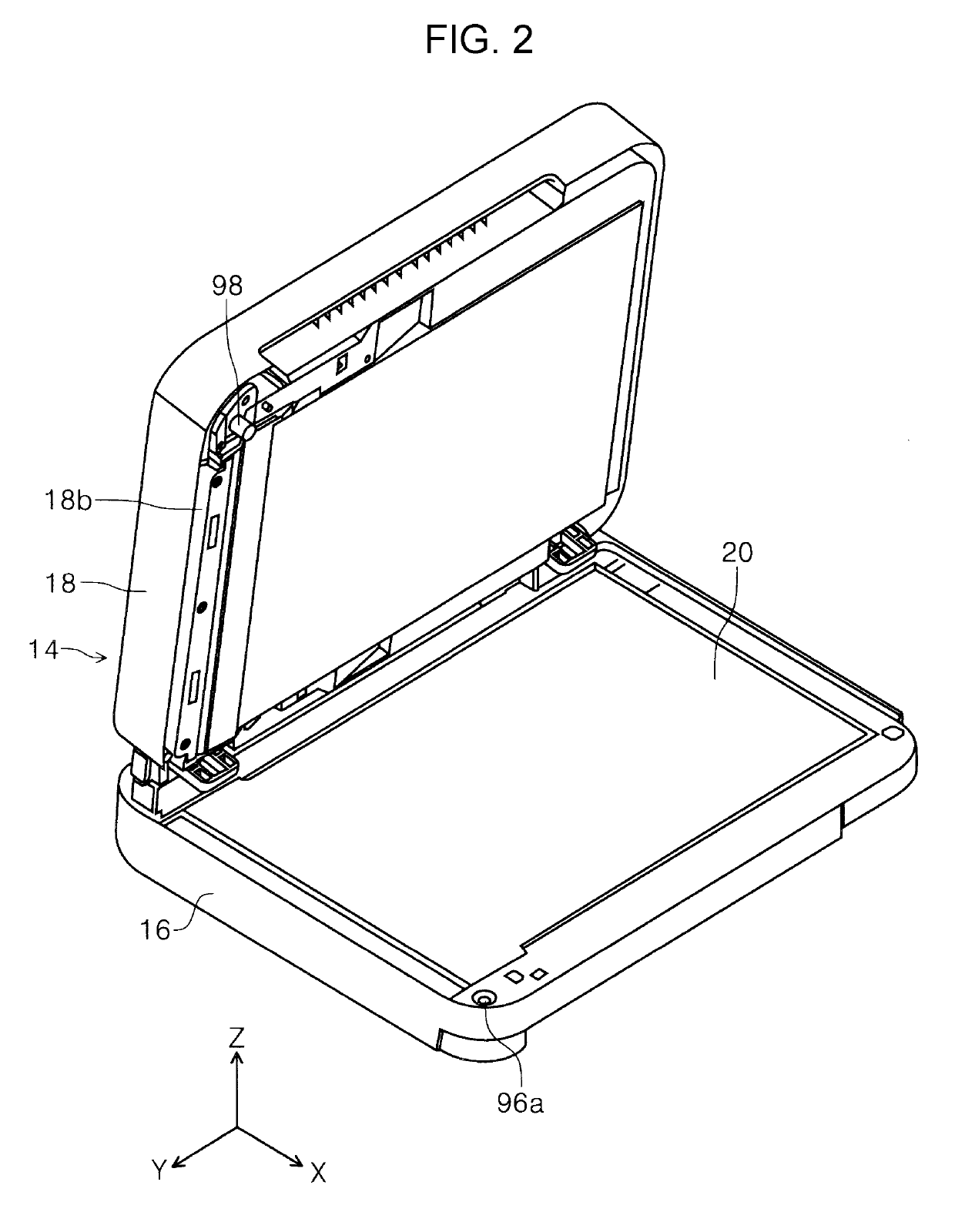

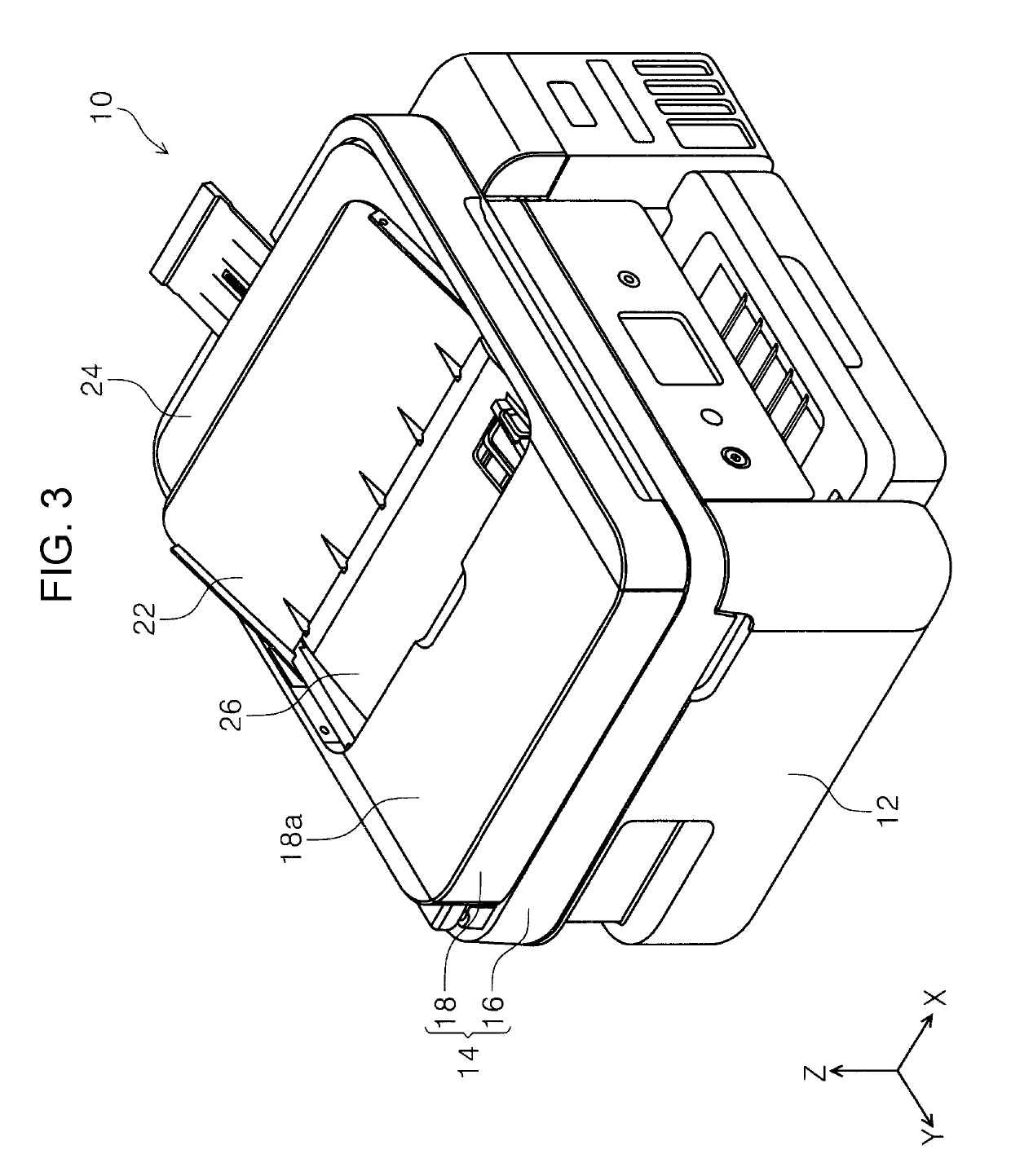

Image reading device

ActiveUS10375260B2Improve shipping accuracyIncrease in sizePile receiversArticle feedersTransmitted powerPower transmission

There is provided an image reading device including a power transmission unit that transmits power of a driving source to a transportation roller and a discharging roller, in which the power transmission unit is configured to include a first gear group that constitutes a first power transmission route and a second gear group that constitutes a second power transmission route and that is configured to include a smaller number of gears than the first gear group, the second gear group includes a transportation roller driving gear and is disposed inside a curved inversion route as seen from an axial direction of a rotation shaft, and at least a portion of the transportation roller driving gear is positioned inside a medium transportation region in a width direction of a medium.

Owner:SEIKO EPSON CORP

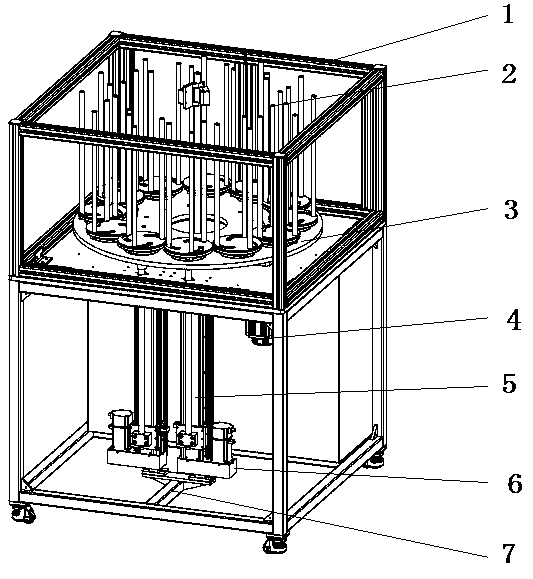

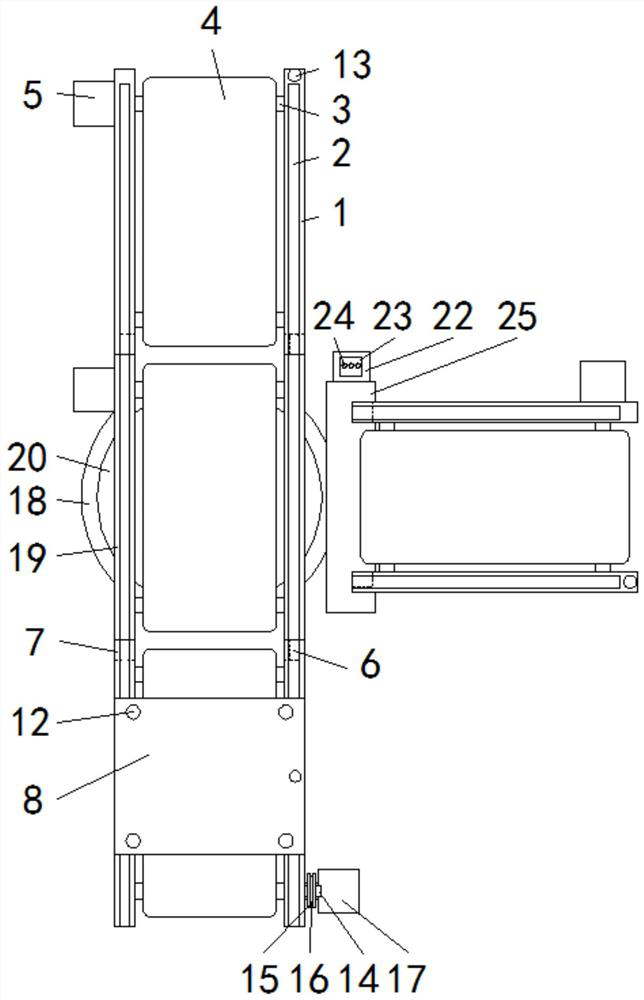

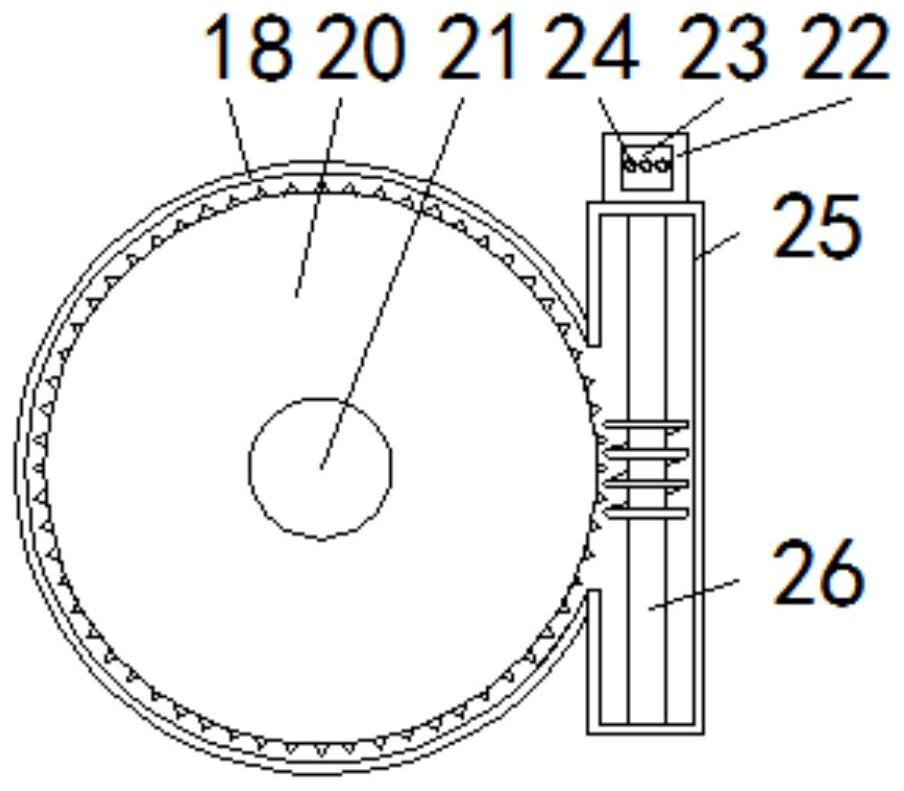

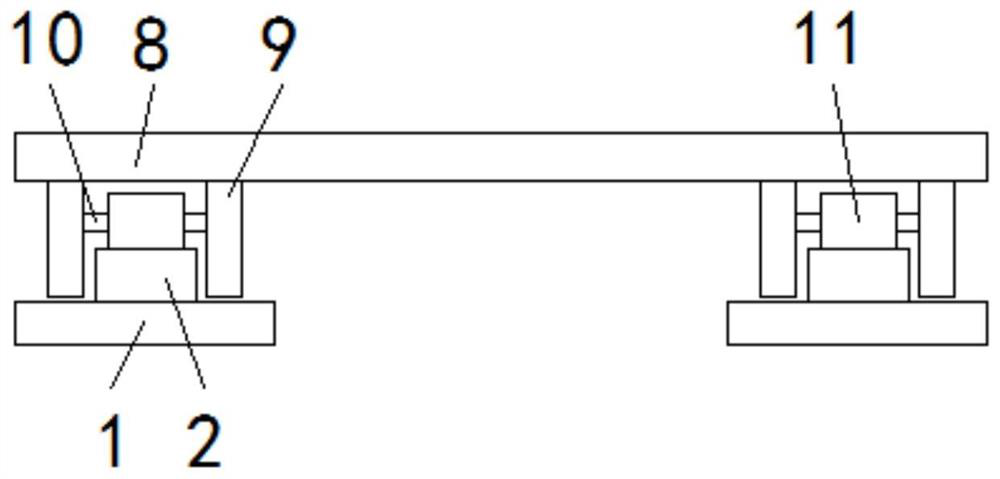

Lifting type multi-rotation self-positioning device

InactiveCN109081055AReduce the chance of machine damageImprove Shipping AccuracyMechanical conveyorsIndustrial engineeringSelf positioning

The invention discloses a lifting type multi-rotation self-positioning device which comprises an outer frame, a lifting shaft and a stock bin, wherein the outer frame comprises a lifting support shaftand the stock bin; the stock bin is fixedly connected with the lifting support shaft to realize the lifting function of the stock bin; a partition board is arranged between the stock bin and the lifting support shaft to avoid influence of material falling to normal operation of a machine; a rotary disc is arranged above the partition board; a plurality of self-rotation discs are uniformly arranged on the rotary disc along the edge of the rotary disc, the independent areas and functions are divided, and the purpose of consistent integrity and substep operation is realized; the transportation processes of the integrity are divided into a plurality of parts, so that the transportation precision is improved, the positioning precision is greatly improved, and the problem that the positioning of excessive material is not precise during the transportation process is avoided; and what's more, the substep operation process can be simultaneously realized, so that the transportation time is shortened, and the transportation production efficiency is improved. The lifting type multi-rotation self-positioning device is widely applied to the field of mechanical production and processing.

Owner:江苏汉峰数控科技有限公司

A kind of automatic delivery pallet for goods in small cold storage

ActiveCN110294250BGuaranteed stabilityImprove shipping accuracyConveyorsStorage devicesMotor driveTransmission belt

The invention relates to the technical field of cold storage and discloses an automatic cargo transporting tray for a small size cold storage. The automatic cargo transporting tray comprises three support frames, wherein a limiting strip is fixedly connected with the obverse side of each of the support frames; a transmission rod is movably connected with the inner side of the support frame; a transmission belt is in transmission connection with the external part of the transmission rod; a first motor is fixedly mounted at the right end of the support frame at the top end, and another first motor is fixedly mounted at the external part of the support frame at the right end; and positioning grooves are formed in opposite sides of the three support frames. According to the automatic cargo transporting tray, the first motors and a second motor drive the transmission belts to do rotational motion; when a designated tray reaches the transmission belts on the inner side of a fixed frame, a third motor is started to change the conveying direction according to the demanded transmission direction; and optical sensors on the tray and the support frames are adopted to sense the position of thetray on the transmission belts, so that the transporting precision of equipment is improved, and manual operation can be reduced while ensuring the transmission efficiency.

Owner:冯志高

Medium transport device and printing apparatus provided therewith

ActiveUS9604481B2Improve shipping accuracyOther printing apparatusWebs handlingTransport engineering

Provided is a medium transport device transporting a medium. The medium transport device includes a skew correcting mechanism disposed on a transport path for transporting a long medium, a first transport roller disposed on the transport path and transporting the medium, and a second transport roller transporting the medium to the first transport roller. The first transport roller is disposed upstream of the skew correcting mechanism. The second transport roller is disposed upstream of and next to the first transport roller. The second transport roller contacts one surface of the medium, and the first transport roller contacts the other surface of the medium.

Owner:DAINIPPON SCREEN MTG CO LTD

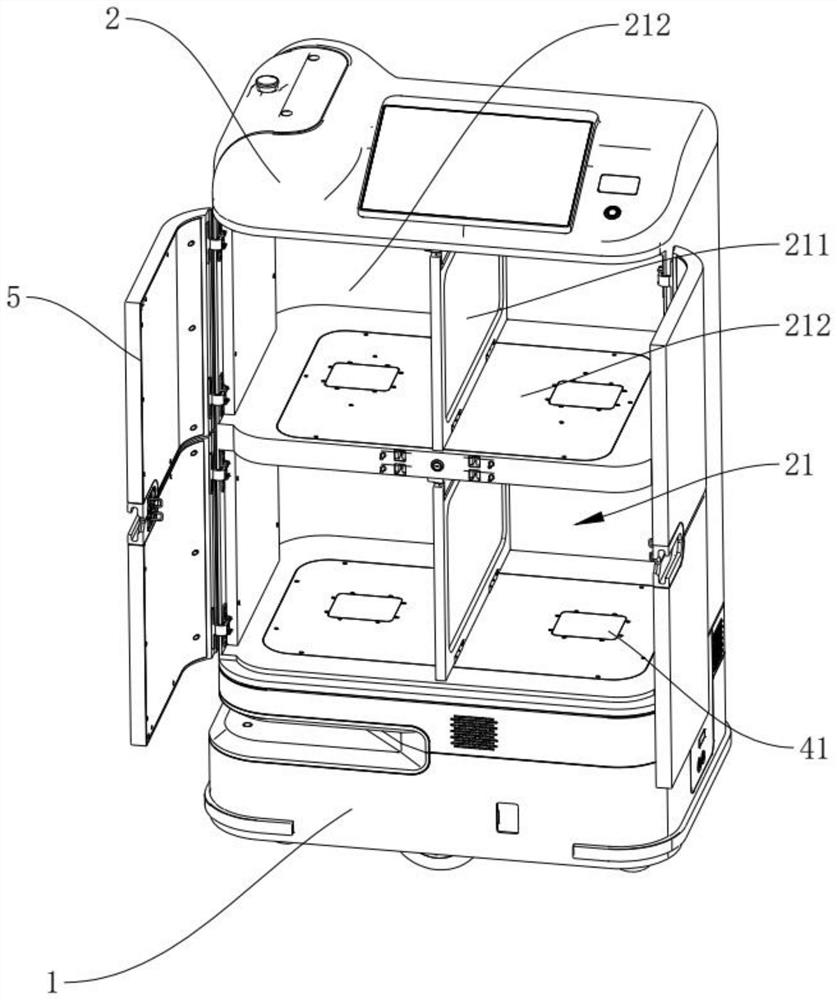

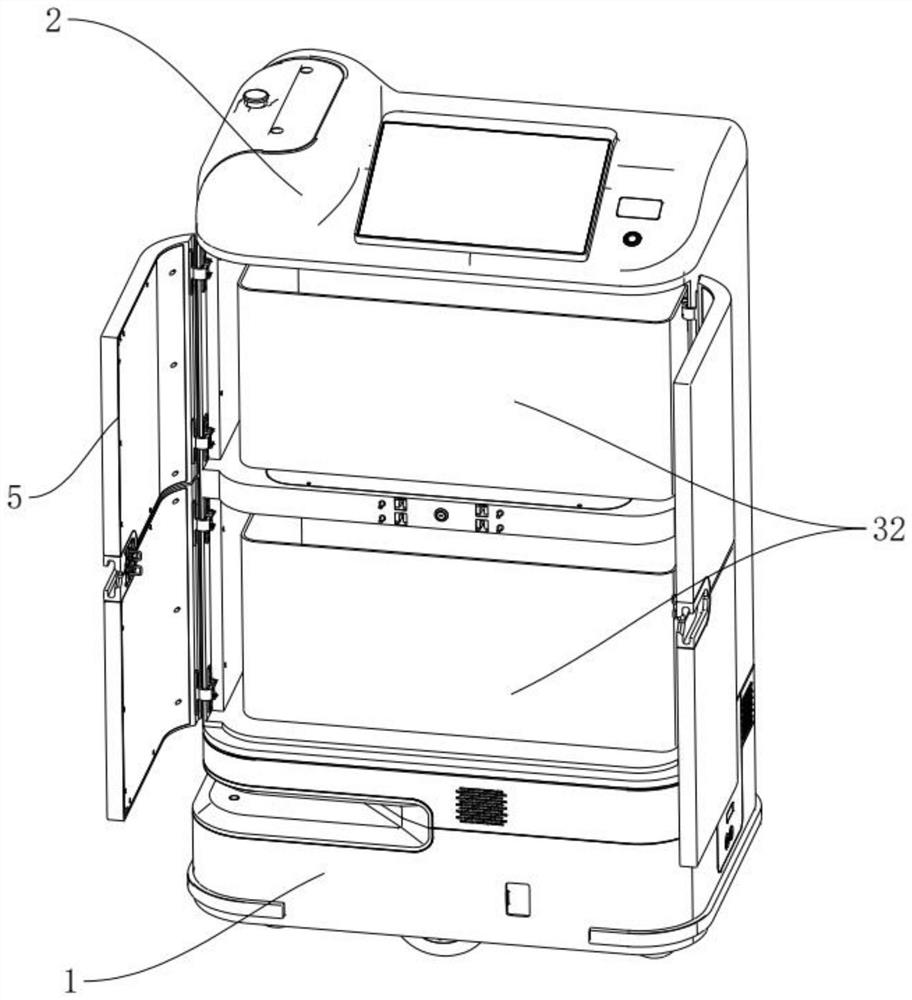

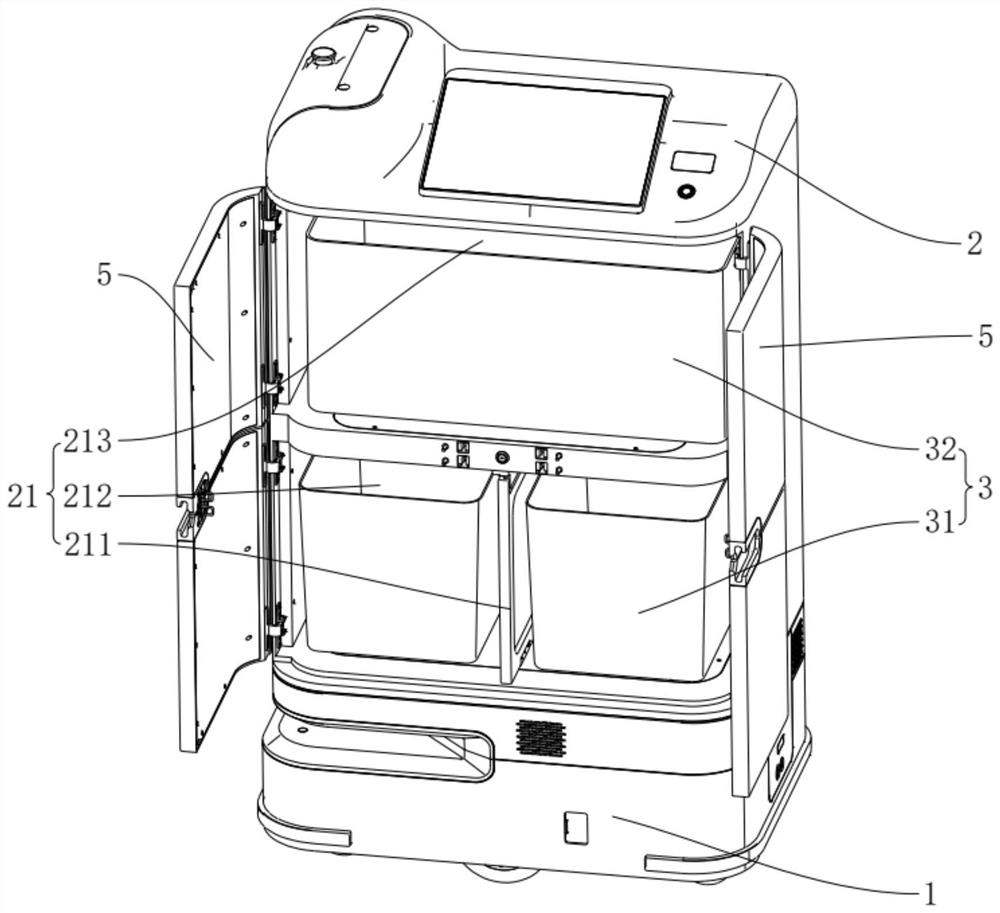

Transportation robot and control method thereof

PendingCN114313570AReduce manufacturing costIncrease profitVehiclesInternal fittingsRobotySystems engineering

The invention relates to the technical field of robots, and discloses a transportation robot and a control method thereof. The transportation robot comprises a robot body, a container and a detection mechanism. The cargo box is arranged on the robot body, the cargo box comprises at least one layer of storage bin, the storage bin is divided into a plurality of cells through partition plates in the horizontal direction, the partition plates are detachably installed in the storage bin so that the adjacent cells can be spliced to form a through bin, and the cells and the through bin correspond to specimen boxes of preset models; the detection mechanism is in signal connection with the robot main body and is used for detecting whether the specimen box is correctly placed in the cell or the through bin or not and sending a first detection signal; the robot body determines whether to move according to the first detection signal. Objects of different sizes can be placed in specimen boxes of different models, the utilization rate of the cargo box is increased, the transportation accuracy of the transportation robot is improved, and the production efficiency is improved.

Owner:SHANGHAI TMI ROBOTICS TECH CO LTD

A highly intelligent double-sided milling production line for chain rail links

ActiveCN112404534BImprove processing efficiencyImprove machining accuracyWork clamping meansMilling equipment detailsMilling cutterFeed drive

The invention discloses an intelligent double-sided milling production line with high chain rail section, comprising a feeding module, a milling module and a feeding module, wherein a milling station is arranged in the milling module; the feeding module includes a feeding mechanism and a feeding module Transfer mechanism; the feeding mechanism includes a feeding belt and a feeding driving mechanism, and a plurality of positioning components are arranged on the feeding belt; the feeding transfer mechanism includes a feeding moving part, a feeding clamping assembly, a feeding clamping drive mechanism and a blanking transfer drive mechanism; the guiding and receiving mechanism includes a support frame and a guiding slide rail, the guiding slide rail is inclined downward from the rear to the front, and the front end of the guiding slide rail is arranged corresponding to the receiving device; The milling module includes two oppositely arranged milling cutters and a milling drive mechanism that drives the two milling cutters to rotate. The invention realizes the fully automatic processing of the double-sided milling of the chain rail section, the workpiece loading and unloading do not need manual participation, saves manpower, and is beneficial to improve the processing accuracy.

Owner:GUANGZHOU YUEYAN INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com