Pipe gallery type jumper supporting structure and power transmission system and method

A support structure and pipe gallery technology, which is applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of cage jumper string discharge and irregular jumper wires, so as to improve electrical performance, ensure electrical characteristics, and avoid The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

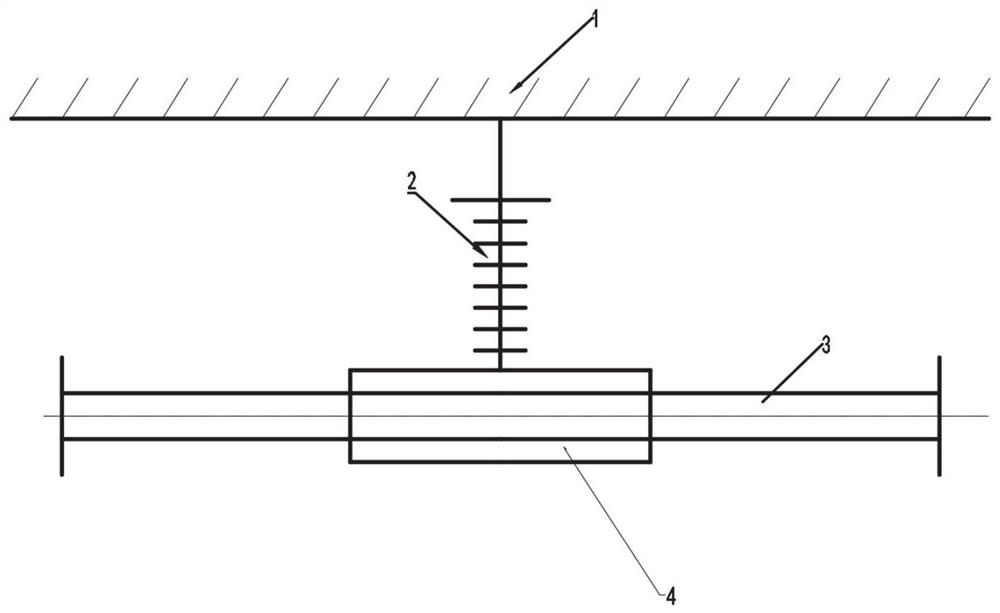

[0024] as attached figure 1 As shown, the present invention provides a pipe gallery support structure for a jumper, including: a sleeve, and several wire brackets connected to the sleeve; the wire bracket is used to fix several wires of the jumper to the sleeve tube inside. The direction in which the wire holder fixes the wire is parallel to the axial direction of the bushing.

[0025] Further, the casing includes several aluminum tubes, the casing is a pipe gallery structure, and the pipe gallery structure is a space formed by setting longitudinal connecting members, such as longitudinal beams or trusses, between adjacent aluminum pipes. The structure is a pipe gallery structure.

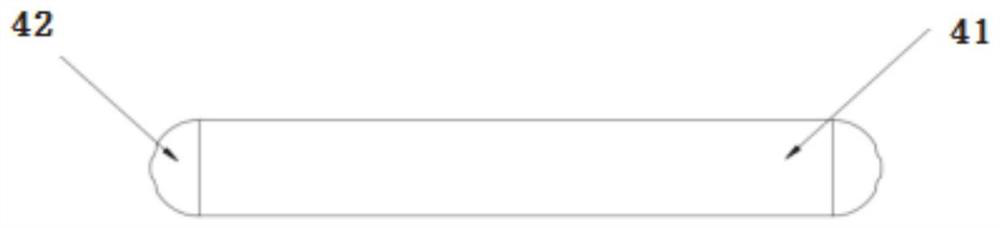

[0026] Further, the cross-section of the casing is square, oval or polygonal, preferably circular; the casing is split and formed by splicing several arc-shaped tubes.

[0027] Further, the sleeve is formed by splicing two semicircular tubes.

[0028] Further, the wire bracket includes a suppor...

Embodiment 2

[0039] A method of using the jumper pipe gallery type support structure described in the above embodiment, the steps include:

[0040] Depending on the voltage level, the length of the jumper is different, that is, the length of the support mechanism of the pipe gallery jumper is also different, and the number of wire suspension brackets installed inside is also determined.

[0041] When installing, first fix the jumper on the wire clip of the wire bracket, and the wire clip will hold the jumper through the action of the built-in spring. The type of wire clip of this structure is convenient for construction. Sure.

[0042] Then put the sleeve of the pipe gallery jumper support mechanism, that is, the aluminum tube (split type, composed of two semicircular aluminum tubes) on the outside of the jumper, and fix it with the fixing bracket of the suspension bracket through fasteners , and finally cover the end cap and fasten it with fasteners; the fasteners can be bolts, pins, scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com