Gear tooth type powder metallurgy part surface extrusion machining die

A powder metallurgy and extrusion processing technology, which is applied in the field of powder metallurgy, can solve the problems of being unable to fix and clamp different types of parts, not having the function of collecting debris, and not having the function of washing debris, etc., so as to achieve easy operation and ensure extrusion Pressure stability, the effect of ensuring cushioning stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

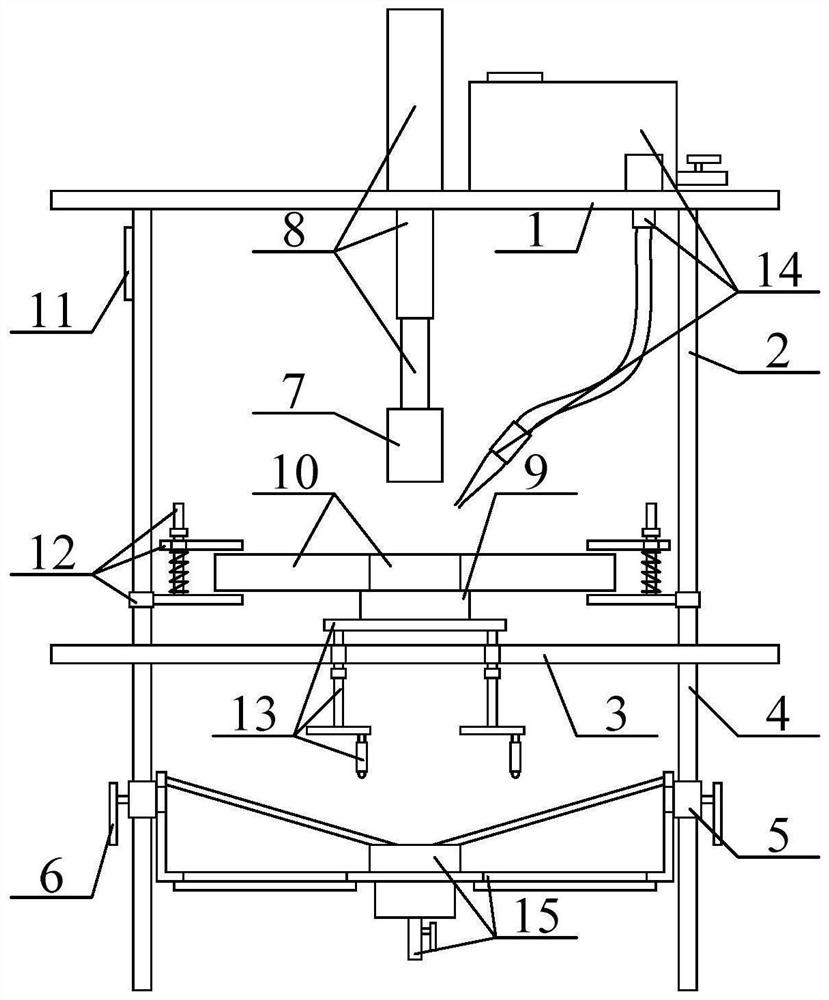

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

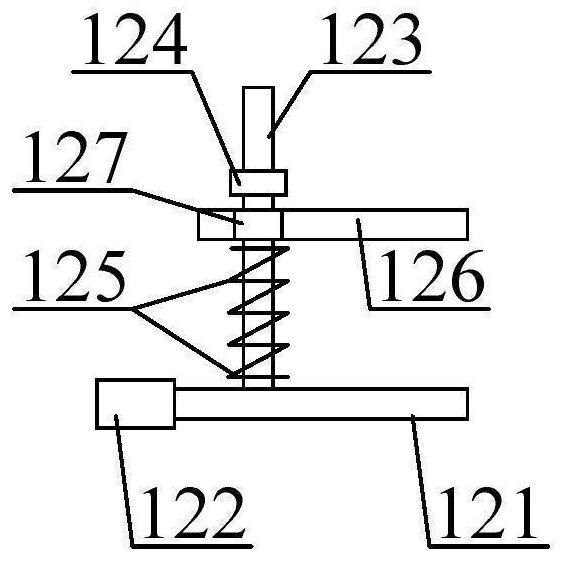

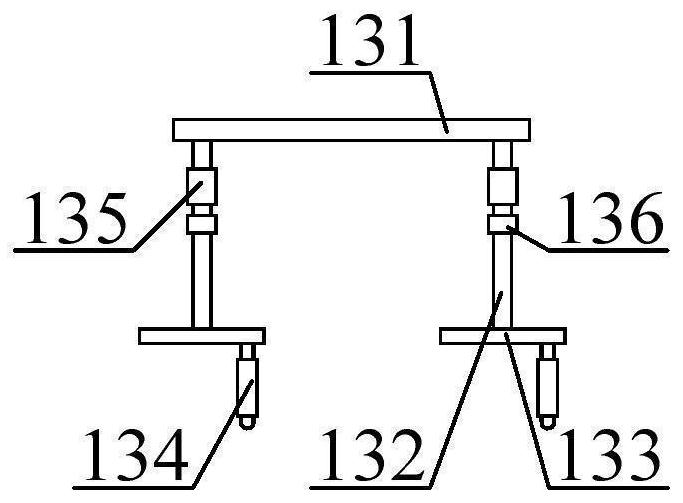

[0037] as attached figure 1 And attached figure 2As shown, a gear tooth powder metallurgy part surface extrusion processing mold according to the present invention includes a beam 1, a column 2, a frame 3, a support leg 4, an adjustable tube 5, an adjustable bolt 6, and an upper mold 7 , mold extrusion hydraulic rod 8, lower mold 9, part body 10, control panel 11, buffer type part clamping plate structure 12, adjustable processing seat structure 13, debris washing protection nozzle structure 14 and impurity collection and separation box structure 15. The left and right sides of the lower part of the beam 1 are bolted to the columns 2; the longitudinal lower ends of the columns 2 are bolted to the middle part of the upper left and right sides of the frame 3; the four corners of the bottom of the frame 3 are bolted A support leg 4 is connected; the outer wall of the support l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com