Lens assembly for super-resolution microscopy

A lens component and super-resolution technology, applied in microscopes, analytical materials, optical components, etc., can solve problems such as microscope resolution limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

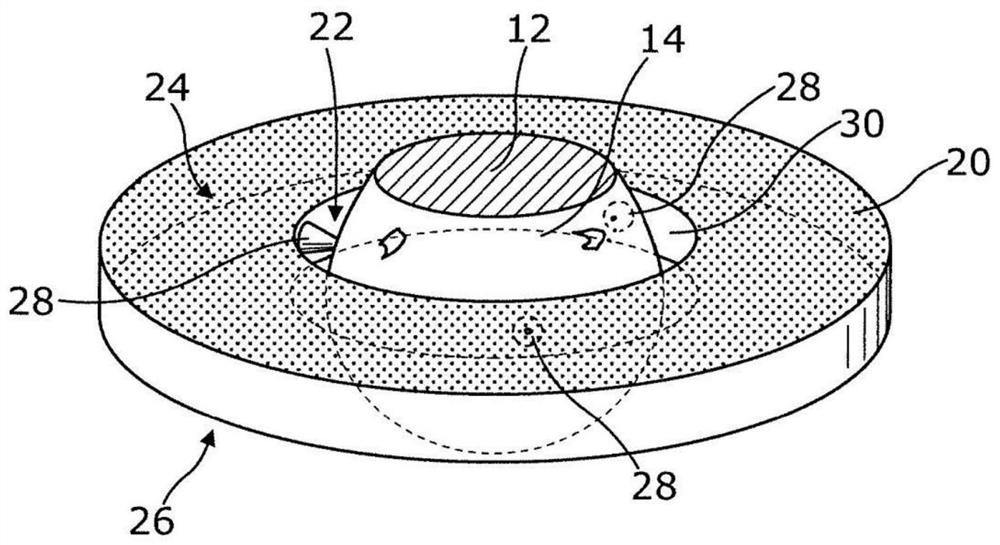

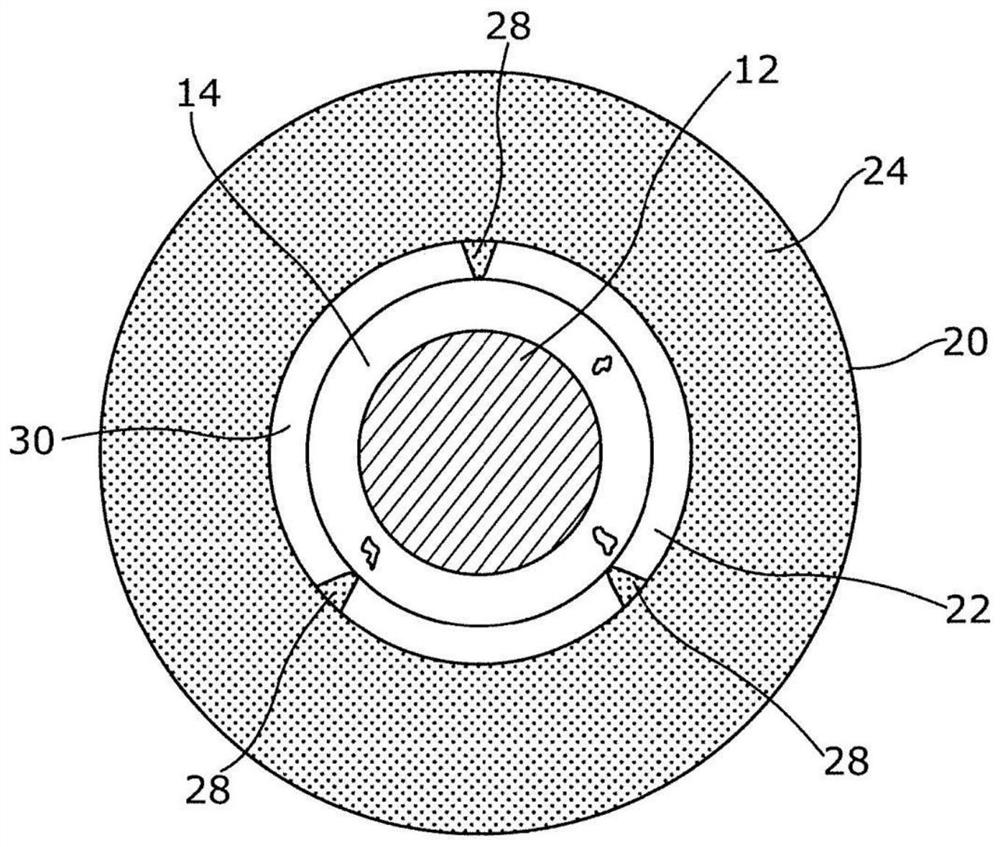

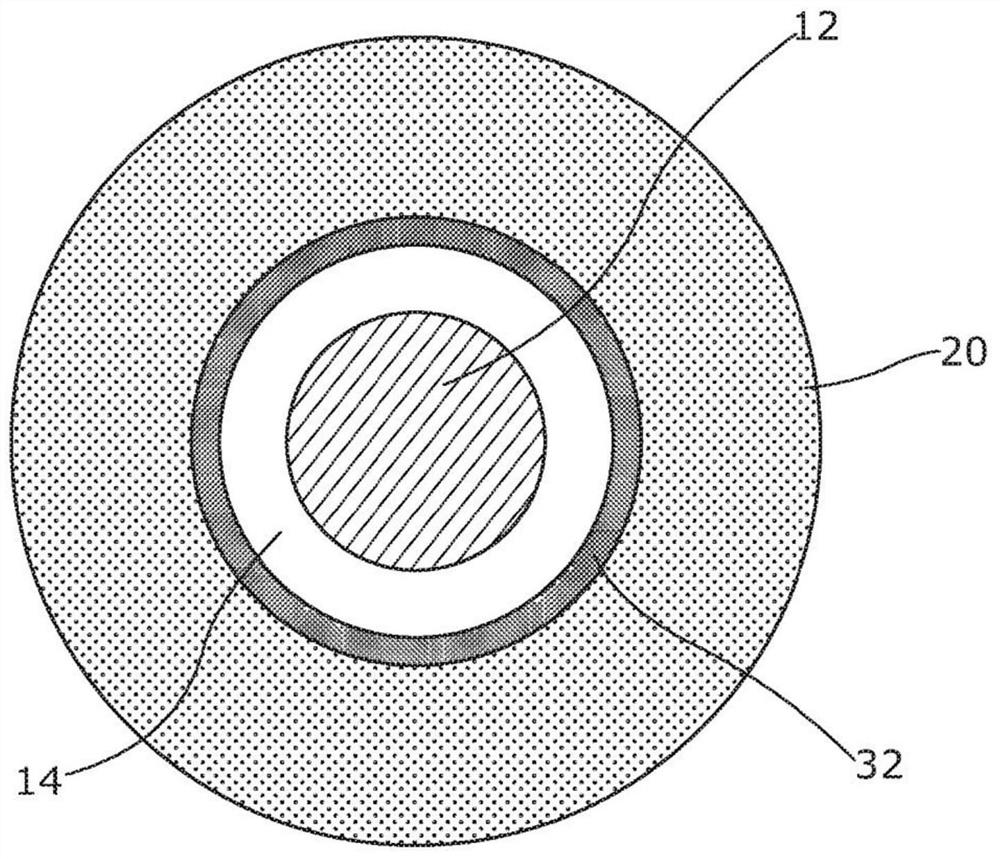

[0037] now refer to figure 1 , shows a perspective view of a lens assembly 10, which is used for microscopy of a sample in a cryogenic environment, such as super-resolution optical microscopy. exist figure 2 The corresponding floor plan is shown in , and image 3 The corresponding plan views of the adhesive material described below are shown also in place. For clarity, figure 1 and figure 2 Adhesive materials commonly used in these arrangements are omitted.

[0038] A sample (not shown in these figures) for imaging or other analysis using the microscope may be located adjacent to or in contact with plane 12 of solid immersion lens 14 . Specifically, and as figure 1 As shown, it can be provided as a non-planar solid state immersive lens (ASIL), which takes the form of a truncated spherical lens discussed in more detail below. The lens assembly also includes a planar base 20 having opposed and generally parallel major faces 24, 26 that are positioned between figure 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com