an oxygen reduction catalyst

A technology of catalyst and catalyst ink, which is applied in the chemical industry, can solve the problems of high price, reduced catalytic activity, and limited resources, and achieve the effects of easy-to-obtain raw materials, good methanol resistance, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

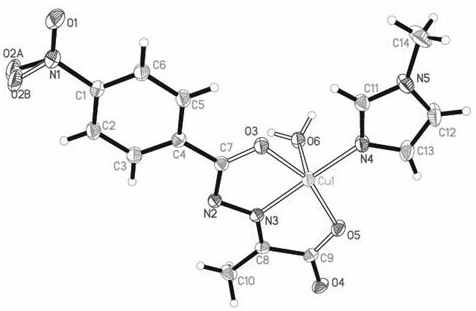

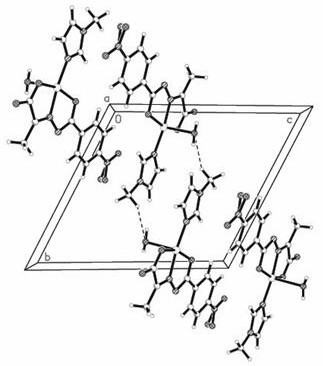

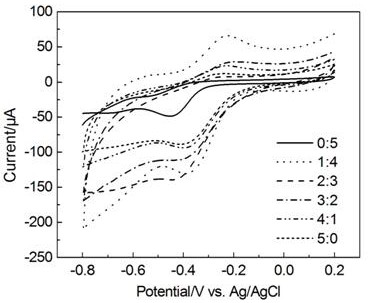

[0020] The 2-carbonylpropionic acid-4-nitrobenzoyl hydrazone and 1-methylimidazole are in a certain amount ratio (0:5, 1:4, 2:3, 3:2, 4:1, 5 :0) is dissolved in absolute ethanol, copper sulfate is dissolved in distilled water, and then a single crystal of the complex is prepared by the test tube diffusion method. Specifically, 0.2 mmol of copper sulfate pentahydrate (CuSO 4 ⋅5H 2 O) Dissolve with 5 mL of distilled water and place it at the bottom of the test tube, then add 5 mL of methanol-water mixed solution with a volume ratio of 1:1 as a buffer layer, drop it into the test tube with a syringe, and then add about 0.2 mmol of 2- Carbonylpropionic acid-4-nitrobenzoylhydrazone was mixed with about 0.8 mmol of 1-methylimidazole, dissolved in 5 mL methanol solution, carefully added dropwise to the test tube, placed on the upper layer of the solution, and finally the test tube was sealed with plastic wrap Mouth, after standing for two weeks, dark green needle-like crystals are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com