Freeze-dried ball and preparation method thereof

A freeze-drying and polysaccharide technology, used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of poor resolubility of freeze-dried balls, achieve excellent mechanical strength and toughness, high economic benefits, and solve the problem of resolubility. poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A second aspect of the present invention provides a method for preparing freeze-dried balls, comprising the following steps:

[0053] S01: Dissolving polyols, polysaccharides, hyaluronate, and okra hydrolyzed glycoprotein in deionized water to form a solution;

[0054] S02: Pour the solution obtained in step S01 into the detachable upper and lower hemispherical molds, put the upper and lower molds with the solution in the freeze dryer, freeze at -45°C for 1-2 hours, and then remove the mold from the freeze dryer Take it out, put it at room temperature for 20-30 minutes, then separate the upper and lower molds, and freeze the solution into a sphere and place it in the lower mold;

[0055] S03: Put the lower mold with the sphere back into the freeze dryer, keep it warm at -45°C for 20-40 minutes, then raise the temperature to 5°C, control the vacuum at 10-30Pa, and dry for 10-20 hours; then raise the temperature again to 25°C, dry for 1-3 hours, then dry at 35-40°C, and ...

Embodiment 1

[0061] The invention relates to a freeze-dried ball. The raw materials for preparation include, in parts by weight, 2 parts of mannitol, 0.5 part of pullulan, 0.1 part of sodium hyaluronate, and 0.04 part of okra hydrolyzed glycoprotein.

[0062] The average molecular weight of okra hydrolyzed glycoprotein is 700000.

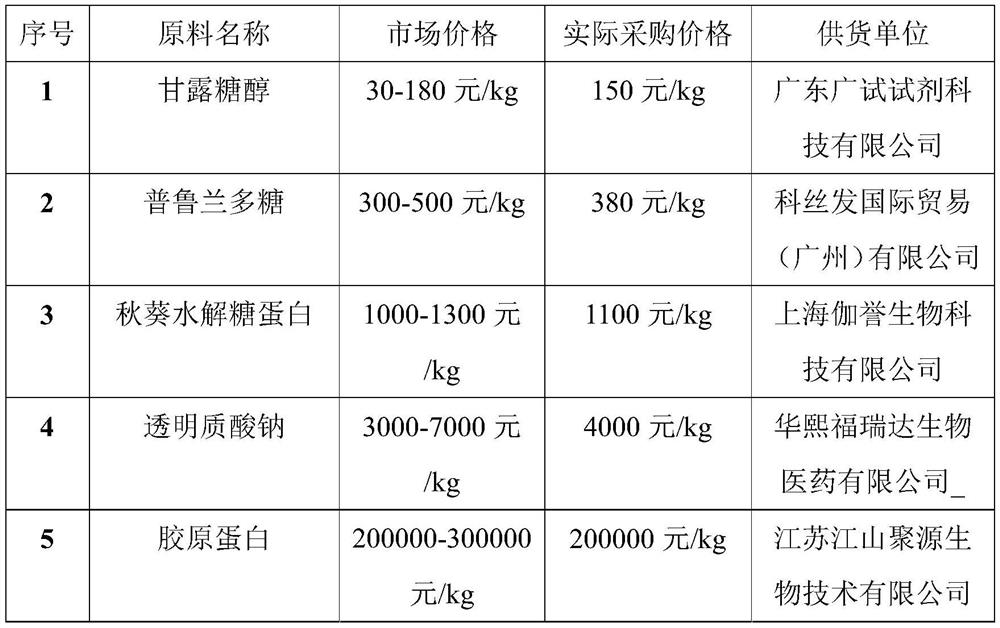

[0063] Okra hydrolyzed glycoprotein was purchased from Shanghai Jiayu Biotechnology Co., Ltd.; sodium hyaluronate was purchased from Bloomage Freda Biomedicine Co., Ltd.

[0064] A preparation method of freeze-dried balls, comprising the following steps:

[0065] S01: Dissolving mannitol, pullulan, sodium hyaluronate, and okra hydrolyzed glycoprotein in deionized water to form a solution;

[0066] S02: Pour the solution obtained in step S01 into the detachable upper and lower hemispherical molds, put the upper and lower molds containing the solution into a freeze dryer, freeze at -45°C for 2 hours, and then take the mold out of the freeze dryer, Place it at ro...

Embodiment 2

[0069] The invention relates to a freeze-dried ball. The raw materials are prepared in parts by weight, including: 4 parts of mannitol, 2 parts of pullulan, 0.3 part of sodium hyaluronate, and 0.1 part of okra hydrolyzed glycoprotein.

[0070] The average molecular weight of okra hydrolyzed glycoprotein is 700000.

[0071] Okra hydrolyzed glycoprotein was purchased from Shanghai Jiayu Biotechnology Co., Ltd.; sodium hyaluronate was purchased from Bloomage Freda Biomedicine Co., Ltd.

[0072] A preparation method of freeze-dried balls, comprising the following steps:

[0073] S01: Dissolving mannitol, pullulan, sodium hyaluronate, and okra hydrolyzed glycoprotein in deionized water to form a solution;

[0074] S02: Pour the solution obtained in step S01 into the detachable upper and lower hemispherical molds, put the upper and lower molds containing the solution into a freeze dryer, freeze at -45°C for 2 hours, and then take the mold out of the freeze dryer, Place it at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com