Display backplane, manufacturing method thereof, and display device

A display backplane and display device technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problem of separation of characteristics of driving thin film transistors and switching thin film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

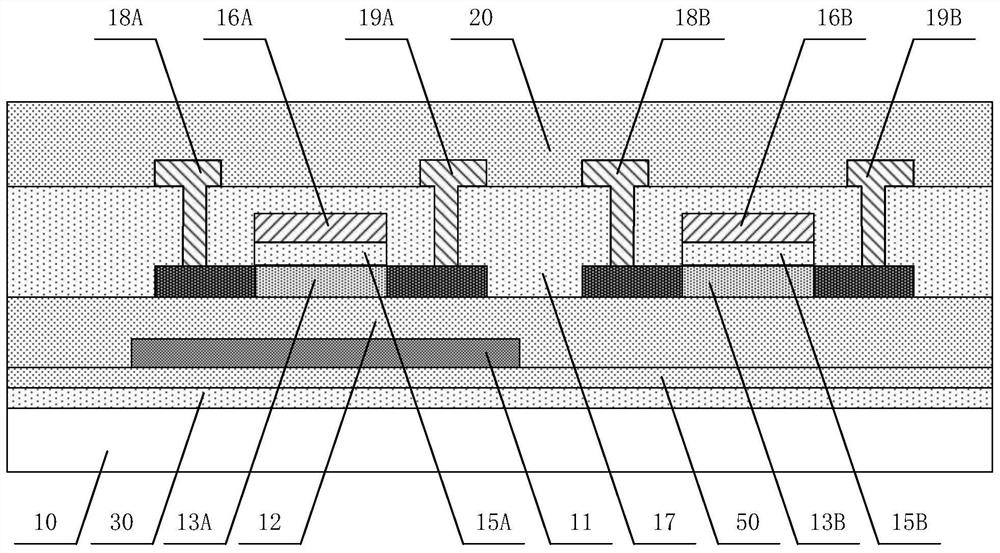

[0066] figure 1 It is a schematic structural diagram of the first embodiment of the display backplane according to the present invention, only illustrating the driving thin film transistor and the switching thin film transistor. Such as figure 1 As shown, the main structure of the top gate bottom emission structure OLED display backplane in this embodiment includes a transparent heat conduction layer formed on the substrate, a shielding layer formed on the transparent heat conduction layer, a top gate type first thin film transistor and a second thin film transistor. The transparent thermal conduction layer includes a transparent conductive layer and a first buffer layer, the first thin film transistor is used as a driving thin film transistor (DRTFT), and the second thin film transistor is used as a switching thin film transistor (SW TFT). Specifically, the present embodiment shows that the backplane includes: a transparent conductive layer 30 and a first buffer layer 50 se...

no. 2 example

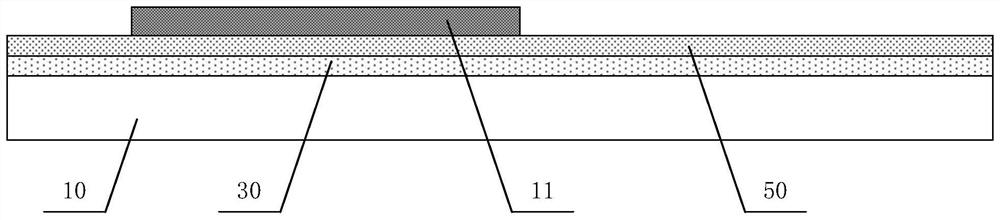

[0079] Figure 8 A schematic structural diagram of the second embodiment of the backplane is shown in the present invention. This embodiment is an extension of the aforementioned first embodiment. The main structure of the top-gate bottom-emission structure OLED display backplane includes a transparent heat conduction layer formed on the substrate, a shielding layer formed on the transparent heat conduction layer, and a top-gate type first a thin film transistor and a second thin film transistor. Different from the aforementioned first embodiment, the transparent heat conduction layer of this embodiment includes a transparent semiconductor layer 40 and a first buffer layer 50, such as Figure 8 shown.

[0080] In this embodiment, the material of the transparent semiconductor layer can be metal oxide or silicon material, and the metal oxide can include a metal oxide semiconductor formed by one or more metal elements such as indium (In) or gallium (Ga), such as Indium Gallium...

no. 3 example

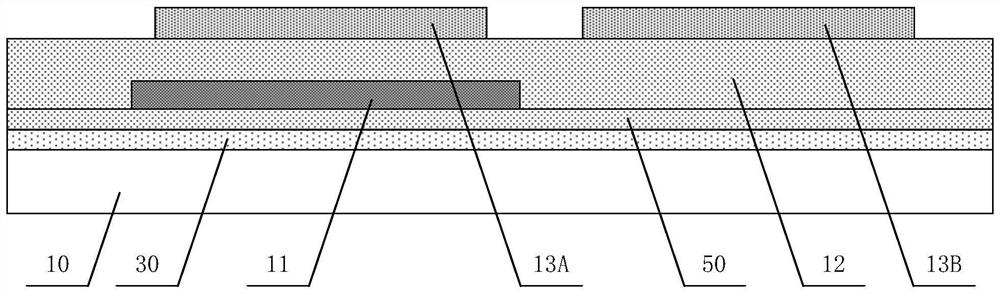

[0083] Figure 9 A schematic structural diagram of the third embodiment of the backplane is shown for the present invention. This embodiment is an extension of the aforementioned first and second embodiments. The main structure of the top-gate bottom-emitting structure OLED display backplane includes a transparent heat conduction layer formed on the substrate, a shielding layer formed on the transparent heat conduction layer, and a top-gate type. The first thin film transistor and the second thin film transistor. Different from the aforementioned first and second embodiments, the transparent heat conduction layer in this embodiment includes a transparent conductive layer 30, a transparent semiconductor layer 40 and a first buffer layer 50, such as Figure 9 shown.

[0084] In this embodiment, the material of the transparent conductive layer can be indium tin oxide ITO or indium zinc oxide IZO, the material of the transparent semiconductor layer can be metal oxide or silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com