PTC (positive temperature coefficient) ring production method

A ring, metal foil technology, applied in the direction of current-responsive resistors, resistors with positive temperature coefficient, etc., can solve the problems of unsuitability for mass production and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

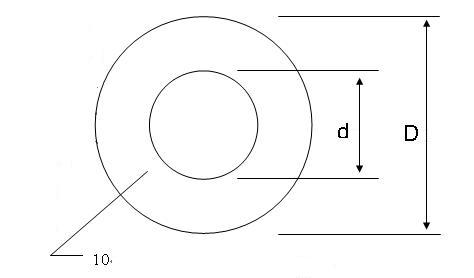

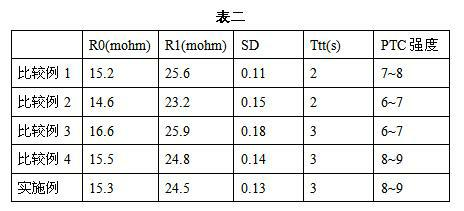

[0024] A kind of preparation method of circular PTC, circular PTC such as figure 1 As shown, the outer dimension is composed of outer diameter D, inner diameter d and thickness of a ring piece, including two metal foils and a PTC material layer, wherein: the rough surface of the two metal foils is in direct physical contact with the PTC material layer, The PTC material layer is interposed between the two metal foils. The upper and lower metal foils and the upper and lower metal nickel sheets are assembled into a battery cap to form a component, and connected to a power supply to form a conductive circuit. The preparation steps are in sequence for:

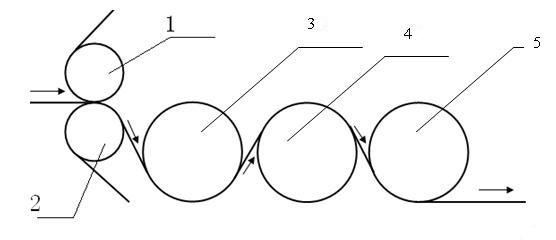

[0025] First, the ring PTC is a polymer-based PTC, and each component is weighed according to the formula. If there is a granular material in the raw material, it should be ground into a powder with a particle size of less than 0.1 mm before weighing; The material is pre-mixed physically with a mixer for 15-40 minutes; the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com