A Reactor Monocrystalline Silicon Irradiation Control System

A control system, single crystal silicon technology, applied in the direction of reactor, nuclear reactor monitoring, greenhouse gas reduction, etc., can solve the radial neutron fluence rate of the core, cannot grasp the irradiation information in real time, and is difficult to ensure the calculation of neutron fluence Accuracy, illumination uniformity and other issues, to achieve the effect of high measurement accuracy, improved calculation accuracy, and improved human factors engineering characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

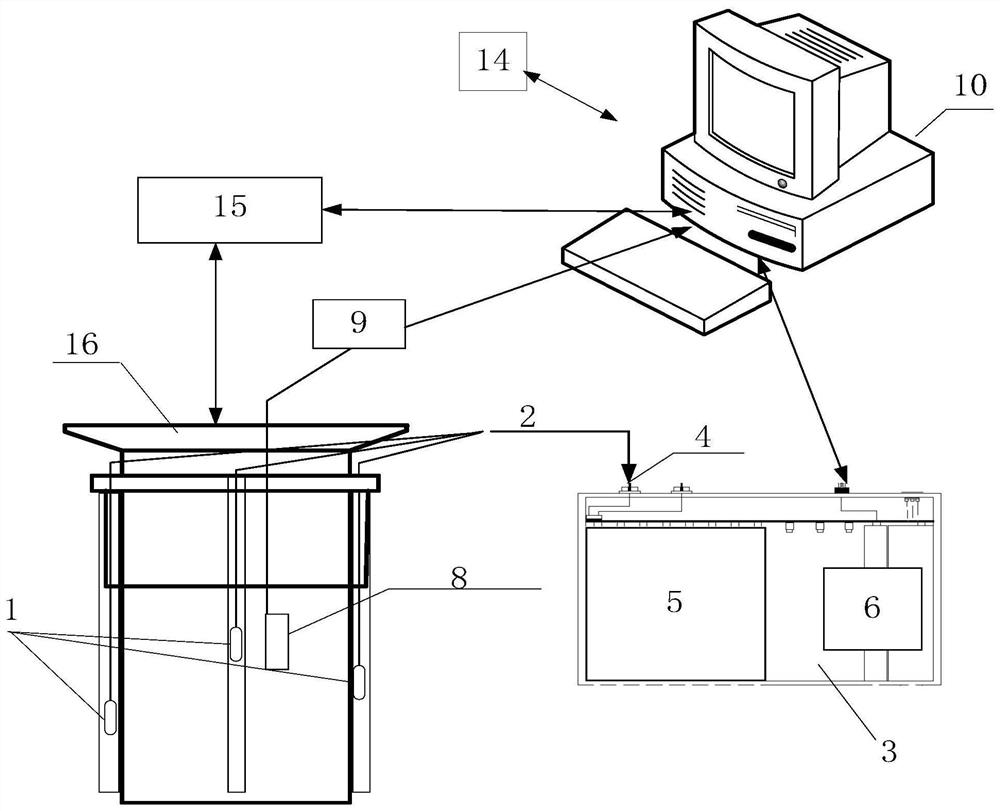

[0087] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0088] A single crystal silicon irradiation control system for a reactor, including an irradiation device, a sensing device, and a control device;

[0089] The irradiation device includes: vertically arranged reactor core irradiation tunnels and single crystal silicon to be irradiated;

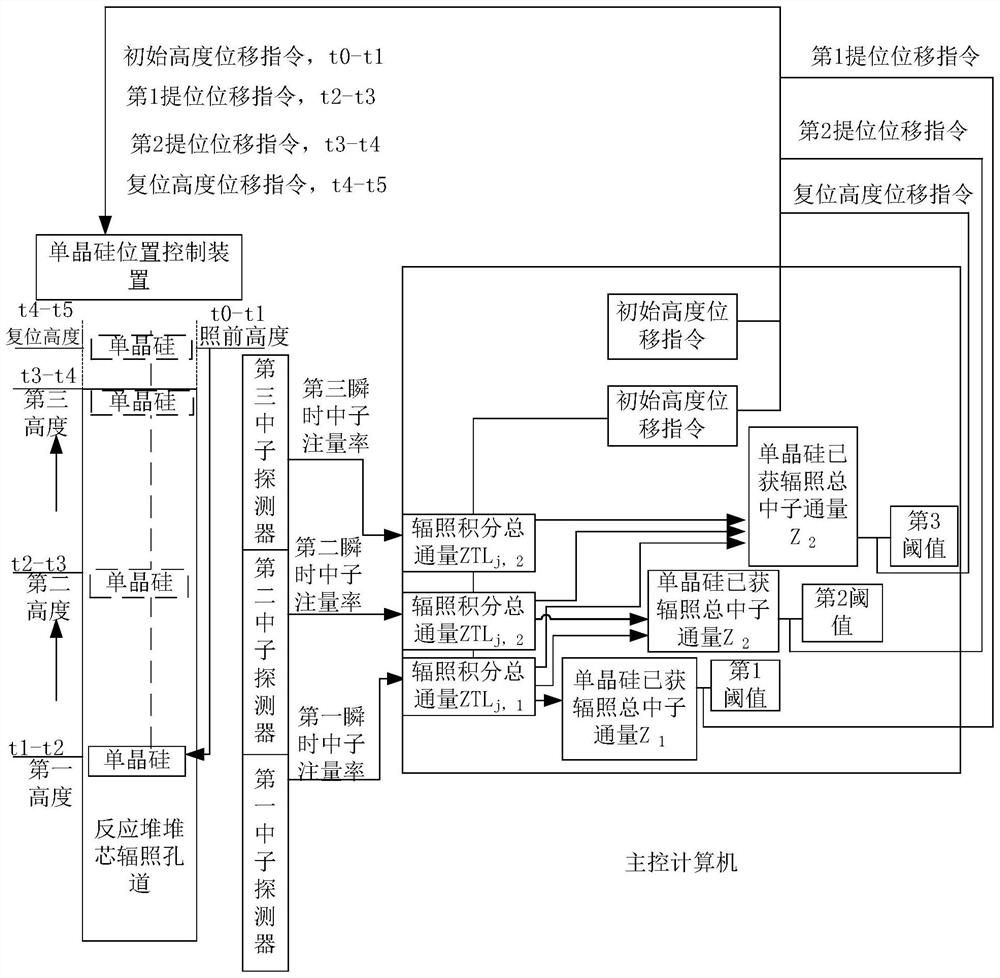

[0090] see figure 2 , the sensing device includes: corresponding i neutron detectors are arranged at i heights along the reactor core irradiation tunnel; i is greater than or equal to 2;

[0091] The i heights include: the first height, the second height, ..., the Nth height, the N+1th height, ..., the i-th height, the first The instantaneous neutron fluence rate corresponding to the height, the second height, ..., the Nth height, the N+1th height, ..., the i-th height becomes smaller in turn;

[0092] The control device includes: main control computer, single crystal silicon position control device;

[0093] Master com...

Embodiment 2

[0106] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

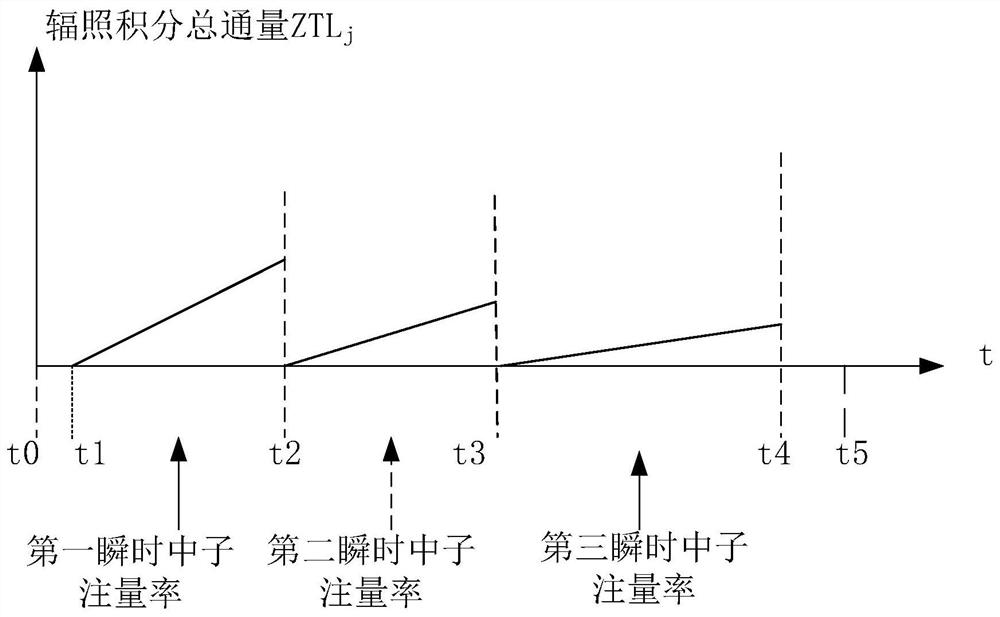

[0107] Preferably, in order to improve the radiation production efficiency, the instantaneous neutron fluence rate at the bottom of the tunnel is generally the largest. Therefore, the initial height corresponds to the first height, that is, after the initial height displacement command is issued, the radiation of single crystal silicon from the reactor core is controlled. The pre-irradiation height outside the irradiation tunnel is moved to the first height in the reactor core irradiation tunnel, and the first height corresponds to the preset bottommost area of the tunnel. Generally, the lifting threshold is set to be 80% of the total neutron flux threshold required for single crystal silicon irradiation, and the subsequent lifting threshold is set to 90% of the total neutron flux threshold value required for single crystal silicon irradiation. The whole control process is as follows: the total neutron flu...

Embodiment 3

[0109] like figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0110]Preferably, if the initial placement of monocrystalline silicon to the first height is directly used for irradiation, the technical effect can improve production efficiency and shorten the entire irradiation time; but because the instantaneous neutron fluence rate at the first height is relatively low Large, so the uniformity of the neutron amount in this section will fluctuate greatly, resulting in non-uniform radiation transmutation doping. Therefore, in order to obtain high-quality and uniform radiation transmutation doping products; it is necessary to look for neutrons The optimal section of uniform distribution of fluence, and irradiating on the basis of the initial irradiation, the uniformity of the obtained product in the irradiation transmutation doping will be greatly improved. In order to achieve the above object, the present invention proposes the following two preferred methods.

[0111] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com