Double-station rotary screen printing machine

A dual-station, printing machine technology, used in screen printing machines, printing machines, screen printing and other directions, can solve the problems of limiting the flexibility and diversity of pattern registration, difficulty in arranging production, and production restrictions. Improve market competitiveness, improve production efficiency, and apply to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

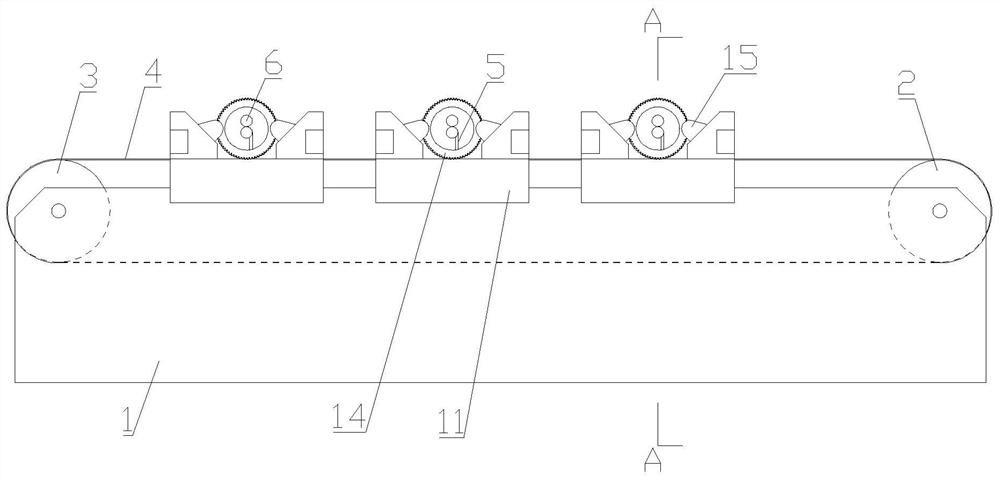

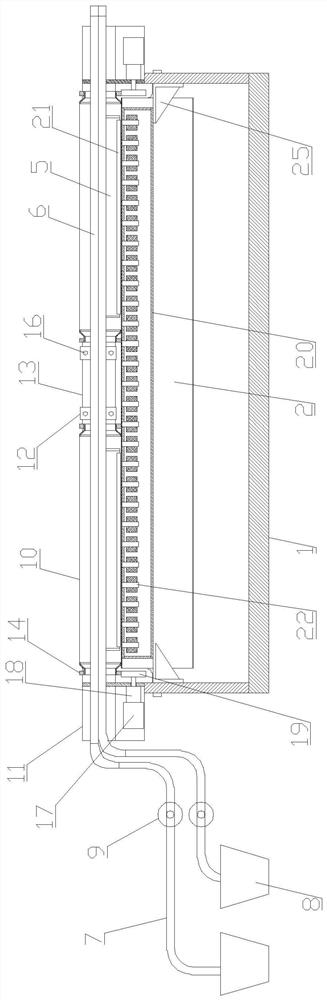

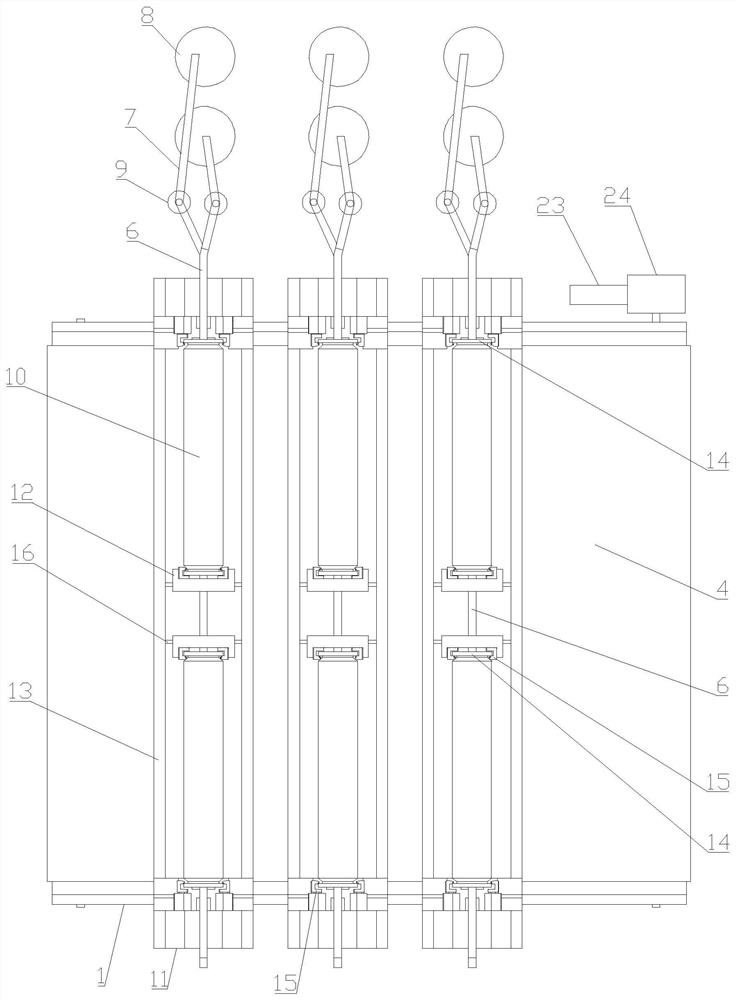

[0037] Such as Figure 1 to Figure 3 As shown, the present invention includes a frame 1, a guide belt transmission mechanism installed on the frame 1, and a plurality of double-station printing units installed on the frame 1. 1 The driving roller 2 at the head, the driven roller 3 installed in the tail of the frame 1, and the printing guide belt 4 sleeved on the outside of the driving roller 2 and the driven roller 3 and driven by the driving roller 2, a plurality of The double-station printing units are arranged sequentially along the length direction of the frame 1, and each of the double-station printing units includes two printing cylinders 10, a slurry supply mechanism and a cylinder scraping mechanism, each of which The two printing cylinders 10 in the double-station printing unit are installed on the frame 1 through a cylinder mounting frame, and the printing cylinders 10 are located above the process surface of the printing guide belt 4;

[0038] The rotary screen ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com