Integrated circuit pin three-dimensional detection system and detection technology

A technology of three-dimensional detection and integrated circuits, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as difficult clamping and removal, decreased product qualification rate, cumbersome clamping operations, etc., and achieves simple structure, The effect of taking out the chip easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

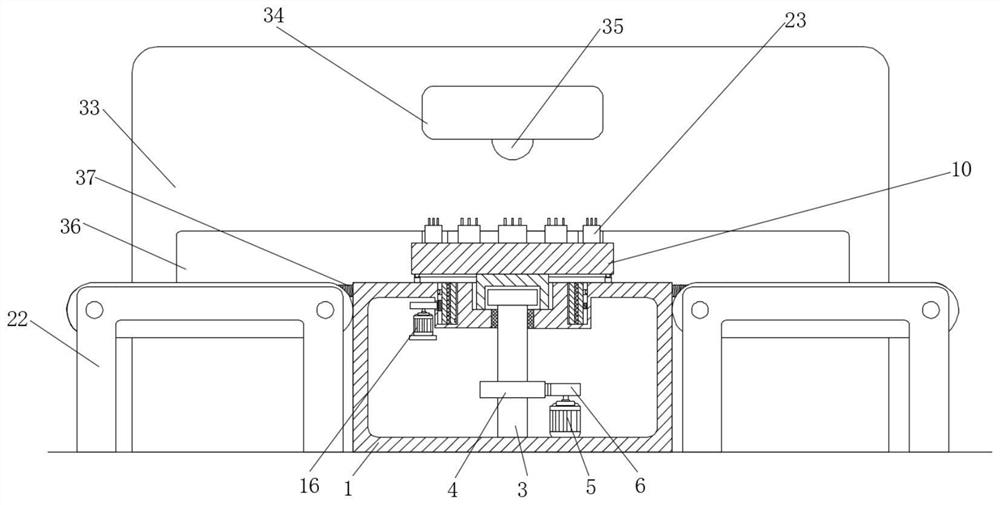

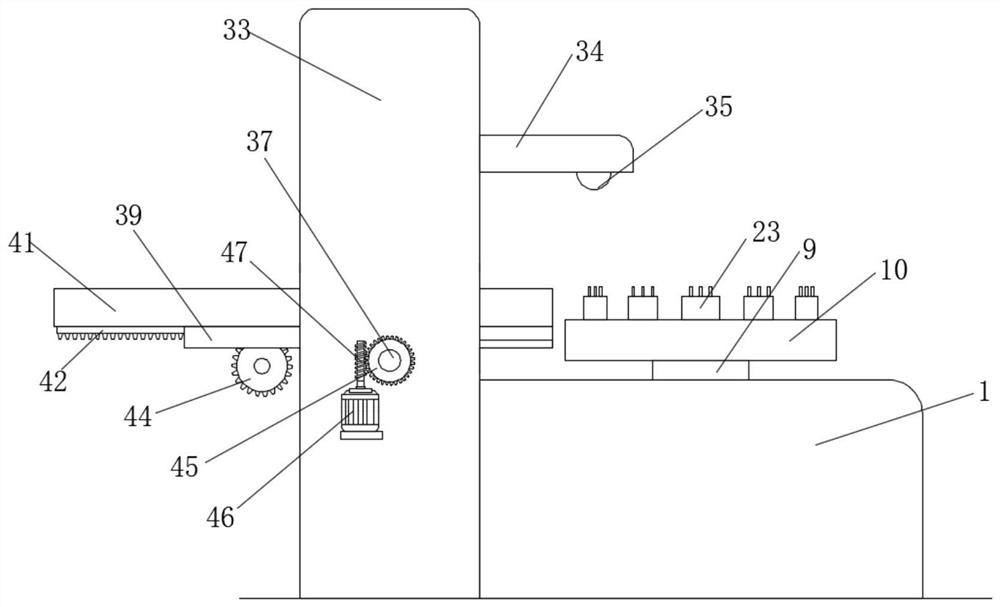

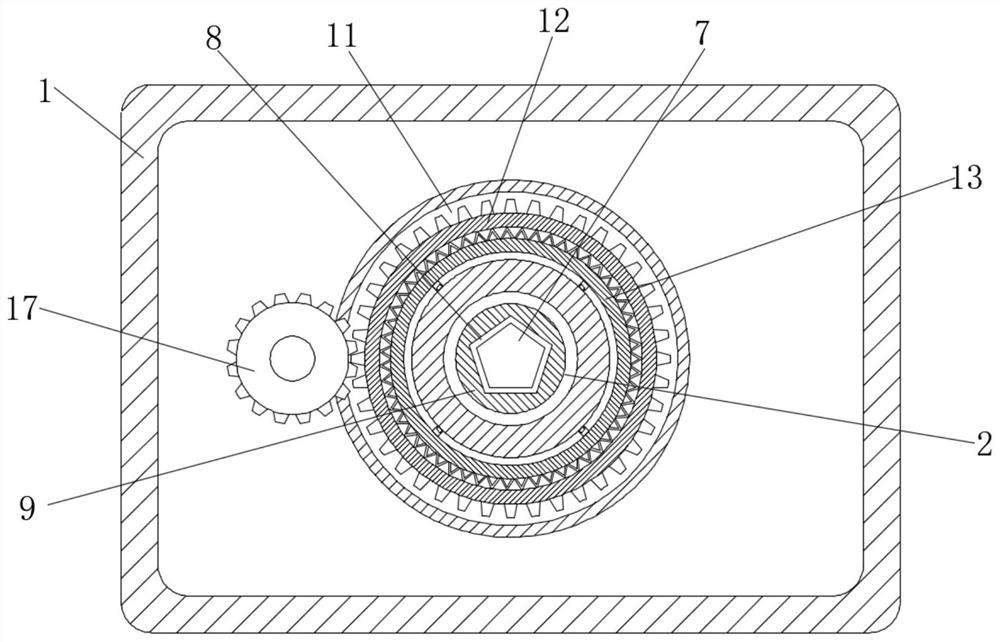

[0052] refer to Figure 1-15 , a three-dimensional detection system for integrated circuit pins, including a workbench 1, a circular groove 2 is arranged on the top of the workbench 1, a cylinder 9 is slidingly connected to the top of the circular groove 2, and a pentagonal groove 8 is arranged in the cylinder 9 , the top of the cylinder 9 is fixedly connected with a turntable 10, the workbench 1 is provided with a rotating assembly for making the turntable 10 rotate intermittently at 45 degrees, and the workbench 1 is provided with a pusher for pushing the turntable 10 and the cylinder 9 upwards. Assemblies, both sides of the workbench 1 are equipped with conveyor belts 22, and the top of the turntable 10 is arranged with a plurality of clamping boxes 23 equidistantly arranged in a ring with the cylinder 9 as the center of the circle. Chips 27 are arranged in the clamping boxes 23. A clamping assembly for clamping the chip 27 is provided in the box 23, a support 33 is fixedly...

Embodiment 2

[0068] Embodiment two: if Figure 16 As shown in -18, a three-dimensional detection system for integrated circuit pins, the difference between this embodiment and Embodiment 1 is that: the inner wall of the bottom of the groove 18 is fixedly connected with a support block 19, and the support block 19 is slidably connected with a slide bar 20, The end of the slide bar 20 away from the circular groove 2 touches the second ring 13, the outer wall of the slide bar 20 is provided with a tension spring 21, and the end of the tension spring 21 away from the circular groove 2 is fixedly connected with the support block 19, and the tension spring 21 One end away from the support block 19 is fixedly connected to the outer wall of the slide bar 20. When the slot 15 is flush with the slide bar 20, the slide bar 20 slides to the left under the tension of the tension spring 21 and extends into the slot 15. Two circular rings 13 brake.

[0069] However, as those skilled in the art know, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com