High-precision die assembly machine and die assembly process

A high-precision, mold-clamping machine technology, applied in the field of mold-clamping, can solve problems such as the inability of the mold-clamping assembler to deliver batches of molds in batches, reduce production efficiency, and have a low degree of automation, so as to improve mold clamping and production efficiency, improve The effect of mold clamping accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

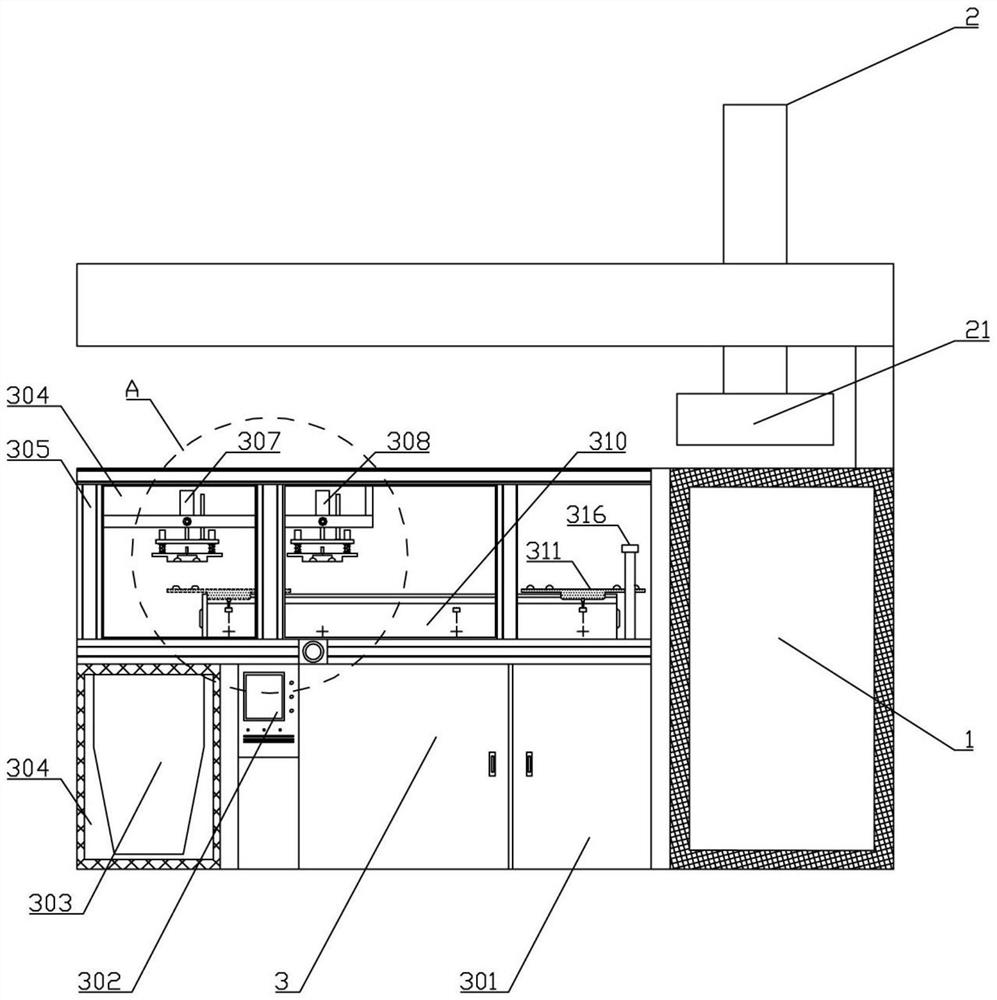

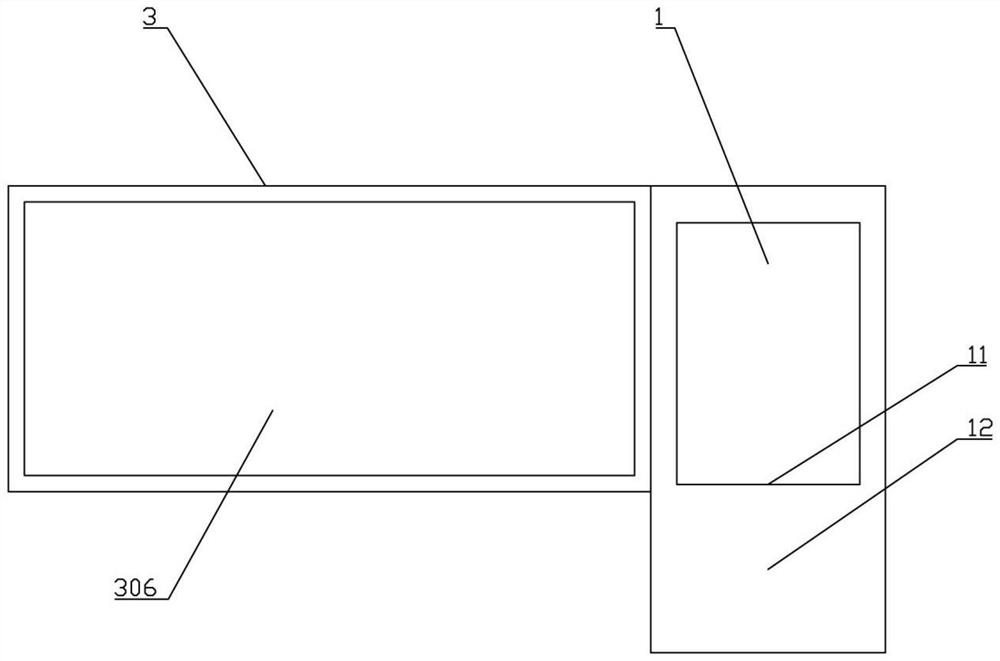

[0046] Such as Figure 1-6 As shown, a high-precision mold clamping assembly machine of the present invention includes an injection molding machine 1, a manipulator 2 and a mold clamping machine 3; the injection molding machine 1 is provided with a discharge port 11 and a pick-up area 12, and the pick-up area 12 is located at the output front of mouth 11;

[0047] The manipulator 2 is provided with a reclaimer 21;

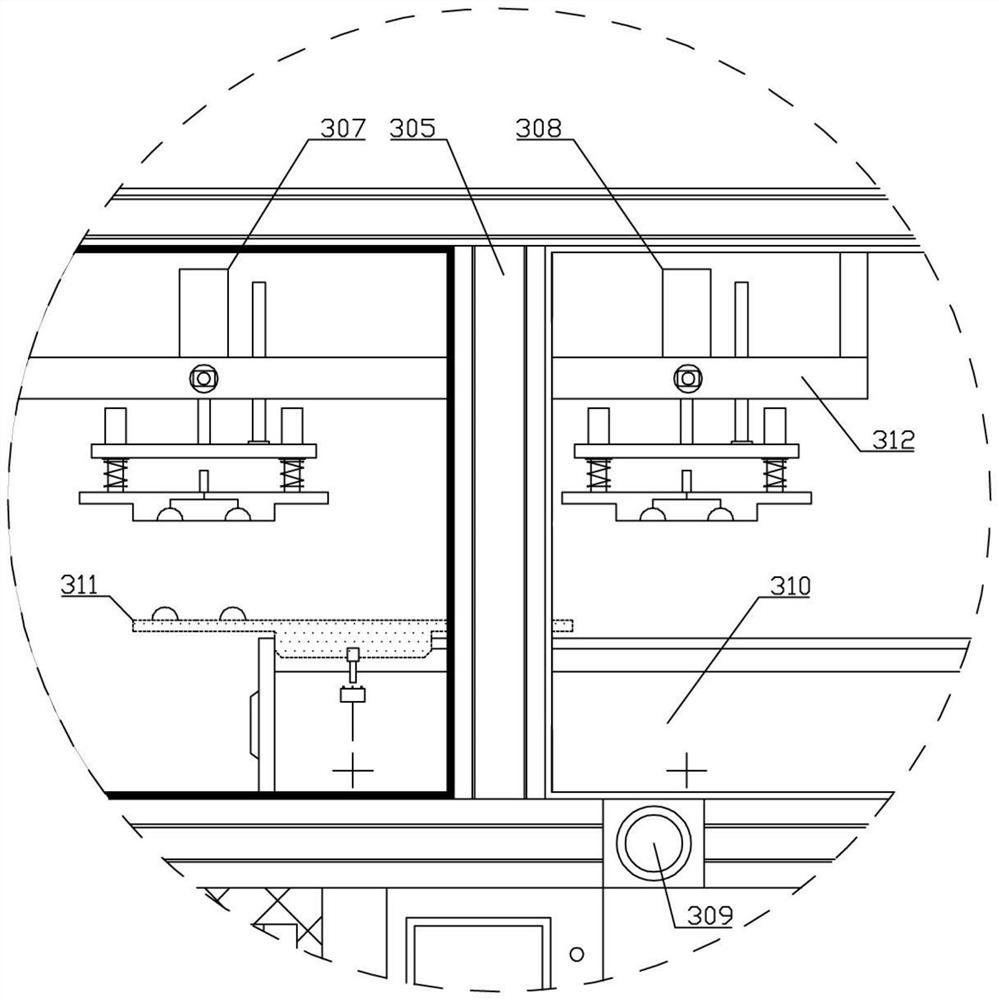

[0048] The mold clamping machine 3 is divided into a material loading mold clamping area and a control unloading area. The material loading mold clamping area is on the top and the control unloading area is on the bottom. The material loading mold clamping area is equipped with a conveying mechanism 310, a mold clamping left mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com