Gob-side entry retaining wall construction system and method based on concrete 3D printing technology

A 3D printing and concrete technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of many machines at the end, poor working environment, and high work intensity, and achieve convenient operation paths, mechanisms, and personnel requirements The effect of less, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

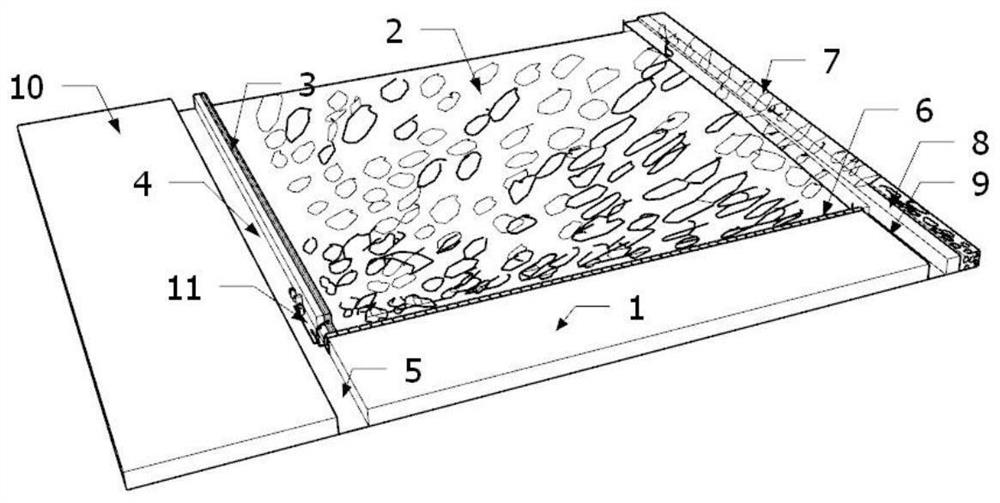

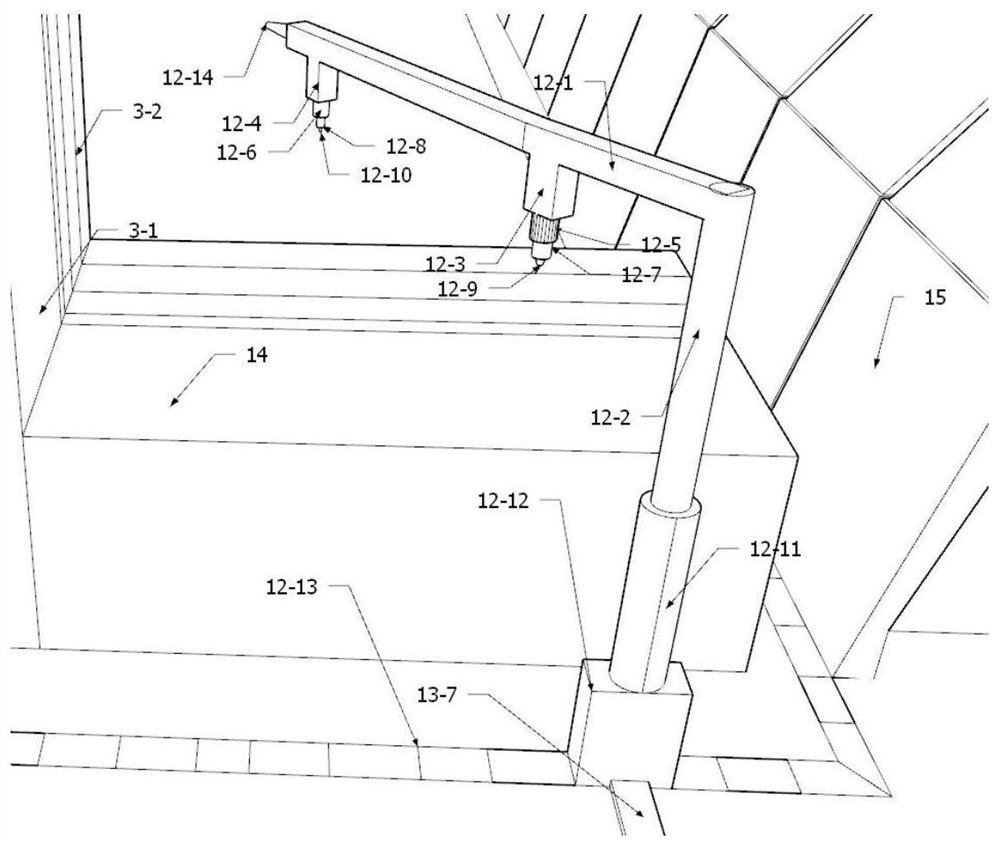

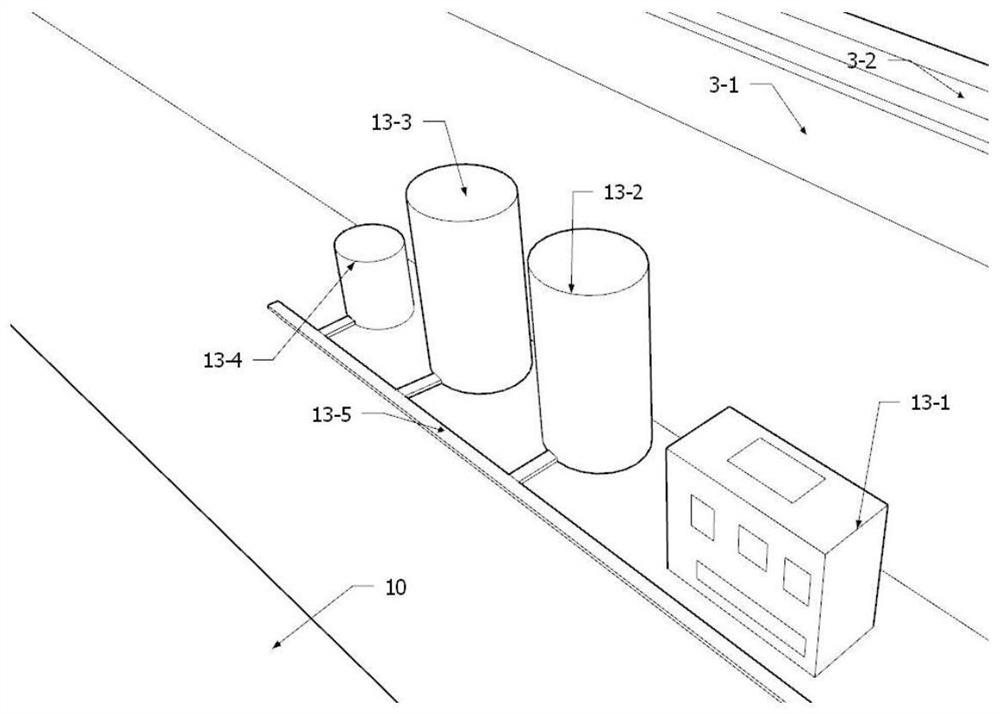

[0032] Such as figure 1 As shown, the front end of the working face 6 is an unmined coal body 1, and the rear is a goaf 2. The working face 6 is provided with a roadway 4 on the side of the coal body 10 in the lower section, and a roadway wall 3 is built in the roadway 4; the present invention Gobside entry retaining wall construction system based on concrete 3D printing technology, which includes extrusion system slide rails 12-13 and concrete 3D printing system 11 arranged in the fully mechanized mining face where the entry retaining wall needs to be constructed. The 3D printing system 11 includes a material extrusion system 12 and a material preparation system 13, wherein the material extrusion system 12 is set on the extrusion system slide rails 12-13 through driving wheels, the material preparation system 13 is set in the lane keeping section, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com