3D vapor chamber structure applied to phase change cold storage device and manufacturing method of 3D vapor chamber structure

A technology of phase change cold storage and vapor chamber, which is applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of affecting the performance of cold storage devices, the heat transfer limitation of restricted heat transfer structural materials, and the strengthening effect Limited and other problems, to meet the needs of rapid heat transfer, improve the temperature of the heat source, and improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

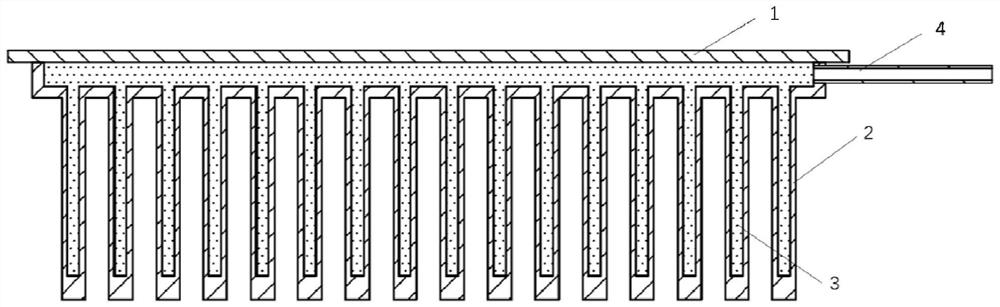

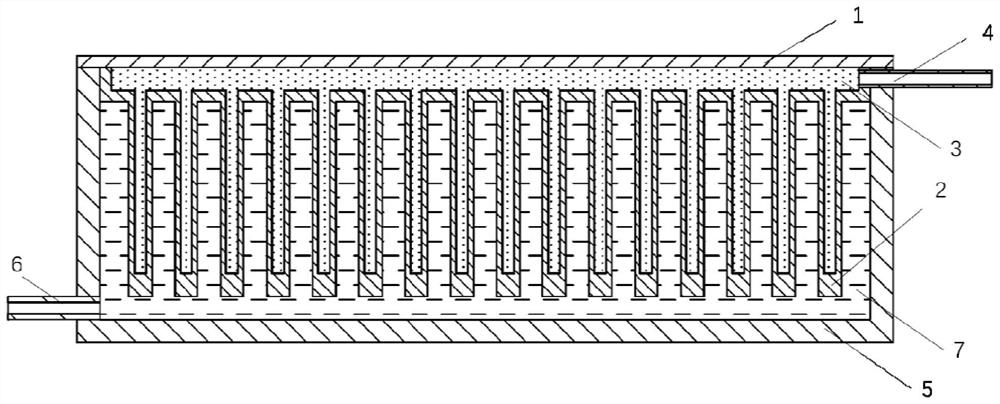

[0025] Such as Figure 1-Figure 2 The shown 3D vapor chamber structure applied to a phase change cold storage device includes a heat transfer enhanced shell 2 and a cover plate 1 installed on the top of the heat transfer enhanced shell 2 . The enhanced heat transfer shell 2 is a special-shaped structure that is integrally processed and formed, and has a large surface area. The enhanced heat transfer shell 2 and the cover plate 1 form a special-shaped closed space, and the special-shaped closed space is provided with a 3D capillary core formed by sintering aluminum powder.

[0026] Further, the 3D capillary core 3 adopts an integral sintered structure. Specifically, the 3D capillary core 3 is formed by sintering aluminum powder. Together, a sintered housing assembly is formed.

[0027] Further, the enhanced heat transfer shell 2 and the cover plate 1 are made of aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com