A highly intelligent double-sided milling production line for chain rail links

A chain rail link and double-sided milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, manufacturing tools, etc., can solve the problems that continuous processing cannot be realized, the accuracy of manual clamping workpieces is difficult to be guaranteed, and the processing efficiency of chain rail links is affected. , to achieve the effect of shortening the moving distance and moving difficulty, improving the processing quality, improving the processing efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

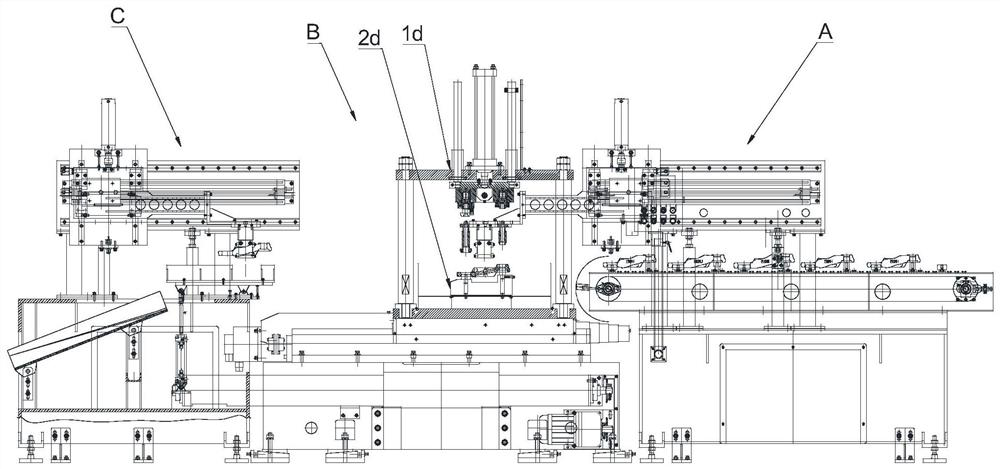

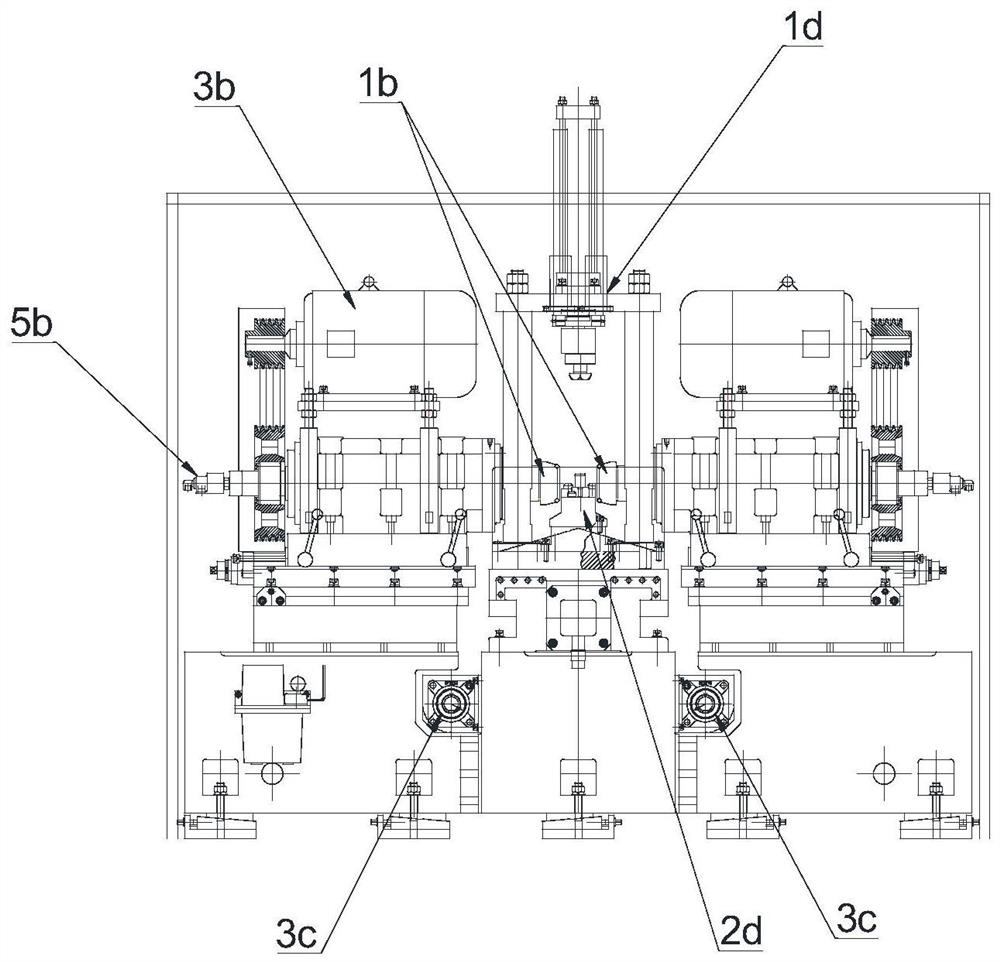

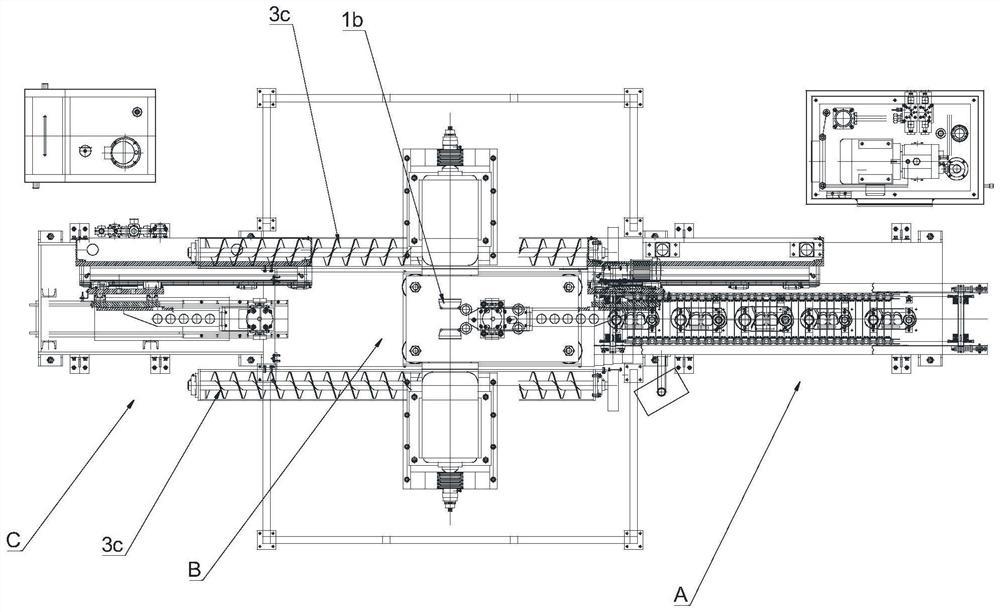

[0037] see Figure 1-Figure 3 , the high-intelligence double-sided milling production line for chain rail joints in this embodiment includes a feeding module A, a milling module B, and an unloading module C. Along the moving direction of the chain rail joints, the feeding module A, milling module B and the blanking module C are arranged in turn, and the milling station 1c is provided in the milling module B; wherein:

[0038] see Figure 1-Figure 3 and Figure 5-Figure 10 , the feeding module A includes a feeding mechanism and a feeding transfer mechanism; the feeding mechanism includes a feeding belt 1 and a feeding driving mechanism that drives the movement of the feeding belt 1, along the moving direction of the chain rail joint, on the feeding belt 1 There are a plurality of positioning assembli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com