Brushless direct current motor controlled by servo system

A brush DC motor and servo system technology, applied in the field of servo systems, can solve the problems of surface rust vibration, connection end face gap, poor fixing effect, etc., and achieve the effect of avoiding screw rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Appendfigure 1 AdherentFigure 5 Down:

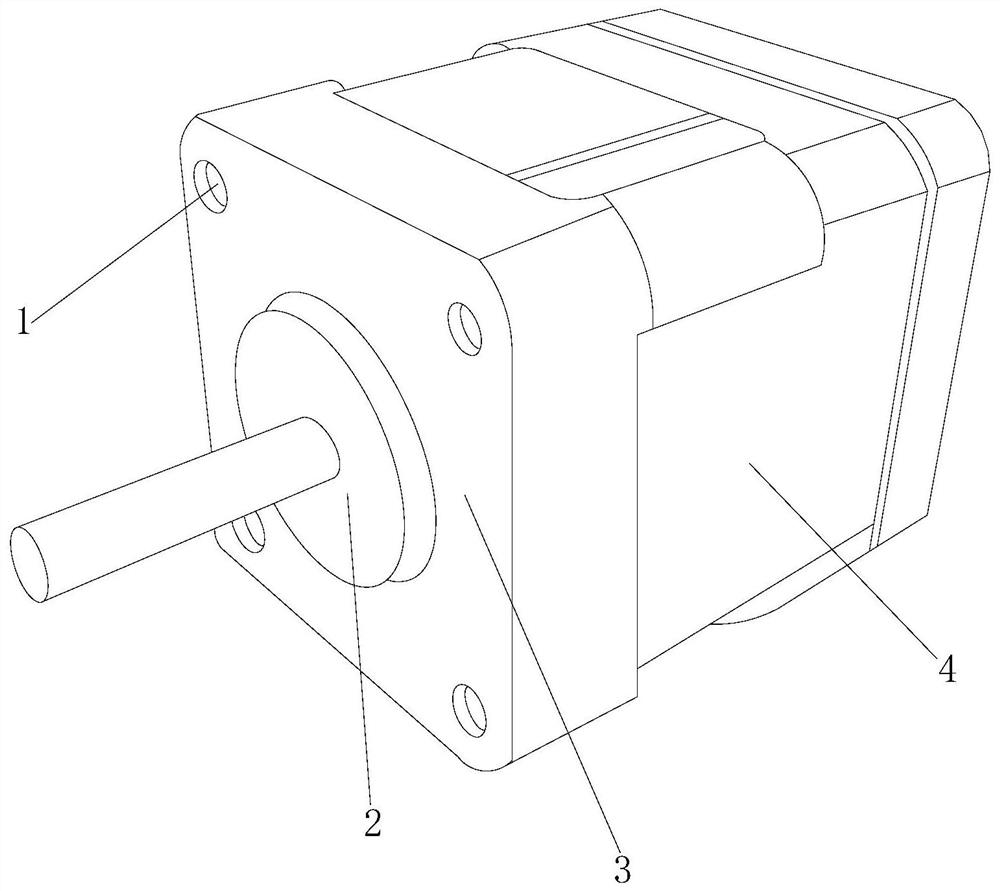

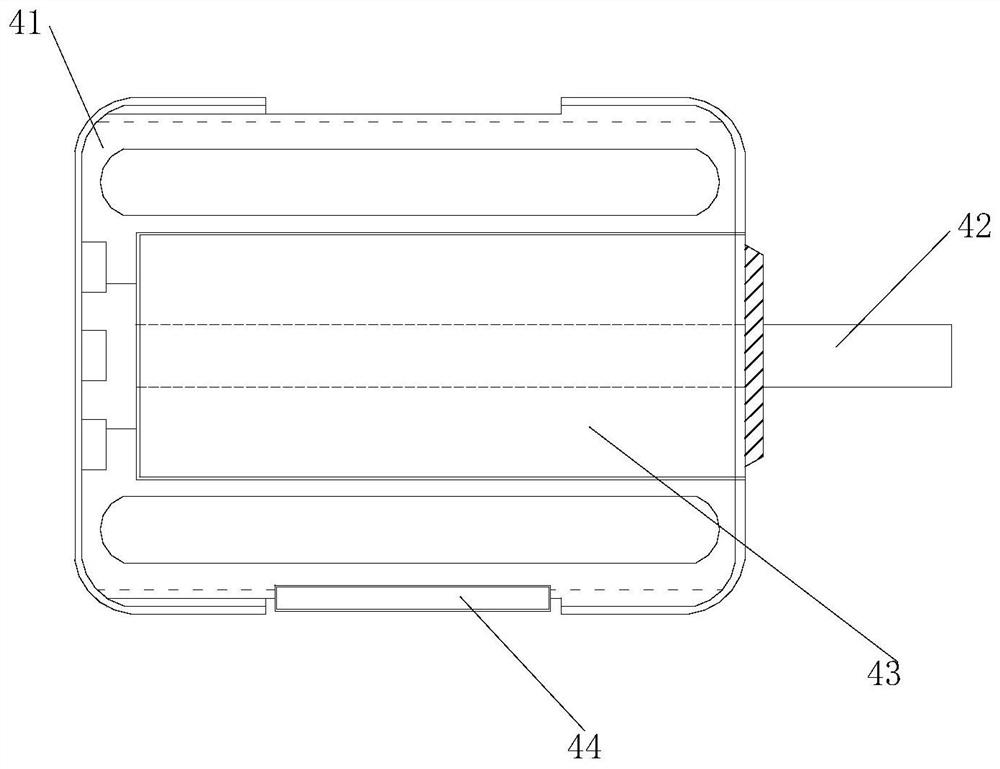

[0028]The present invention provides a brushless DC motor controlled by a servo system comprising a bolt hole 1, a fixing ring 2, a cover plate 3, a housing 4, and the bolt hole 1 and the cover plate 3 are integrated structures, the fixation The ring 2 outer ring is solidly coupled to the inner ring of the cover plate, the cover plate 3 acts on the end face of the housing 4, the fixing ring 2 located at the front end of the housing 4; the housing 4 is from the inner frame 41 The shaft 42, the permanent magnet 43, the mounting assembly 44, the rotating shaft 42 and the permanent magnet 43 as an integrated structure, the permanent magnet 43 active engage inside the inner frame 41, the mounting assembly 44 activity is engaged The middle portion of the frame 41 is located below the permanent magnet 43.

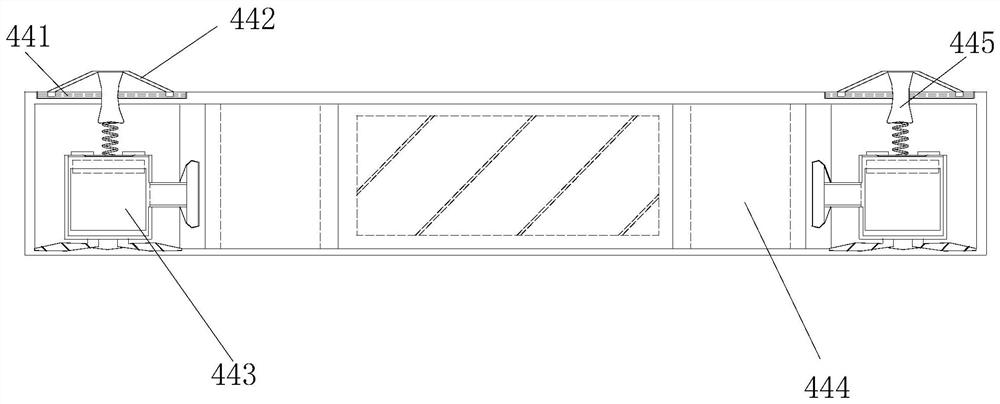

[0029]Wherein, the mounting assembly 44 is composed of a slide rail 441, a control rod 442, a rustting device 443, a mounting hole 444, and a low...

Embodiment 2

[0035]AppendFigure 6 AdherentFigure 8Down:

[0036]Wherein, the communication tube 332 is composed of inner groove 321, a rear plate 322, a discharge plate 323, and the inner groove 321 is embedded on the right end surface of the rear plate 322, the discharge plate 323 and the inner groove 321. In the integrated structure, the discharge plate 323 is located on the right side of the rear plate 322, and the inner groove 321 is constantly gathering from left to the right, and the inner groove 321 is constantly narrowed, thereby facilitating collecting liquid into the discharge plate 323. It increases its injection pressure to facilitate spraying.

[0037]Wherein, the discharge plate 323 consists of a circular ring tube 231, a trapezoid tube 232, a diffusing port 233, a connecting plate 234, and the outer ring is embedded in the upper end of the ladder tube 232, the trapezoid tube 232. The embedded panel 234 is fitted over the connecting plate 234, and the diffusing port 233 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com