Semitrailer truck fuel tank cleanliness detection device

A detection device and technology for cleanliness, applied in the directions of cleaning hollow objects, cleaning methods and utensils, filtration and separation, etc., can solve the problems of large volume and weight of semi-trailer truck fuel tank, long shaking and cleaning time, and high quality control risk, etc. Effective quality control, easy cleanliness measurement, and the effect of increasing the number of inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

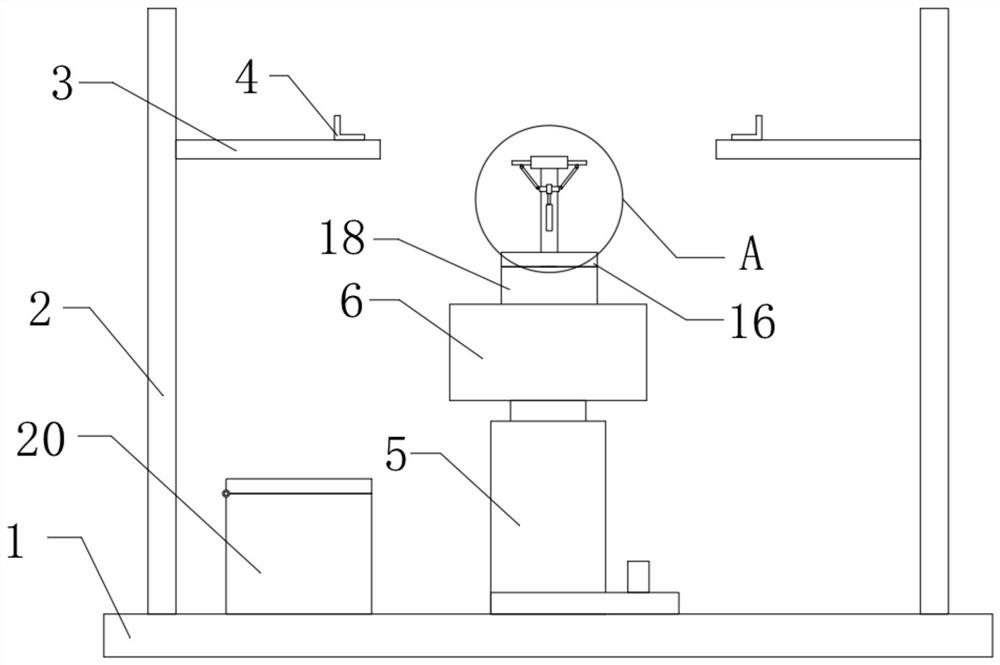

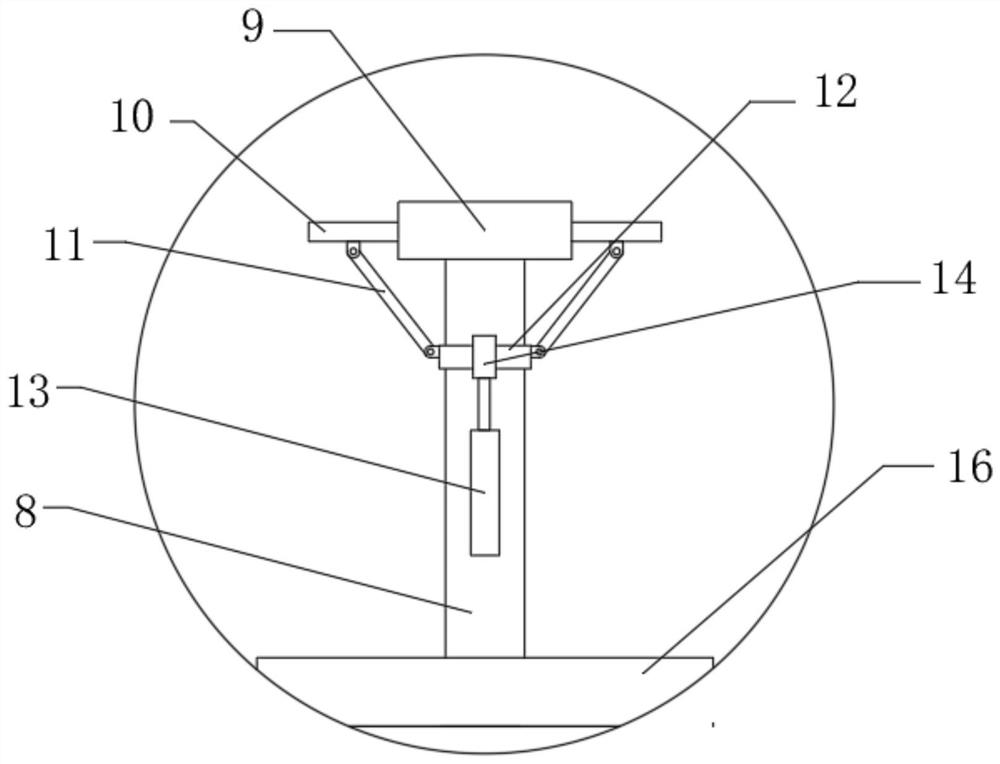

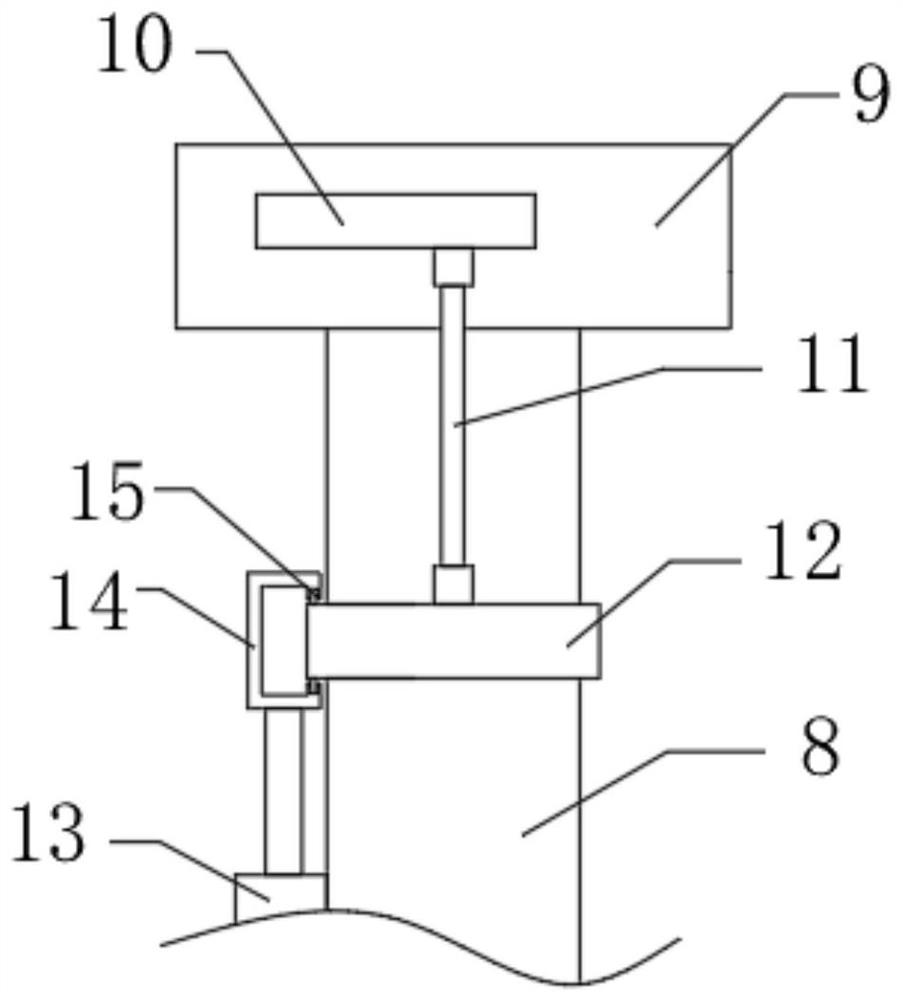

[0033] see Figure 1-9, in an embodiment of the present invention, a device for detecting the cleanliness of a semi-trailer truck fuel tank includes a bottom plate 1, a support frame 2 is connected to the upper surface of the bottom plate 1, and support rods 3 are fixedly connected to the side walls of the support frame 2 close to each other , the upper surface of the support rod 3 is fixedly connected with four limit blocks 4, and by setting two separately arranged support rods 3, it is convenient for the user to use a forklift to move and transfer the fuel tank of a semi-trailer truck, and the upper surface of the base plate 1 Suppose that a hydraulic push rod 5 is fixedly connected, and the upper end of the hydraulic push rod 5 is fixedly connected with a water tank 6, the inner wall of the water tank 6 is fixedly connected with a water pump 7, and the upper end of the water pump 7 is connected with a cleaning pipe 8, and the cleaning pipe 8 The upper end is rotatably conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com